Kawasaki Standard Interface Commands

This section describes standard interface commands used in TCP communications between a Kawasaki robot and Mech-Mind Vision System. The robot (the client) sends commands to Mech-Mind Vision System (the server), and Mech-Mind Vision System returns the processed data to the robot.

Command Overview

Commands related to Mech-Vision |

Commands related to Mech-Viz |

|

Switch Mech-Vision Parameter Recipe Get Planned Path in Mech-Vision Store Vision Result or Planned Path (TCP) Store Planned Path (joint positions) |

Set Exit Port for Branch by Msg Step in Mech-Viz Store Vision Result or Planned Path (TCP) Store Planned Path (joint positions) |

Precautions

-

When programming a Kawasaki robot, pay attention to the following items:

-

Parameters in the parameter list of a command must be separated by commas (,).

-

Variable-type parameters of a command should use local variables and take effect only in the command.

-

Input and output parameters can be customized in commands.

-

Arguments in a command: The input arguments can be constants, global variables, or local variables. The output arguments can be global variables or local variables.

-

-

Unit of data:

-

The unit of joint positions is degree (°).

-

A robot’s flange pose or TCP consists of the position and pose. The position is represented in XYZ coordinates and is measured in millimeters (mm); the pose is represented in Euler angles and is measured in degrees (°).

-

-

Vision point and waypoint:

-

Vision point: An object recognized by Mech-Vision. A vision point has information including the object pose, label, dimensions, and custom data.

-

Waypoint: Each point that the robot reaches when moving along the planned path. A waypoint has information including the robot pose, label, and motion type. Waypoints can be divided into two categories:

-

Vision Move waypoint: Waypoint corresponding to the Vision Move Step.

-

Non-Vision Move waypoints, which refer to the waypoints corresponding to Move-type Steps other than the Vision Move Step.

-

-

Communication Initialization

Command Format

mm_init_skt(.ip1,.ip2,.ip3,.ip4,.port)Input Parameters

.ip1~.ip4

.port

This parameter specifies the port number used by the IPC to establish the communication between the IPC and the robot. This port number must be consistent with the host port number that is specified for robot communication in the toolbar of Mech-Vision.

Run Mech-Vision Project

Command

This command triggers the Mech-Vision project to run. When the Mech-Vision project is running, the vision system triggers the camera to capture images and then process the returned images with algorithms to produce a series of vision points or waypoints.

|

Calling Sequence

-

You should set Step parameters before starting a Mech-Vision project. Therefore, call Switch Mech-Vision Parameter Recipe or Input Object Dimensions to Mech-Vision Project before calling Run Mech-Vision Project.

-

Vision system gets vision points and waypoints only after a Mech-Vision project runs. Therefore, call Run Mech-Vision Project before calling Get Vision Result, Get Planned Path in Mech-Vision, or Get Mech-Vision Custom Data.

Command Format

mm_start_vis(.job,.pos_num_need,.sendpos_type,.#start_vis)Input Parameters

.job

Mech-Vision project ID. You can view the project ID of a Mech-Vision project in the Project List section of Mech-Vision. The project ID is the number before the project name.

.pos_num_need

This parameter specifies the expected number of vision points or waypoints to be obtained from the Mech-Vision project. Value range: 0 to the largest positive integer.

| If the Mech-Vision project has a Path Planning Step, this parameter indicates the expected number of waypoints. Otherwise, it indicates the expected number of vision points. |

-

0: Obtain all vision points or waypoints from the Mech-Vision project.

-

A positive integer: Obtain the specific number of vision points or waypoints from the Mech-Vision project.

-

If the total amount of vision points or waypoints output by the Mech-Vision project is smaller than the parameter value, this command will obtain the number of all vision points or waypoints.

-

If the total amount of vision points or waypoints output by the Mech-Vision project is larger than or equal to the parameter value, this command will obtain the number of vision points or waypoints as specified by this parameter.

-

|

.sendpos_type

This parameter specifies the way in which the real robot pose is sent to the Mech-Vision project. Valid values: 0, 1, 2, and 3. The following table describes the details.

| .sendpos_type | Description | Applicable scenario |

|---|---|---|

0 |

The command does not send the robot pose data to the Mech-Vision project. If the Path Planning Step is used in the Mech-Vision project, the start point of the planned path will be the Home point set in the path planning tool. |

This setting should be used if the camera is mounted in eye to hand mode and the project does not require images to be captured beforehand. |

1 |

The current joint positions and flange pose of the robot must be input to the Mech-Vision project. |

This setting should be used when the camera is mounted in eye in hand mode. This setting is recommended for most scenarios except those involving gantry robots. |

2 |

The robot flange pose must be input to the Mech-Vision project. |

This setting is recommended for scenarios involving gantry robots. |

3 |

This command sends custom joint positions to the Mech-Vision project. These joint positions will be sent to the Path Planning Step in the Mech-Vision project as the start point, where the robot will move from this start point to the first waypoint of the planned path. |

This setting should be used if the camera is mounted in eye to hand mode and the project requires images to be captured beforehand. |

|

.#start_vis

This parameter specifies the custom joint positions.

-

If .sendpos_type is set to 3, the joint positions will be sent to the Path Planning Step in the Mech-Vision project as the start point, where the robot moves from this start point to the first waypoint of the planned path.

-

If .sendpos_type is set to a parameter value other than 3, this parameter can be set to #start_vis.

Example

CALL mm_start_vis(1,1,1,#start_vis)In the preceding example, the Mech-Vision project whose ID is 1 is run, and one vision point is expected to be returned by the Mech-Vision project. At the same time, the robot sends the current joint position and flange pose data to the Mech-Vision project. In this example, #start_vis has no practical use, but its value must be set.

Get Vision Result

Command

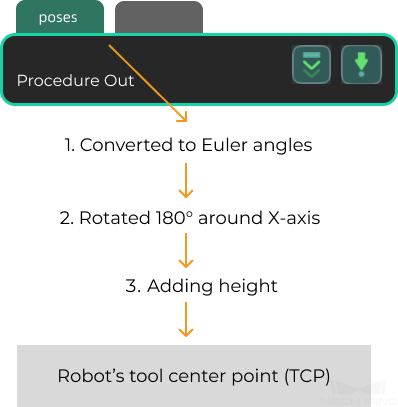

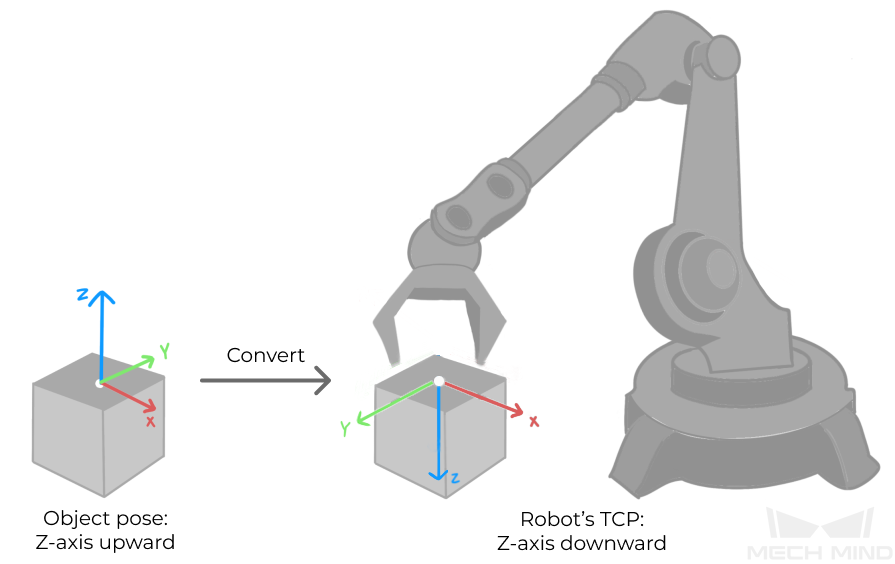

This command obtains vision result, namely, a series of vision points, from Mech-Vision. The object pose of the vision point (namely, the output of the poses port of the Output Step) will be automatically converted to the robot’s TCP by the vision system. The process is as follows.

