About Mech-DLK

Mech-DLK is machine vision deep learning software independently developed by Mech-Mind. With a variety of built-in industry-leading deep learning algorithms, it can solve many problems that traditional machine vision cannot handle, such as highly difficult segmentation, positioning, and classification.

Through intuitive and simple UI interactions, even without programming or specialized deep learning knowledge, users can quickly implement model training and validation with Mech-DLK.

The software includes the following algorithm modules: Fast Positioning, Defect Segmentation, Classification, Object Detection, Instance Segmentation, Text Detection, Text Recognition, and Unsupervised Segmentation.

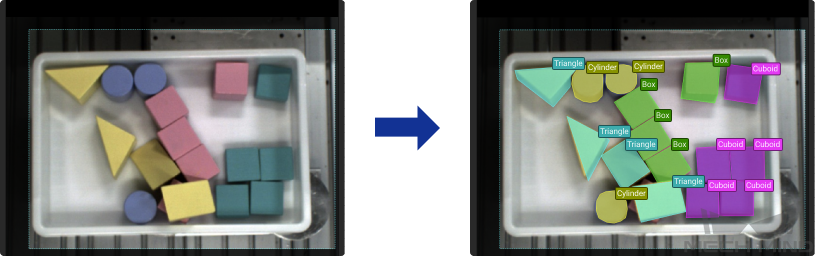

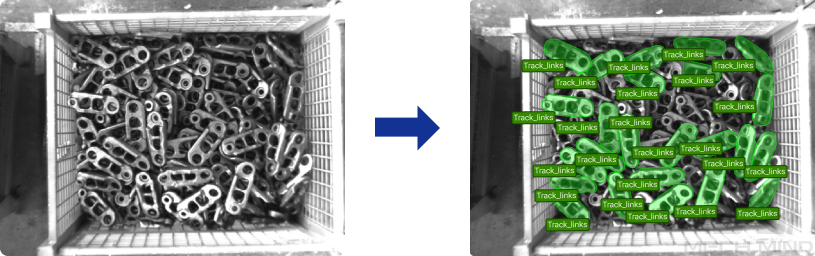

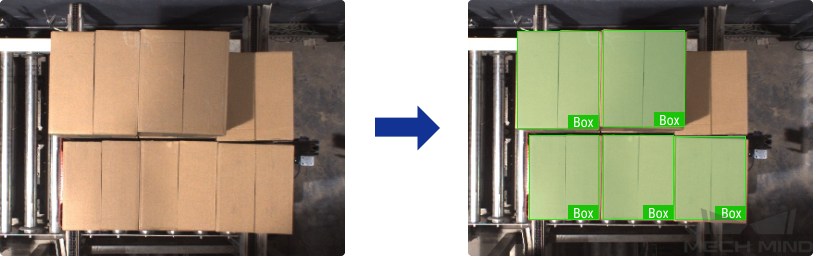

Instance Segmentation

Segments the contour of target objects and outputs the corresponding labels of the classes.

This module can produce more refined segmentation results than the module Object Detection. The module can recognize single or multi-class objects and segment the corresponding contours. It is used for depalletizing, machine tending, piece picking, etc., and it cooperates with Mech-Vision and Mech-Viz to complete object picking.

-

Segments blocks of various types.

-

Segments scattered and overlapping track links.

-

Segments cartons closely fitted together.

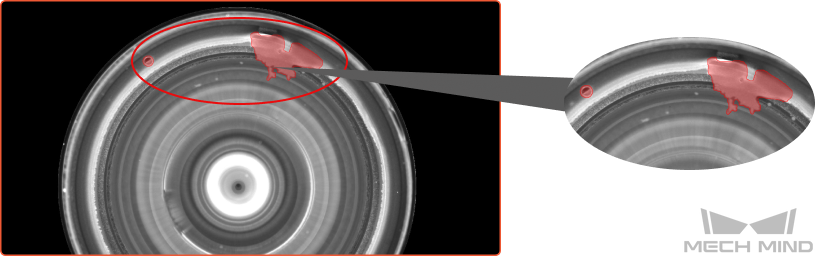

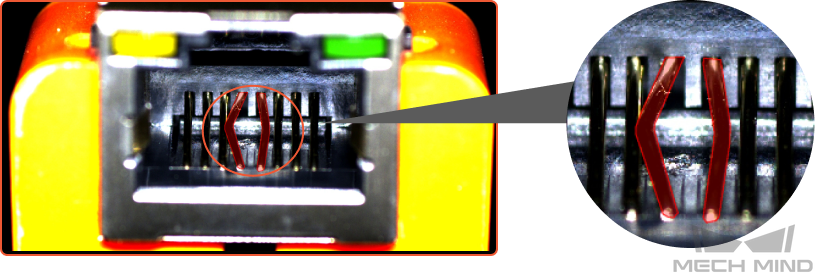

Defect Segmentation

Detects and segments the defect regions in the image.

