Defect Inspection for Brake Pads (Blob Analysis)

About the Solution

This solution is designed to inspect brake pads and thus ensure the processing quality. Brake pads play a big part in the vehicle’s braking system, and their quality is directly linked to the vehicle’s performance and safety. Through automated surface defect inspection, defects on the brake pads can be efficiently identified during the production process, and unqualified products can be detected for timely repair or replacement.

Inspection Target

-

Depressions on the surface of brake pads

Inspecting the presence of depressions on the surface of brake pads is essential because these depressions may affect the performance of brake pads and shorten their service life.

Inspection Challenges

This solution can meet the following challenges:

-

Defect detection: Brake pads’ surfaces often feature complex patterns and irregular shapes, making it challenging for traditional 2D or 3D algorithms to distinguish between normal surface patterns and actual defects, such as cracks and pits.

-

External interference: Dust, oil, or other contaminants may adhere to the surface of brake pads, which may lower the accuracy of 3D imaging and lead to false defect alarms.

-

Production efficiency: In mass production, defect inspection efficiency is crucial, and inspection accuracy and speed must be ensured.

Key Technical Specifications

The key technical specifications of the solution are as follows:

-

Repeatability: <20 μm

-

Cycle time: The cycle time of inspection should be no more than 2 seconds.

| In different application scenarios, key technical specifications may vary and should be adjusted flexibly according to the actual situation. |

Solution Design

According to project requirements, the sensor head of a Mech-Eye 3D laser profiler should be fixed above the target brake pad. Make sure the sensor head faces the surface of the brake pad and adjust its tilt to fit the working space and scan the whole target as much as possible.

Hardware and Software Requirements

-

Mech-Eye 3D Laser Profiler + Mech-Eye Viewer software

Quickly scans the surface of an object and generates surface data (including depth map and intensity image).

-

Mech-MSR software

Obtains and processes surface data and identifies the depressions on the surface of the brake pad.

Deployment Process

| Before deploying the solution, you need to get the Defect Inspection for Brake Pads (Blob Analysis) solution from Mech-MSR’s solution library. See Quick Guide to Solution Library to learn how to get the solution. |

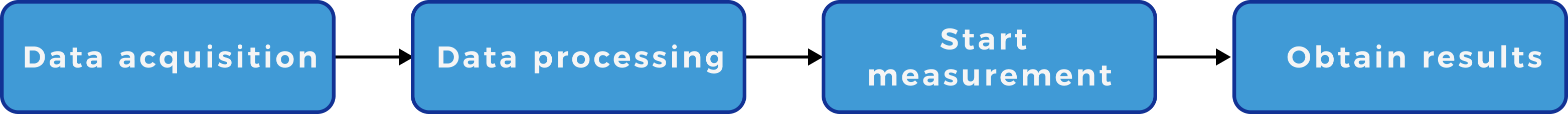

The deployment process of the solution is as follows:

-

Build the software and hardware environment to acquire and view image data.

-

Align the surface data and extract the data for the detection of depressions on the brake pad surface.

-

Fit a reference plane and detect depressions on this basis.

-

Set the acceptable ranges for the measurement item and output measurement and inspection results.

Next, you can get started with solution deployment.