Usage Scenarios of Deep Learning

2D Camera + Deep Learning

The following show the usage scenarios of a 2D camera + deep learning. Use these deep learning modules according to actual needs.

Fast Positioning

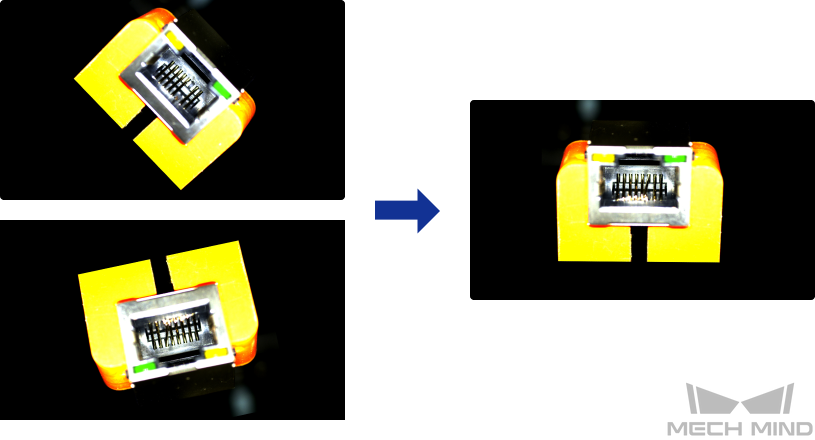

You can use the Fast Positioning module to correct the object orientations.

-

Recognizes object orientations in images and rotates these images so that objects in them have a uniform orientation.

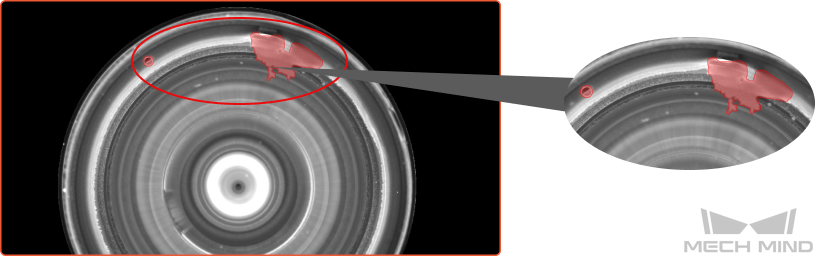

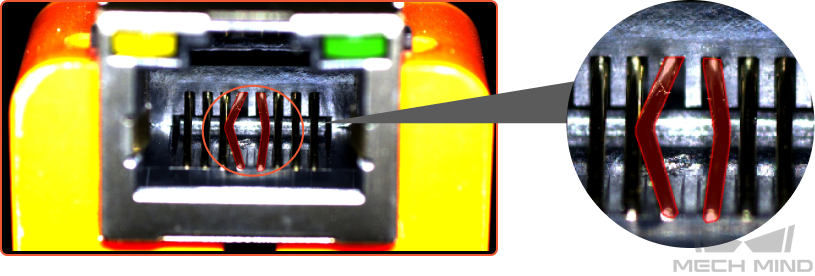

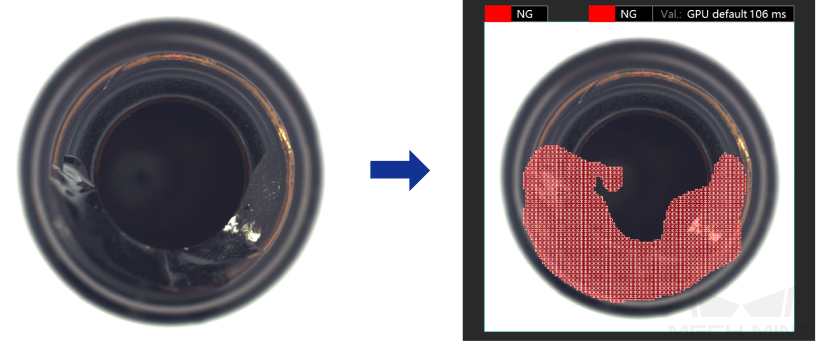

Defect Segmentation

You can use the Defect Segmentation module to detect all types of defects. These defects include surface defects, such as stains, bubbles, and scratches, and positional defects, such as bending, abnormal shape, and absence. Moreover, this module can be applied even under complex conditions, such as small defects, complicated background, or random object positions.

