Before You Upgrade

2.1.2 Upgrade Notes

Mech-Vision & Mech-Viz 2.0.0 and 2.1.0 can be directly upgraded to version 2.1.2, and the solutions created by the previous version can still function properly. However, there may be some compatibility issues. See Mech-Vision2.1.2 Upgrade Notes and Mech-Viz2.1.2 Upgrade Notes for detailed instructions.

However, Mech-Vision & Mech-Viz 2.1.2 is not compatible with Mech-Vision & Mech-Viz earlier than 2.0.0. If you want to upgrade the software, please back up the data before upgrading it to 2.1.2. After the upgrade is complete, refer to 2.0.0 Project Migration Guide to upgrade the Mech-Vision solutions and Mech-Viz projects created in earlier versions.

Mech-Vision 2.1.2 Upgrade Notes

Please pay attention to the following issues when upgrading Mech-Vision from the previous version to 2.1.2.

-

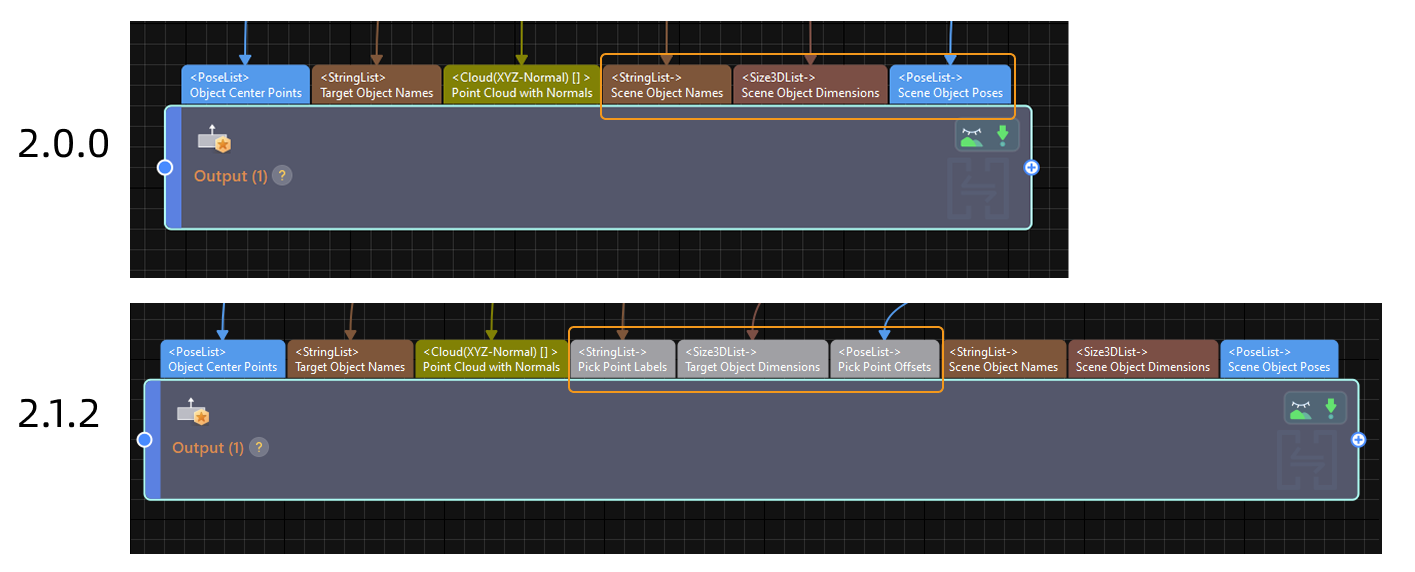

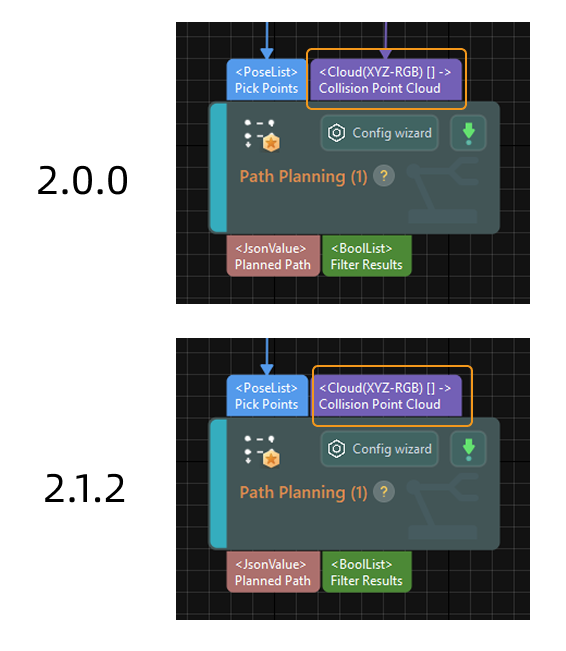

The ports of the Output and Path Planning Steps have been improved in Mech-Vision 2.1.2. In a solution created with an earlier software version, if optional ports are connected with other Steps, upgrading to the new version may cause the following issues due to changes in port sequence:

-

If these optional ports have the same type as their neighboring ones, the data flow may be incorrectly redirected to a nearby port of the same type, as shown in the figure below.

-

If the types of these optional ports differ from those of the nearby left-side optional ports, the data flow may be disconnected, as shown in the figure below. Under this circumstance, please connect the input ports manually.

-

-

Please pay attention to the following issues when using the Solution Access Control feature:

-

Solutions that were configured with access control using versions prior to 2.0.0 cannot be opened in 2.1.2 version software.

-

When opening a solution created with versions 2.0.0 or 2.1.0 in the 2.1.2 version software, the software will automatically delete user accounts with duplicate usernames, passwords, and lower permission levels.

-

After opening the solution with version 2.1.2, do not open it again with versions 2.0.0 or 2.1.0, as this may result in access control not working properly. If it is necessary to open the solution with the 2.0.0 or 2.1.0 version software, please back up the solution first.

-

-

The Step library has been improved in Mech-Vision 2.1.2. Some Steps have been deleted. See the following for details.

No. Removed Step Alternative Step 1

Map to Multiple Pick Points

2

Predict Object Poses (Sim2Pick)

N/A

Mech-Viz 2.1.2 Upgrade Notes

-

In the earlier version software, 180° symmetry was applied to boxes by default in the Box depalletizing mode of the “Vision Move” Step. In Mech-Viz 2.1.2, 180° symmetry is no longer applied to boxes. After upgrading the software to 2.1.2, if you want to maintain the same picking effect as in earlier versions, please generate pick point arrays for the boxes in the target object editor.

-

The collision detection logic has been improved in Mech-Viz 2.1.2, with stricter criteria applied under specific conditions. If a collision-free path could be successfully planned in an earlier version but fails to be planned after upgrading to Mech-Viz 2.1.2 due to a collision of the held target object, please follow the steps below to resolve the issue:

-

Navigate to the Collisions functional panel, and turn on the switch to the right of Problem 2 under Solution to common problems.

-

Click the Split parameters button, and adjust the Path length exempt from collision detection after picking as needed.

-