| If the first input port of the Output Step is Object Center Points, the Output Step will convert the object center points into the corresponding pick points. Therefore, the object poses obtained by running this command are actually poses of pick points, instead of poses of object center points. |

-

Convert the object pose from a quaternion to Euler angles.

-

Rotate the object’s pose around the X-axis by 180° to orient its Z-axis downward.

Calling Sequence

This command should be called after Run Mech-Vision Project. After you call this command, call Store Vision Result or Planned Path (TCP) to access pose data.

Command Format

mm_get_visdata(.job,.pos_num,.ret)Input Parameters

.job

Mech-Vision project ID. You can view the project ID of a Mech-Vision project in the Project List section of Mech-Vision. The project ID is the number before the project name.

Output Parameters

.pos_num

This parameter stores the number of vision points returned by Mech-Vision.

.ret

This parameter stores the status code of this command. If the command is successfully executed, the status code is 1100. If a command fails to be run, a specific error code is returned. For details, see Status Codes and Troubleshooting.

|

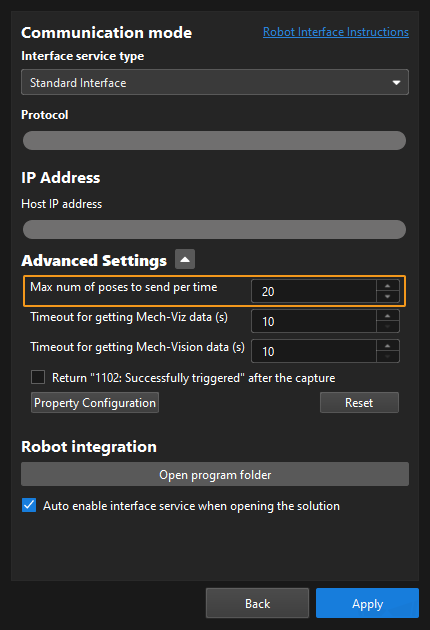

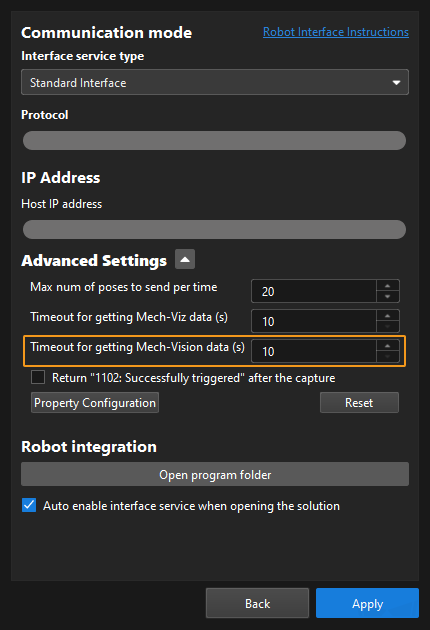

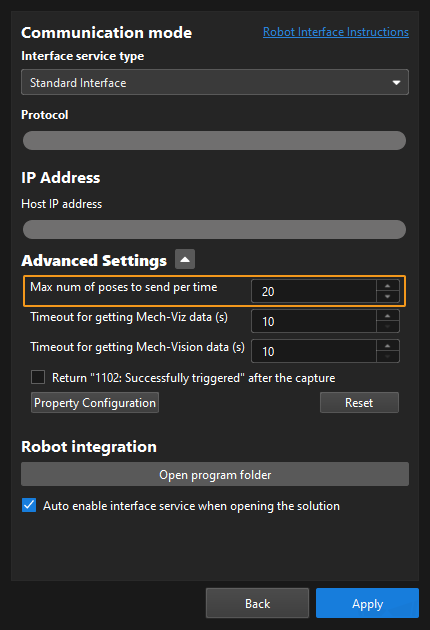

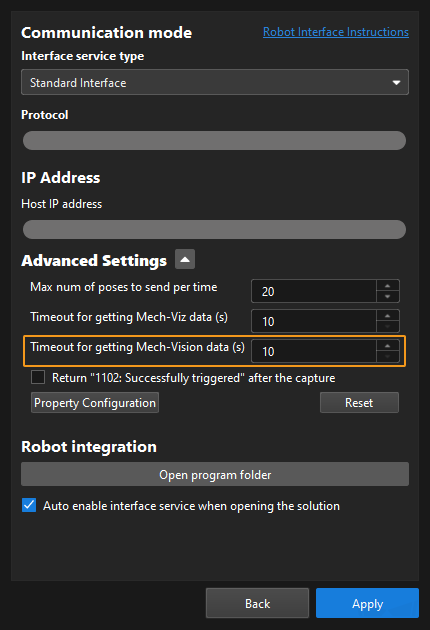

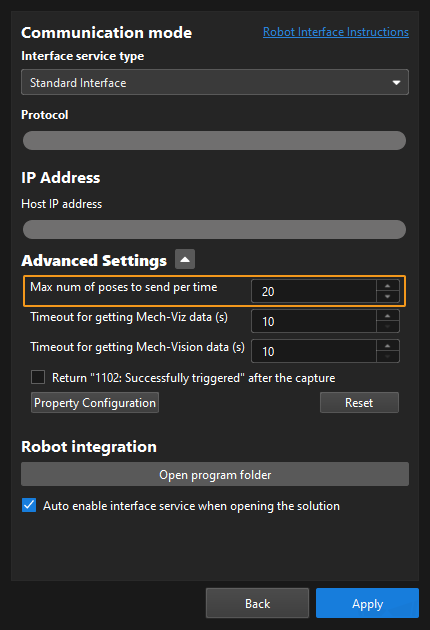

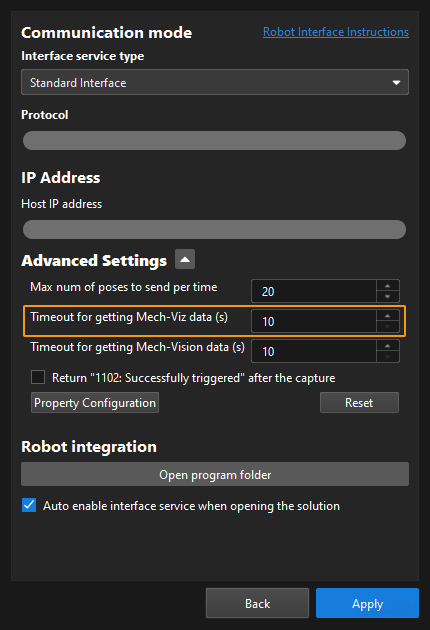

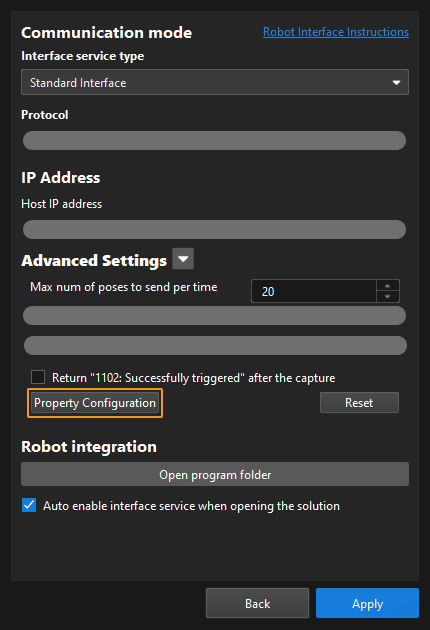

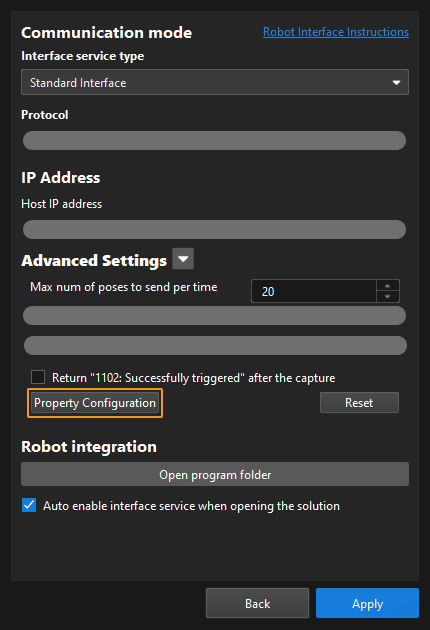

By default, after the robot sends this command, the vision system returns the result in 10 seconds. If the vision system fails to return any result in 10 seconds, a timeout error code is returned. To modify the default timeout period as needed, go to Robot and Communication > in the toolbar of Mech-Vision.

|

Store Vision Result or Planned Path (TCP)

Command

This command stores the TCP, label, and tool ID of the vision point or waypoint in the variables.

Command Format

mm_get_pose(.index,.&targetpos,.label,.toolID)Input Parameters

.index

This parameter specifies the index of the vision point or waypoint. The TCP, label, and tool ID of the vision point or waypoint that corresponds to the index are stored in the variables. Indexes start with 1.

Output Parameters

.&targetpos

This parameter stores the TCP of the vision point or waypoint that corresponds to the index. The & sign indicates that the parameter value is TCP.

.label

This parameter stores the label of the vision point or waypoint that corresponds to the index.

.toolID

This parameter stores the tool ID of the vision point or waypoint that corresponds to the index.

Store Planned Path (joint positions)

Command

This command stores the joint positions, label, and tool ID of the waypoint in the variables.

