Data Monitoring

The vision system lacks an early warning mechanism during actual production, and issues are often only detected after a major incident occurs, raising potential risks.

In order to resolve this issue, this tool provides a Data monitoring feature. You can monitor accuracy drift and evaluate the vision system’s drift correction status during the production process.

Check Drift Correction Data

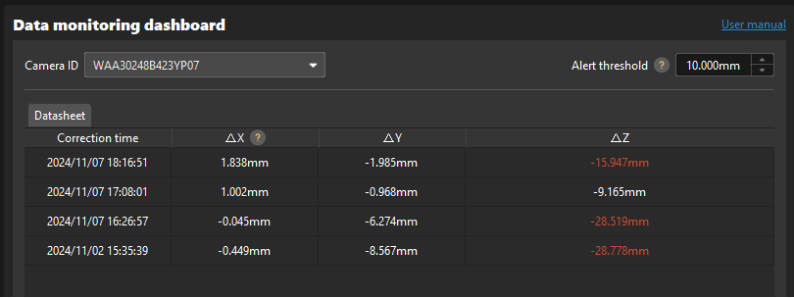

Click the Data monitoring button in the upper-left corner of the home page to open the data monitoring dashboard and view the datasheet.

After deploying the drift correction solution, configure the alert threshold in the upper-right corner of the data monitoring dashboard to ensure long-term stable operation in actual production. Typically, the alert threshold can be set to 10 mm. If the project requires high precision, adjust the alert threshold value downward accordingly.

When the drift compensation in the datasheet exceeds the alert threshold, the data will be displayed in red, indicating a significant accuracy drift before correction. In such cases, please verify that the camera and robot tool are securely mounted and that the robot’s zero position is accurate.

|

After completing the deployment, you can check the drift compensation in the status area at the top of the production interface. |

|

△X is the drift compensation for the X-value of the calibration sphere pose. This compensation value represents the maximum correction applied to the X-value of the calibration sphere pose among all poses collected from the image-capturing points. The same applies to △Y and △Z. |