This module can be used to detect all types of defects. Defects that can be detected include surface defects such as stains, bubbles, and scratches and positional defects such as bending, abnormal shape, and absence. Moreover, this module can be applied even under complex conditions, such as small defects, complicated background, or random object positions.

-

Detects air bubbles and glue spills on lenses.

-

Detects bending defects of parts.

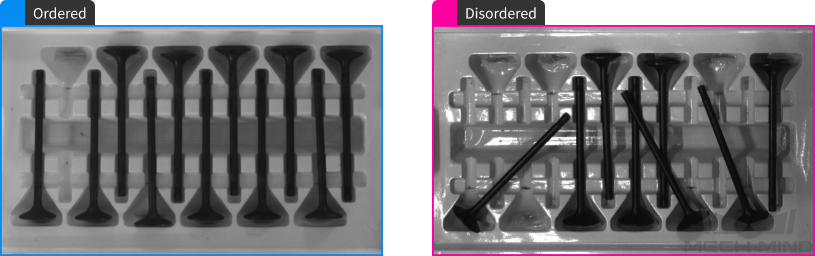

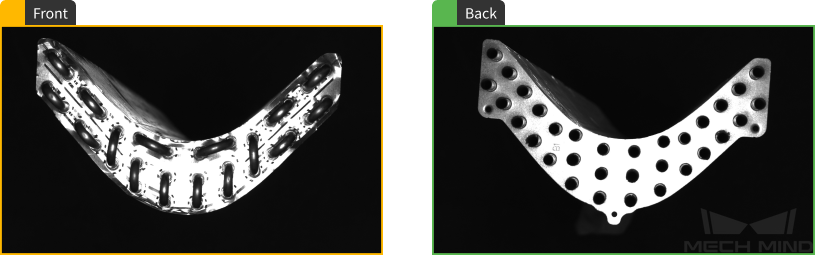

Classification

Recognizes object classes in images.

The module is used to recognize workobject front and back faces, workobject orientations, and defect types, and to recognize whether objects are missing, or whether objects are neatly arranged.

-

Recognizes whether workobjects are neatly arranged or scattered.

-

Recognizes the fronts and backs of objects.

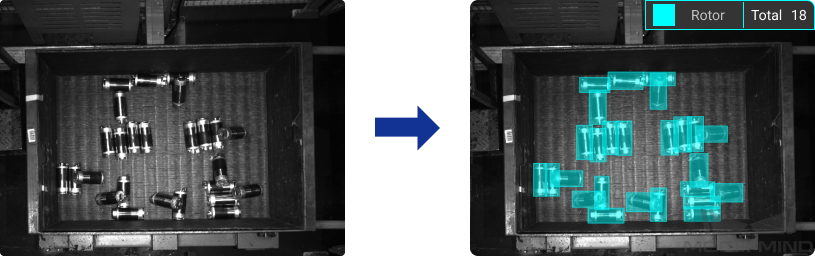

Object Detection

Detects the positions of all target objects and recognizes their categories at the same time.

This module is used to detect the absence of workobjects of fixed position, such as missing components in a PCB; it can also be used for object counting. Even for hundreds or thousands of objects, the module can quickly locate and count them.

-

Detects the positions of rotors.

-

Counts all rebars.

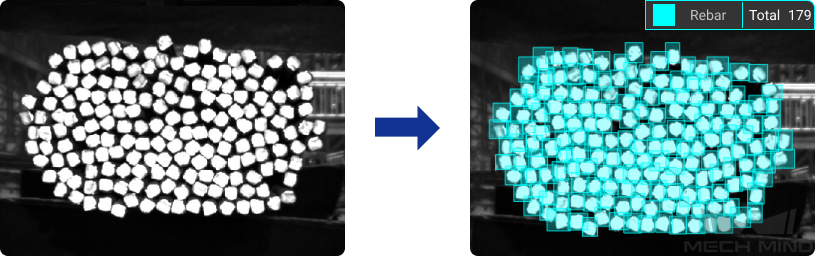

Fast Positioning

Recognizes the object orientation in an image and corrects the image based on the recognition result.