Command Format

mm_get_jps(.index,.#targetpos,.label,.toolID)Input Parameters

.index

This parameter specifies the index of the waypoint. The joint positions, label, and tool ID of the waypoint that corresponds to the index are stored in the variables. Indexes start with 1.

Output Parameters

.#targetpos

This parameter stores the joint positions of the waypoint that corresponds to the index. The # sign indicates that the parameter value is joint positions.

.label

This parameter stores the label of the waypoint that corresponds to the index.

.toolID

This parameter stores the tool ID of the waypoint that corresponds to the index.

Switch Mech-Vision Parameter Recipe

Command

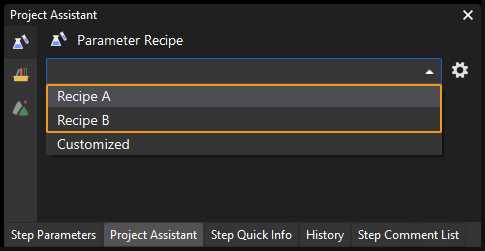

This command triggers Mech-Vision to switch the parameter recipe used by the project. The image below shows how to manually switch the parameter recipe for a Mech-Vision project. For details about parameter recipes, see the parameter recipe guide.

Calling Sequence

This command should be called before Run Mech-Vision Project.

Command Format

mm_switch_model(.job,.model_number)Input Parameters

.job

Mech-Vision project ID. You can view the project ID of a Mech-Vision project in the Project List section of Mech-Vision. The project ID is the number before the project name.

.model_number

This parameter specifies the parameter recipe ID in the Mech-Vision project. For information about how to view the parameter recipe ID, see View the Parameter Recipe ID.

Get Planned Path in Mech-Vision

Command

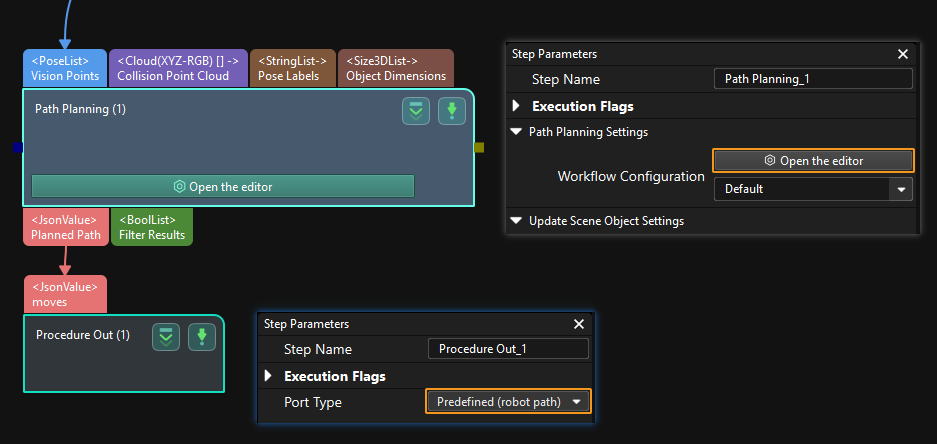

This command obtains the path planned by the Mech-Vision project as a series of waypoints. The path is planned by the path planning tool, which you may enter by clicking Config wizard as shown in the image below. For details about Path Planning, see Path Planning.

| Set the Port Type parameter of the Output Step in Mech-Vision to Predefined (robot path). |

Calling Sequence

This command should be called after Run Mech-Vision Project. After you call this command, call Store Vision Result or Planned Path (TCP) or Store Planned Path (joint positions) to access pose data.

Command Format

mm_get_vispath(.job,.getpos_type,.pos_num,.vispos_num,.ret)Input Parameters

.job

Mech-Vision project ID. You can view the project ID of a Mech-Vision project in the Project List section of Mech-Vision. The project ID is the number before the project name.

.getpos_type

This parameter specifies the type of waypoint poses to be obtained. can be set to 1 or 2.

-

1: joint positions. After you run this command, run Store Planned Path (joint positions) to access joint position data.

-

2: tool poses. After you run this command, run Store Vision Result or Planned Path (TCP) to access tool pose data.

