Learning Guidance for AI-Based Quality Inspection

Learning Guidance

|

Overview of AI-Based Quality Inspection

Overview of AI-Based Quality Inspection

The Mech-Mind AI-based quality inspection solution is an automated defect detection and precision measurement system integrated with advanced artificial intelligence technology, specifically designed for product quality control in the manufacturing industry. Utilizing deep learning algorithms, this solution can accurately identify minute defects on product surfaces, achieving fast and precise quality inspections, significantly enhancing production efficiency and reducing reliance on manual inspections.

The core components of this solution include:

-

Mech-DLK deep learning software: provides powerful image processing and analysis capabilities, capable of adapting to various complex inspection tasks.

-

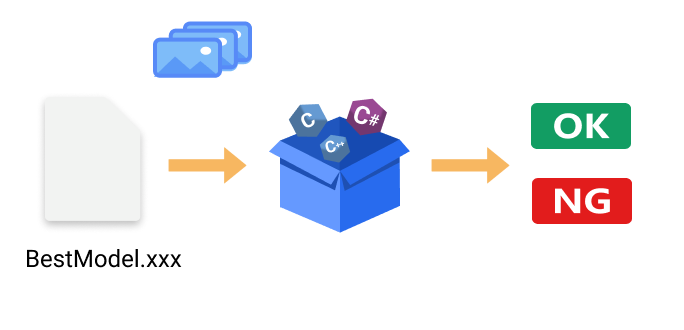

Mech-DLK SDK deep learning software development kit: provides developers with a complete set of tools for quickly developing and deploying customized AI-based quality inspection applications.

-

IPC: a stable and reliable hardware platform that ensures the system operates consistently over extended periods.

-

2D camera: a high-resolution image acquisition device that provides clear image data for deep learning software.

The Mech-Mind AI-based quality inspection solution is applicable to various industrial scenarios, including but not limited to the manufacturing processes in consumer electronics, automotive, lithium battery, and home appliance industries. By implementing this solution, companies can achieve intelligent production processes, improve product quality, reduce costs, and ultimately enhance market competitiveness.

For more information, refer to Introduction to AI-Based Quality Inspection.

Practical Application Deployment

Practical Application Deployment

Provides the approach to, operation guide of, and experience for deploying applications in actual projects. After you learn about the AI-based quality inspection solution, you can continue to learn the knowledge and expertise required for deploying AI-based quality inspection applications in this part.

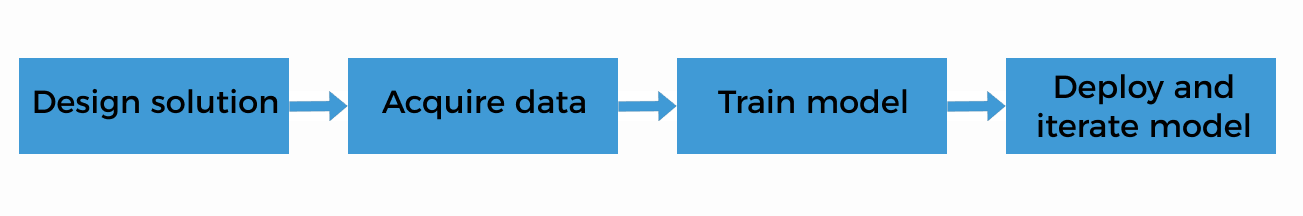

The approach to deploying an AI-based quality inspection application is shown in the following figure.

Designing the AI-based quality inspection solution refers to determining the camera and working environment requirements, and selecting the appropriate IPC model, software license version, and algorithm module based on the project’s actual needs.

For details, refer to Design AI-Based Quality Inspection Solution.

Before training the deep learning model, you need to collect high-quality image data according to the "Data Acquisition Standard" for subsequent model training.

For details, refer to Acquire Data.

Based on the collected image data, you can use Mech-DLK for training, validating, and exporting the deep learning model.

For details, refer to Train Deep Learning Model.

You can deploy the trained deep learning model to the production line for inference, enabling quality inspection. After model deployment, iterate and optimize the model as needed.

For details, refer to Deploy and Iterate Deep Learning Model.

For practical guidance on more application scenarios, please refer to Typical Case Practices of AI-Based Quality Inspection.