-

Detects air bubbles and glue spills on lenses.

-

Detects bending defects of parts.

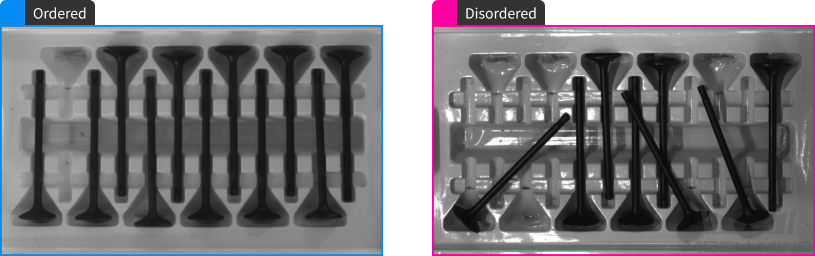

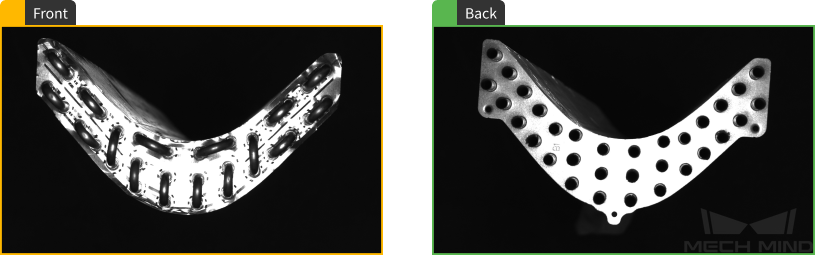

Classification

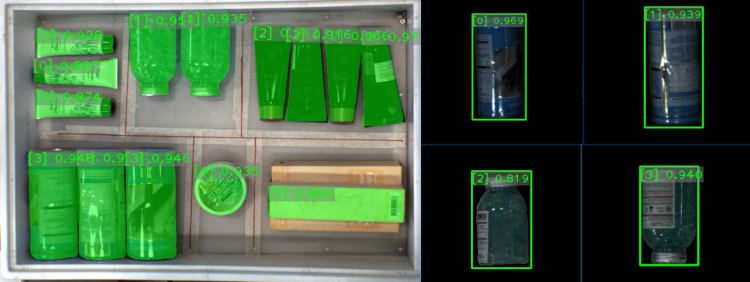

You can use the Classification module to recognize the fronts and backs of objects, object orientations, and defect types and to judge whether objects are missing or neatly arranged.

-

Recognizes whether objects are neatly arranged or scattered.

-

Recognizes the fronts and backs of objects.

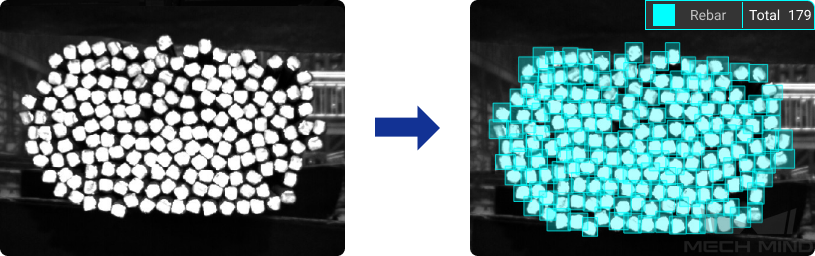

Object Detection

You can use the Object Detection module to detect the absence of objects in fixed positions, such as missing components in a PCB. You can also use it for object counting.