Output Parameters

.pos_num

This parameter stores the number of waypoints returned by the vision system. By default, the vision system can send 20 waypoints at most. As such, the maximum default value of this parameter is 20. To modify the default maximum number of poses to obtain each time as needed, go to Robot and Communication > in the toolbar of Mech-Vision. The upper limit is 30.

| Before you call Get Planned Path in Mech-Vision, set .pos_num_need of Run Mech-Vision Project to 0 to reduce the number of Get Planned Path in Mech-Vision calls. If .pos_num_need of Run Mech-Vision Project is set to 1, only one waypoint is obtained each time you call Get Planned Path in Mech-Vision. You need to call Command 105 several times to obtain all waypoints. |

.vispos_num

The sequence number of the Vision Move waypoint (the waypoint corresponding to the Vision Move step of the path planning tool) in the path. If the waypoint does not exist in the path, the petameter value is 0.

If the planned path consists of the following waypoints in sequence: Fixed-Point Move_1, Fixed-Point Move_2, Vision Move, and Fixed-Point Move_3, the sequence number of the Vision Move waypoint is 3.

.ret

This parameter stores the status code of this command. If the command is successfully executed, the 1103 status code is returned. If a command fails to be run, a specific error code is returned. For details, see Status Codes and Troubleshooting.

|

By default, after the robot sends this command, the vision system returns the result in 10 seconds. If the vision system fails to return any result in 10 seconds, a timeout error code is returned. To modify the default timeout period as needed, go to Robot and Communication > in the toolbar of Mech-Vision.

|

Example

CALL mm_get_vispath(2,2,posnum,vis_index,statuscode)In the preceding example, the planned path of the Mech-Vision project No.2 is returned, the waypoints of the path are stored in the TCP format, the number of waypoints is stored in posnum, the sequence number of the Vision Move waypoint in the planned path is stored in vis_index, and the command execution status code is stored in statuscode.

Get Mech-Vision Custom Data

Command

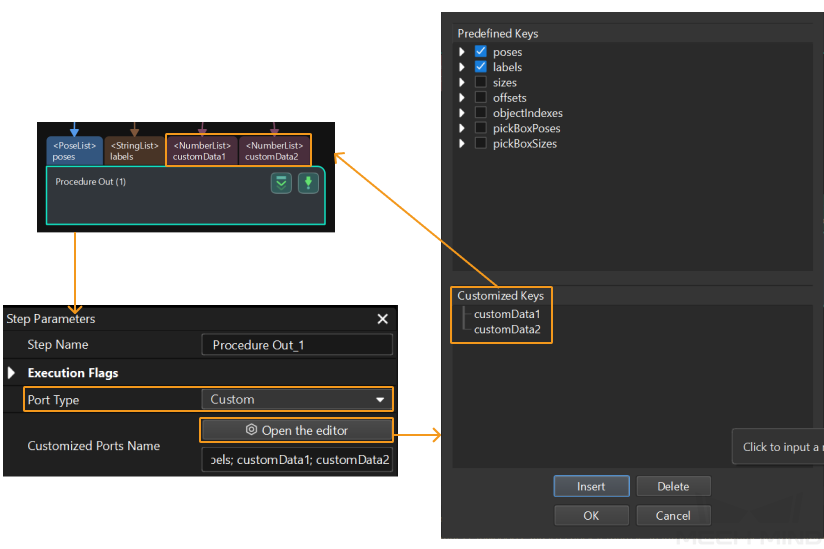

This command obtains data from the custom port(s) of the Output Step in Mech-Vision. One command call saves all port data of the Output Step to robot memory.

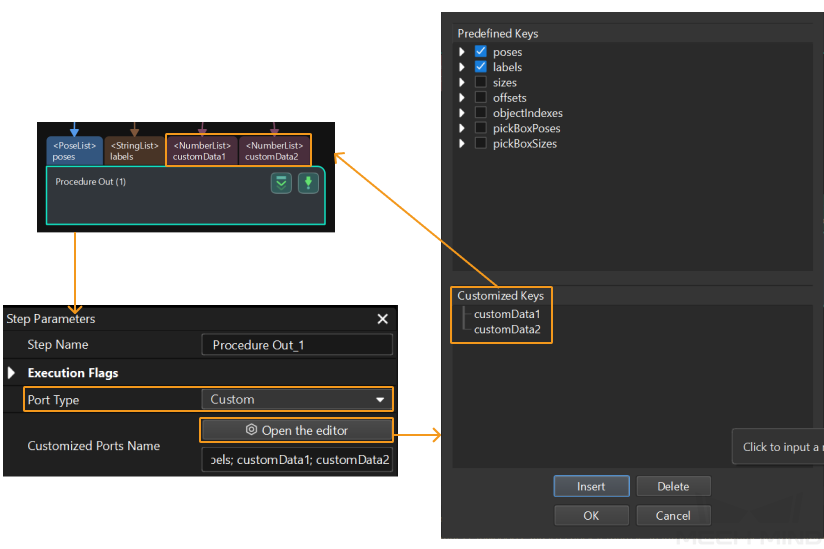

Select the Output Step, set Port Type to Custom, and then click Open the editor to go to the custom port configuration window. The Customized Keys section of the window displays custom port names, such as customeData1 and customeData2 as shown in the following figure.

|

Calling Sequence

This command should be called after Run Mech-Vision Project. After you call this command, call mm_get_pose to obtain the poses, labels, and tool IDs of vision points.

Command Format

mm_get_dydata(.job,.pos_num,.count,.ret)Input Parameters

.job

Mech-Vision project ID. You can view the project ID of a Mech-Vision project in the Project List section of Mech-Vision. The project ID is the number before the project name.

Output Parameters

.pos_num

This parameter stores the number of vision points returned by Mech-Vision.

.count

This parameter stores the number of custom elements.

Custom number of data items indicates the total number of elements in the data output of all custom ports. For example, the following table displays the output data of the ports of the Output step. customData1 and customData2 are custom ports, with 3 and 2 columns in their respective output data. Therefore, the number of elements in custom output data is 5 (3 + 2).

Port name |

poses |

labels |

customData1 |

customData2 |

Output data |

[ [0, 0, 0, 1, 0, 0, 0], [0, 0, 0, 1, 0, 0, 0] ] |

[ "0", "1" ] |

[ [0, 0, 1], [1, 0, 0] ] |

[ [0, 0], [1, 1] ] |

Number of rows (i.e. number of items in the list) |

2 |

2 |

2 |

2 |

Number of columns (i.e. number of elements in each item of the list) |

7 |

1 |

3 |

2 |

The custom data obtained by this command is stored in the two-dimensional array vis_custom_data[]. For example, [0, 0, 1] of the customData1 port is stored in vis_custom_data[1,1], vis_custom_data[1,2], and vis_custom_data[1,3] respectively and [0, 0] of the customData2 port is stored in vis_custom_data[1,4] and vis_custom_data[1,5] respectively.

.ret

This parameter stores the status code of this command. If the command is successfully executed, the status code is 1100. If a command fails to be run, a specific error code is returned. For details, see Status Codes and Troubleshooting.

Example

CALL mm_get_dydata(2,pos_num,count,statuscode)In the preceding example, the custom data of the Mech-Vision project No.2 is obtained, the number of vision points is stored in pos_num, and the status code of the The custom number of data items is stored in count. command is stored in statuscode.

