Introduction to the Vision System

What Is the Mech-Mind Vision System?

The Mech-Mind Vision System is a comprehensive 3D vision solution from Mech-Mind for various industries, including automotive, logistics, supermarkets, and heavy industry. It offers a wide range of applications such as workpiece loading, depalletizing and palletizing, locating and assembly, piece picking, and quality inspection.

The Mech-Mind Vision System is usually used together with industrial robots and collaborative robots.

Components of the Vision System

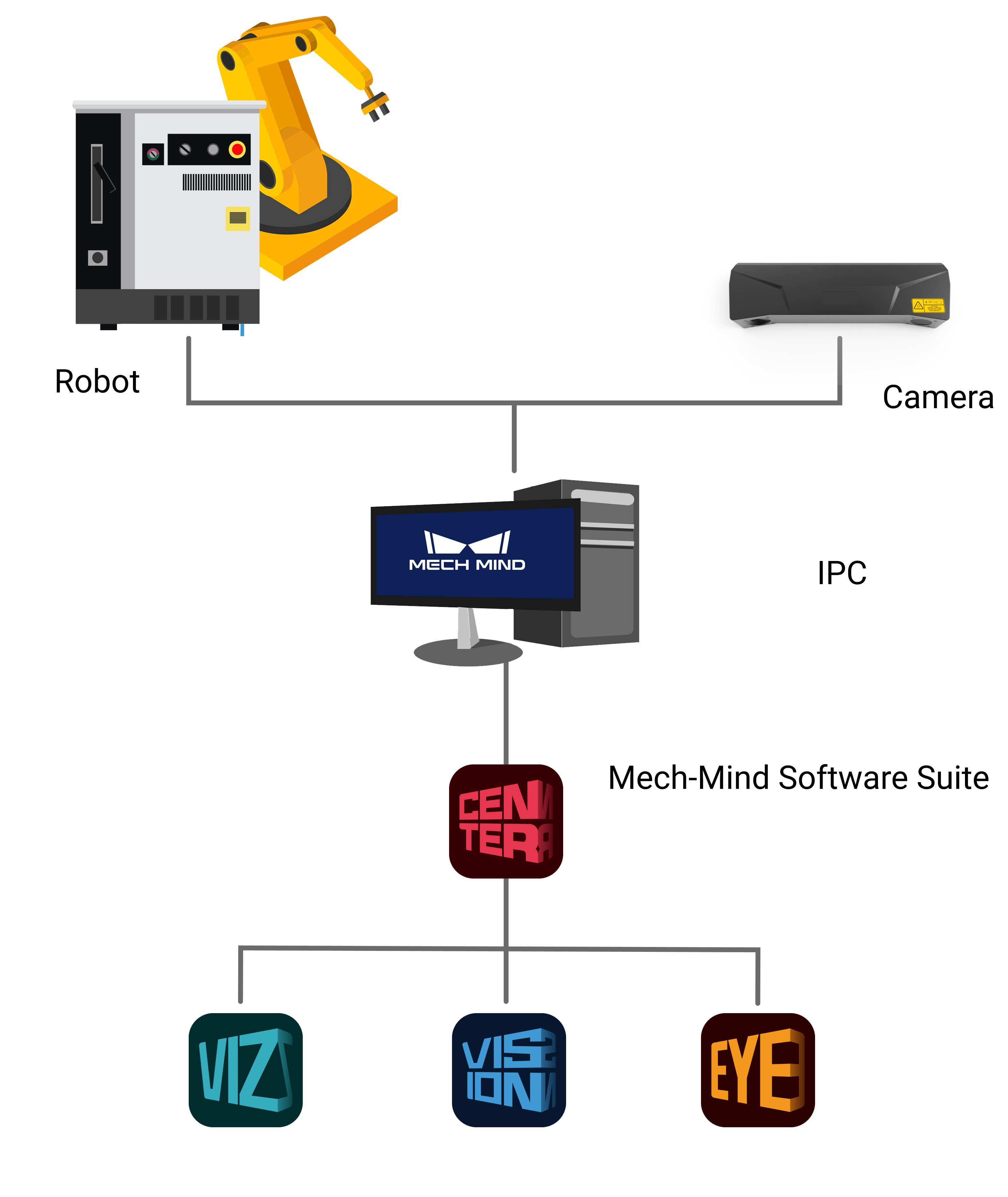

The Mech-Mind Vision System usually consists of the camera, Mech-Mind Software Suite, IPC (industrial personal computer), and the robot, as shown below.

- Camera

-

It is the Mech-Eye industrial 3D camera developed by Mech-Mind, which is used to capture image and location information of the objects.

- Mech-Mind Software Suite

-

The Mech-Mind Software Suite performs vision processing based on image and location information captured by the camera, and outputs the location and orientation of the objects and the planned motion path of the robot, thus guiding the robots to complete intelligent tasks, such as picking, depalletizing and palletizing, gluing, sorting, etc.

