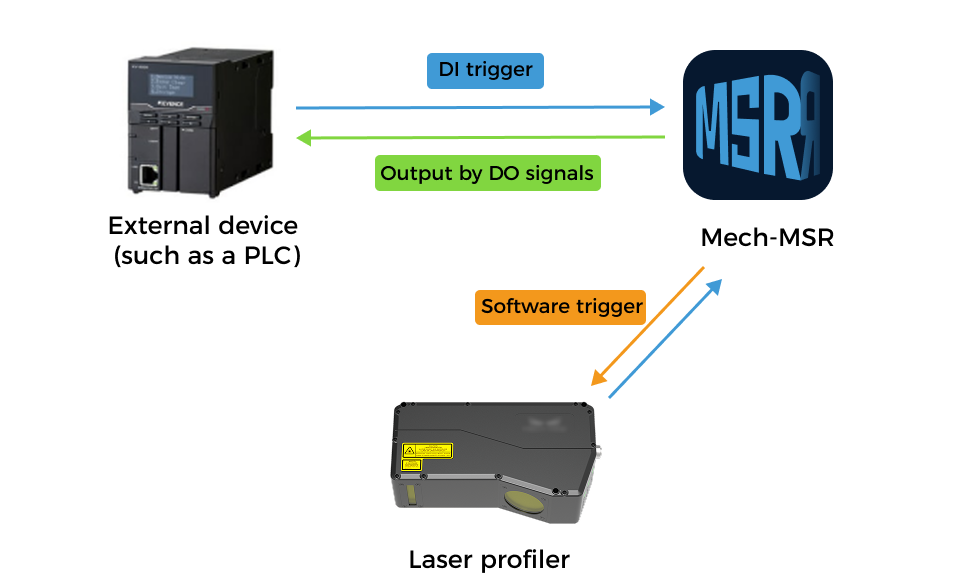

Communication and I/O Control

This chapter introduces how external devices (such as PLCs), the Mech-MSR software, and laser profilers interact in 3D measurement and inspection applications.

Overview

External devices (such as PLCs) can communicate with the Mech-MSR software in the following ways:

-

Protocol-based communication

External devices can interact with the Mech-MSR software using standard or custom industrial communication protocols.

Mech-MSR supports various communication protocols, such as TCP ASCII, PROFINET, Mitsubishi MELSEC (MC), EtherNet/IP, Modbus TCP, and Siemens S7. For more information, refer to Protocol-Based Communication.

-

I/O control

External devices interact with the Mech-MSR software through the general-purpose digital input or output (DI/DO) terminals of the laser profiler. This method is suitable for production scenarios that require fast response or a fixed cycle time. For more information, refer to I/O Control.

In the process, Mech-MSR needs to obtain data (surface data or point cloud) from the laser profiler. The data acquisition trigger source of the laser profiler can be one of the following:

Typical Interaction Methods

| Method | Triggering a Mech-MSR project to run | Data acquisition trigger source of the laser profiler | How an external device obtains results |