This module is used to detect objects in targeted regions of an image and rotate the image to a specified orientation and position.

-

Recognizes object orientations in images and rotates these images so that objects in them have a uniform orientation.

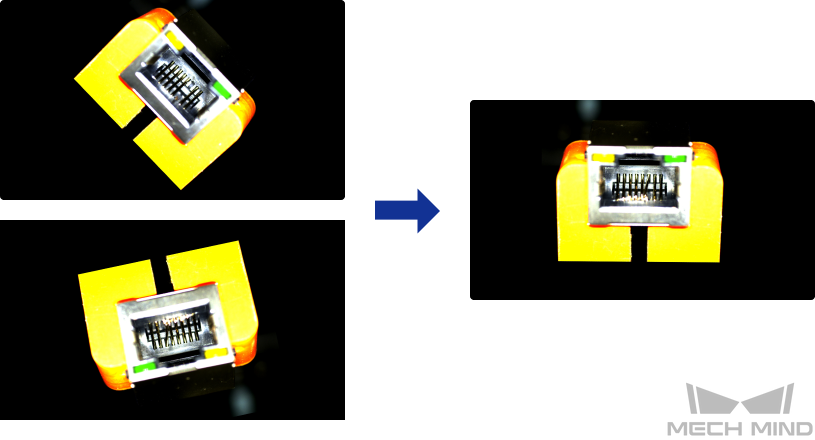

Text Detection

Detects the text areas of an image.

You can use the Text Detection module to detect the text area in an image and thus reduce the interference from the background. When the Text Recognition module is preceded by a Text Detection module, after selecting , make sure the Rectify image(s) option is enabled to rectify images to the positive direction (0°).

-

Detects the text areas of an image.

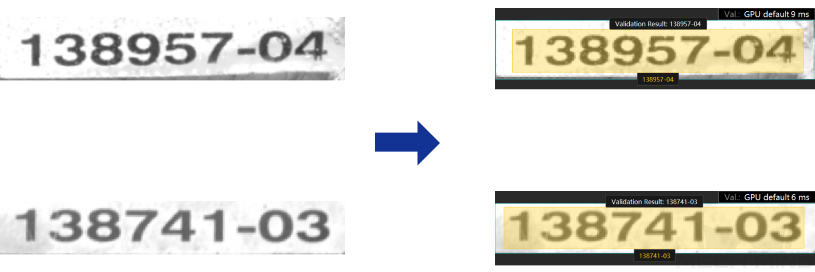

Text Recognition

Recognizes the text in an image, including letters, numbers, and some special symbols.

This module is used to recognize the characters in the text area of an image, often applied in the fast recognition of codes on all kinds of labels.

-

Recognizes the characters in an image.

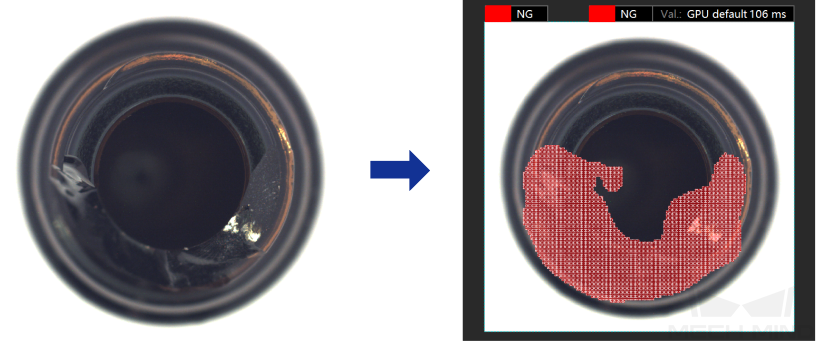

Unsupervised Segmentation

Judges whether an image is OK, NG, or Unknown according to set thresholds and displays the possible areas with defects.

Images should be labeled as OK or NG, and only OK images will be used as the training set for model training. The trained model can help judge whether there is any defect in an image.

-

Judges whether an image is OK, NG, or Unknown according to set thresholds.