Siemens S7 Client Communication

Mech-MSR can communicate with external devices by using the Siemens S7 protocol where the software acts as the client. Before you read the following content, make sure that the communication configuration has been completed in Mech-MSR.

About Siemens S7 Client

Communication can be established between a Siemens SIMATIC S7 PLC and Mech-MSR based on the Siemens S7 protocol by using the TIA Portal software. Under this communication mode, Mech-MSR acts as the client and the PLC acts as the server.

Hardware and Software Requirements

Hardware

-

The following S7 series PLCs from Siemens are supported:

-

S7-300: Integrated PN network port or CP343-1

-

S7-400: Integrated PN network port or CP443-1

-

S7-1200: No special requirement for modules

-

S7-1500: No special requirement for modules

-

-

Power adapter: 220V AC to 24V DC

-

Supports the following industrial personal computer (IPC):

-

The standard IPC provided by Mech-Mind (recommended)

-

Self-owned device

-

-

Ethernet cable

Software

-

Siemens PLC programming software TIA Portal V15.1

-

3D measurement and inspection software Mech-MSR (latest version 2.1.1 recommended)

-

Interface file for S7 communication between Siemens TIA Portal and Mech-MSR:

MM MSR Interface.db(for data communication)

|

Communication Workflow

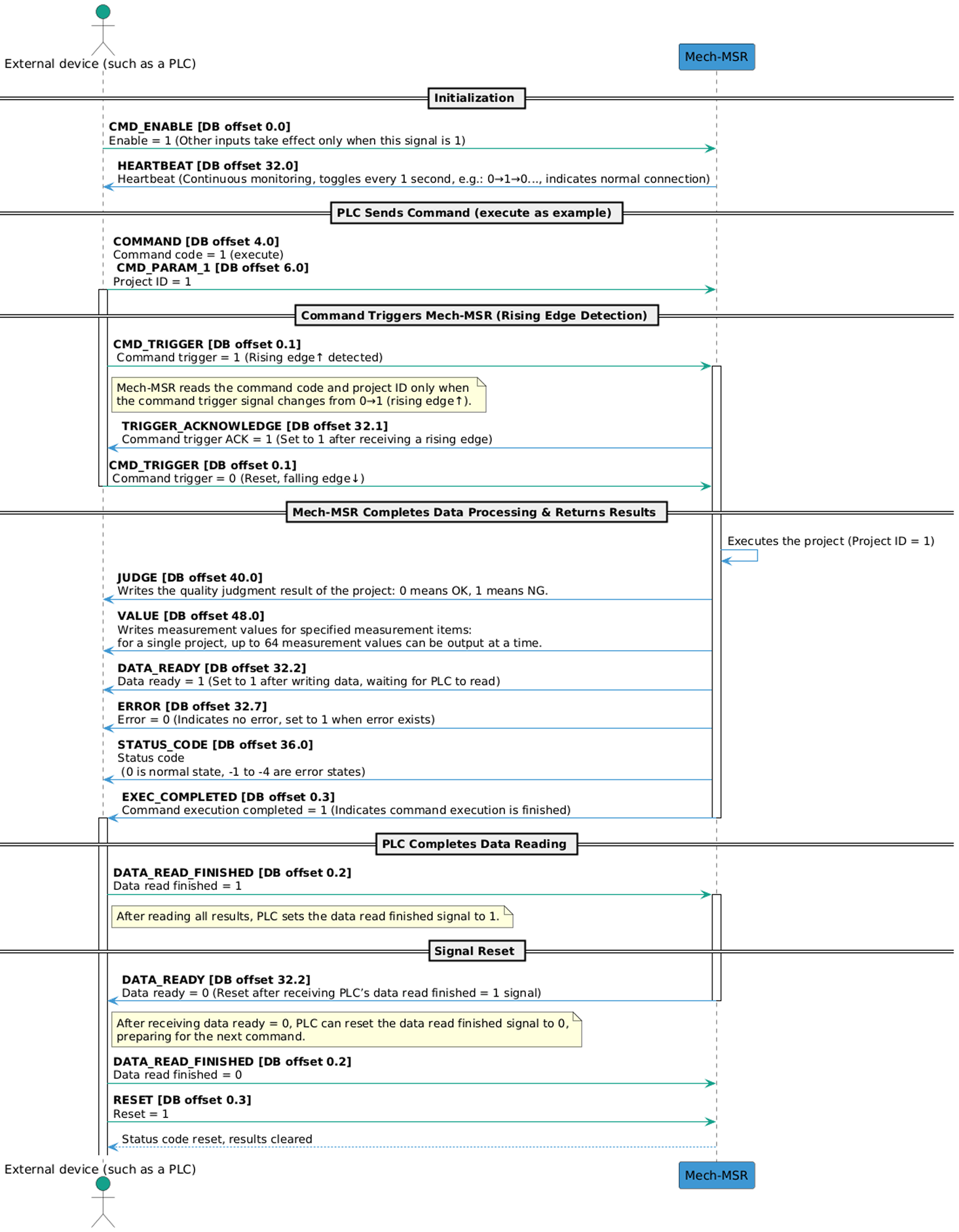

The workflow of Siemens S7 Client communication is shown in the figure below.

| You can check Input signals and Output Signals to learn the meaning of each signal. |

