Introduction to AI-Based Quality Inspection Solution

What Is the AI-Based Quality Inspection Solution?

The Mech-Mind AI-based quality inspection solution is an automated defect detection and precision measurement system integrated with advanced artificial intelligence technology, specifically designed for product quality control in the manufacturing industry. Utilizing deep learning algorithms, this solution can accurately identify minute defects on product surfaces, achieving fast and precise quality inspections, significantly enhancing production efficiency and reducing reliance on manual inspections.

The Mech-Mind AI-based quality inspection solution is applicable to various industrial scenarios, including but not limited to the manufacturing processes in consumer electronics, automotive, lithium battery, and home appliance industries. By implementing this solution, companies can achieve intelligent production processes, improve product quality, reduce costs, and ultimately enhance market competitiveness.

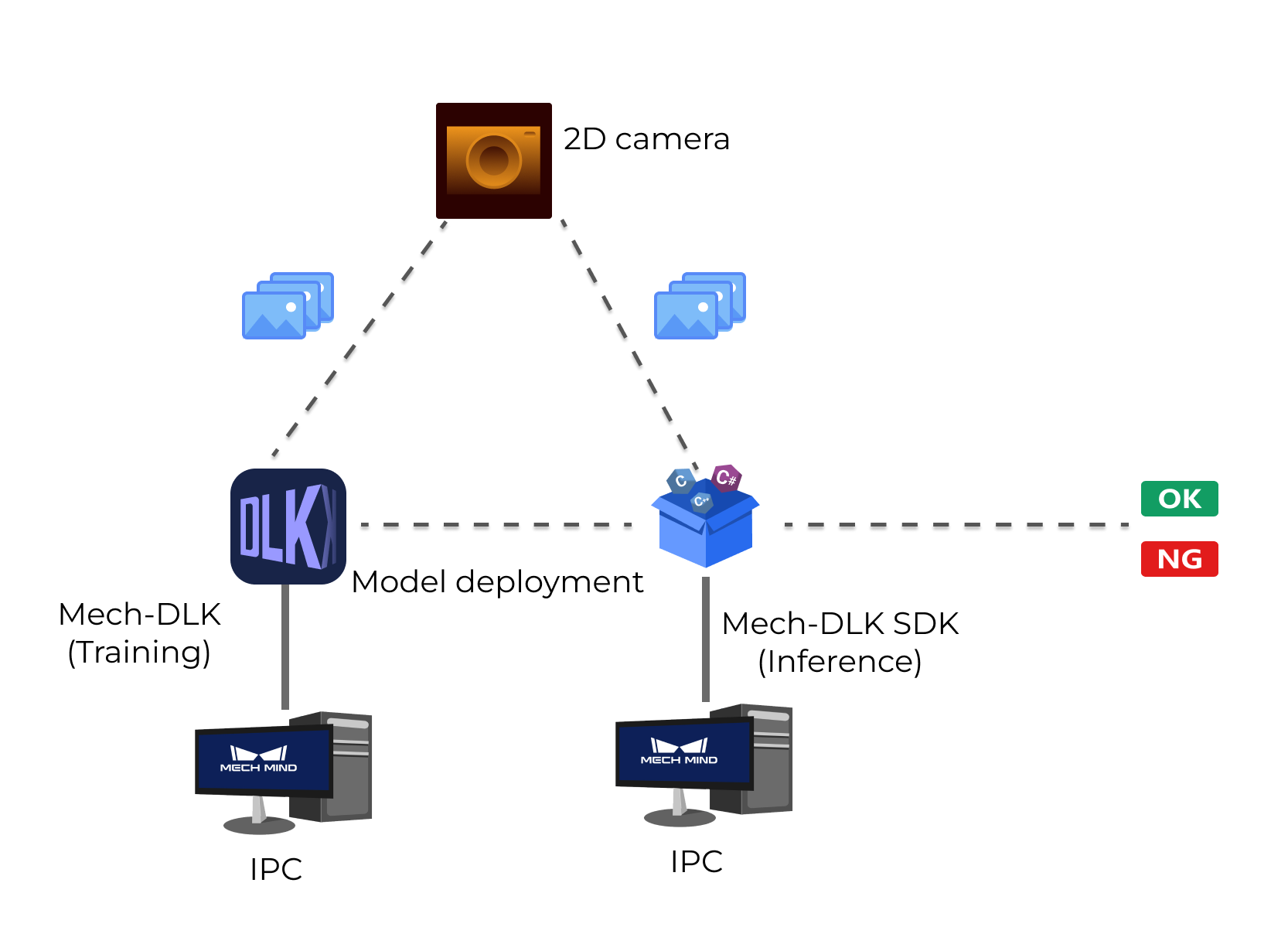

System Components of the AI-Based Quality Inspection Solution

The AI-based quality inspection solution consists of the following components:

2D Camera

The 2D camera is used to acquire image data of the target objects. Before deploying the solution to the production line, the 2D camera is used to acquire image data for deep learning model training. After deployment, the 2D camera is used to acquire image data for model inference to perform quality inspection on the target objects.

Industrial Personal Computer (IPC)

The computer that provides the stable operating environment for the Mech-Mind’s software products.

