About Mech-DLK

Mech-DLK is machine vision deep learning software independently developed by Mech-Mind. With a variety of built-in industry-leading deep learning algorithms, it can solve many problems that traditional machine vision cannot handle, such as highly difficult segmentation, positioning, and classification.

Through intuitive and simple UI interactions, even without programming or specialized deep learning knowledge, users can quickly implement model training and validation with Mech-DLK.

The software includes five algorithm modules: Fast Positioning, Defect Segmentation, Classification, Object Detection, and Instance Segmentation.

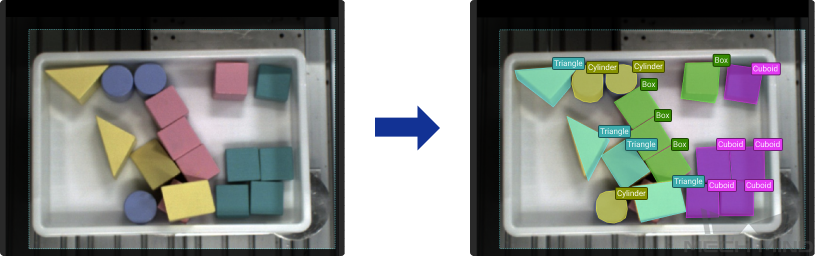

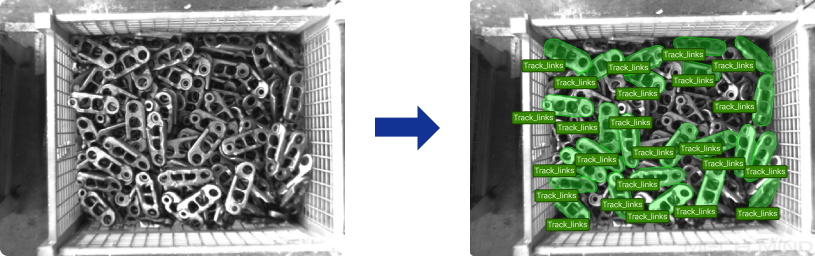

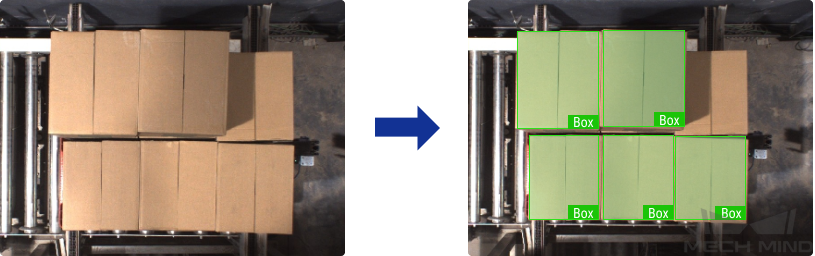

Instance Segmentation

Segment the contour of target objects and output the corresponding labels of the classes.

This module can produce more refined segmentation results than the module Object Detection. The module can recognize single or multi-class objects and segment the corresponding contours. It is used for depalletizing, machine tending, piece picking, etc., and it cooperates with Mech-Vision and Mech-Viz to complete object picking.

-

Segment blocks of various types.

-

Segment scattered and overlapping track links.

-

Segment cartons placed tightly and parallelly together.

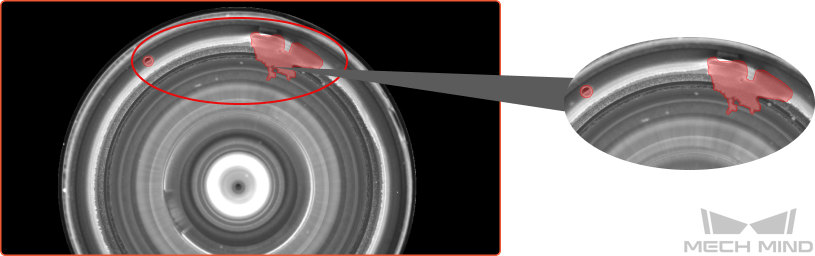

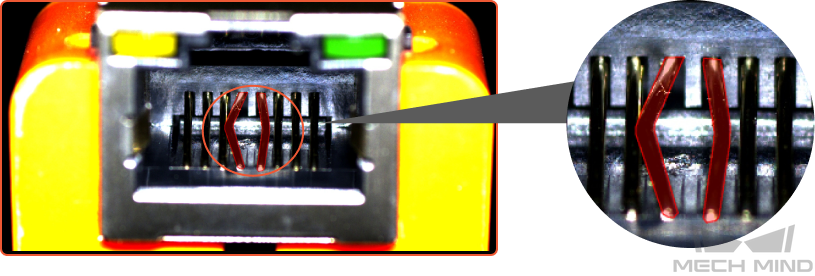

Defect Segmentation

Detect and segment the defect regions in the image.

This module can be used to detect all types of defects. Defects that can be detected include surface defects such as stains, bubbles, and scratches and positional defects such as bending, abnormal shape, and absence. It can be applied in complex situations such as small defects, complex backgrounds, and unstable workpiece positions.

-

Detect air bubbles and glue spill defects on the lens surface.