-

Counts all rebars.

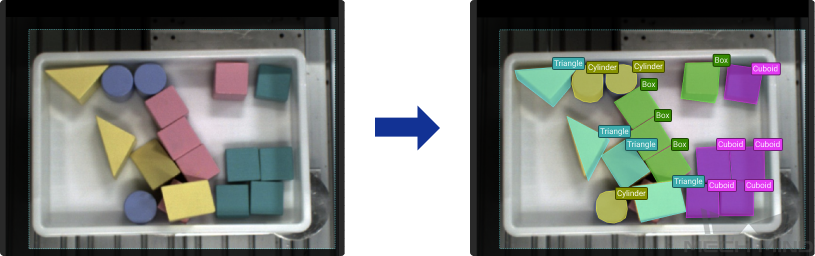

Instance Segmentation

You can use the Instance Segmentation module to distinguish objects of a single type or multiple types and segment their contours.

-

Segments blocks of various shapes.

-

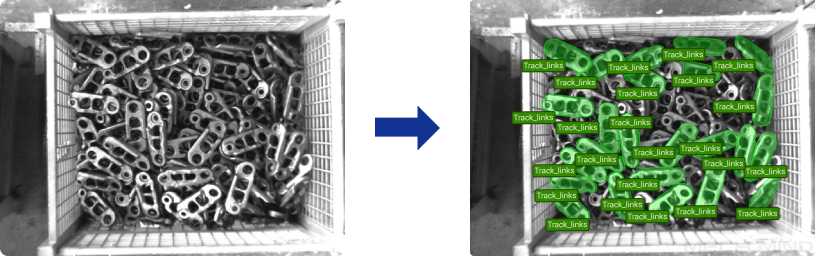

Segments scattered and overlapping track links.

-

Segments cartons closely fitted together.

Text Detection

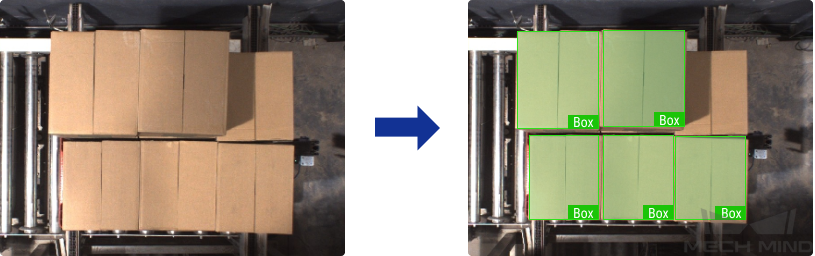

You can use the Text Detection module to detect the text area in an image and thus reduce the interference from the background.

-

Detects the text areas of an image.

Text Recognition

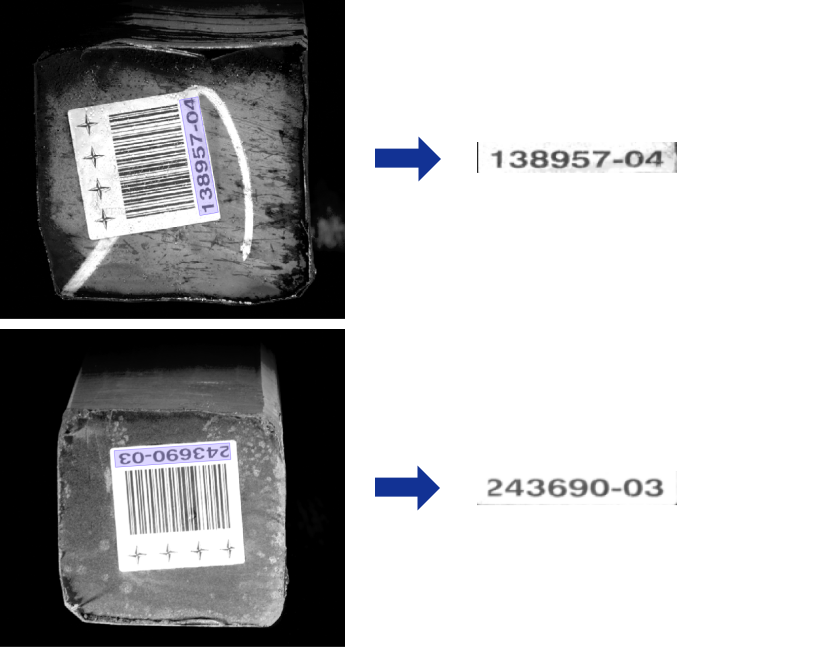

You can use the Text Recognition module to recognize the text in an image, including letters, numbers, and some special symbols.

-

Recognizes the characters in an image.

Unsupervised Segmentation

You can use the Text Recognition module to train a model on the basis of only OK images as the training set. The trained model can judge whether an image is OK, NG, or Unknown.

-

Judges whether an image is OK, NG, or Unknown according to set thresholds and displays the possible areas with defects.

3D Camera + Deep Learning

In the following scenarios, the data of point clouds cannot assure accurate recognition and positioning of objects. Therefore, we use 3D matching + deep learning to recognize and position objects.

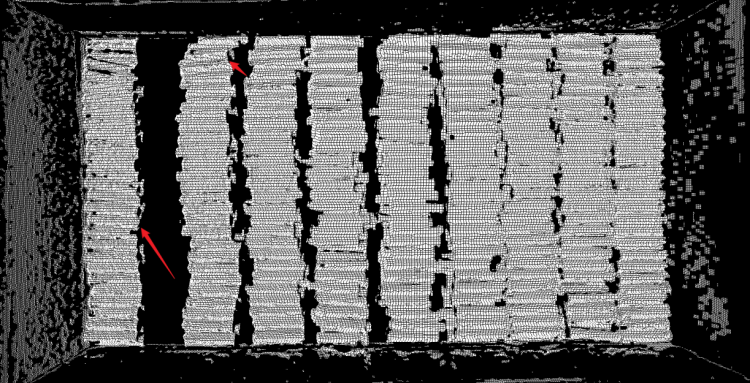

Seriously Incomplete Point Clouds

The workobjects in the following figures are used as an example.

-

2D image: In the figure below, large quantities of reflective workobjects are in contact with each other, but their edges and shape features are clear.

-

Point cloud: As the workobjects are reflective, the point clouds are incomplete. Analysis shows that missing point clouds are mostly along the workobject axis.

If point clouds are incomplete along the workobject axis, 3D matching using the point clouds may be inaccurate and thus results in largely deviated picking poses. As the workobjects are in contact with each other, the point clouds may not be correctly segmented and thus lead to incorrect matching. In addition, the quantity of workobjects is large, the vision cycle time will be long.

In such scenarios, you can use the Instance Segmentation module to train the corresponding model and then use the deep learning-related Steps in Mech-Vision to recognize the workobjects. Then, extract the point cloud corresponding to the mask of the workobject and calculate its Pose A on the basis of 3D matching. Finally, calculate Pose B on the basis of the extracted point cloud and correct the X and Y components of Pose A.