|---|---|---|---|

Communication commands |

Software |

Communication commands |

|

Run upon Image Update |

External |

TCP ASCII protocol or DO signals |

|

DI signal |

External |

TCP ASCII protocol or DO signals |

|

Communication commands |

External |

Communication commands |

|

DI signal |

Software |

DO signal |

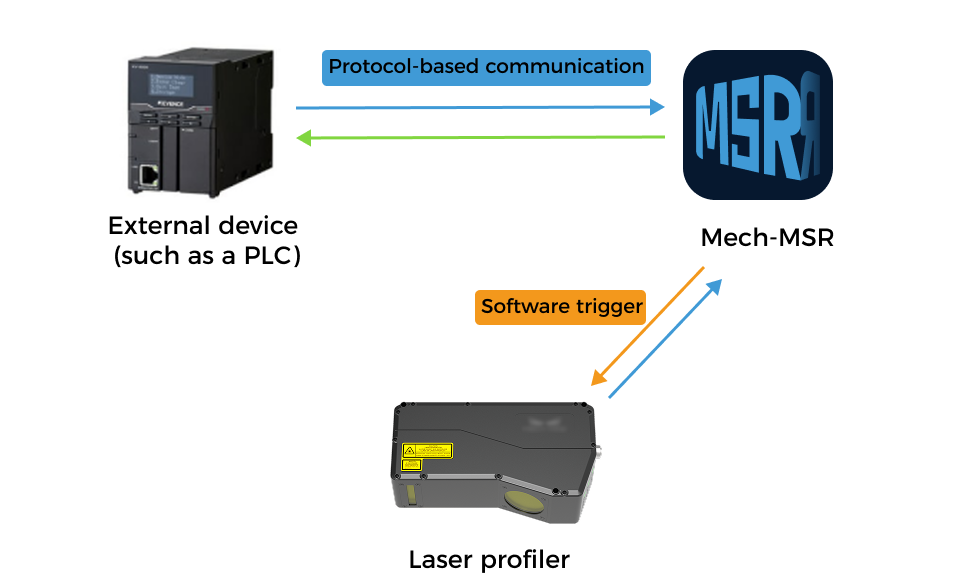

Method 1: Protocol-Based Communication + Software Trigger

In this method, the communication between the external device and the Mech-MSR software is based on industrial protocols, and the laser profiler is triggered by Mech-MSR to acquire data.

Advantage |

The laser profiler’s parameter group can be easily switched in Mech-MSR. |

|---|---|

Disadvantage |

Communication and software triggers both introduce uncertain time delays. The trigger link contains multiple non-instantaneous steps, making precise timing control difficult. Therefore, this method is not suitable for scenarios requiring acquisition synchronized with the motion platform or acquisition at a fixed rate. |

The interaction between an external device, Mech-MSR, and the laser profiler is as follows:

-

The external device sends a command to trigger the Mech-MSR project to run.

-

The Mech-MSR project starts to run and triggers the laser profiler to acquire data.

-

Upon Mech-MSR receiving the acquired data, the project continues its execution until completion.

-

According to the commands sent by the external device, Mech-MSR returns results to the external device accordingly.

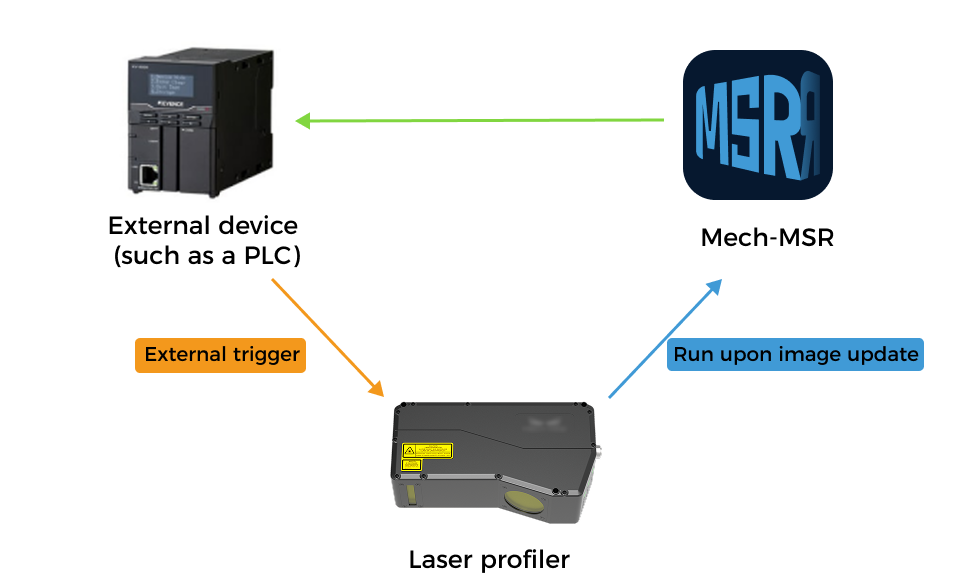

Method 2: Run upon Image Update + External Trigger

In this method, the external device triggers the laser profiler to acquire data. Mech-MSR automatically runs the corresponding project upon receiving the acquired data (namely that Run upon Image Update is enabled) and sends the project execution result to the external device through the TCP ASCII protocol or DO signals.

Advantage |

External trigger introduces no delay and provides fast response. |

|---|---|

Disadvantage |

The laser profiler’s parameter group cannot be switched, and thus this method is not suitable when multiple Mech-MSR projects share the same laser profiler. The laser profiler’s parameter group cannot vary from project to project. |

The interaction between an external device, Mech-MSR, and the laser profiler is as follows:

-

The external device triggers the laser profiler to acquire data.

-

Run upon Image Update is enabled for the project that uses this laser profiler in Mech-MSR. The project starts to run automatically upon receiving the data acquired by the laser profiler.

-

According to the configuration, Mech-MSR sends the project execution results of the project to the external device.

There are two ways for the external device to obtain the project execution results:

-

Obtaining all results in a timely manner through the Auto-push result feature supported by the TCP ASCII protocol.

-

Based on the DO configuration in Mech-MSR, obtaining the overall quality judgment result (OK or NG) of the Mech-MSR project through the general DO terminals of the laser profiler.

-

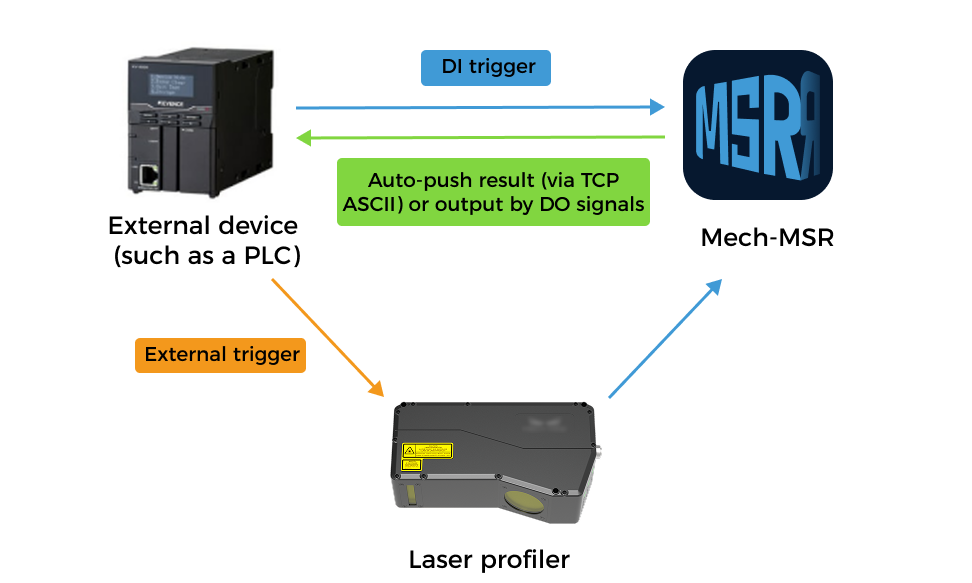

Method 3: DI Trigger + External Trigger

In this method, the external device triggers the laser profiler to acquire data, triggers the Mech-MSR project to run through general-purpose DI terminals, and obtains the project results through the TCP ASCII protocol or DO signals.

Advantage |

External trigger introduces no delay and provides fast response. |

|---|---|

Disadvantage |

The laser profiler’s parameter group cannot be switched, and thus this method is not suitable when multiple Mech-MSR projects share the same laser profiler. The laser profiler’s parameter group cannot vary from project to project. |

The interaction between an external device, Mech-MSR, and the laser profiler is as follows:

-

The external device triggers the laser profiler to acquire data.

-

Based on the DI configuration in Mech-MSR, the external device triggers the corresponding Mech-MSR project to run through the general-purpose DI terminals of the laser profiler.