Get Gripper DO List

Command

This command obtains the control signal list for the multi-section vacuum gripper from the Mech-Vision or Mech-Viz project. The robot applies the DO signals obtained by Set Gripper DO List as the tool.

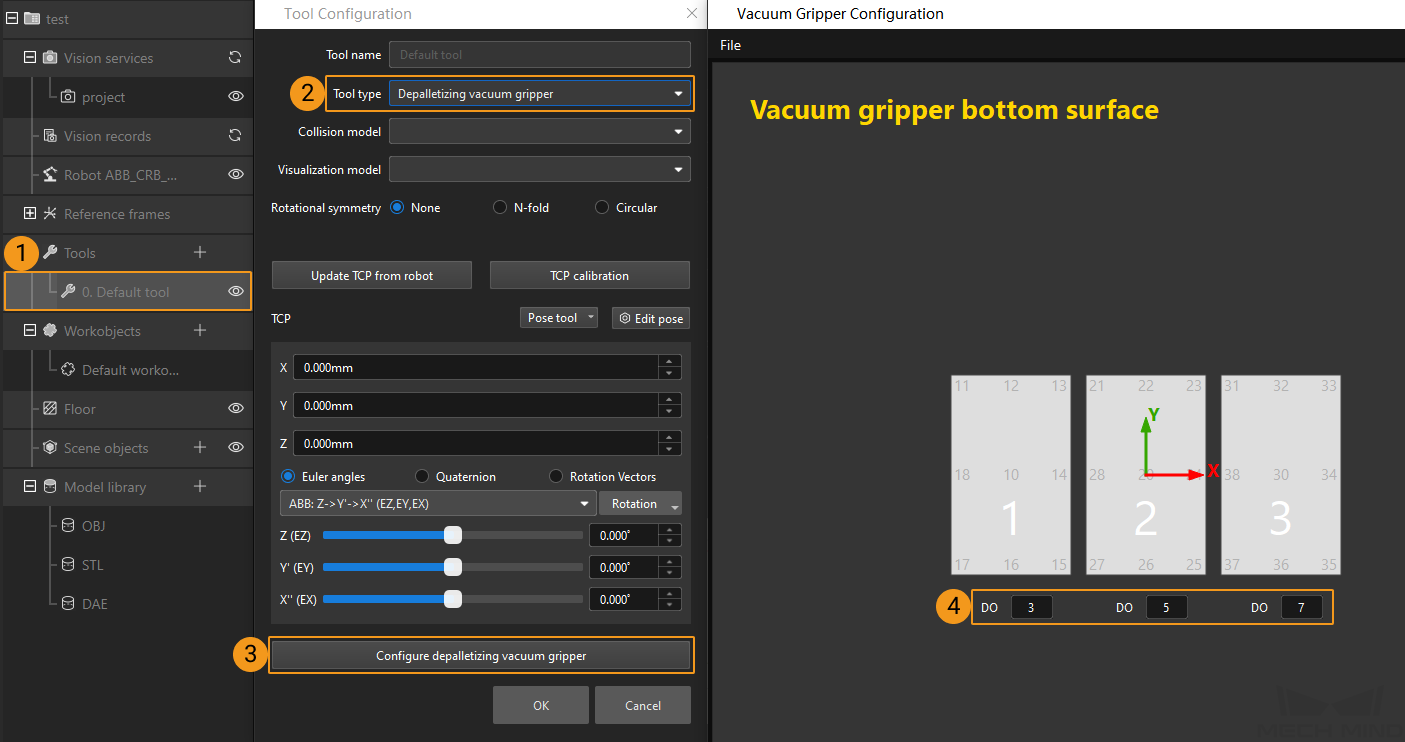

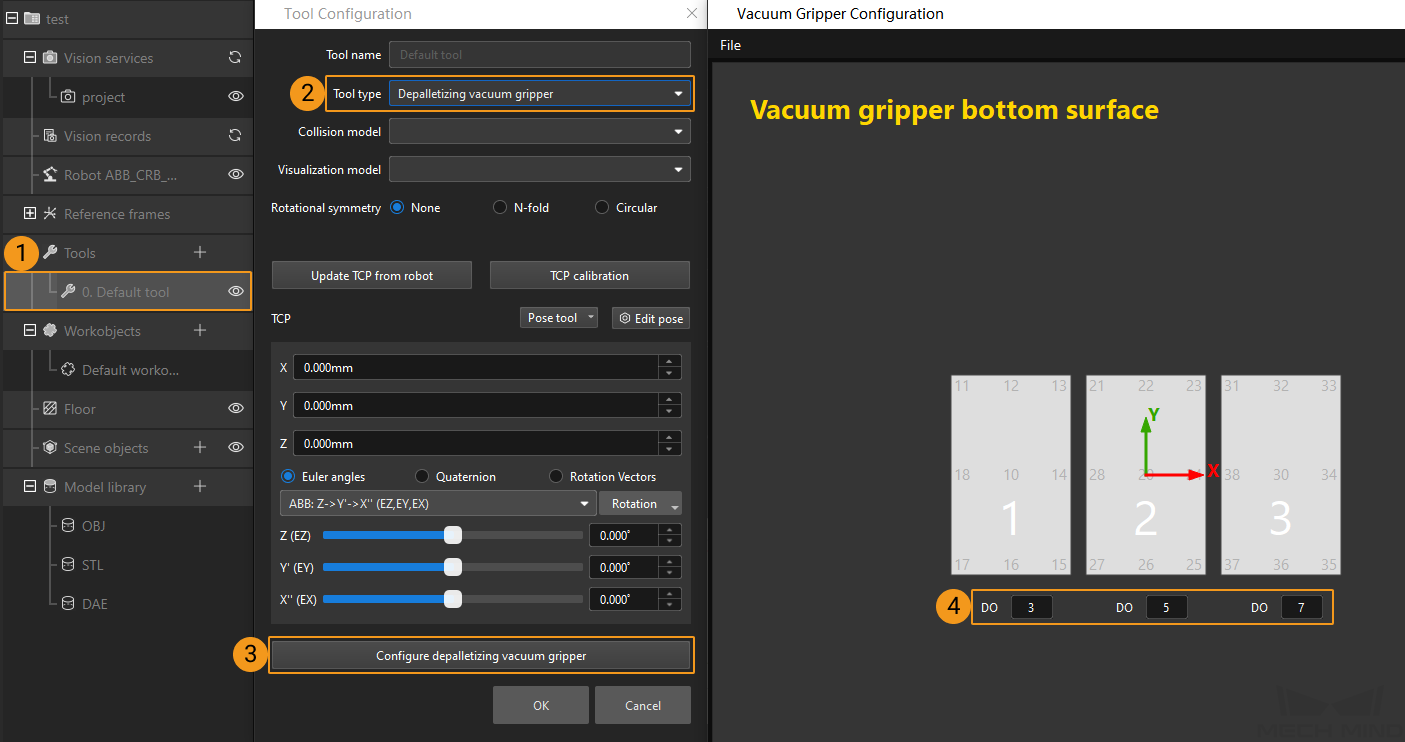

Before using this command, you must perform the following configurations in Mech-Vision or Mech-Viz.

