Quick Guide to Output Management

This section introduces the operations related to output management.

Output management provides two main functions:

-

Quality judgment: Evaluate the measurement data of the project to determine whether the target object meets predefined quality standards or specifications. Quality judgment can be used to evaluate all the measurement items as a whole and finally obtain the overall quality judgment result of the project. You can configure the comprehensive judgment rule or customize judgment rules for quality judgment.

-

Communication output: Can be used to customize the output content. By default, the Mech-MSR software outputs only the overall quality judgment result of the project. This function allows you to customize the output of the project. For example, you can add the measurement result (judgment result and measured value) of a specific measurement item to the output.

|

The following operations are mainly introduced:

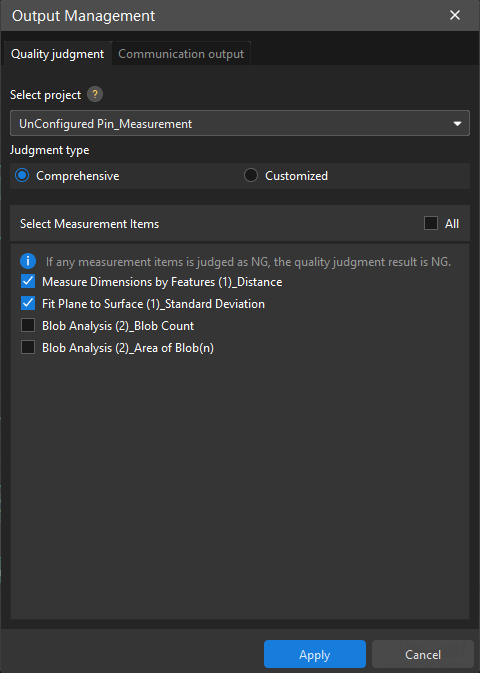

Configure the Comprehensive Judgment Rule for the Project

The comprehensive judgment rule can be used to evaluate the measurement data of multiple measurement items as a whole. If the result of any measurement item is unqualified (NG), the result of the whole project is NG. Only if the results of all measurement items are OK, the overall judgment result of the project is OK.

To configure the comprehensive judgment rule, follow these steps:

-

On the toolbar of Mech-MSR, select .

-

In the Quality judgment tab, set the Select project parameter to the desired project, and then select the Comprehensive option.

-

In the Select Measurement Items area, select the measurement items to be used for comprehensive judgment, and then click the Apply button.