-

Detect bending defects of workpieces.

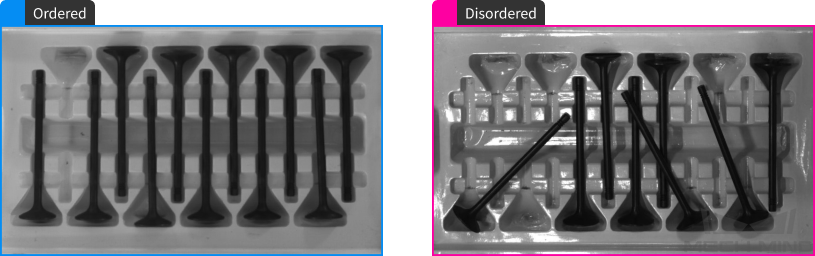

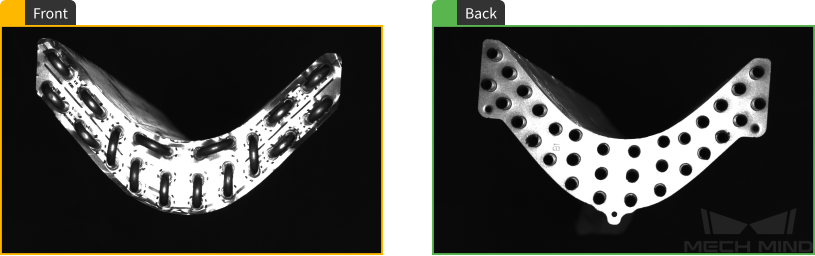

Classification

Recognize object classes in images.

The module is used to recognize workpiece front and back faces, workpiece orientations, and defect types, and to recognize whether objects are missing, or whether objects are neatly arranged.

-

Recognize whether workpieces are neatly arranged or scattered.

-

Recognize the fronts and backs of workpieces.

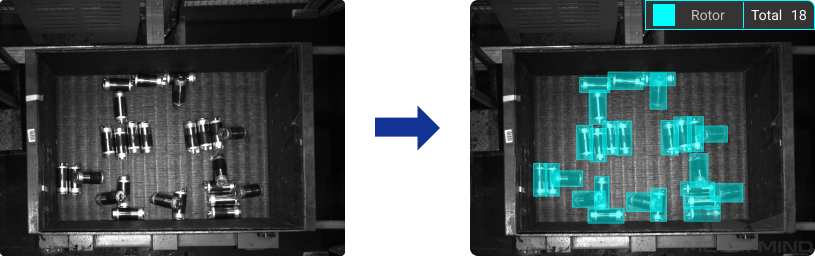

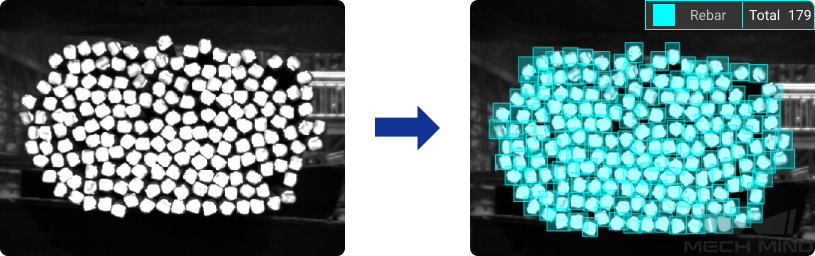

Object detection

Detect the positions of all target objects and recognize their categories at the same time.

This module is used to detect the absence of workpieces of fixed position, such as missing components in a PCB; it can also be used for object counting. Even for hundreds or thousands of objects, the module can quickly perform locating and counting.

-

Detect the positions of rotors.

-

Count all rebars.

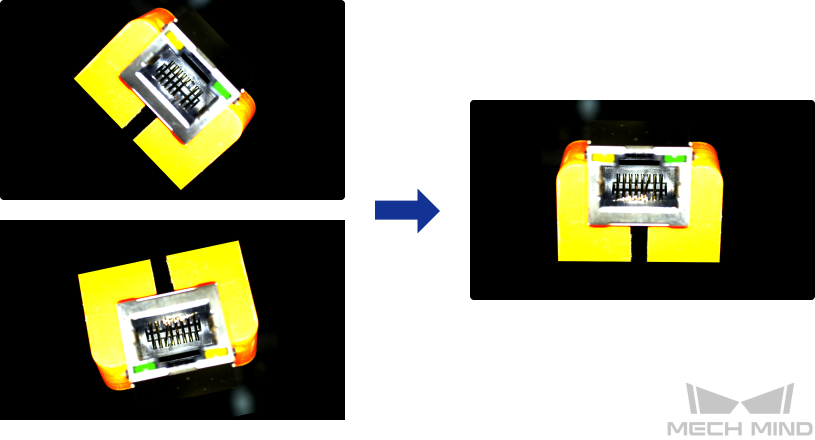

Fast Positioning

Recognize the object orientation in an image and correct the image based on the recognition result.

This module is used to detect objects in targeted regions of an image and rotate the image to a specified orientation and position.

-

Recognize workpiece orientations in images and rotate the images to a specified orientation.