-

Configure the Mech-Vision project

-

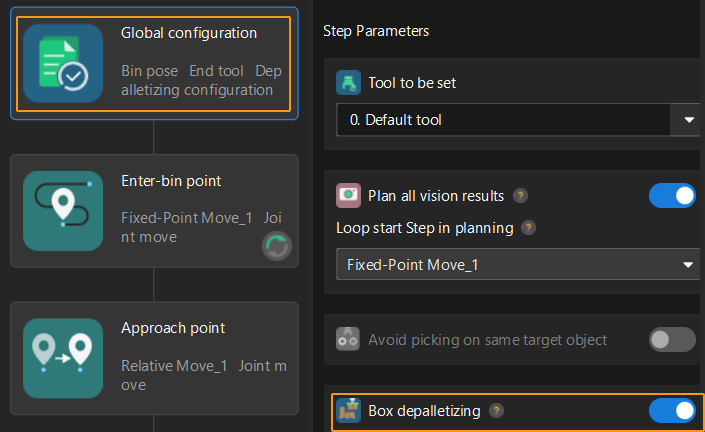

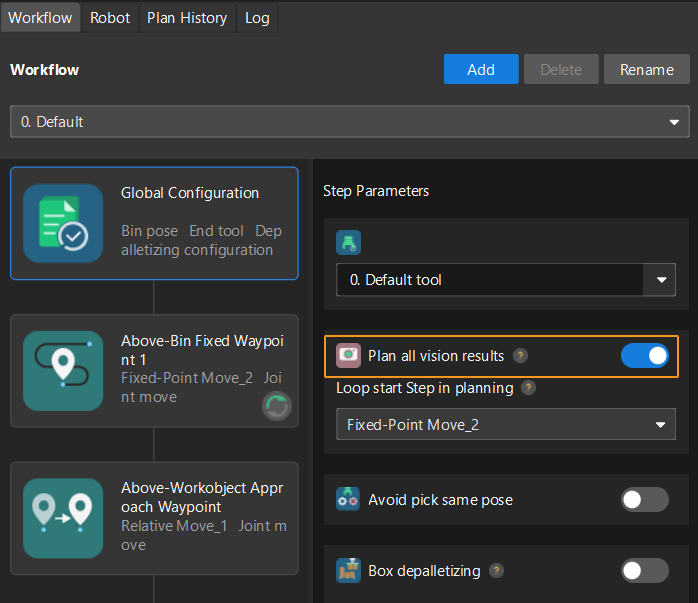

In the Path Planning Step, click Config wizard. In Global configuration, enable Box depalletizing.

-

In the Path Planning Step, click Config wizard, and then double-click the name of the robot tool. In the pop-up window, select Depalletizing vacuum gripper for Tool type, click Configure depalletizing vacuum gripper, and then configure DO signals according to needs.

-

-

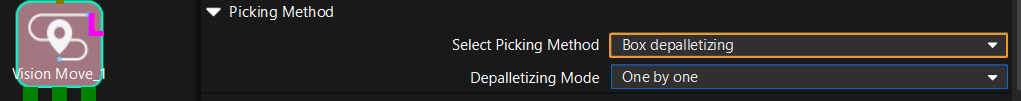

Configure the Mech-Viz project

-

In the Vision Move Step of Mech-Viz, set Select Picking Method to Box depalletizing.

-

In Mech-Viz, double-click the tool name, select Depalletizing vacuum gripper for Tool type, click Configure depalletizing vacuum gripper, and then configure the DO signal values according to needs.

-

Calling Sequence

-

This command must be called before the Get Planned Path in Mech-Vision, Get Planned Path in Mech-Viz, or Get Vision Move Data or Custom Data command. This means that the robot must obtain the motion path and then obtain gripper DO signals of the Vision Move waypoint.

-

This command should be called before Set Gripper DO List.

Command Format

mm_get_dolist(.resource,.blocknum)Input Parameters

.resource

This parameter specifies the source of the DO signal list. Value range: 0 to the largest positive integer.

-

0: Get DO signal list from Mech-Viz.

-

A positive integer: Get DO signal list from Mech-Vision. The positive integer is the Mech-Vision project ID.

.blocknum

This parameter specifies the number of gripper sections that are specified in the gripper configuration tool. For example, the number of gripper sections in the above image is 3.

The DO signals returned by this command vary based on the deployed project.

-

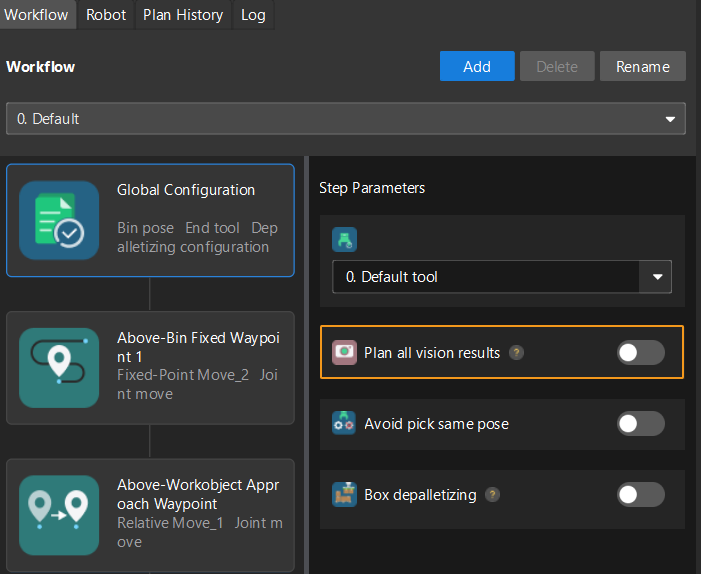

Gripper DO signals planned by the Mech-Vision project

-

Under Global Configuration of the path planning tool, if Plan all vision results is disabled, this command returns 64 gripper DO signals that are planned in this round. Valid DO signals are non-negative integers ranging from 0 to 999. Invalid DO signals are -1, which serves as a placeholder.

For example, valid DO signals in the table below are 1, 3, 5, and 6, which means that the robot will set the values of these DO signals to ON.

1st

2nd

3rd

4th

5th

6th

7th

8th

…

63rd

64th

1

3

5

6

-1

-1

-1

-1

…

-1

-1

-

Under Global Configuration of the path planning tool, if Plan all vision results is enabled, Mech-Vision can perform multiple rounds of planning based on the same vision result. The 64 gripper DO signals returned by this command are obtained during all rounds of planning. In this case, you can use the number of vacuum gripper sections to differentiate the gripper DO signals obtained during each round of planning.

For example, if the number of vacuum gripper sections is 4 and the command returns 64 DO signals in total, each 4 DO signals are multi-section vacuum gripper signals obtained during each round of planning.