- IPC (Industrial Personal Computer)

-

It refers to the computer that provides the operating environment for the Mech-Mind Software Suite.

- Robot

-

A robot is a programmable multi-purpose handling device with some autonomy that can perform tasks such as movement, manipulation or positioning. In the Mech-Mind Vision System, it performs intelligent tasks based on the results output by the vision system.

|

Introduction to the Mech-Mind Software Suite

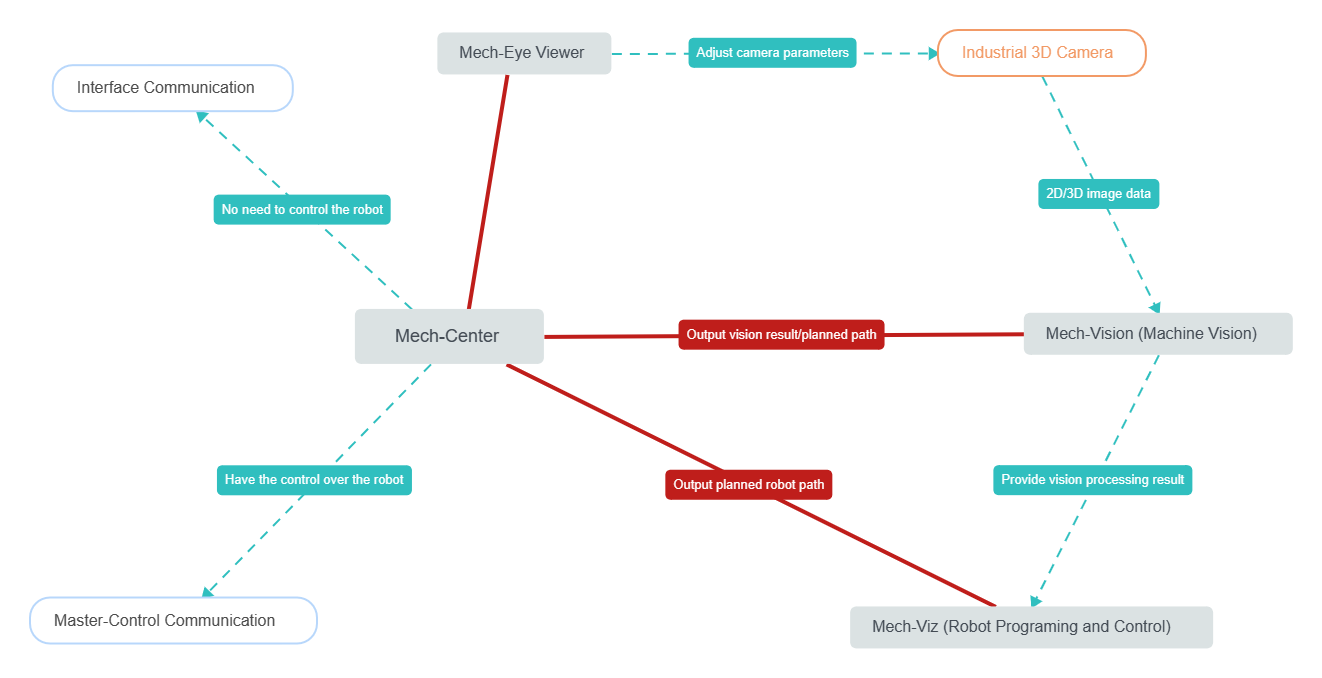

The Mech-Mind Software Suite is developed by Mech-Mind and provides 3D vision solutions for robots and peripherals. It mainly includes the following software:

-

Mech-Eye Viewer

Mech-Eye Viewer allows users to adjust the parameters of the Mech-Eye industrial 3D camera according to the characteristics of the target object, and obtain high-quality 2D images, depth maps, and point clouds.

-

Mech-Vision

Mech-Vision is a state-of-the-art machine vision software. With its fully graphical interface, advanced machine vision applications such as piece picking, high-precision positioning, assembly, industrial inspection/measurement, and automatic path planning can be completed without writing codes.

Based on the image data captured on site, this software performs a series of vision processing and outputs the vision results (such as the position and orientation of the target object). In addition, based on the vision results, this software can perform collision-free path planning for the robot, and output the planned path.

