Measure Surface Deviation

Description

This Step is used to calculate deviations between surface data and 3D model.

| Before using the Step, ensure that a 3D model file (in STL or PLY format) and its corresponding pose file (in JSON format) are prepared. Otherwise, the Step cannot be executed. |

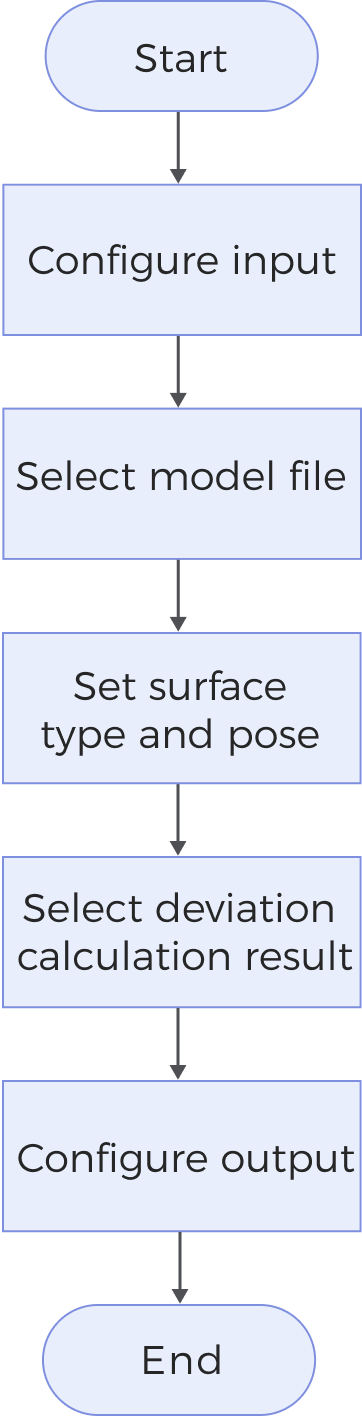

Workflow

The process of configuring this Step is shown below:

-

Configure the input. Connect the ports manually in the graphical programming workspace or select the input under Input in the parameter configuration panel.

-

Specify the model file format and model file path.

-

Select the model surface type and model pose JSON file path.

-

Select the deviation calculation result.

-

Select the Output item under the Output tab.

Parameters

| Parameter | Description | ||

|---|---|---|---|

Model File Format |

Select the format of the 3D model file to be loaded. Only supports STL and PLY formats. |

||

Model File Path |

The path to the 3D model file. |

||

Model Surface Type |

Select the reference surface (the model’s top or bottom surface) for deviation calculation. |

||

Model Units |

Units used by the model. Value list: millimeters, meters |

||

Model Pose JSON File Path |

The JSON file stores the pose information of the model’s surface data. |

||

Deviation Calculation Result |

Select the deviation calculation and statistics result saved via Deviation Viewer to calculate the output items Feature Points and Deviation.

|

Output Description

Select the output item(s) to add the output port(s) to the Step, and the corresponding data will be output after the Step is run. You can select the output according to the actual measurement requirements.

|

If you select an expandable output item (with a ▶ on the left), you should expand it by clicking ▶, and then set the Min and Max values to determine the acceptable range. If the output value falls within the acceptable range, the measurement item is judged as passing (OK), or else it is judged as failing (NG). |

| Output item | Description |

|---|---|

Surface data |

The surface data obtained after comparing the surface data with the model, and the Z value represents the deviation. |

Feature Points |

The center of each circle ROI drawn in the “Deviation Viewer.” |

Deviation |

The mean deviation within each circle ROI drawn in the “Deviation Viewer.” |

Troubleshooting

|

CV-W4101

Error: The number of points in the PLY file must be greater than or equal to 3.

Solution: Check the file and make sure the number of points in the PLY file is greater than or equal to 3.

CV-W4102

Error: The number of points must equal the number of normals in the PLY file.

Solution: Check the file and make sure the number of points is equal to the number of normals in the PLY file.

CV-W4103

Error: The magnitude of normals must be equal to 1 in the PLY file.

Solution: Check the file and make sure the magnitude of normals in the PLY file is equal to 1.

CV-W4104

Error: The PLY file contains invalid point(s) (NaN values).

Solution: Check the file and make sure the PLY file contains no invalid points.