|

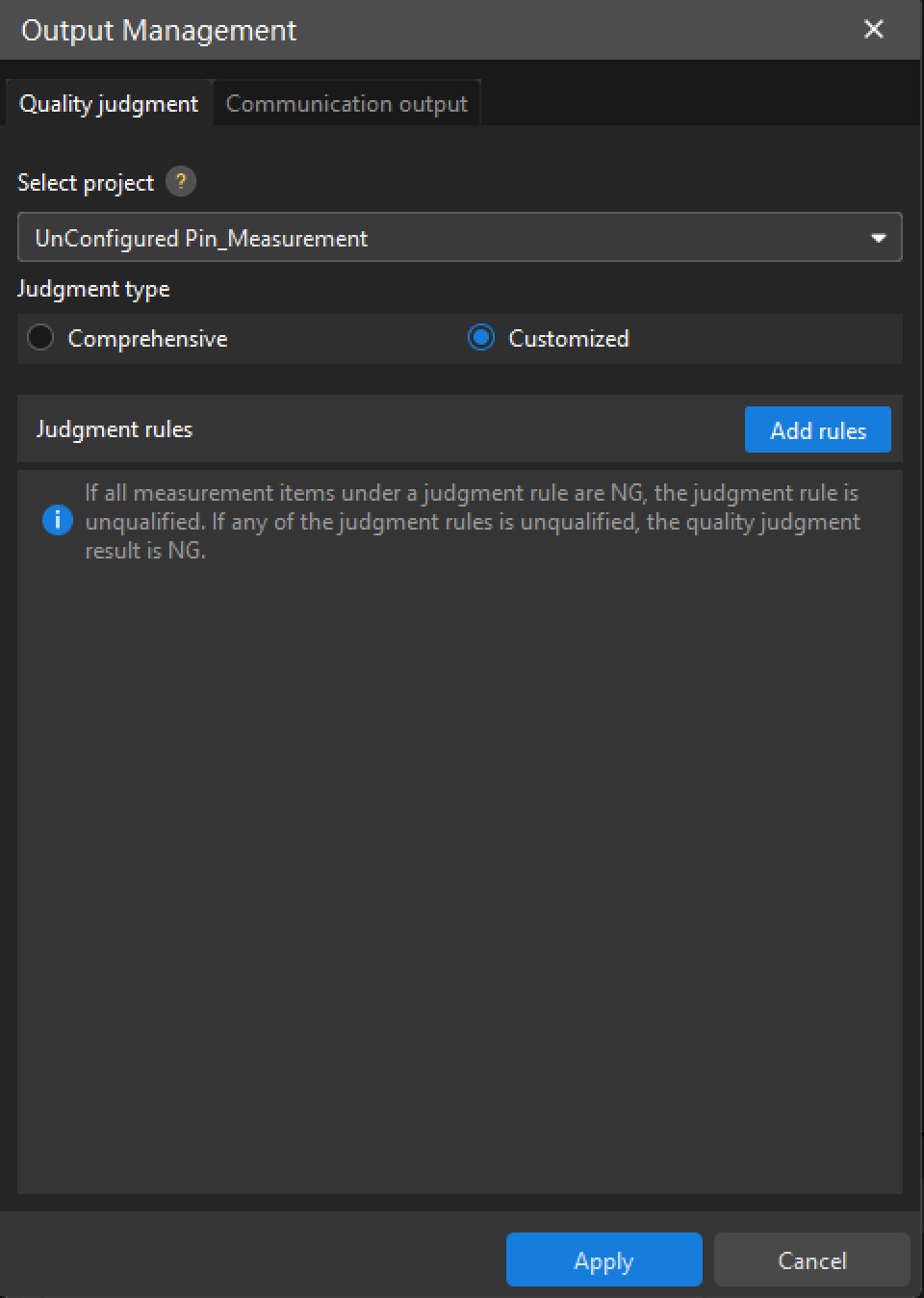

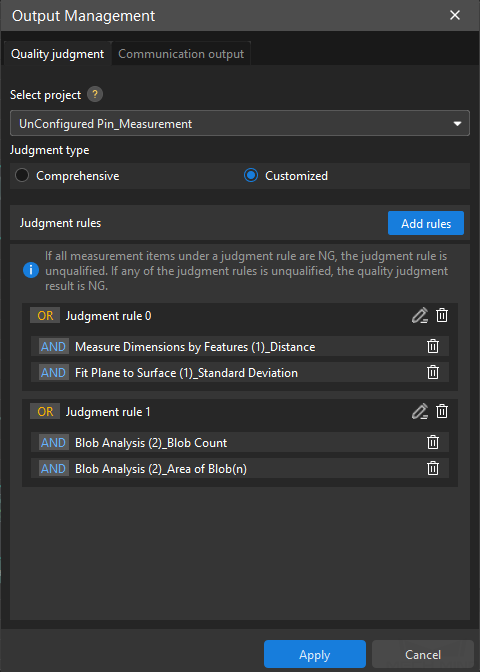

Configure Custom Judgment Rules for the Project

Custom judgment rules are used to meet complex quality judgment needs. You can configure multiple custom judgment rules, and each rule can contain multiple measurement items.

The fit relationship between the judgment rules and measurement items is as follows:

-

If all measurement items under a judgment rule are unqualified (NG), the judgment rule is NG.

-

If any of the judgment rules is unqualified (NG), the quality judgment result of the whole project is NG.

To configure custom judgment rules for the project, follow these steps:

-

On the toolbar of Mech-MSR, select .

-

In the Quality judgment tab, set the Select project parameter to the desired project, and select the Customized option.

-

In the Judgment rules area, click the Add rules button.

-

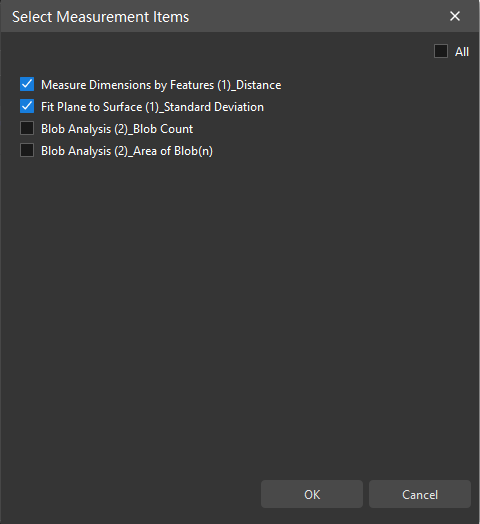

In the pop-up Select Measurement Items dialog box, select the measurement items you need, and then click the OK button.