First round of planning

Second round of planning

…

16th round of planning

1st

2nd

3rd

4th

5th

6th

7th

8th

…

61st

62nd

63rd

64th

1

3

4

-1

1

4

-1

-1

…

-1

-1

-1

-1

-

-

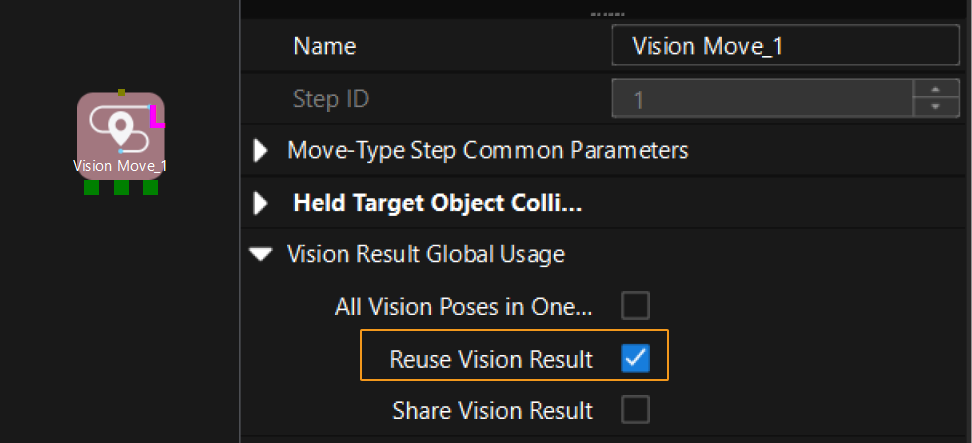

Gripper DO signals planned by the Mech-Viz project

-

If Reuse Vision Result is not selected for the Vision Move Step, this command returns 64 gripper DO signals that are planned during this round. Valid DO signals are non-negative integers ranging from 0 to 999. Invalid DO signals are -1, which serves as a placeholder.

For example, valid DO signals in the table below are 1, 3, 5, and 6, which means that the robot will set the values of these DO signals to ON.

1st

2nd

3rd

4th

5th

6th

7th

8th

…

63rd

64th

1

3

5

6

-1

-1

-1

-1

…

-1

-1

-

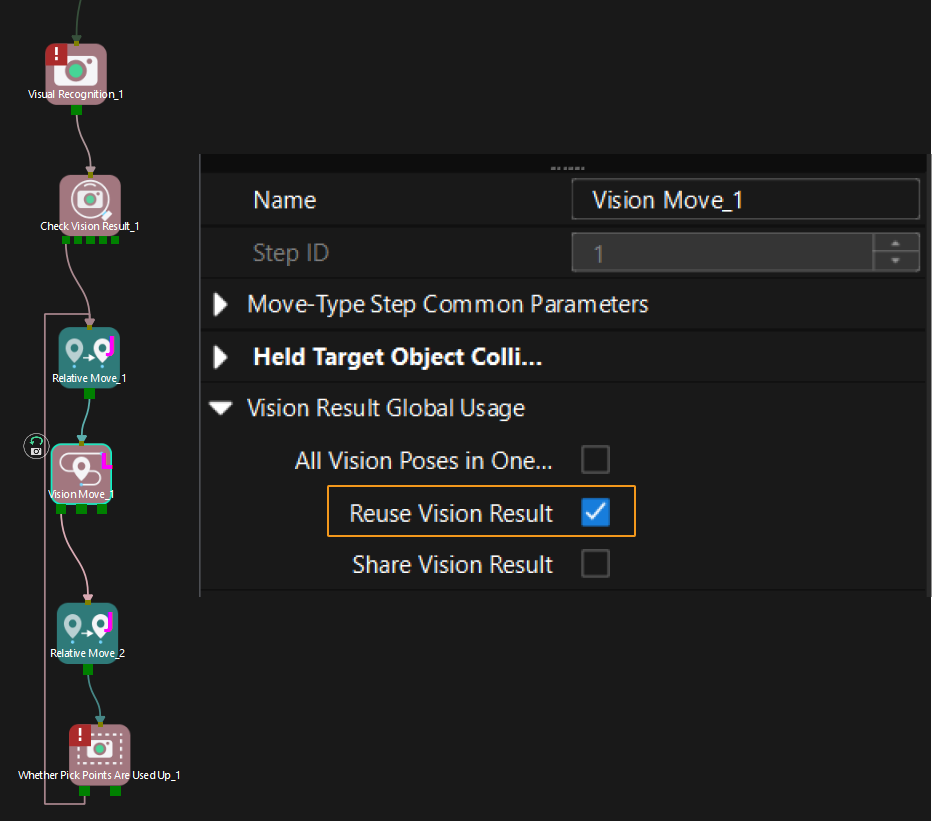

If Reuse Vision Result is selected for the Vision Move Step and the Vision Move Step is used in a loop, Mech-Viz can perform multiple rounds of planning based on the same vision result. The 64 gripper DO signals returned by this command are obtained during all rounds of planning. In this case, you can use the number of vacuum gripper sections to differentiate the gripper DO signals obtained during each round of planning.

For example, if the number of vacuum gripper sections is 4 and the command returns 64 DO signals in total, each 4 DO signals are multi-section vacuum gripper signals obtained during each round of planning.

First round of planning

Second round of planning

…

16th round of planning

1st

2nd

3rd

4th

5th

6th

7th

8th

…

61st

62nd

63rd

64th

1

3

4

-1

1

4

-1

-1

…

-1

-1

-1

-1

-

Set Gripper DO List

Calling Sequence

This command should be called after Get Gripper DO List.

Example

CALL mm_get_vizdata(2,posnum,vis_index,statuscode) ;receive path

CALL mm_get_dolist(0,1) ;receive DO from viz

CALL mm_get_pose(vis_index,pt1,label1,speed1) ; save the pick point to pt1

LAPPRO pt1,200

LMOVE pt1 ;move to pick point

CALL mm_set_dolist(1) ;turn on DO for picking

twait 1 ;wait for gripping

LDEPART 200In the preceding example, after the robot moves to the Vision Move waypoint, mm_set_dolist is called to set the specific DO signals of the gripper to ON.

Run Mech-Viz Project

Command

This command triggers the Mech-Viz project to run. Mech-Viz plans the robot’s motion path based on the vision result output by Mech-Vision.

| Right-click the project name in the project resource panel in Mech-Viz and select Autoload Project. |

Calling Sequence

You should set Step parameters before starting a Mech-Viz project. Therefore, call Read Mech-Viz Step Parameter or Set Mech-Viz Step Parameter before calling Run Mech-Viz Project.

