Mech-Vision Release Notes

Mech-Vision 2.1.2 Release Notes

This document introduces the new features, improvements, and resolved issues of Mech-Vision 2.1.2.

New Features

Added the “Auto-Correct Accuracy Drift in Vision System” Feature

The Auto-correct accuracy drift in vision system feature was added to Mech-Vision 2.1.2. Deploying this feature in the Error Analysis Tool can correct the accuracy drift in the vision system, improving its stability and reducing subsequent maintenance costs.

New “Point Cloud Preprocessing” Procedure

The new “Point Cloud Preprocessing” Procedure in Mech-Vision 2.1.2 performs pre-processing operations such as point filtering, point cloud merging, and image filtering on the original point cloud to delete interfering points, thus speeding up the processing of subsequent Steps.

Improvements

Improved Camera Calibration Tool

The “Save Calibration result” feature in the camera calibration tool has been improved in Mech-Vision 2.1.2, enabling the saved calibration parameter group to be applied to the current project or to all projects in the current solution.

Improved Target Object Editor

The target object editor has been improved in Mech-Vision 2.1.2. See the following for details.

-

Adapted the “Auto-correct accuracy drift in vision system” feature.

A “Collect data for drift correction” step has been added to all workflows containing the “Teach pick point” step in the target object editor. If the pick point of a target object model was added by jogging the robot, additional data collection for EIH/ETH drift correction is required after enabling the drift correction feature in the latest software version. This update allows for effective drift compensation and reverse correction, ensuring that pick points added through robot jogging remain precise and reliable.

-

Improved the “Import STL file” workflow.

-

The “Point cloud generation mode” can be selected, enabling a point cloud to be generated from a specified view or an entire surface.

-

-

Improved the “Jog robot and get point cloud” workflow.

-

Multiple pick points can be added by jogging the robot.

-

A “Set pick point” step is added to enable the adjustment of pick points added by jogging the robot.

-

-

Improved the “Import processed point cloud” workflow.

-

When creating a target object, you can choose to set pick points by using project Steps, manual editing, or robot jogging. Different pick point setting methods correspond to different target object configuration processes.

-

The imported project information will be saved when saving the target object or closing the target object editor.

-

-

Improved the “No point cloud model required” workflow.

-

The “Recognize without matching” workflow is renamed to “No point cloud model required.”

-

By removing the mutual exclusion between this workflow and others, you can use it to create multiple target objects, and other workflows under the same solution will not be disabled.

-

If the target object is a horizontal cylinder, after adjusting the pick point to the surface of the target object, the object center point will not move.

-

The object center point and the pick point’ offset to the object center point will be displayed in the visualization area. Setting the visibility of the pick point and the object center point in the visualization settings is not supported.

-

-

Other Improvements

-

In the “Edit model” step, generating reversed point cloud normals is now supported.

-

In the “Set pick point” step, the option to process the vision result with pick point arrays is available. This feature is not supported in the “No point cloud model required” workflow.

-

In the “Set pick point” step, when previewing the picking effect, the tool displayed in the visualization area is the first enabled tool, rather than the first one in the tool list.

-

In the “Teach pick point” step, the entered TCP and robot flange poses for the pick points will now be saved when the target object is saved and the target object editor is closed, and will no longer be cleared. Note that if multiple robot flange poses for pick points are entered, only the last one will be saved when the target object editor is closed.

-

In all configuration workflows, the object center point and pick points no longer affect each other — modifying one will no longer change the other.

-

The measurement feature is supported in the visualization area.

-

The error message shown when saving a target object in the target object editor has been improved.

-

When entering poses in the target object editor, the Euler angle convention automatically switches based on the selected robot model in “Robot Communication Configuration.”

-

Improved the “Capture Images from Camera” Step

The “Capture Images from Camera” Steps has been improved in Mech-Vision 2.1.2.

-

Selecting a robot service name from the dropdown list of the “Robot Service Name in Communication Component” parameter is supported.

-

The default value of the “2D Image Type” parameter has been changed from “Internal IR Image” to “External Color Image.”

-

When the “2D Image Type” is set to “External Color Image,” the “Rectify to Depth Map” parameter is unselected by default.

Improved the “Trigger Control Flow Given No Output” Feature in the “3D Target Object Recognition” and “Adjust Poses V2” Steps

In Mech-Vision 2.1.2, when “Trigger Control Flow Given No Output” is selected in the “3D Target Object Recognition” and “Adjust Poses V2” Steps, control flow can now be triggered as expected.

Improved Runtime Performance of 3D Matching Steps

Mech-Vision 2.1.2 improved the runtime performance of 3D matching Steps, reducing runtime when multiple 3D matching Steps are executed simultaneously.

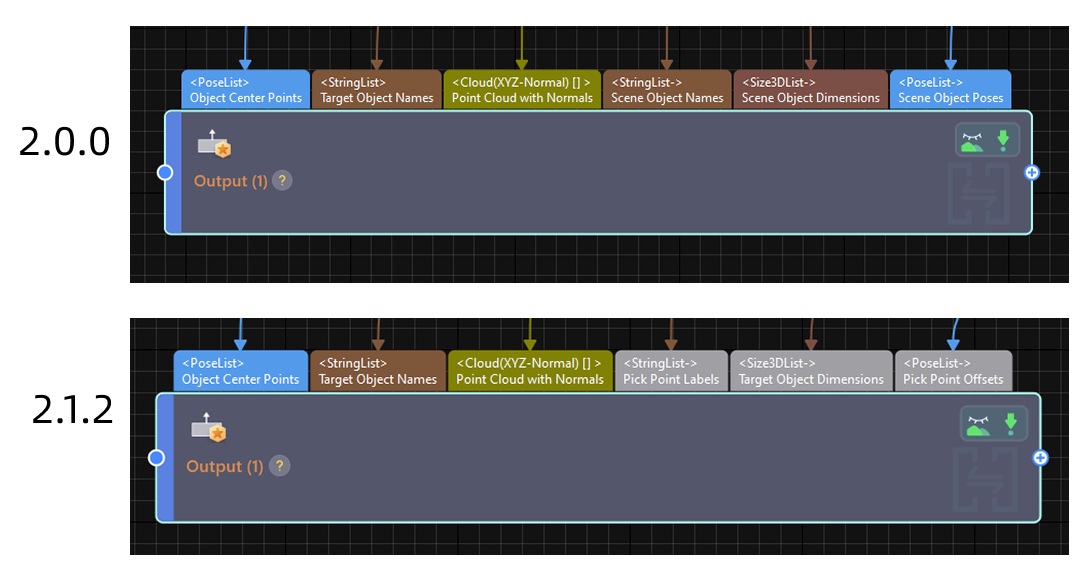

Improved the “Output” Step

The Output Step has been improved in Mech-Vision 2.1.2. See the following for details.

-

Added the “Auto-Correct Accuracy Drift in Vision System” parameter. Once selected, the latest generated drift correction data will be used to correct the accuracy drift in the vision system. This parameter will only be displayed after the Auto-correct accuracy drift in EIH/ETH vision system feature is deployed.

-

When the target object is saved using the “No point cloud model required” workflow in the target object editor, the pick point should be input directly, and the Step will output the same pick point as the one input.

-

The default option for “Port Type” has been changed from “Predefined (robot path)” to “Predefined (vision result).”

-

The “Matching” option in the “Select Scenario” parameter has been renamed to “Matching (Machine Tending/Positioning/Assembly)” to specify the usage scenarios more clearly.

-

A new “Target Object without Point Cloud Model” parameter is added. Please configure this parameter when the usage scenario is set to “Depalletizing” or “Others.”

-

The parameter “Remove Point Cloud of Target Object” has been renamed to “Remove Point Cloud of Irregular Shape.” This parameter removes point clouds that overlap with the collision model of target objects with non-standard 3D shapes, helping prevent interference during collision detection.

-

When the “Port Type” is set to “Custom,” point clouds can be sent to an external service.

-

When opening a solution created with an earlier version in Mech-Vision 2.1.2, if a port of the “Output” Step was previously connected and the related parameter is unselected, the port will be grayed out instead of hidden, and the data flow will remain connected.

For example, in a solution created with an earlier version, the scene object-related ports of the “Output” Step was connected. After opening this solution in Mech-Vision 2.1.2 and unselect the “Update Scene Object” parameter, the scene object-related ports will be grayed out, but the data flow will not be disconnected. In this case, the data flow connected to the scene object-related ports should be manually removed.

|

As for other compatibility issues about the Output Step, please refer to Before You Upgrade. |

Improved the “Path Planning” Step

The Path Planning Step has been improved in Mech-Vision 2.1.2. See the following for details.

-

The “Matching” option in the “Select Scenario” parameter has been renamed to “Matching (Machine Tending/Positioning/Assembly)” to specify the usage scenarios more clearly.

-

A new “Target Object without Point Cloud Model” parameter is added. Please configure this parameter when the usage scenario is set to “Depalletizing” or “Others.”

-

The parameter “Remove Point Cloud of Target Object” has been renamed to “Remove Point Cloud of Irregular Shape.” This parameter removes point clouds that overlap with the collision model of target objects with non-standard 3D shapes, helping prevent interference during collision detection.

-

When opening a solution created with an earlier version in Mech-Vision 2.1.2, if a port of the “Path Planning” Step was previously connected and the related parameter is unselected, the port will be grayed out instead of hidden, and the data flow will remain connected.

|

As for other compatibility issues about the Path Planning Step, please refer to Before You Upgrade. |

Improved the “Generate Picking Strategy for Target Object” Step

The Generate Picking Strategy for Target Object Step has been improved in Mech-Vision 2.1.2. See the following for details.

-

A “Target Object without Point Cloud Model” parameter has been added. This parameter can be configured when the “Method to Convert Data” is set to “Generate picking strategy based on object center point” or “Generate pick point based on object center point.”