You can use the standard IPC provided by Mech-Mind (recommended) or use your own device as the IPC. For more information about the IPC, refer to Select IPC Model.

Mech-Mind’s Software Products

The Mech-Mind’s software products train the deep learning models based on the 2D image data acquired by cameras. Mech-Mind provides a software development kit that supports rapid deployment of deep learning models, allowing you to flexibly integrate deep learning-based quality inspection functions into quality control systems.

The AI-based quality inspection solution mainly involves the following software:

-

Mech-DLK

Mech-DLK is machine vision deep learning software independently developed by Mech-Mind. With a variety of built-in industry-leading deep learning algorithms, it can solve many problems that traditional machine vision cannot handle, such as highly difficult segmentation, positioning, and classification.

Through intuitive and simple UI interactions, even without programming or specialized deep learning knowledge, users can quickly implement model training and validation with Mech-DLK.

-

Mech-DLK SDK

Mech-DLK SDK is a secondary development software kit specifically designed to be used with Mech-DLK. Its main purpose is to help developers easily do deep learning inference in their software systems.

Developers can rapidly deploy deep learning models and flexibly integrate deep learning functionality into their own applications. You can use the provided APIs to build applications in C#, C++, and C languages.

Workflow of AI-Based Quality Inspection Applications

The general workflow of an AI-based quality inspection application is below:

-

Use the camera to acquire 2D images for training.

-

Use Mech-DLK to train deep learning models by using 2D images.

-

Use Mech-DLK SDK for secondary development to integrate deep learning inference functions into the quality control system (software) of the production line.

-

The quality control system (software) performs deep learning inference by calling the Mech-DLK SDK APIs and retrieves the inference results.

Application Scenarios of the AI-Based Quality Inspection Solution

The AI-based quality inspection solution can provide inline quality inspection for industries such as consumer electronics, automotive, lithium battery, home appliances manufacturing, printing, and packaging. It meets the defect inspection needs across various end-to-end processes, including presence detection, defect detection, and anomaly detection.

The typical application scenarios include:

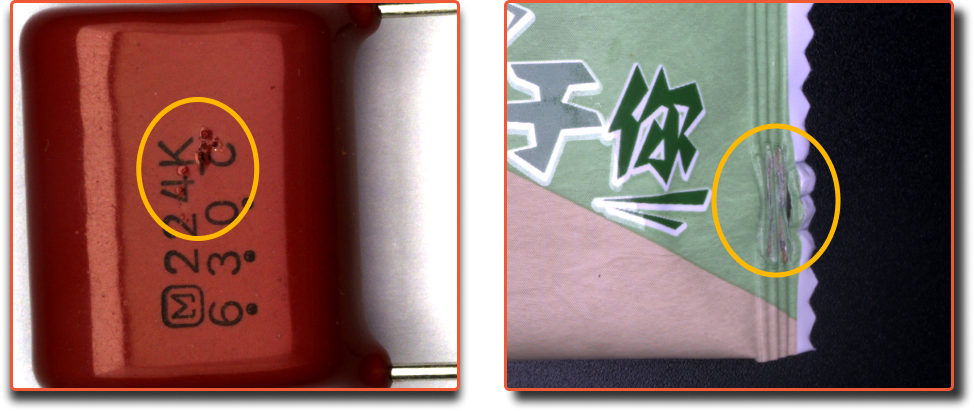

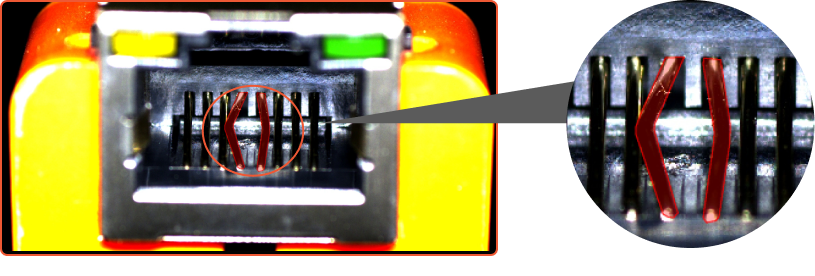

Defect inspection

Defect detection for functional modules and electronic components:

Surface defect detection for PCB substrates:

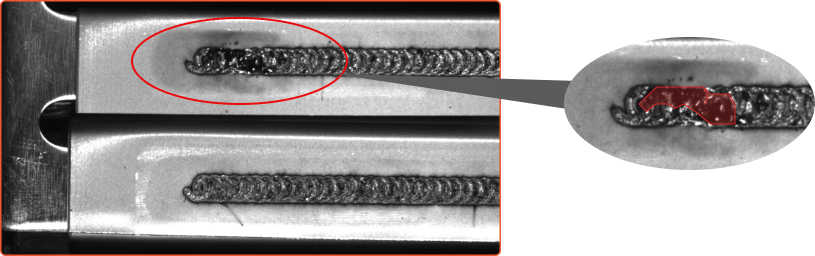

Appearance inspection

Weld seam inspection and appearance inspection of lithium-ion batteries:

Surface anomaly detection for printing products, daily necessities, and other objects: