Start Measurement

After data processing, the surface data of pin tips, i.e., blobs, are relatively stable. Next, you can use the data to measure the height of pins.

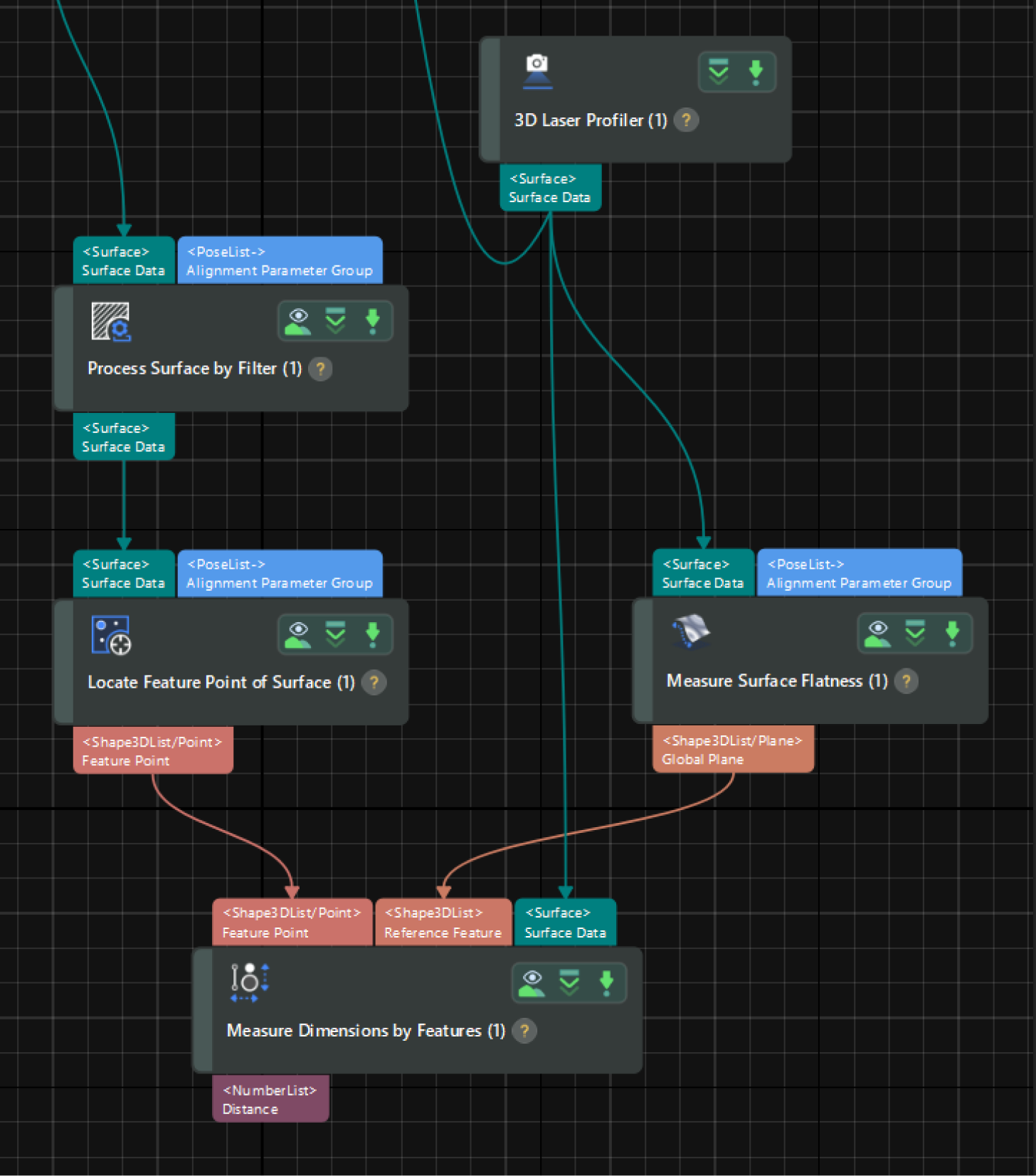

Measurement Workflow

Pin height usually refers to the distance from the tip of a pin to a reference plane (such as the surface of the PCB board). Therefore, you can measure the distance from the center point of blobs to the reference plane to obtain the height of pins.

-

Obtain center points

Use the Locate Feature Point of Surface Step to extract the center points (or feature points) from the surface data of pin tips, which will represent the position of pin tips.

Set the feature point type to Mean in the parameter configuration panel. After the Step is run, it will output the center points of all pin tips.