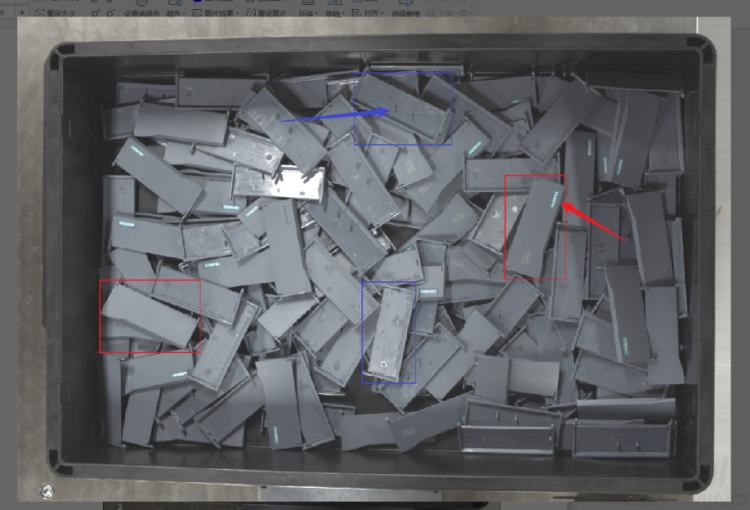

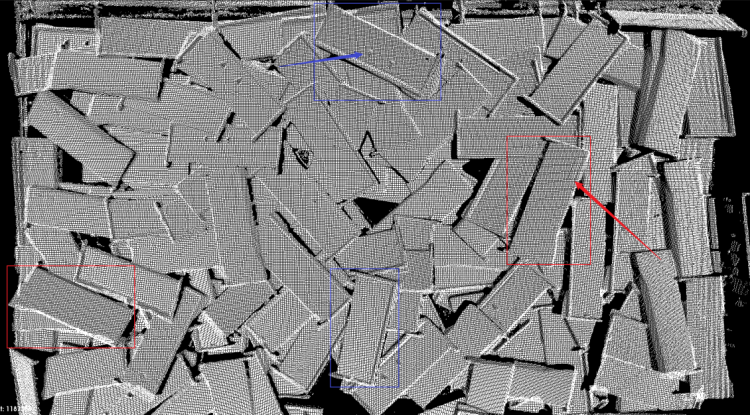

Key Features Missing from Point Cloud

The workobjects in the following figures are used as an example.

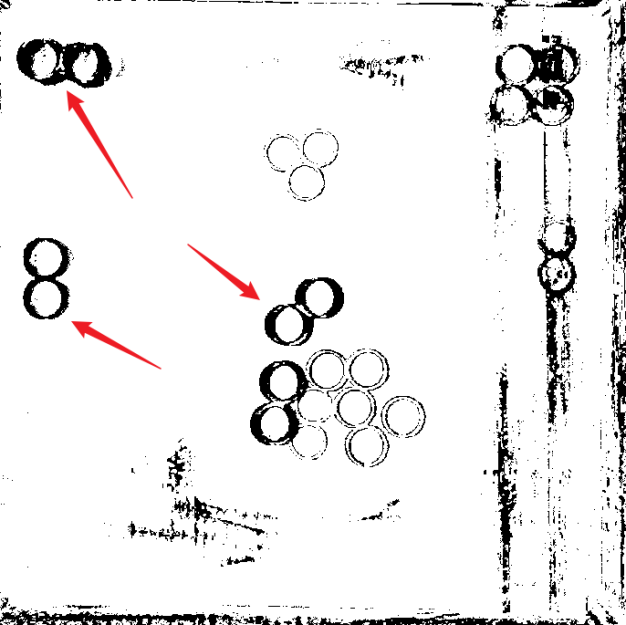

-

2D image: In the figure below, the workobjects in the red boxes have their fronts facing up, while the workobjects in the blue boxes have their backs facing up. The arrows point to key features used to distinguish between fronts and backs.

-

Point cloud: In the point cloud, the key features used to distinguish between fronts and backs of workobjects are missing.

As the key features used to distinguish workobject types are very small (even missing from the point cloud), when 3D matching is used to recognize different workobject types, the matching result may be incorrect, which results in the wrong classification of the workobjects.

In such scenarios, you can use the Instance Segmentation module to train the corresponding model and set corresponding labels for different types of workobjects. When this model is used in the deep learning-related Steps in Mech-Vision, the Steps will not only extract the masks of each workobject but also output the type labels of workobjects.