-

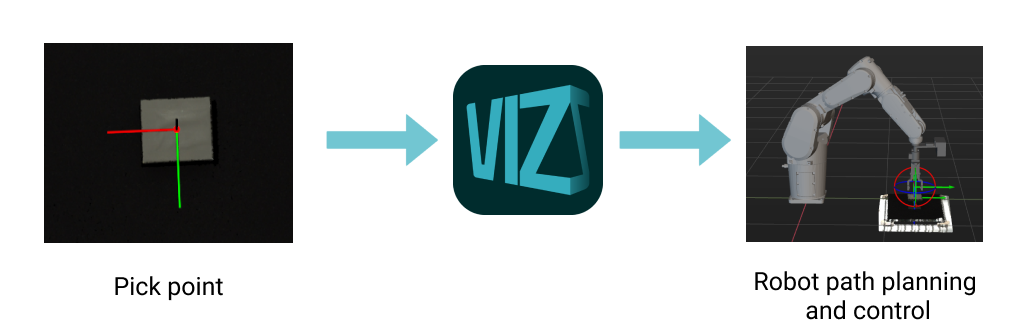

Mech-Viz

Mech-Viz is a robot path planning software. It uses the information provided by Mech-Vision, including the point clouds and workpiece positions, to intelligently plan the robot path for picking, carrying, and palletizing and other complex application scenarios.

This software allows users to build a workflow for the robot in a visualized manner and provides a 3D simulation function for validation before using the real robot. It has already been adapted to many major robot brands around the world.

-

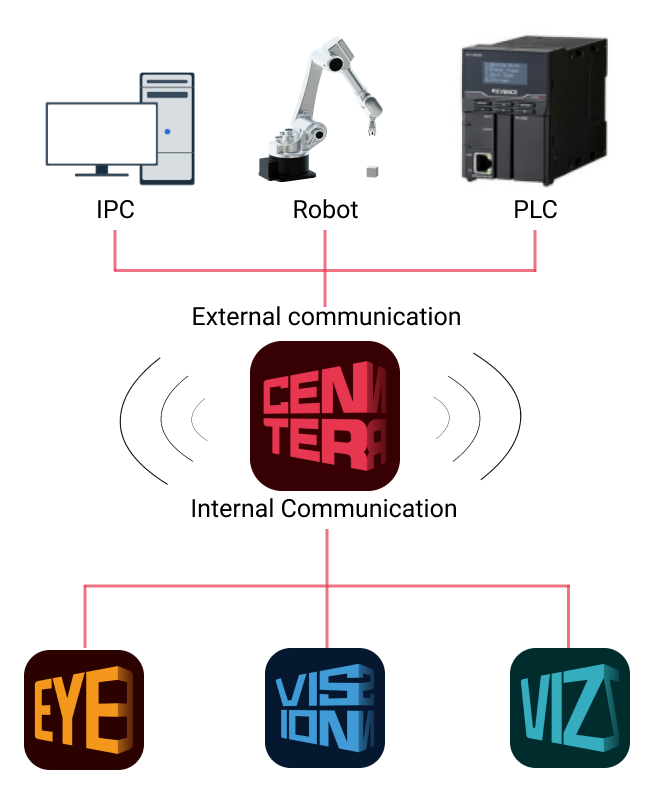

Mech-Center

Mech-Center is the communication hub and control center. It provides standard interface protocols and can help customers customize communication services, thus implementing communication with external devices and jointly completing smart manufacturing tasks with vision-guided robots.

Within the Software Suite, Mech-Center is responsible for internal communication between the software. For example, it sends the vision result output from Mech-Vision to Mech-Viz for planning the robot’s collision-free path. When Mech-Center communicates with external devices, it sends the vision result from Mech-Vision or the planned collision-free path output from Mech-Vision or Mech-Viz to the robot, PLC, or host computer. More information about the communication between the {company} Software Suite and external devices will be discussed in the following section.

The relationship between the individual software of the Mech-Mind Software Suite is shown in the following figure.

Communication with the Robot Side

To ensure that the vision result (output by Mech-Vision) or the planned robot picking path (output by Mech-Vision or Mech-Viz) can be successfully sent to the robot side, the Mech-Mind Vision System should be able to communicate with the robot side.

The Mech-Mind Vision System supports the following communication modes:

-

Master-Control communication

In this mode, the vision side has control over the robot, i.e., the vision side acts as the master device, while the robot slave device. The vision side controls the robot to perform tasks based on the planned path, such as workpiece loading or depalletizing/palletizing.

When this mode is used, the robot can be controlled by loading a master-control program to the robot or by using the robot’s SDK (Software Development Kit). This mode does not support communication with the PLC or host computer.

-

Interface communication

In this mode, the vision side does not need to take control of the robot. Typically, the robot side acts as the master device, while the vision side is the slave device. The robot side and the vision side use the same standard communication protocol to communicate (such TCP socket). The robot side sends requests while the vision side processes them and sends responses back. Depending on the request, the vision side returns either the vision result or the planned picking path. The robot makes further decisions or performs the appropriate tasks according to the responses returned from the vision side.

When this mode is used, you should load the Mech-Mind robot interface program (for communicating with the vision side and for receiving the data returned from the vision side) to the robot controller. The robot controller should be configured to use the Mech-Mind robot interface program. Furthermore, it is necessary to write a robot program (routine) for controlling the robot to perform tasks, using the data from the vision side. This mode supports communication with the robot, the PLC, and the host computer.

For more information about the communication modes, refer to the section Communication Basics.