Example Program 15: MM_S15_Viz_GetDoList

Program Introduction

Description |

After obtaining the picking path and DO signals, the robot can perform picking and placing by moving to the picking waypoint and setting the DO signals in a loop. This example program is used in depalletizing scenarios, and the tool used by the robot is a multi-section vacuum gripper. |

File path |

You can navigate to the installation directory of Mech-Vision and Mech-Viz and find the file by using the |

Project |

Mech-Vision project and Mech-Viz project (the tool is a depalletizing vacuum gripper) |

Prerequisites |

|

| This example program is provided for reference only. Before using the program, please modify the program according to the actual scenario. |

Program Description

This part describes the MM_S15_Viz_GetDoList example program.

| Compared with the MM_S2_Viz_Basic example program, this example program contains only the following modification (the code of this modification is bolded). As such, only the modification is described in the following section. For information about the parts of MM_S15_Viz_GetDoList that are consistent with those of MM_S2_Viz_Basic, see Example Program 2: MM_S2_Viz_Basic. |

NOP

'--------------------------------

'FUNCTION: trigger Mech-Viz

'project, then get planned path

'and gripper control signal using

'command 210

'Mech-Mind, 2023-12-25

'--------------------------------

'clear I50 to I69

CLEAR I050 20

'initialize p variables

SUB P071 P071

SUB P072 P072

SUB P073 P073

'move to robot home position

MOVJ C00000 VJ=50.00

'initialize communication

'parameters (initialization is

'required only once)

CALL JOB:MM_INIT_SOCKET ARGF"192.168.170.22;50000;1"

'move to image-capturing position

MOVJ C00001 VJ=50.00 PL=0

'open socket connection

CALL JOB:MM_OPEN_SOCKET

'trigger Mech-Viz project

CALL JOB:MM_START_VIZ ARGF"2;30"

'get planned path

CALL JOB:MM_GET_PLANDATA ARGF"0;3;51;52;53"

'check whether planned path has

'been got from Mech-Viz

'successfully

IFTHENEXP I053<>2100

'add error handling logic here

'according to different error

'codes

'e.g.: I053=2038 means no

'point cloud in ROI

PAUSE

ENDIF

'get gripper control signal list

CALL JOB:MM_GET_DOLIST ARGF"0;0"

'close socket connection

CALL JOB:MM_CLOSE_SOCKET

'save waypoints of the planned

'path to local variables one

'by one

CALL JOB:MM_GET_PLANPOSE ARGF"1;71;61;31"

CALL JOB:MM_GET_PLANPOSE ARGF"2;72;71;31"

CALL JOB:MM_GET_PLANPOSE ARGF"3;73;81;31"

'follow the planned path to pick

'move to approach waypoint of

'picking

MOVJ P071 VJ=50.00 PL=0

'move to picking waypoint

MOVJ P072 VJ=10.00 PL=0

'set gripper control signal when

'current waypoint is picking

'waypoint

CALL JOB:MM_SET_DOLIST ARGF"0"