Almost No Point Cloud of Workobjects

The workobjects in the following figures are used as an example.

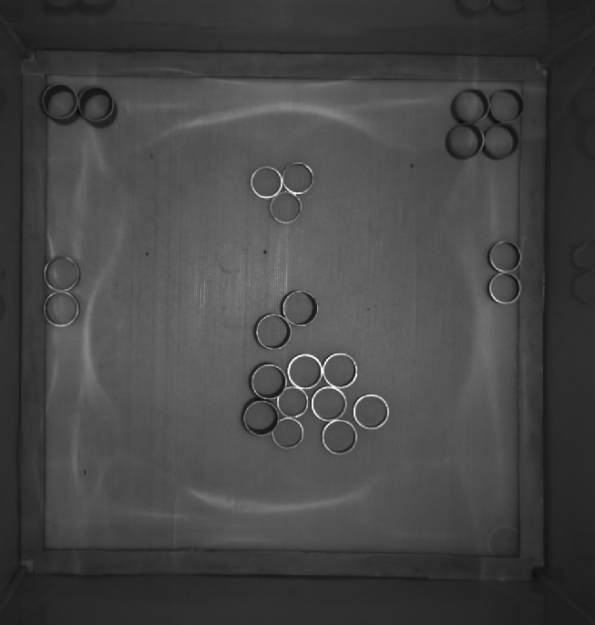

-

2D image: Wave washers are reflective and are placed close to each other in the bin.

-

Point cloud: The point clouds of the workobjects are unstable. Chances are that the points of some workobjects are completely missing.

As many object features are missing from the point clouds, it is impossible to use the point clouds for positioning the workobjects and calculating their poses by 3D matching. When 3D matching is used, incorrect matching with the bin bottom is likely to occur.

In such scenarios, although the workobjects are reflective, their edges are clear in the 2D images. Therefore, you can use the Instance Segmentation module to train the corresponding model and use this model in the deep learning-related Steps in Mech-Vision. The Steps output workobject masks, on the basis of which point clouds of workobjects are extracted. The poses of these point clouds are then calculated and used as the picking pose.

Recognize Patterns and Colored Region on Workobject Surface

The workobjects in the following figures are used as an example.

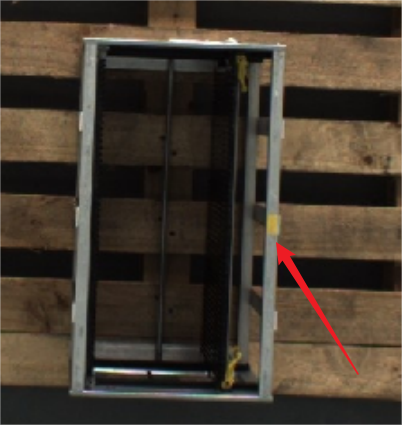

-

2D image: A piece of yellow tape is attached to one side of the aluminum bin, used to mark the orientation of the bin.

-

Point cloud: The point clouds are good, but the yellow tape cannot be reflected by the point clouds.

As the target feature is a colored region and is only visible in the color image, the orientation of the bin cannot be recognized through the point clouds.

In such scenarios, as long as the rough location of the yellow tape is determined, the orientation of the aluminum bin can also be determined. You can use the Object Detection module to train the corresponding model and use this model in the deep learning-related Steps in Mech-Vision to recognize the workobjects.

Random Picking from Deep Bin

The workobjects in the following figures are used as an example.

-

2D image: Steel bars are randomly piled in the bin, and some regions of some steel bars reflect light. In addition, the steel bars overlap each other.

-

Point cloud: For workobjects not overlapped, their point clouds are good. For overlapped workobjects, it is difficult to render the point cloud of each workobject by clustering, and the clustering performance is unstable.

