Vision Move

Function

This Step guides the robot to move according to the poses received from vision services.

| Exit Port | Description |

|---|---|

Success |

The path was planned successfully. |

Plan failure |

The path planning failed. |

Other failures |

There are no available poses for planning. Possible causes: Mech-Vision did not output poses. The poses output by Mech-Vision cannot meet the requirement. |

Parameters

![]() indicates that the option is not selected, and

indicates that the option is not selected, and ![]() indicates that the option is selected.

indicates that the option is selected.

General Parameters of Move-Type Steps

Send Waypoint

Selected by default to send waypoint poses to the receiver, such as the robot. When this option is unselected, the waypoint will not be sent. However, the waypoint will remain in the planned path.

Try Continuously Running through Succeeding Non-Moves

Unselected by default. When non-move Steps, such as Vision Look, Set DO, Check DI, etc., are connected between move-type Steps, the robot’s path planning will be interrupted, and the actual robot will take a short pause, reducing the smoothness of running. When this option is selected, the project will continue to run without waiting for the current move-type Step to complete execution, and therefore the robot can move in a smooth way without pauses. However, enabling this option may cause the execution of the Step to end prematurely.

|

Why will this option cause the execution of the Step to end prematurely? Mech-Viz will send multiple poses simultaneously to the robot when the project is running. When the currently returned JPs of the robot correspond to the last pose sent by Mech-Viz, Mech-Viz will assume that the robot has moved to the last position. For example, there are 10 move-type Steps in a path, and the pose of the 5th move-type Step is the same as that of the last move-type Step. When the robot moves at low speed, it sends JPs to Mech-Viz when it moves to the 5th move-type Step, Mech-Viz may mistakenly determine that the robot has finished the move-type Steps and prematurely ends the Steps since the poses of the 5th move-type Step and the last move-type Step are the same in the path. |

Do Not Check Collision with Placed Workobject

Unselected by default, namely that the collision with the already placed objects will not be detected. When this option is selected, the collisions between the robot, end tool, and placed objects will be detected.

In palletizing scenarios, the two possible cases of error are as follows:

-

In palletizing scenarios, when the robot is placing a carton, the carton to place may come into light contact with the placed cartons while no deformation will be caused. After Mech-Viz detects this collision in simulation, it will plan other positions for placing the carton, and therefore a full stack cannot be formed.

-

Usually, the TCP of a suction cup is inside the suction cup model instead of on the surface of it. Under this circumstance, the suction cup may be embedded in the model of the carton to be picked in the simulation of picking, while Mech-Viz does not detect the collision between the end tool and the object to be picked. After the robot places the object and the carton model turns into an object model in the scene, a collision between the suction cup and the carton will be detected and the palletizing cannot be completed.

When this option is selected, no collision between the robot, end tool, and the placed object will be detected, and the above two cases of errors can be avoided.

Point Cloud Collision Detection Mode

Select the proper mode according to the requirement of the on-site situation. Usually, the default setting Auto can be used. Do not check collision mode can be used in move-type Steps before the robot picks the object, and Check collision mode can be used after the robot picks the object.

| Auto |

Default setting. Collision with point cloud is checked only for the “Vision Move” Step and the “Relative Move” Step that depends on the “Vision Move” Step, but not for all move-type Steps. |

| Do not check collision |

Point cloud collisions for all move-type Steps will not be detected. |

| Check collision |

Point cloud collisions for all move-type Steps will be detected. |

| When is switched on, Mech-Viz will detect collisions between the robot model, end tool model, and point cloud when planning the path. Normally, Mech-Viz detects whether the robot collides with other objects during picking and placing. When there are point cloud outliers, non-exiting collisions will be detected, which leads to errors in path planning. |

Ignore Workobject Symmetry

This parameter will only take effect when Waypoint type of the Step is set to Workobject pose.

| None |

Default setting, i.e., do not disable symmetry on any axis. |

| Around workobject frame Z axis |

Only disable symmetry on Z-axis of the workobject reference frame. |

| Around workobject frame X&Y axis |

Disable symmetry on X-axis and Y-axis of the workobject reference frame. |

| Around all axes |

Disable symmetry on all axes. |

Once the object symmetry is disabled, the robot will place the objects strictly according to the workobject poses.

|

In some special cases, objects are not pickable due to their peculiar poses. Setting Rotational symmetry under in Resources may solve this problem. Candidate poses of the recognized workpiece will be calculated according to the set rotational symmetry angle. When Mech-Viz plans to pick workpieces, if the default pose is not feasible for picking, the candidate poses will be tried. As the candidate poses calculated based on the settings of Rotational symmetry are different from the original poses output from Mech-Vision, the consistency of the objects’ place poses cannot be guaranteed. |

Vision Result Global Usage

All Waypoints in One Move

Once this option is selected, the robot will move through all poses received from the vision service in sequence at one time. This option is usually used when the robot moves in a fixed path where no DO signals will be sent, such as the gluing application. This parameter cannot be adjusted with other parameters at the same time. Once this option is selected, other parameters will be hidden.