-

Fit a reference plane

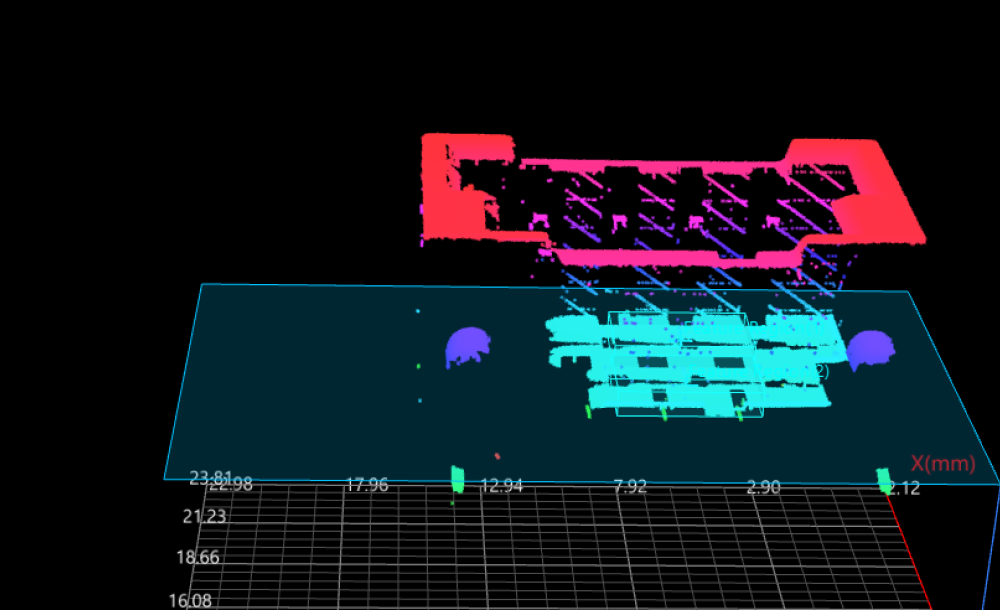

Use the Measure Surface Flatness Step to fit a reference plane.

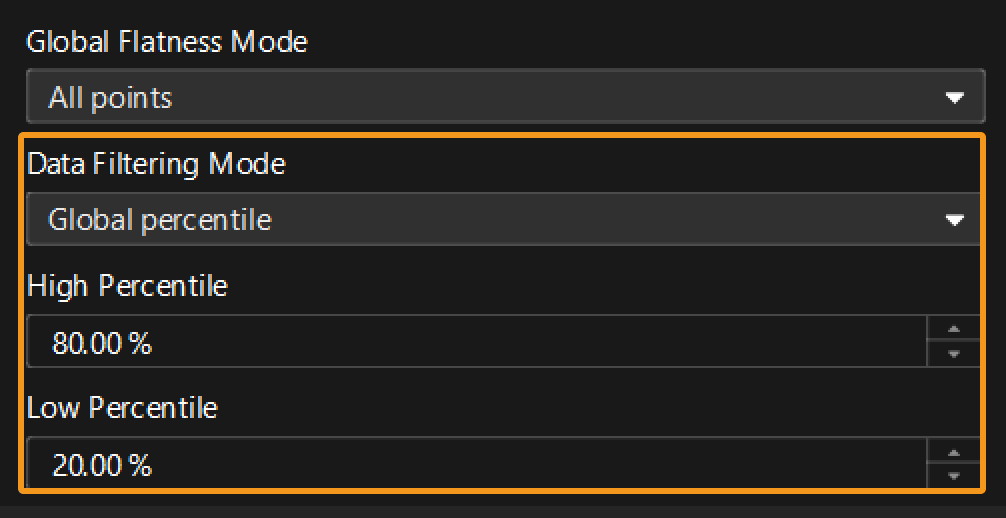

You can use feature regions to select the flat surface data and set data filtering parameters (as shown below) to filter out noise so that the fitted plane can be stable and accurate.

Select Global Plane in the Output section of the Step. After the Step is run, it will output a fitted plane.

-

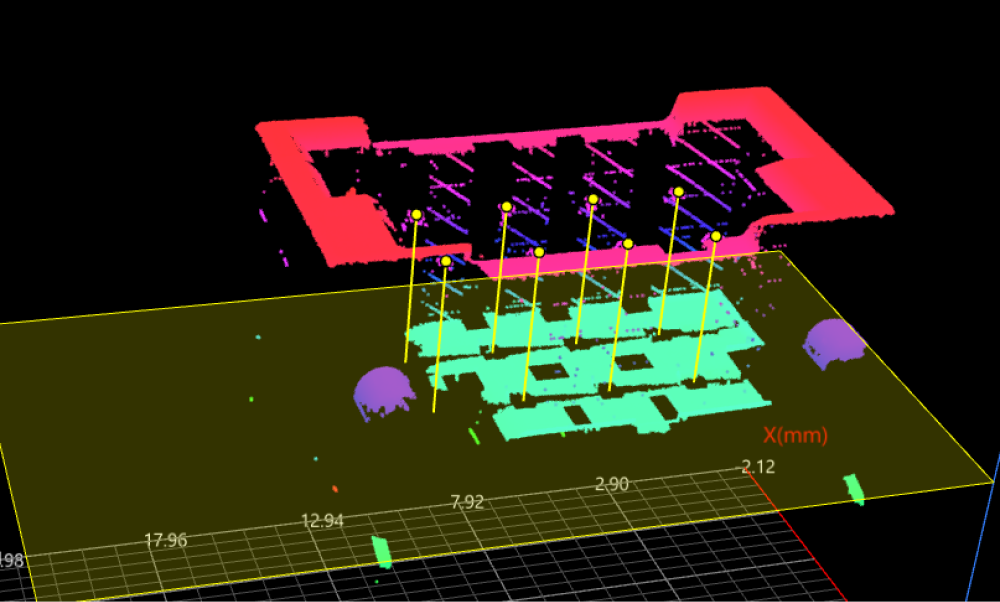

Measure height

Use the Measure Dimensions by Features Step to measure the pin height.

Select Distance in the Output section of the Step. After the Step is run, it will output the distance from each center point to the reference plane, namely, pin height.

Up to now, you have finished high-precision pin height measurement.

Next, you can inspect whether the measured height of pins is qualified.