Output

Function

This Step sends the vision result of the current project to the Mech-Viz or communication component for subsequent picking.

|

Only one “Output” Step can be added in a vision project, which means that each vision project contains exactly one “Output” step. |

Usage Scenario

This Step is usually used to send various vision results from the current project to other services.

Input and Output

Since this Step outputs results to external services, it has no output ports connected to subsequent Steps and only has input ports, which come in three port types: Custom, Predefined (vision result) and Predefined (robot path). Each corresponds to a different type of data input.

|

All default ports must be connected to valid input data; otherwise, an error will occur when running the "Output" Step. |

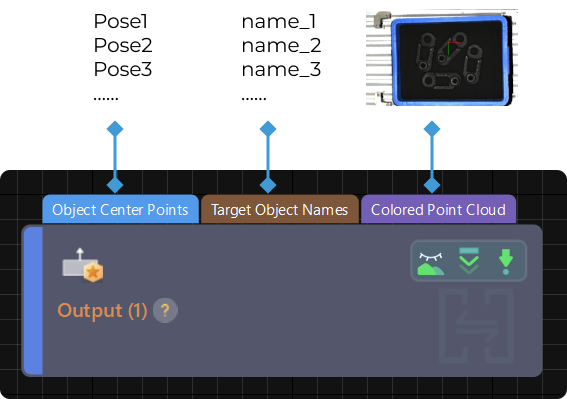

Take the “Predefined (vision result)” port type as an example; the input for this Step is shown in the figure below.

|

When the target object is saved using the “No point cloud model required” workflow in the target object editor, the pick point should be input directly, and the Step will output the same pick point as the one input. |

Parameter Description

Port Type Settings

- Port Type

-

Description: This parameter is used to select the port type of the Step.

Value list: Predefined (vision result), Predefined (robot path), Custom

-

Predefined (vision result): Select this port type when Mech-Vision is only used for vision processing and then the vision result is sent to Mech-Viz or external service.

-

Predefined (robot path): Select this port type when using Mech-Vision for both vision processing and path planning.

-

Custom: Select this port type if you need to customize the data sent to Mech-Viz.

Default value: Predefined (vision result)

Instruction: Select the port type according to the actual requirements.

-

Predefined (vision result)

This port type is suitable for Master-Control, Standard Interface or Adapter communication.

Mech-Viz can receive the vision results output from this type of port under different communication modes, with only the communication logic differing:

-

When the Master-Control communication mode is used, the vision system sends the vision result to the robot.

-

When the Standard Interface or Adapter communication mode is used, the external device (robot, PLC or host computer) sends commands to the vision system, and the vision system returns the vision result to the external device.

Usage Scenario

- Select Scenario

-

Description: Select the usage scenario of the current solution.

Value list: Matching (Machine Tending/Positioning/Assembly), Depalletizing, Others

Scenario Description Quick Guide to Target Object Recognition Matching (Machine Tending/Positioning/Assembly)

Suitable for scenarios where target objects are created in the target object editor and the target object poses are obtained by matching with the point cloud model. For example, the machine tending, positioning, and assembly applications.

Depalletizing

Suitable for depalletizing scenarios. Target object poses can be obtained by deep learning or other methods without matching with the point cloud model.

Others

Suitable for picking in other scenarios, such as picking versatile objects in supermarket and box picking scenarios.

Default value: Matching (Machine Tending/Positioning/Assembly)

- Method to Convert Data

-

Description: By selecting the result conversion method, this Step converts the recognition result to the data type needed for picking.

Value list: Generate picking strategy based on object center point, Generate picking strategy based on pick points

-

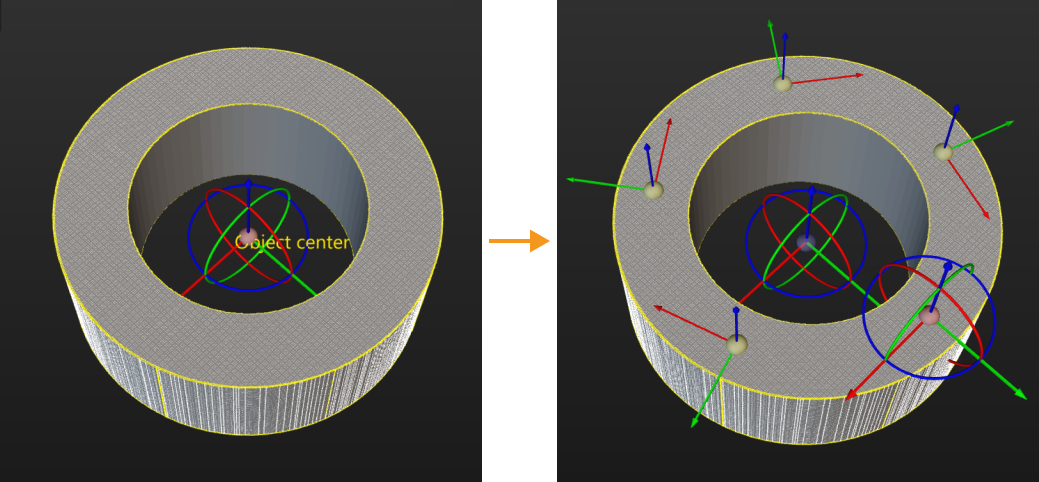

Generate picking strategy based on object center point: Suitable for symmetrical target objects, requiring orientation adjustment of the object center point. Once this option is selected, you need to input the object center point for the “Output” Step, which will automatically convert the object center point to the corresponding pick point.

