How to Use Mech-Viz

This section will introduce the basic workflow of using Mech-Viz to calculate a collision-free path and to pick objects.

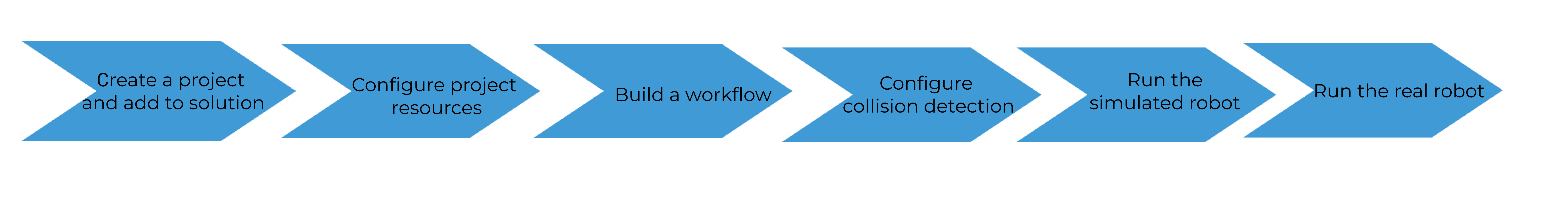

In real situations, the workflow of using Mech-Viz includes six steps, as is shown in the figure below:

Create a Project and Add a Solution

A solution is a collection of functional configurations and data for robot, communication, vision processing, and path planning required for a vision application. You need to create a Mech-Viz project first before moving on to the next process.

You can refer to Example Projects to learn about the workflow and parameter configuration, so as to get yourself familiar with related features quickly. You can also refer to New Blank Project in the user manual.

Configure Project Resources

After creating a new blank project, you need to configure necessary Project Resource Tree for the project, including tools, target objects and scene objects. These resources can help create a more accurate simulation environment, thus calculating a collision-free trajectory for robot motion.

Build a Workflow

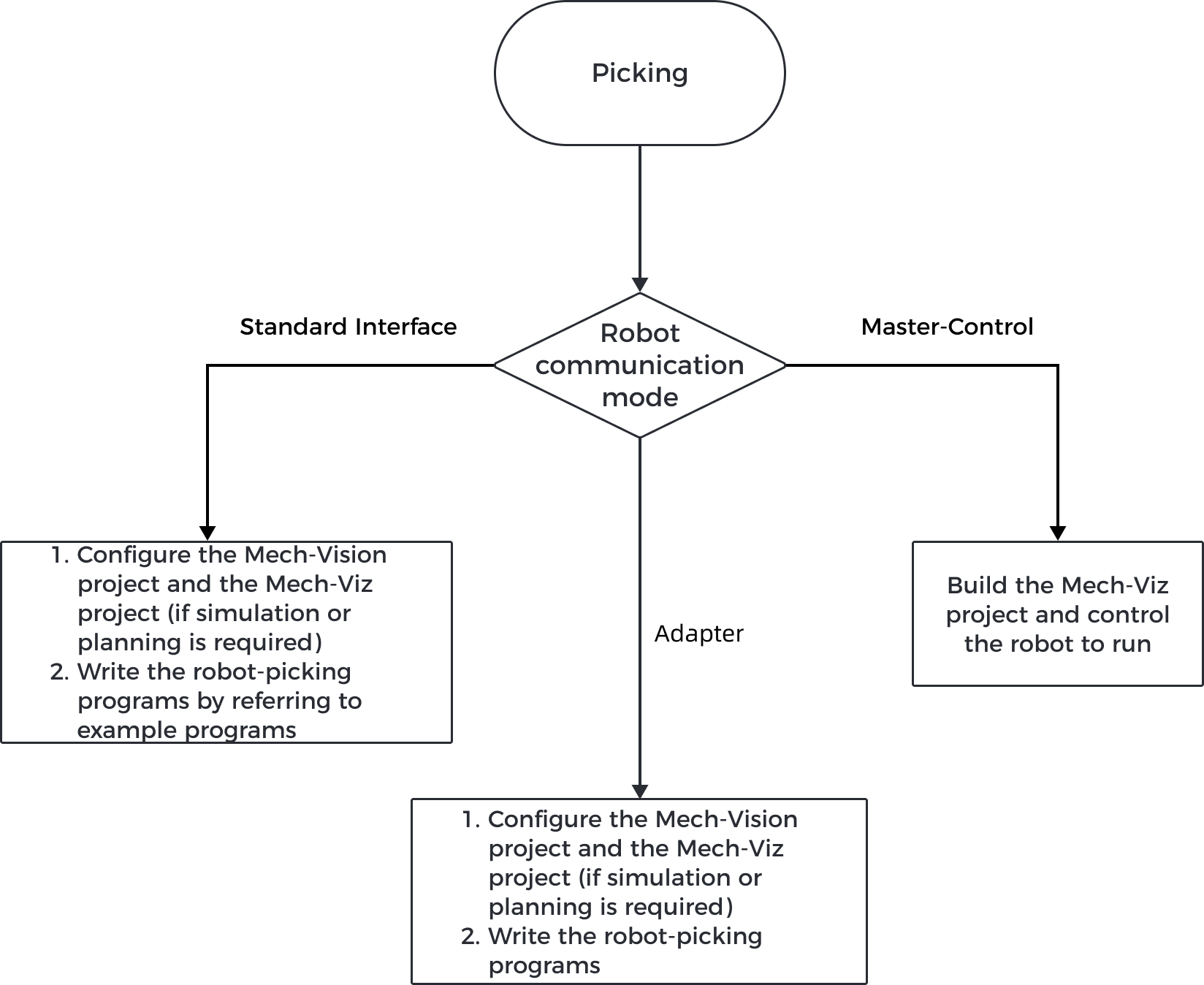

After the project resource configuration, you can start to build a workflow, so as to make the robot pick objects precisely under the guidance of vision results. Depending on the different robot communication modes selected, the way to build the workflow also varies, as shown in the figure below.

-

To use the Standard Interface Communication mode, you need to write a robot picking program on the robot side so the robot can perform picking tasks based on the vision results. For details, see Build a Workflow under Standard Interface Communication.

-

To use the Master-Control communication mode, you should build a robot picking workflow (i.e. the Mech-Viz project) through a graphical interface in Mech-Viz.

For details on how to build a Mech-Viz workflow, please refer to Build a Mech-Viz Workflow.

Configure Collision Detection

In the picking application, it is crucial to prevent collisions happened between the tool and other scene objects, including target objects and the bin. Before starting the simulation, please configure Collision Detection to identify potential collision risks.

Run the Simulated Robot

After the collision detection configuration, you can Run Simulated Robot and test the project, so as to ensure the picking project meets the on-site demand.

If an error occurs during the simulation, such as a collision or unreachable waypoint occurs, you can check the error messages in Plan history and Log, and therefore you can locate the error quickly and then improve the project.

Run a Real Robot

After the success of the simulation, you can Run a Real Robot for picking.