View Visualized Data in Mech-MSR

In Mech-MSR, you can use the data viewer to check the visualized data and adjust the feature region(s).

| You can use data viewer only after Debug Output is enabled in the graphical programming workspace. |

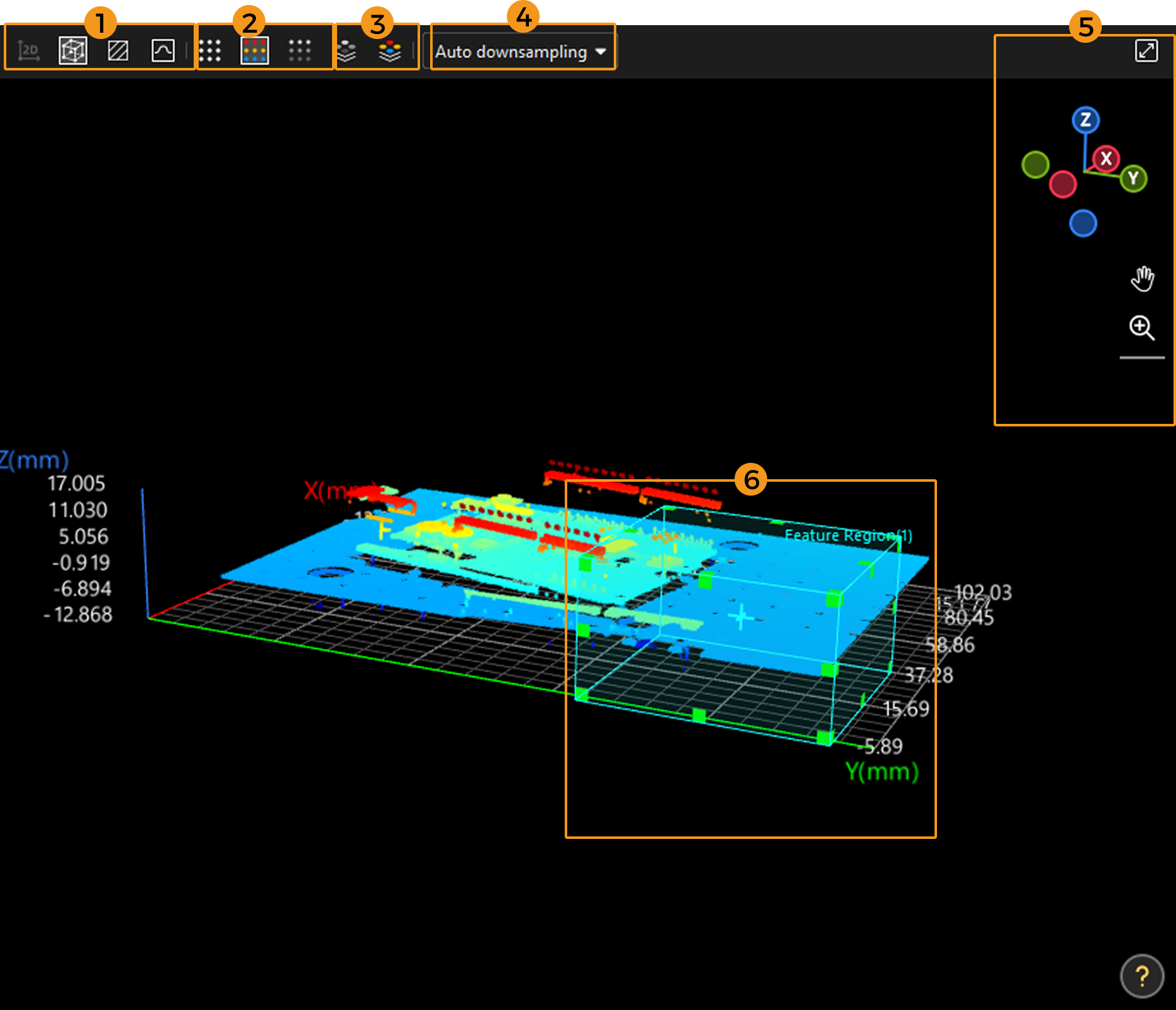

The following figure shows the interface of the data viewer. The usage of each feature is introduced below.

Switch the Display Mode (①)

Use the following icons to switch the display mode:

-

Click

to switch to the 2D image mode and view the data in a 2D perspective. Switchable only when 2D images are available.

to switch to the 2D image mode and view the data in a 2D perspective. Switchable only when 2D images are available. -

Click

to switch to the Perspective mode and view the data in a 3D perspective.

to switch to the Perspective mode and view the data in a 3D perspective. -

Click

to switch to the Surface mode and view the data on the XOY plane.

to switch to the Surface mode and view the data on the XOY plane. -

Click

to switch to the Profile mode and view the data on the XOZ plane. Profiles are usually processed in this view.

to switch to the Profile mode and view the data on the XOZ plane. Profiles are usually processed in this view.

Switch the Point Cloud Mode (②)

Use the following icons to switch the point cloud mode:

-

Click

to switch to the Monochrome point cloud.

to switch to the Monochrome point cloud. -

Click

to switch to the Color point cloud.

to switch to the Color point cloud. -

Click

to switch to the Grayscale point cloud.

to switch to the Grayscale point cloud.

Switch the Intensity Image Mode (③)

Use the following icons to switch the intensity image mode:

-

Click

to switch to the Intensity image.

to switch to the Intensity image. -

Click

to switch to the Color intensity image.

to switch to the Color intensity image.

Downsampling Settings (④)

When the image size is large, the software may take longer to process the data for visualization. Enabling Debug Output could result in performance lag. You can reduce the image resolution by downsampling to lower the data volume and speed up visualization.

-

Auto-downsampling: Automatically selects the optimal downsampling ratio according to the image size to balance the visualization speed and image details.

-

No downsampling: Maintains the original image resolution without applying downsampling.

-

Fixed ratio: Scales the image down to 1/2, 1/4, 1/6, 1/8, 1/10, 1/12, 1/14, or 1/16 of its original width and height. A smaller ratio (e.g., 1/16) means faster visualization but a greater loss of image details.

| The downsampling setting only affects the display and does not impact the calculation results of the Steps. |

|

Mech-Mind IPC provides the standard operation environment for Mech-Mind’s software products and therefore can maximize the function and performance of the software. For better user experience, please select an appropriate IPC according to the data volume of images or point clouds in the actual project:

Note that even if the number of points in the image or point cloud is within the processing capacity of the selected IPC, enabling Debug Output may still cause lag when using the software due to high system resource usage. If a severe lag occurs, it is recommended to increase the degree of downsampling. |

Adjust the View (⑤)

Use the following buttons or shortcuts to adjust the view:

| Action | Instructions |

|---|---|

Rotate the view |

Press and hold the left mouse button and drag in any direction. |

Pan the view |

Press and hold |

Zoom in/out |

Press and hold |

Fit the view |

Click |

The navigation gizmo ![]() shows the orientation of the current view. Click the icon of each axis (X, Y, Z, -X, -Y, -Z) to align the view with the axis.

shows the orientation of the current view. Click the icon of each axis (X, Y, Z, -X, -Y, -Z) to align the view with the axis.

Set the Feature Region(s) (⑥)

Feature regions define the target regions for algorithm processing. You can roughly and intuitively adjust the position and size of the feature region(s) in the data viewer area.

For detailed instructions, see Adjust Feature Region in Data Viewer Area.