-

Generate picking strategy based on pick points: Suitable for target objects with multiple pick points that need to be filtered. Once this option is selected, you need to input the pick point and pick point information to the “Output” Step.

Default value: Generate picking strategy based on object center point

-

- Target Object without Point Cloud Model

-

Description: Select a target object that does not require a point cloud model, and this Step can output pick point information for the target object. Please set this parameter when the usage scenario is “Depalletizing” or “Others.”

Collision Detection Settings

- Send Point Cloud to External Service

-

Description: This parameter is used to send the point cloud to Mech-Viz. It is usually used for debugging or checking the running result of the project.

Default setting: Selected

- Point Cloud Type

-

Description: This parameter is used to select the type of the point cloud to send to Mech-Viz.

Value list: CloudXYZRGB (colored point cloud), CloudXYZ (point cloud), and CloudXYZNormal (point cloud with normals)

Default setting: CloudXYZRGB

- Point Cloud in Camera Frame

-

Description: Please select this parameter when the point cloud is in the camera reference frame. Once this option is selected, the point cloud will be converted to the robot reference frame and sent to Mech-Viz. If this option is not selected, the point cloud will be sent to Mech-Viz directly.

Default setting: Selected

- Remove Point Cloud of Irregular Shape

-

Description: Once this option is enabled, any point cloud overlapping with the collision model of the target object with a non-standard 3D shape will be removed by Mech-Vision to prevent interference in collision detection. Please set this parameter when the usage scenario is “Matching (Machine Tending/Positioning/Assembly).”

Default setting: Unselected

Instruction: If you need to detect collisions on target objects throughout the entire process from picking to placing, please select this parameter and make sure that the collision model is configured for the target object. Please note that this parameter is invalid for target objects generated with common 3D shapes in the target object editor.

- Search Radius of Target Object Point Cloud

-

Description: Take any point in the point cloud of the target object as the center, and the point cloud within the search radius will be removed. Please set this parameter when Remove Point Cloud of Irregular Shape is selected.

Default value: 3 mm

Other Input Settings

- Other Inputs

-

Description: Once this option is selected, new input ports “Pick Point Labels”, “Target Object Dimensions”, and “Pick Point Offsets” will be added to the Step.

Default setting: Unselected

Instruction: Once this parameter is selected, please make sure that the newly added input ports have data input. Otherwise, the “Output” Step will fail.

Update Scene Object Settings

- Update Scene Object

-

Description: This parameter is usually used in scenarios where the bin pose needs to be updated dynamically. Once this option is selected, ports “Scene Object Names”, “Scene Object Dimensions”, and “Scene Object Poses” will be added to the Step.

Default setting: Unselected

Accuracy Drift Correction

- Auto-Correct Accuracy Drift in Vision System

-

Description: Once this parameter is selected, the accuracy drift of the vision system will be corrected automatically. This parameter will only be displayed after the Auto-correct accuracy drift in EIH/ETH vision system feature is deployed in the Error Analysis Tool.

Default setting: Selected

Instruction: Once the Auto-correct accuracy drift in EIH/ETH vision system feature is deployed, you can select this parameter to enable the auto-correction feature.

Predefined (robot path)

Suitable for Standard Interface or Adapter communication mode. The external device (robot, PLC or host computer) sends commands to the vision system, and the vision system returns the planned waypoints to the external device.

Once this port type is selected, only the “Path Planning” Step can be used to receive the vision result corresponding to this port type. Receiving vision results via Mech-Viz is not supported.

Custom

Suitable for Standard Interface or Adapter communication mode. The external device (robot, PLC or host computer) sends commands to the vision system, and the vision system returns the planned waypoints to the external device.

Once this port type is selected, predefined keys and custom keys can be used. Typically, it is recommended to use predefined keys. If a predefined key does not meet the requirements of a custom communication command, you can use a custom key.

- Customized Ports Name

-

Description: This parameter is used to customize the input port.

Instruction: Click Open the editor, and select the input port you want to add in the Output Setting Assistant window.

Input ports Description Note poses

Object poses. Array format.

Required

labels

Object labels. Array format with the same length with poses.

Optional

sizes

Object 3D dimensions with the same length as the poses or with a length of 0.

Optional

offsets

Offset of the pick point relative to the object center point. Array format with the same length as the poses or with a length of 0.

Optional

objectIndexes

Index of the object. Array format with the same length as the poses or with a length of 0.

Optional

scene_object_names

List of scene object names to be updated.

Optional

scene_object_sizes

List of scene object dimensions to be updated.

Optional

scene_object_poses

List of scene object poses to be updated.

Optional

workobject_data

Target object picking strategy to be input to Mech-Viz. Once this port is selected, connect it to the “Picking Strategy” output port of the Generate Picking Strategy Step. The “Picking Strategy” output port appears when the “Method to Convert Data” is set to “Generate picking strategy based on pick points” or “Generate picking strategy based on object center point”.

Required when using Mech-Viz

|