-

According to the configuration, Mech-MSR sends the project execution results of the project to the external device.

There are two ways for the external device to obtain the project execution results:

-

Obtaining all results in a timely manner through the Auto-push result feature supported by the TCP ASCII protocol.

-

Based on the DO configuration in Mech-MSR, obtaining the overall quality judgment result (OK or NG) of the Mech-MSR project through the general DO terminals of the laser profiler.

-

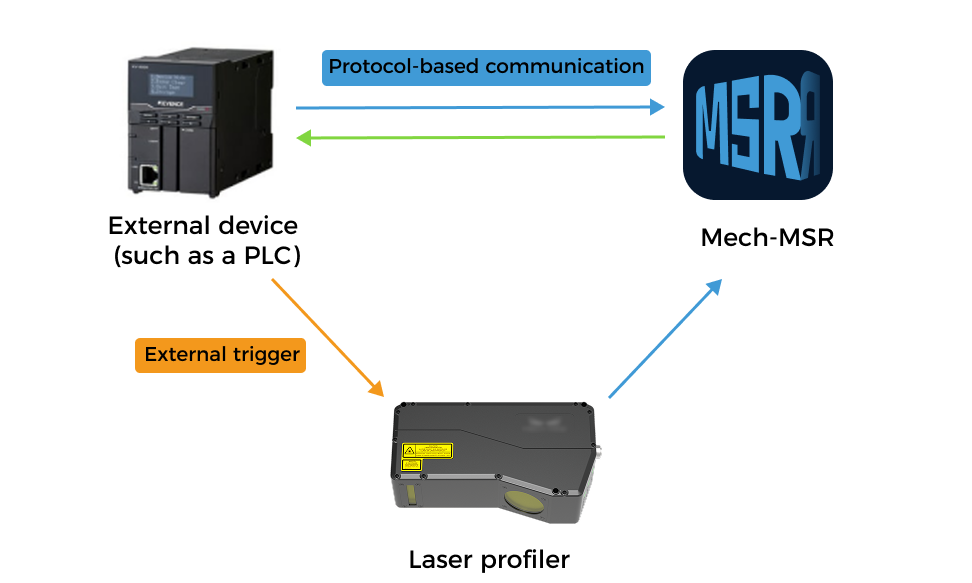

Method 4: Protocol-Based Communication + External Trigger

In this method, the external device triggers the laser profiler to acquire data and communicates with the Mech-MSR software based on industrial protocols.

Advantage |

External trigger introduces no delay and provides fast response. |

|---|---|

Disadvantage |

The laser profiler’s parameter group cannot be switched, and thus this method is not suitable when multiple Mech-MSR projects share the same laser profiler. The laser profiler’s parameter group cannot vary from project to project. |

The interaction between an external device, Mech-MSR, and the laser profiler is as follows:

-

The external device triggers the laser profiler to acquire data.

-

The external device sends a command to trigger the Mech-MSR project to run.

-

According to the commands sent by the external device, Mech-MSR returns results to the external device accordingly.

Method 5: DI Trigger + Software Trigger

In this method, the external device triggers the Mech-MSR project to run via a general-purpose DI terminal of the lase profiler and obtains the project execution result through DO signals. The laser profiler is triggered by Mech-MSR to acquire data.

Advantage |

Pure hardware connection, with no programming required. |

|---|---|

Disadvantage |

External devices can only obtain the overall quality judgment result (OK or NG) of the project; measurement values and their individual judgment results are not available. |

The interaction between an external device, Mech-MSR, and the laser profiler is as follows:

-

Based on the DI configuration in Mech-MSR, the external device triggers the corresponding Mech-MSR project to run through the general-purpose DI terminals of the laser profiler.

-

The Mech-MSR project starts to run and triggers the laser profiler to acquire data.

-

Based on the DO configuration in Mech-MSR, the external device obtains the overall quality judgment result (OK or NG) of the Mech-MSR project through the general-purpose DO terminals of the laser profiler.