Input Signals (from the PLC to Mech-MSR)

| Name | Description | Data type | DB offset |

|---|---|---|---|

The signal to enable the command. |

Boolean |

0.0 |

|

The signal to trigger the command. |

Boolean |

0.1 |

|

The data is read. |

Boolean |

0.2 |

|

The output data is reset. |

Boolean |

0.3 |

|

BIT_SPARE_1 |

A reserved field. |

Boolean |

0.4 |

BIT_SPARE_2 |

A reserved field. |

Boolean |

0.5 |

BIT_SPARE_3 |

A reserved field. |

Boolean |

0.6 |

BIT_SPARE_4 |

A reserved field. |

Boolean |

0.7 |

BYTE_SPARE_1 |

A reserved field. |

Byte |

1.0 |

BYTE_SPARE_2 |

A reserved field. |

Byte |

2.0 |

BYTE_SPARE_3 |

A reserved field. |

Byte |

3.0 |

Command code |

Integer |

4.0 |

|

CMD_PARAM_1 |

The command parameter 1. |

Integer |

6.0 |

CMD_PARAM_2 |

The command parameter 2. |

Integer |

8.0 |

CMD_PARAM_3 |

The command parameter 3. |

Integer |

10.0 |

CMD_PARAM_4 |

The command parameter 4. |

Integer |

12.0 |

WORD_SPARE |

A reserved field. |

Word (0 to 8) |

14.0 |

CMD_TRIGGER

When the command trigger signal changes from 0 to 1 (a rising edge is detected), Mech-MSR reads command codes and command parameters. When Mech-MSR returns the command trigger acknowledge signal, the command trigger signal can be set to 0.

DATA_READ_FINISHED

When the PLC completes data reading, this signal will be set to 1. When the data ready signal changes to 0, this signal can be set to 0.

RESET

When this signal is set to 1, the PLC clears the received judgement result and measurement result. At this point, the PLC can send new commands and status code signals are reset.

COMMAND

The following table describes the commands supported by the Siemens S7 Client communication, the command codes, and the command parameters.

| Command | Command code | Command parameter | Description |

|---|---|---|---|

execute |

1 |

The project ID. Only one project ID can be set each time. |

Used to trigger the project and obtain project judgement result and measurement result. |

trigger |

2 |

The project ID. One to four project IDs can be set at a time. |

Used to trigger the project to run. |

return |

3 |

The project ID. Only one project ID can be set each time. |

Used to obtain the judgement result and the measurement result of the specified project. |

judge |

4 |

Used to obtain the overall quality judgment result of the specified project or the judgment results of individual measurement items. |

|

value |

5 |

Used to obtain the measured values of a specified project. |

| You can check Project List of Mech-MSR to learn how to view the ID of a project. |

Output Signals (from the PLC to Mech-MSR)

| Name | Description | Data type | DB offset |

|---|---|---|---|

The heartbeat signal. |

Boolean |

32.0 |

|

The trigger acknowledge signal, which acknowledges the command trigger signal. |

Boolean |

32.1 |

|

The data ready signal. |

Boolean |

32.2 |

|

The execution completed signal, which indicates that the command execution is completed. |

Boolean |

32.3 |

|

BIT_SPARE_1 |

A reserved field. |

Boolean |

32.4 |

BIT_SPARE_2 |

A reserved field. |

Boolean |

32.5 |

BIT_SPARE_3 |

A reserved field. |

Boolean |

32.6 |

The error signal. |

Boolean |

32.7 |

|

The overall judge signal. |

Boolean |

33.0 |

|

JUDGE_SPARE_1 |

A reserved field. |

Boolean |

33.1 |

JUDGE_SPARE_2 |

A reserved field. |

Boolean |

33.2 |

JUDGE_SPARE_3 |

A reserved field. |

Boolean |

33.3 |

JUDGE_SPARE_4 |

A reserved field. |

Boolean |

33.4 |

JUDGE_SPARE_5 |

A reserved field. |

Boolean |

33.5 |

JUDGE_SPARE_6 |

A reserved field. |

Boolean |

33.6 |

JUDGE_SPARE_7 |

A reserved field. |

Boolean |

33.7 |

BYTE_SPARE_1 |

A reserved field. |

Byte |

34.0 |

BYTE_SPARE_2 |

A reserved field. |

Byte |

35.0 |

The status code signal. |

Integer |

36.0 |

|

BYTE_SPARE_3 |

A reserved field. |

Byte |

38.0 |

BYTE_SPARE_4 |

A reserved field. |

Byte |

39.0 |

The judge signal. |

Boolean (0 to 63 bits) |

40.0 |

|

The measure signal. |

Floating-point (0 to 63 bits) |

48.0 |

HEARTBEAT

System heartbeat that flips every 1 second. Used to determine whether the PLC and Mech-MSR are connected or disconnected.

TRIGGER_ACKNOWLEDGE

When Mech-MSR receives the rising edge for the command trigger signal, this signal is set to 1. When a failing edge is detected for the command trigger signal, this signal is set to 0.

DATA_READY

Mech-MSR writes data to output ports and waits for the PLC to read the output data. When the data read signal is set to 1, this signal is set to 0.

EXEC_COMPLETED

When the command execution completes, this signal is set to 1, which indicates that the command execution is completed.

ERROR

If the status code returned by Mech-MSR is not 0, an error occurred and this signal will be set to 1.

OVERALL_JUDGE

The overall judgement of the project. 0 indicates OK, and 1 indicates NG.

| You need to set quality judgment rules for the project in the Output Management window in Mech-MSRand determine the measurement items to be considered. You must complete the configuration to obtain a valid judgement result. |

STATUS_CODE

Five status codes may be returned by Mech-MSR:

-

Normal status code: 0, which indicates that the command has been successfully executed.

-

Error codes: -1, -2, -3, and -4. For more information, see Error Codes.

JUDGE

Judgement results were added for measurement items on the Communication output tab in the Output Management window. 0 indicates OK, and 1 indicates NG.

| At most 64 judgement results can be output for a single project at a time. |

VALUE

Measurement results are added for measurement items on the Communication output tab in the Output Management window.

| At most 64 measurement results can be output for a single project at a time. |