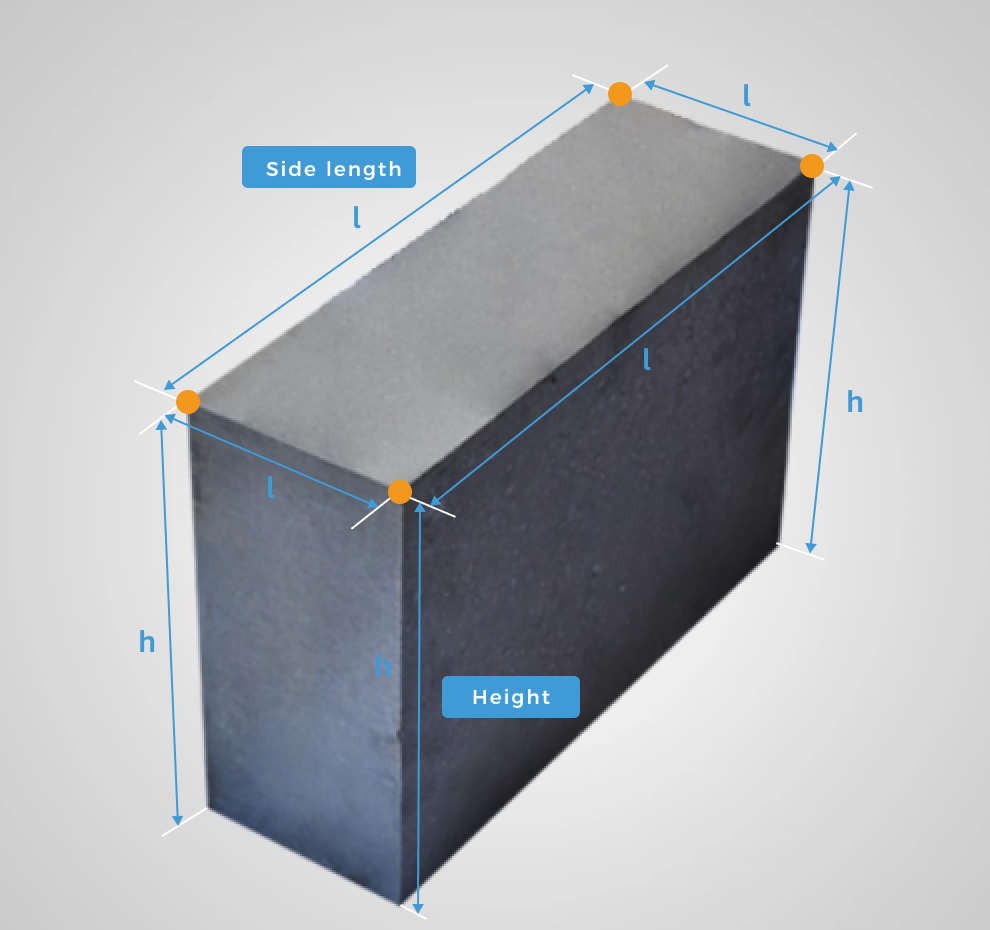

Dimensional Measurement of Refractory Bricks

About the Solution

This solution is mainly used to measure the dimensions of refractory bricks to ensure their processing accuracy. The dimensional accuracy of refractory bricks is critical to their sealing performance during assembly, thermal shock resistance, and service life. If the dimensions of the bricks are not up to standard, the joints between them may be too large or too small, which will lower the overall heat resistance and wear resistance of the equipment. Therefore, during the production process, each batch of refractory bricks requires strict dimensional measurement and quality inspection to ensure smooth installation.

Inspection Targets

-

Height of each corner on the top surface of refractory bricks

By accurately measuring the height of each corner on the top surface of the refractory bricks, you can evaluate the surface flatness of the refractory bricks. If the height is not within the acceptable range, it may lead to uneven contact during assembly, affecting the stability of the overall structure.

-

Side length of the top surface of refractory bricks

By accurately measuring the length of each side of the top surface of the refractory bricks, you can ensure that their dimensions meet the design requirements. Dimensional errors may lead to a series of installation problems, such as mismatching or excessive gaps.

Inspection Challenges

This solution can meet the following challenges:

-

Data acquisition: A large amount of point cloud data will be generated during the measurement process, and efficient algorithms need to be used to remove redundant data and accurately extract the required geometric features.

-

Measurement accuracy: Since small deviations in the dimensions of refractory bricks will affect their assembly and heat resistance, high measurement accuracy is required.

-

Production efficiency: In mass production, measurement and inspection efficiency are crucial, and measurement accuracy and speed must be ensured.

Key Technical Specifications

The key technical specifications of the solution are as follows:

-

Repeatability: <50 μm

-

Cycle time: The cycle time of measurement should be no more than 2 seconds.

| In different application scenarios, key technical specifications may vary and should be adjusted flexibly according to the actual situation. |

Solution Design

According to project requirements, the sensor head of a Mech-Eye 3D laser profiler should be fixed above the refractory brick. Make sure the sensor head faces the top surface of the refractory brick and adjust its tilt to fit the working space and scan the whole brick as much as possible.

Hardware and Software Requirements

-

Mech-Eye 3D Laser Profiler + Mech-Eye Viewer software

Quickly scans the surface of an object and generates surface data (including depth map and intensity image).

-

Mech-MSR software

Obtains and processes surface data and calculates the height and side length of refractory bricks.

Deployment Process

| Before deploying the solution, you need to get the Dimensional Measurement of Refractory Bricks solution from Mech-MSR’s solution library. See Quick Guide to Solution Library to learn how to get the solution. |

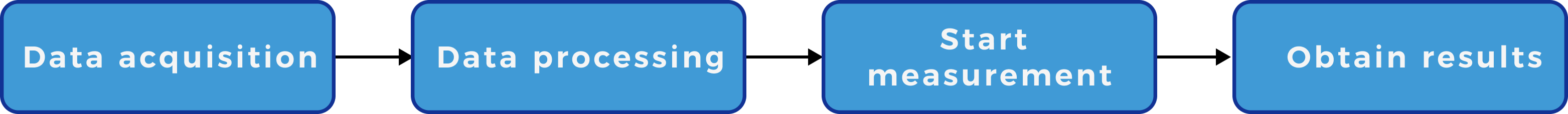

The deployment process of the solution is as follows:

-

Build the software and hardware environment to acquire and view image data.

-

Adjust the tilted top surface of the refractory brick to a horizontal level and obtain the corners on its top surface.

-

Measure the height of each corner on the top surface of the refractory brick and the side length of its top surface.

-

Set acceptable ranges for height and side length and obtain measurement and inspection results.

Next, you can get started with solution deployment.