PAUSE

'move to departure waypoint of

'picking

MOVJ P073 VJ=50.00 PL=0

'move to intermediate waypoint of

'placing

MOVJ C00002 VJ=50.00

'move to approach waypoint of

'placing

MOVL C00003 V=166.6 PL=0

'move to placing waypoint

MOVL C00004 V=50.0 PL=0

'add object releasing logic here,

'such as DOUT OT#(1) OFF

PAUSE

'move to departure waypoint of

'placing

MOVL C00005 V=166.6 PL=0

'move back to robot home position

MOVJ C00006 VJ=50.00

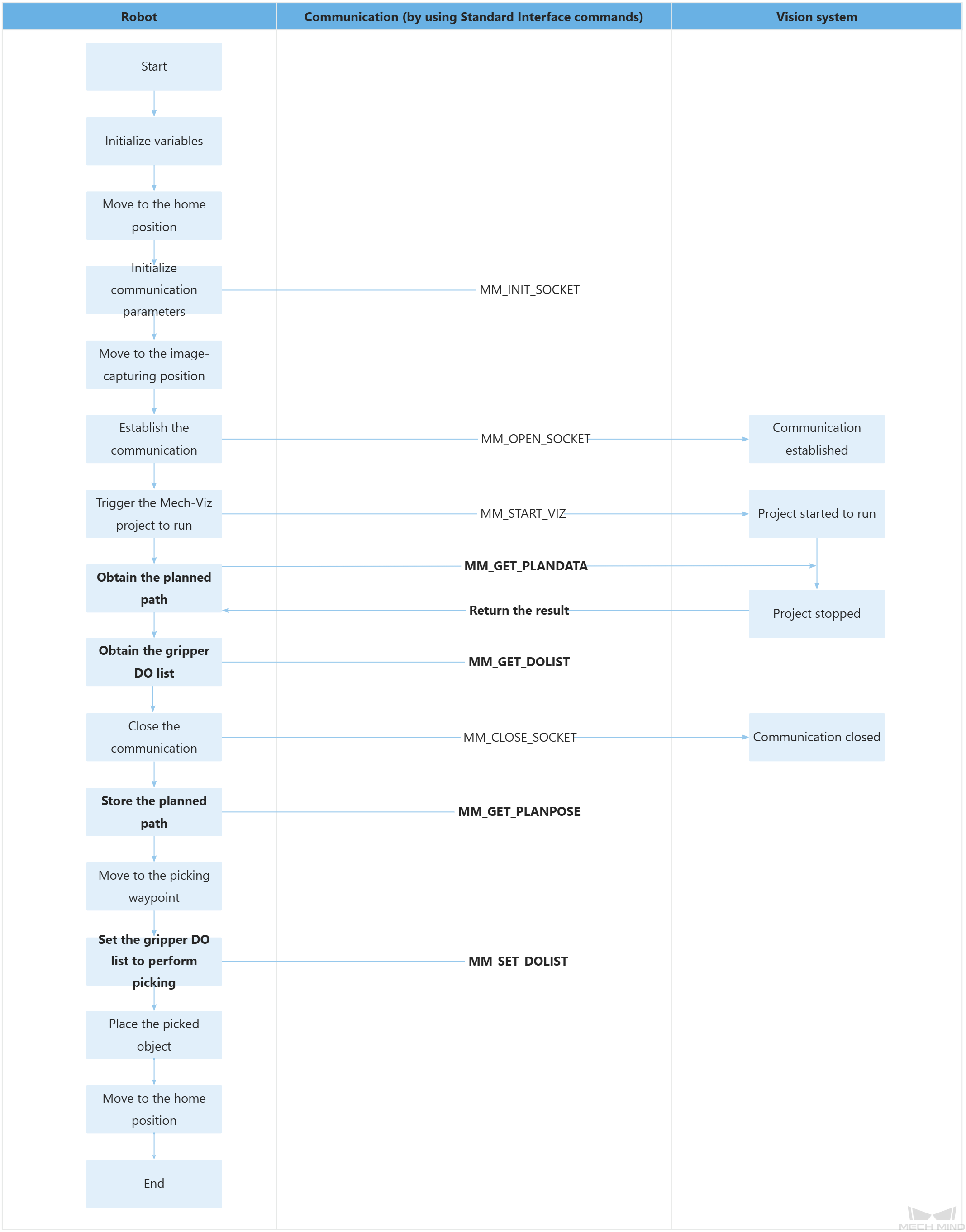

ENDThe workflow corresponding to the above example program code is shown in the figure below.

The table below describes the bolded code. You can click the hyperlink to the command name to view its detailed description.

| Feature | Code and description | ||

|---|---|---|---|

Obtain the planned path |

|

||

Obtain the gripper DO list |

|

||

Store the planned path |

The entire statement “CALL JOB:MM_GET_PLANPOSE ARGF"1;71;61;31"” indicates that the pose, motion type, tool ID, velocity, Vision Move data, and custom data of the first waypoint are stored in the specified variables.

|

||

Move to the picking waypoint to perform picking |

The above statement indicates that the robot moves to the picking waypoint (P072) and then runs the MM_SET_DOLIST command to set gripper DO signals to perform picking. |