Point cloud clustering cannot stably cluster out the point cloud of each workobject. It is difficult to train a suitable model for 3D matching in that the orientations of workobjects vary greatly. 3D matching might also output incorrect matching results, which leads to inaccurate pose calculation. In addition, using only point cloud models for global matching will result in a very long vision cycle time.

In such scenarios, you can use the Instance Segmentation module to train the corresponding model and use this model in the deep learning-related Steps in Mech-Vision to extract the masks of individual workobjects. Then, extract the point clouds corresponding to the masks and then use the point clouds for the matching of individual workobjects.

Point Cloud Clustering Fails to Separate Point Clouds of Overlapped Workobjects

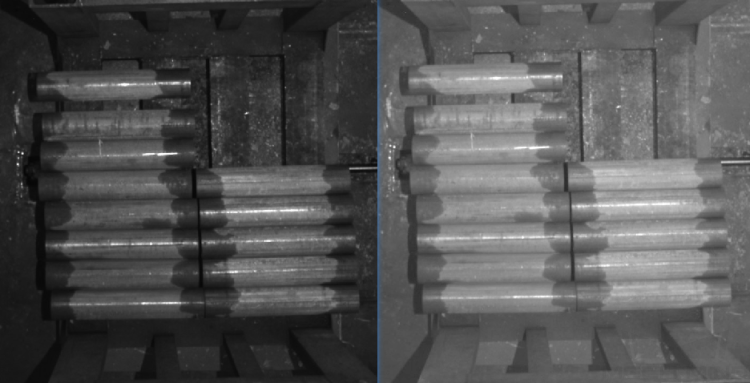

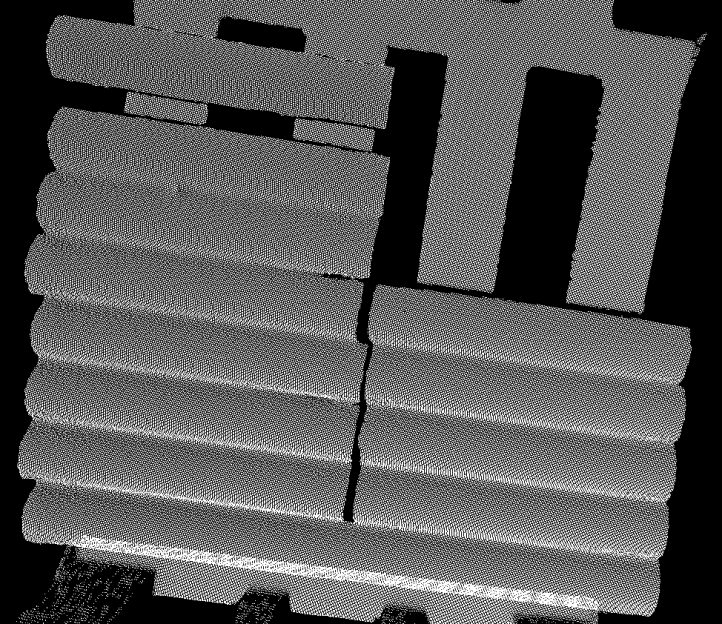

The workobjects in the following figures are used as an example.

