Output

Function

This Step sends the vision result of the current project to the Mech-Viz or communication component for subsequent picking.

Usage Scenario

This Step is usually used to send various vision results from the current project to other services.

Input and Output

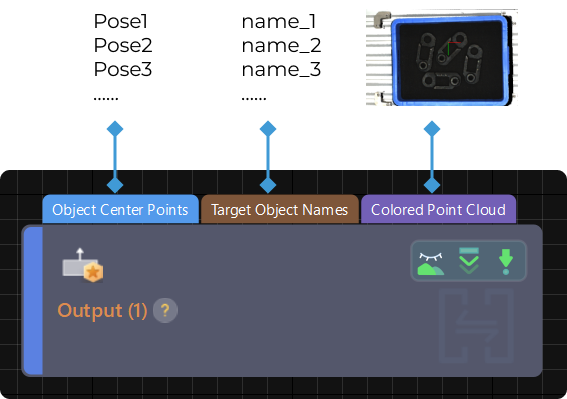

Since this Step outputs results to external services, it does not have output ports connected to subsequent Steps; it only has input ports. There are three port types, each corresponding to a different type of data input.

The input of the “Predefined (vision result)” port type is shown in the figure below.

Parameter Description

Port Type Settings

- Port Type

-

Description: This parameter is used to select the port type of the Step.

Value list: Predefined (vision result), Predefined (robot path), Custom

-

Predefined (vision result): Select this port type when Mech-Vision is only used for vision processing and then the vision result is sent to the Mech-Viz or external service.

-

Predefined (robot path): Select this port type when using Mech-Vision for both vision processing and path planning.

-

Custom: Select this port type if you need to customize the data sent to Mech-Viz.

Default value: Predefined (robot path)

Instruction: Select the port type according to the actual requirements.

-

Predefined (vision result)

Usage Scenario

- Select Scenario

-

Description: Select the usage scenario of the current solution.

Value list: Matching, Depalletizing, Others

-

Matching: Applicable to scenarios where target objects are created in the target object editor and their poses are obtained by point cloud model matching.

-

Depalletizing: Suitable for depalletizing scenarios, where target object poses can be obtained directly through deep learning or other methods without point cloud model matching.

-

Others: Applicable to scenarios where target object poses are obtained by other methods than the above two scenarios.

Default value: Matching

-

- Method to Convert Data

-

Description: By selecting the result conversion method, this Step converts the recognition result to the data type needed for picking.

Value list: Generate picking strategy based on object center point, generate picking strategy based on pick points

-

Generate picking strategy based on object center point: Suitable for symmetrical target objects that require orientation adjustment of the object center point.

-

Generate picking strategy based on pick points: Suitable for target objects with multiple pick points that need to be filtered.

Default value: Generate picking strategy based on object center point

-

Collision Detection Settings

- Send Point Cloud to External Service

-

Description: This parameter is used to send the point cloud to the Mech-Viz. It is usually used for debugging or checking the running result of the project.

Default setting: selected.

- Point Cloud Type

-

Description: This parameter is used to select the type of the point cloud to send to the Mech-Viz.

Value list: CloudXYZRGB (colored point cloud), CloudXYZ (point cloud), and CloudXYZNormal (point cloud with normals)

Default setting: CloudXYZRGB

- Point Cloud in Camera Frame

-

Description: Please select this parameter when the point cloud is in the camera reference frame. Once this option is selected, the point cloud will be converted to the robot reference frame and sent to the Mech-Viz. If this option is not selected, the point cloud will be sent to the Mech-Viz directly.

Default setting: selected.

- Remove Point Cloud of Target Object

-

Description: This parameter is used to remove the point cloud of the part that overlaps with the target object and avoid collisions between the gripper and the part as much as possible.

Default setting: Unselected

- Search Radius of Target Object Point Cloud

-

Description: Take any point in the point cloud of the target object as the center, and the point cloud within the search radius will be removed. Please set this parameter when Remove Point Cloud of Target Object is selected.

Default value: 3 mm

Other Input Settings

- Other inputs

-

Parameter description: Once this option is selected, new input ports “Pick Point Labels”, “Target Object Dimensions”, and “Pick Point Offsets” will be added to the Step.

Default setting: Unselected

Instruction: The new input ports are optional. You can connect the new ports according to the actual requirement.

Update Scene Object Settings

- Update Scene Object

-

Description: This parameter is usually used in scenarios where the bin pose needs to be updated dynamically. Once this option is selected, ports “Scene Object Names”, “Scene Object Dimensions”, and “Scene Object Poses” will be added to the Step.

Default setting: Unselected

Predefined (robot path)

There is no need to adjust parameters in this port type, only to connect the robot path input port.

Custom

- Customized Ports Name

-

Description: This parameter is used to customize the input port.

Tuning instruction: Click Open the editor, and select the input port you want to add in the Output Setting Assistant window.

Input ports Description Note poses

Object poses. Array format.

Mandatory

labels

Object labels. Array format with the same length withposes.

Optional

sizes

Object 3D dimensions with the same length as the poses or with a length of 0.

Optional

offsets

Offset of the pick point relative to the object center point. Array format with the same length as the poses or with a length of 0.

Optional

objectIndexes

Index of the object. Array format with the same length as the poses or with a length of 0.

Optional

scene_object_names

List of scene object names to be updated.

Optional

scene_object_sizes

List of scene object dimensions to be updated.

Optional

scene_object_poses

List of scene object poses to be updated.

Optional

workobject_data

Target object-related information to be sent to Mech-Viz, such as the pick point information (pick point numeric label, the offset of the pick point from the object center point, etc) and the information about the target object on which each pick point is located.

Optional

|

If only the “workobject_data” input port is added, the data cannot be obtained when calling the Standard Interface commands 100, 102, 105, and 110. |