Getting Started with Solution

This part introduces how to build a vision solution.

A solution is a collection of functional configurations and data for robot, communication, vision processing, and path planning required for a vision application.

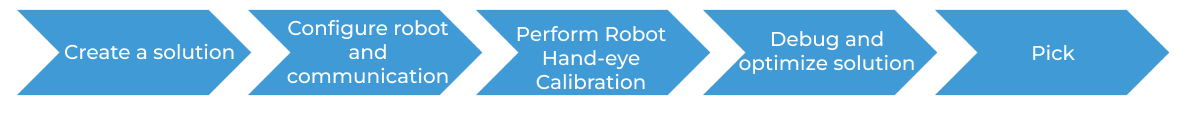

A solution goes through five processes from creation to execution, as shown in the diagram below.

Create a Solution

A solution is a collection of functional configurations and data for robot, communication, vision processing, and path planning required for a vision application. You need to create a solution first before moving on to the next process.

Configure Robot and Communication

After creating a solution, you can start configuring the robot and communication.

Communication refers to the information exchange and transmission between the vision side and the robot side. To ensure normal communication between the vision side and the robot side, you need to configure the communication on both sides.

In Mech-Mind Vision System, there are two communication methods: interface communication and master-control communication. And interface communication can be divided into Standard Interface communication and Adapter communication.

Interface communication

For Interface communication, you need to configure both the vision side and the robot side, and make a trial run to ensure normal communication between the two sides.

Notably, different brands of robot require different methods of communication between the robot side and the vision side.

-

Configure communication on the vision side, and test whether the robot side and the vision side can communicate normally with each other.

Master-Control Communication

For master-control communication, you need to configure communication on the robot side, and then test whether the robot side and the vision side can communicate normally with each other.

-

Configure communication on the robot side.

-

Test whether the robot side and the vision side can communicate normally with each other.

Perform Robot Hand-Eye Calibration

When robot and communication configuration is completed, you can move on to robot hand-eye calibration.

Hand-eye calibration refers to the process of establishing a positional correspondence between the camera frame and the robot frame. During the process, the object poses defined by the vision system are transformed into poses under the robot frame, so as to guide the robot to perform picking tasks.

Robot Hand-eye Calibration is an essential process, as the calibration results and stability have a direct influence on the robot’s accuracy.

Debug and Optimize the Solution

When the above processes are all completed, you can start running and debugging the solution.

Pick

After the solution is debugged and optimized, you can apply it to a real robot to perform picking tasks.

-

If Interface communication is adopted, you need to write a program for the robot to pick and place objects, and, through the Standard Interface, trigger the Mech-Vision solution and acquire its vision point and waypoint outputs from the Mech-Vision project.

-

If master-control communication is adopted, you need to plan the waypoint by building a Mech-Viz project.