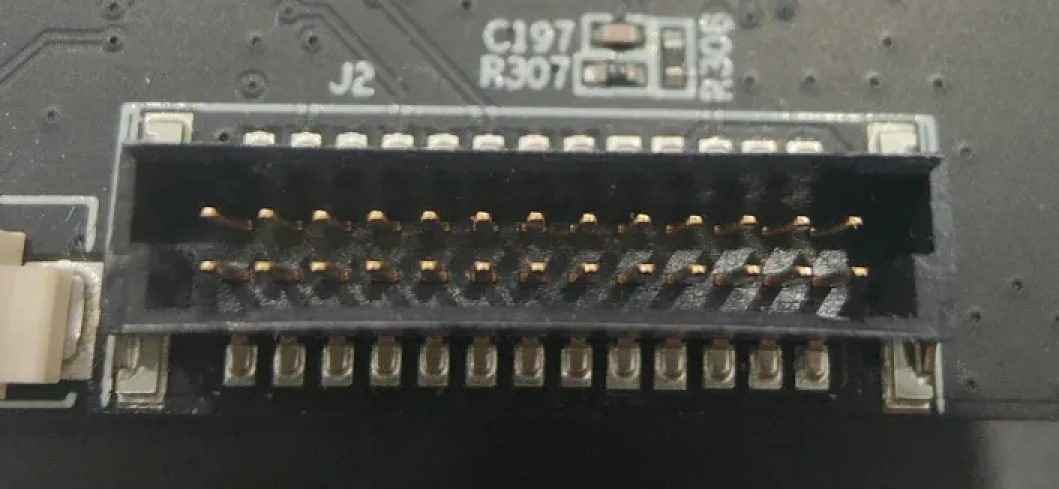

Connector Pin Inspection (Height & Position)

About the Solution

The solution is designed for precision manufacturing to accurately measure and inspect the height and position of pins to ensure their installation and processing accuracy in circuit boards or connectors. The accurate inspection of the height and position of pins can help ensure that the pins function properly in the circuit boards or connectors.

Inspection Targets

-

Pin height

Pin height usually refers to the distance from the tip of a pin to a reference plane (such as the surface of the PCB board). The solution should be able to accurately measure the height of multiple pins to ensure that they meet the design specifications and guarantee the electrical performance and stability of mechanical engagement.

-

Pin position

The solution should be able to measure the horizontal distance from pins to the edges of the connector to ensure that the pin is in the correct position to avoid deviation or poor contact during installation or operation.

Inspection Challenges

This solution can meet the following challenges:

-

Data acquisition: Due to the limited size of the pin tip, it is difficult to obtain accurate point cloud data.

-

Measurement precision: High-precision measurements are required. Thus, effective data preprocessing is required to ensure the stability and accuracy of the results.

-

Layout scheme: Pins are deep, and the surrounding structures may block the camera’s view, resulting in poor imaging clarity during conventional flat scans.

Key Technical Specifications

The key technical specifications of the solution are as follows:

-

Repeatability: <30 μm

-

Cycle time: The cycle time of measurement should be no more than 2 seconds.

| In different application scenarios, key technical specifications may vary and should be adjusted flexibly according to the actual situation. |

Solution Design

According to project requirements, the sensor head of a Mech-Eye 3D laser profiler should be fixed above the pins. Make sure the sensor head is facing the pin tips and adjust its tilt to fit the working space and scan all pins as much as possible.

Hardware and Software Requirements

-

Mech-Eye 3D Laser Profiler + Mech-Eye Viewer software

Quickly scans the surface of an object and generates surface data (including depth map and intensity image).

-

Mech-MSR software

Obtains and processes surface data and calculates the pin height and position.

Deployment Process

| Before deploying the solution, you need to get the Connector Pin Inspection (Height & Position) solution from Mech-MSR’s solution library. See Quick Guide to Solution Library to learn how to get the solution. |

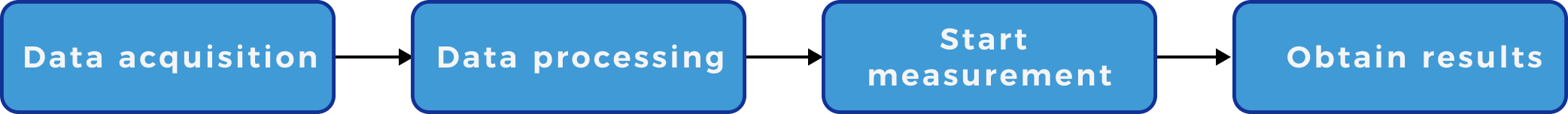

The deployment process of the solution is as follows:

-

Build the software and hardware environment to acquire and view image data.

-

Align the surface data, adjust the surface of pin tips to a horizontal level, filter the surface data, and narrow down the surface data of pin tips.

-

Measures the height and position of pins.

-

Set acceptable ranges for pin height and position and obtain measurement and inspection results.

Next, you can get started with solution deployment.