-

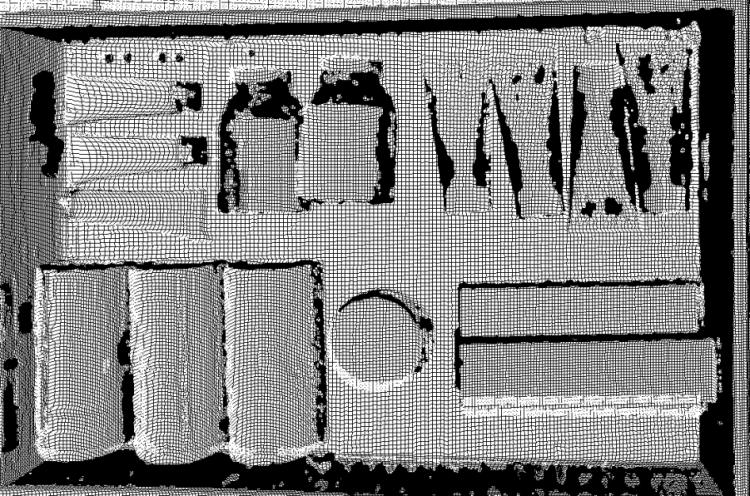

2D image: The obtained 2D images are too dark, and workobject edges may not be discernible. After the image brightness is enhanced, the workobject edge, size, and grayscale value can be obtained.

-

Point cloud: The point clouds are good, but the workobjects are in contact with each other. Therefore, the edges of different workobjects may not be correctly separated.

Although the point clouds are good, but the point clouds of workobjects stick to each other, so point cloud clustering cannot be used to segment the point clouds of individual workobjects. Global 3D matching might output incorrect matching results or even matching to the bin.

In such scenarios, you can use the Instance Segmentation module to train the corresponding model. The trained model can be used in the deep learning-related Steps in Mech-Vision to extract the workobject point clouds and then perform matching.

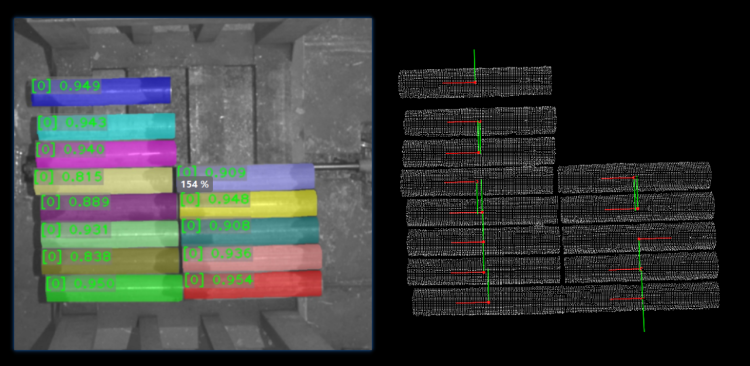

Recognize and Pick Workobjects of Different Types

The workobjects in the following figures are used as an example.

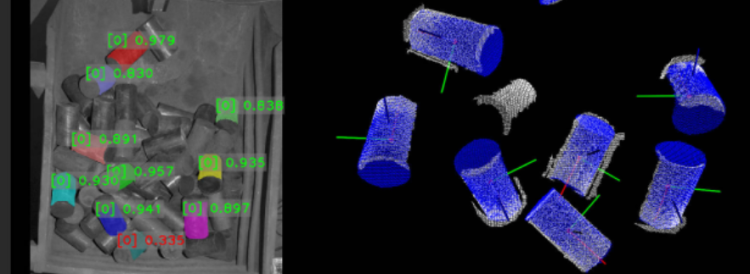

-

2D images: The image on the left is obtained at the station where the workobjects are randomly placed. The image on the right is obtained at the station where secondary judgment is performed. The quality of the 2D images at both stations is good, and the features of different types of workobjects are distinctive.

-

Point cloud: The point clouds are good, and the shape features of the workobjects are clearly reflected in the point clouds.

For cylindrical workobjects, however, the point clouds cannot reflect the orientation or the type of the workobject, so using only 3D matching cannot distinguish the workobject orientation and type.

For the above 2D image on the left, you can use the Instance Segmentation module to train the corresponding model and use the model in the deep learning-related Steps in Mech-Vision to recognize and segment the workobjects. The Steps will output the corresponding workobject masks, which can be used for subsequent point cloud processing.

For the above 2D image on the right, you can use the Instance Segmentation module to recognize individual workobjects and then use the Object Detection module to determine the orientations of workobjects according to the shape and surface features. (The left figure below shows the instance segmentation result, and the right figure below shows the object detection result of determining the orientations of workobjects.)