-

Repeat the previous two steps to add more judgment rules, and then click the Apply button.

To delete a custom judgment rule, click ![]() behind the custom judgment rule in the Judgment rules area, and then click the Apply button.

behind the custom judgment rule in the Judgment rules area, and then click the Apply button.

| In a project, one measurement item can be included in only one custom judgment rule. If you want to add a measurement item to another custom judgment rule, you need to delete the measurement item from the current custom judgment rule before adding it to another rule. |

To delete a measurement item from a custom judgment rule, in the Judgment rules area, click the  behind the measurement item, and then click the Apply button.

behind the measurement item, and then click the Apply button.

To add a measurement item to a custom judgment rule, follow these steps:

-

In the Judgment rules area, click

behind the custom judgment rule.

behind the custom judgment rule. -

In the pop-up Select Measurement Items dialog box, select the measurement items you want to add, and then click the OK button.

-

Click the Apply button.

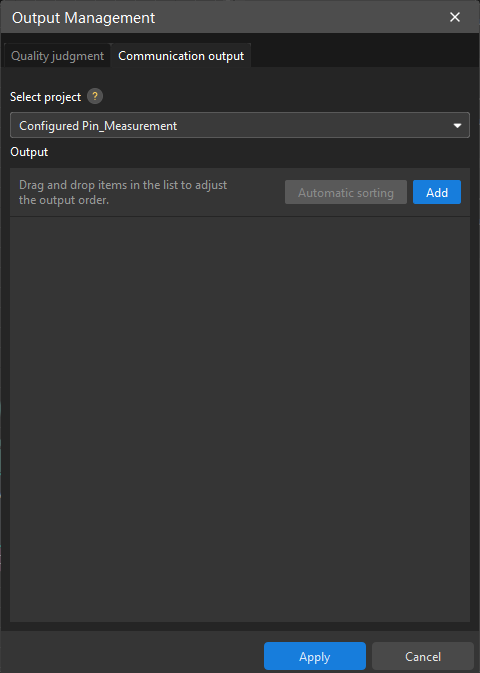

Add Measurement Items to the Project Output

To add measurement items to the output of the project, follow these steps:

-

On the toolbar of Mech-MSR, select .

-

On the Communication output tab, set the Select project parameter to the desired project, and then click the Add button in the Output area.

-

In the pop-up Select Measurement Items dialog box, select the measurement items you need, and then click the OK button.

-

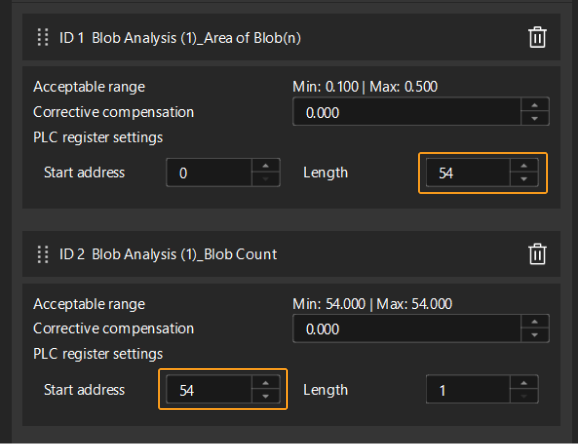

In Output area, set the Corrective compensation parameter for the measurement item according to the actual needs.

-

In the Output area, the ID before the measurement item name is the order of the measurement items in the output of the current project.

-

After Corrective compensation is set for a measurement item, the Output Results panel of the relevant Step will display the measured values before and after correction of the measurement item.

-

-

Perform PLC register settings. For a measurement item, the output measured values occupy space starting from the Starting position according to the set Length.

-

Start position: Represents the offset of the first register to be occupied by the measurement result, relative to the address of the first register for the VALUE module. For more information on the VALUE module, refer to Communication Modes and check the output signal table of the corresponding protocol.

-

Length: Represents the number of values in the measurement result, which equals the number of registers to be occupied by the result.

-

For communication based on the TCP ASCII protocol, there is no need to conduct PLC register settings.

-

For each measurement item, the sum of the start position and length values must not exceed 64; otherwise, the output result may be incomplete.

-

-

After these settings are finished, click the Apply button.

To delete a measurement item from the output of the project, in the Output area, click  on the right side of the measurement item, and then click the Apply button.

on the right side of the measurement item, and then click the Apply button.