-

If the “Target Object Names” input port is connected, and the “Target Object without Point Cloud Model” parameter is configured, the Step will prioritize the target object name provided through the “Target Object Names” input port.

-

If the “Target Object Names” input port is not connected, or is connected but no target object name is obtained, the Step will obtain it according to the “Target Object without Point Cloud Model” parameter.

-

-

When the target object is saved using the “No point cloud model required” workflow in the target object editor, the object center point input to the Step is the same as the output pick point.

More user-friendly production interface.

The production interface has been improved in Mech-Vision 2.1.2. See the following for details.

-

Improved the production interface configurator.

-

When configuring the running views, you can now add multiple running views and customize the point cloud source for the “Picking sequence” view.

-

In general settings, you can now set the “Default startup screen” and choose whether to automatically “Switch production unit during execution.”

-

-

More user-friendly production interface.

-

The Monitoring of Accuracy Drift in Vision System feature has been introduced. After the Auto-Correct Accuracy Drift in EIH/ETH Vision System feature is deployed:

-

You can monitor real-time drift compensation in the status area of the production interface.

-

In the operation area of the production interface, clicking “Maintenance” can navigate to the “Drift correction (EIH/ETH)” tab, where you can monitor the accuracy drift and drift correction status in the vision system.

-

-

The production recipes can be edited in the Target object and recipe info panel.

-

Viewing the most recent editor is now supported in the production recipe window.

-

Improved “Solution Access Control” Feature

The Solution Access Control feature has been improved in Mech-Vision 2.1.2.

-

When adding an account, you can now set a username, and both the username and password must be unique.

-

You can now enable auto-logout after inactivity for each role and customize the inactivity timeout.

-

Login method settings apply globally.

|

Improved Step Library

The Step library has been improved in Mech-Vision 2.1.2. Some Steps have been deleted. See the following for details.

| No. | Removed Step | Alternative Step |

|---|---|---|

1 |

Map to Multiple Pick Points |

|

2 |

Predict Object Poses (Sim2Pick) |

N/A |

Improved Parameter Recipe Editor

The Parameter Recipe Editor has been improved in Mech-Vision 2.1.2. See the following for details.

-

Copying available parameter recipes is supported.

-

Names of parameters in the parameter recipe can be customized.

Improved the Method for Saving Logs Related to Output Result

The method for saving logs related to output results has been improved in Mech-Vision 2.1.2, as detailed below.

-

Output results are printed to the log panel only when the “Debug Output” feature is enabled.

-

When Mech-Vision is triggered by an external device, output results will not be printed to the log panel or saved to the log. If the “Data Storage” feature is enabled, output results will be saved to the designated path specified by the “Data Storage” feature.

Resolved Issues

The following issues have been resolved in Mech-Vision 2.1.2:

-

Opening too many Mech-Vision projects might have caused the software to crash.

-

In the “Capture Images from Camera” Step, if the “Robot Service Name in Communication Component” was not set and the “Flange Pose during Capture” was entered manually, the Euler angle convention defaulted to “X → Y → Z” and could not be changed. This prevented correct input of the capture pose and affected the project results.

-

Hand-eye calibration using 4-axis or 5-axis robots might have produced incorrect extrinsic parameters.

-

The FANUC robot example program generated by the “Auto-correct accuracy drift in ETH vision system” feature contained errors.

-

If a target object only had an edge point cloud model, and the model was aligned with the collision model in the target object editor, the alignment was lost upon reopening the target object editor.

-

After enabling “Rotational symmetry of held target object” for a specific target object in the target object editor, the setting was incorrectly applied to all target objects.

-

When creating a target object using 3D shapes like “Cuboid top surface” or “Cylinder top surface” in the target object editor, the pick point generated based on the object center point during project execution was inaccurate.

-

In some cases, after teaching a pick point manually and flipping the corresponding robot flange pose by 180°, teaching the robot again with the flipped pose still resulted in the same pick point as before.

-

When the “Reload File” option was enabled in the “3D Target Object Recognition” Step, triggering the Mech-Vision project via Standard Interface commands occasionally caused an error: “Unregistered project under solution.”

-

Running the “3D Target Object Recognition” Step with specific data could cause the Step to crash.

If the solution was created with software of earlier versions, the issue might still occur. Please recreate the solution with version 2.1.2 or contact technical support.

-

The linear move set in the “Path Planning” Step might not have taken effect, causing the robot to perform a joint move instead.

-

In rare cases, running point cloud computation with certain data caused project runtime errors.

-

Missing points occur along the edges of the target object in the point cloud output by the “From Depth Map to Point Cloud” Step.

-

Running the “Validate Box Object Masks” Step with image data collected using software versions earlier than 2.0.0 caused the software to crash.

-

When triggering a project that used a virtual camera through Standard Interface communication, an incorrect error code was returned.

-

The video RAM check did not work as expected, potentially causing software crashes due to memory overflow when using memory-intensive features, such as viewing visual outputs or the production interface.