Reuse Vision Result

When there are multiple pickable objects in one vision result and it can be guaranteed that picking one object will not affect the poses of other objects, this option can be selected. The vision result will be reused and no new image will be captured until all pickable objects have been picked.

Share Vision Result

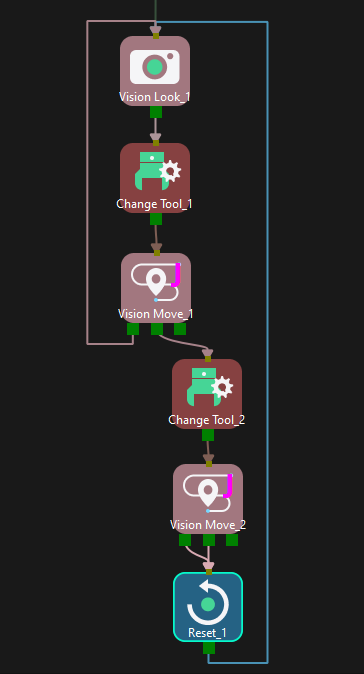

This option can be used to share vision results from the same Vision Look Step among multiple Vision Move Steps. You should specify a Vision Service Name once this option is selected.

Application example: When the workobject cannot be picked easily, various end tools may be used to pick the object several times. If the first attempt to pick fails, the current vision result will be discarded by default. If Share Vision Result is selected, the vision result will be used again when another end tool is used and you do not need to capture an image again. Please note that a “Reset” Step should be connected after the last “Vision Move” Step to clear the shared vision result. Otherwise, if the shared vision results are not used up, the old vision result will still be used even if a new image is captured, which will affect the normal functioning of the entire project.

Remove Point Cloud of Workobjects to Be Picked Next

Select to remove the point cloud of the target workobject to be picked, and only collision between the robot end tool and non-target workobjects will be detected.

X & Y Axes Removal Range Expansion Length

To exclude the workobject point cloud from the collision detection, the point cloud of the workobject to be picked should be removed. Also, the point cloud within a certain range outside the workobject surface should be removed altogether. This parameter specifies the expanded distance on the XY plane in the workobject reference frame for point cloud removal, and the point cloud within the XY plane range will be removed.

Z Axis Removal Range Expansion Length

To exclude the workobject point cloud from the collision detection, the point cloud of the workobject to be picked should be removed. Also, the point cloud within a certain range outside the workobject surface should be removed altogether. This parameter specifies the expanded distance in the Z-axis direction in the workobject reference frame for point cloud removal, and the point cloud within the Z-axis direction range will be removed.

Operation Mode

There are three types of operational modes based on the tool type as shown below, and each of them has different parameters.

Regular |

|

Depalletizing vacuum gripper |

|

Array gripper |

Vision Service Name

The Mech-Vision project selected here is usually the same as the one in Vision Look.

Basic Move Settings

Basic move settings of move-type Steps are used to set the velocity and motion type for the robot when it moves to the waypoint.

Pick or place

| Unspecified |

Default value |

| Pick |

Please select this option when the move-type Step is before “Vision Move”. |

| Place |

Please select this option when the move-type Step is after “Vision Move”. |

| Notes |

Setting this parameter facilitates checking the logic of the Mech-Viz project. Please select a proper option according to the on-site situation and ensure that the Step used to pick is placed before the Step used to place. |

Motion type

| Joint move |

Joint motion, which guides the robot to move in a curved path. It is less likely to reach singularities in the path for joint motion. This motion type is applicable to scenarios where the requirement of path accuracy is not strict and the robot moves in a large space. |

| Linear move |

Linear motion, which guides the robot to move linearly. This motion type is applicable to scenarios where there is a strict requirement for path accuracy, such as welding, gluing, and certain types of picking. |

Velocity & Acceleration

Velocity and acceleration determine how fast the robot can move. Usually, the set acceleration should be lower than the velocity. When the set acceleration is higher than the velocity, the robot will move in a choppy way.

| The velocities of Vision Move and its prior and subsequent Steps should be relatively low to ensure that the objects can be picked steadily. |

Blend radius

| Default value |

50.00 mm |

| Notes |

Usually, the default setting can be used. The blend radius refers to the distance between the target point and the point where the robot starts to turn. The larger the blend radius, the more smoother the robot motion transitions are. If the robot moves in a relatively small space, please set the blend radius to a smaller value. If the robot moves in a relatively large space without obstacles and the distance between two consecutive path segments is long, please set the blend radius to a larger value. |

Only Use Poses with Following Label

The vision result may contain different labels. Once a specific label is selected, only the pickable objects with the selected label will be picked.

| Select the label |

Click Load Labels or Add a Label to select the label. Once the label is selected successfully, the label name will be displayed on the button on the right. |

| Delete the label |

Click |