Use the Production Interface

This chapter will guide you through using the production interface.

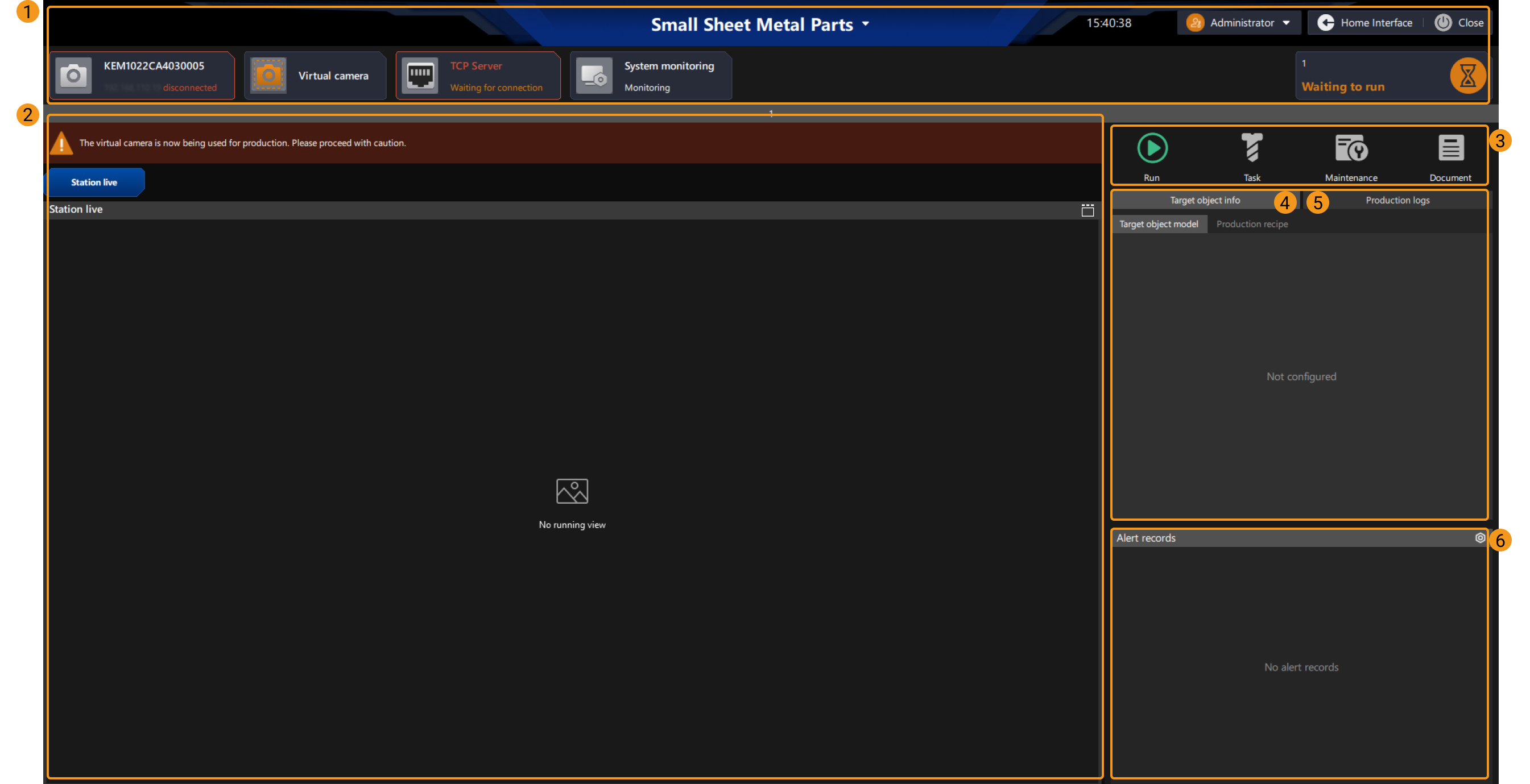

After the engineer finishes the configuration of the production interface, the operator can start to use it. You can refer to the following for the introduction and instruction of the production interface.

The following table describes the functions of each area in the figure above.

| No. | Area | Function | Instruction |

|---|---|---|---|

1 |

Status area |

Displays the brand name, solution name, camera connection status, communication status, and system monitoring status. |

|

2 |

View area |

Displays different types of running views, i.e., Station live, Recognition result, Deep learning result, and Picking sequence. |

|

3 |

Operation area |

For running the project, adding new target objects, switching the target object types, maintaining the solution, and referring to the operation guide. |

|

4 |

“Target object and recipe info” area |

Displays the target object model and production recipe. |

|

5 |

Production logs area |

Displays Mech-Vision log, Console log, and Operation log. |

|

6 |

Alert records area |

Displays the alert messages when running the project. |

|