Command Format

mm_start_viz(.sendpos_type,.#start_viz)Input Parameters

.sendpos_type

This parameter specifies the way in which the real robot pose is sent to the Mech-Viz project. Valid values: 0, 1, and 2. The following table describes the details.

| Robot pose type | Description | Applicable scenario |

|---|---|---|

0 |

This command does not need to send the robot pose to the Mech-Viz project. The simulated robot in the Mech-Viz project will move from the set home position to the first waypoint. |

This setting is recommended when the camera is mounted in eye to hand mode. |

1 |

In this command, the robot sends its current joint positions and flange pose to the Mech-Viz project. The simulated robot in Mech-Viz moves from the input joint positions to the first waypoint. |

This setting is recommended when the camera is mounted in eye in hand mode. |

2 |

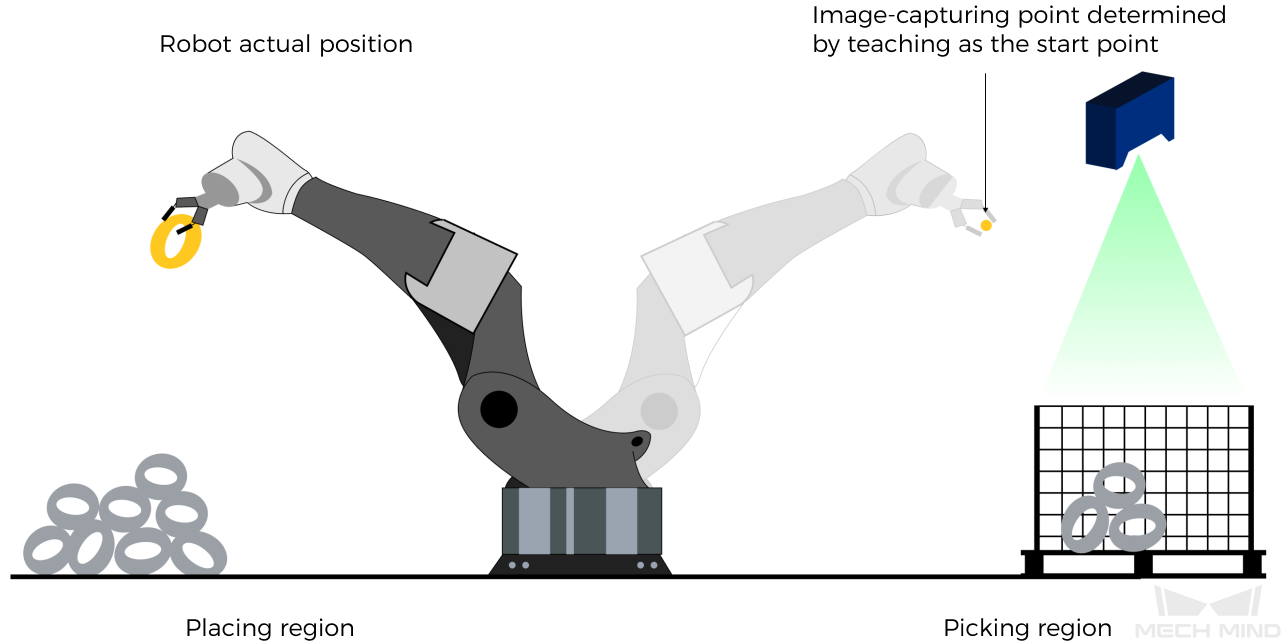

In this command, the robot sends the joint positions of a teach point (the custom joint positions, instead of the current joint positions) to the Mech-Viz project. The Mech-Viz project uses the input joint positions to plan the next path in advance while the robot is not in the camera capture region, as shown in the following figure. The simulated robot in Mech-Viz moves from the input joint positions to the first waypoint. |

This setting is recommended when the camera is mounted in eye to hand mode. |

Why robot pose type 2 is recommended when the camera is mounted in eye to hand mode?

In eye to hand mode, the camera can perform image capturing for the next round of path planning before the robot returns to the image capture region and picking region, thus shortening the cycle time. The image below demonstrates how a robot works in the placing region.

If .sendpos_type is set to 1, the robot will send the current pose to Mech-Viz. It is possible that the real robot moves to other positions before reaching the first waypoint. However, the simulated robot moves directly to the first waypoint of the Mech-Viz project from the pose sent by the robot. Consequently, there may be a mismatch between the paths of the real robot and simulated robot. This mismatch can potentially lead to unpredicted safety hazards, especially if collision is detected in the path of the simulated robot.

On the other hand, if .sendpos_type is set to 2, the robot will send the image-capturing pose set by teach to Mech-Viz. Thus, the real robot can trigger the next round of path planning in Mech-Viz when the real robot is in the image-capturing region and the cycle time can be shortened.

In conclusion, robot pose type should be set to 2 for projects in eye to hand mode.

.#start_viz

This parameter specifies the custom joint positions.

-

If .sendpos_type is set to 2, the joint position data here will be sent to the Mech-Viz project as the start point, where the robot moves from this start point to the first waypoint of the planned path.

-

If .sendpos_type is set to a parameter value other than 2, this parameter can be set to #start_viz.

Set Exit Port for Branch by Msg Step in Mech-Viz

Command

This command sets the exit port for the Branch by Msg Step. When the next Step is a Branch by Msg Step, the Mech-Viz project will wait for this command to specify the exit port.

Calling Sequence

This command should be called after Run Mech-Viz Project.

Command Format

mm_set_branch(.branch_num,.exit_num)Input Parameters

.branch_num

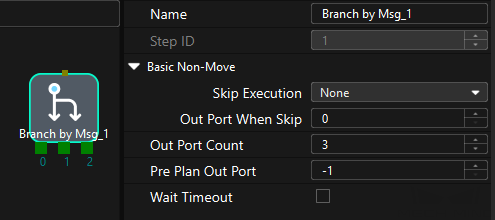

This parameter specifies the Step ID of the Branch by Msg Step. The value is a positive integer. The Step ID is displayed in the Step parameter panel. For example, the Step ID of the Step in the image above is 1.

.exit_num

This parameter specifies the exit port ID of the Branch by Msg Step. The value is a positive integer. When the parameter value is set to N, the Mech-Viz project exits from the port with an ID of N-1 of the Branch by Msg Step.

Set Current Index in Mech-Viz

Command

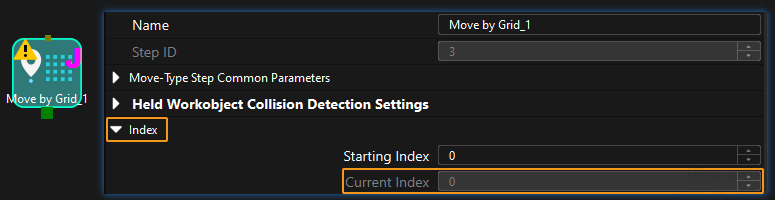

This command sets the value of the Current Index parameter of index-type Steps. Steps that include the Index section include Move by Grid, Move by List, Custom Pallet Pattern, and Predefined Pallet Pattern.

Calling Sequence

Index-type Steps are often preceded by a Branch by Msg Step. The robot should call commands in this order: Run Mech-Viz Project, Set Current Index in Mech-Viz, and Set Exit Port for Branch by Msg Step in Mech-Viz. This is to ensure that Mech-Viz has enough time to set the Current Index value.

Command Format

mm_set_index(.skill_num,.index_num)Input Parameters

.skill_num

This parameter specifies the Step ID of the Index-type Step. The value is a positive integer. The Step ID is displayed in the Step parameter panel. For example, the Step ID of the Step in the image above is 3.

.index_num

This parameter specifies the current index for a Index-type Step. The value is a positive integer. When this parameter value is set to N, the current index of the corresponding Step is N-1.

Get Planned Path in Mech-Viz

Command

This command obtains the path planned by the Mech-Viz project as a series of waypoints.

|

Waypoint: Each point that the robot reaches when moving along the planned path. A waypoint has information including the robot pose, label, and motion type. Waypoints can be divided into two categories:

|

Calling Sequence

This command should be called after Run Mech-Viz Project. After you call this command, call Store Vision Result or Planned Path (TCP) or Store Planned Path (joint positions) to access pose data.

Command Format

mm_get_vizdata(.getpos_type,.pos_num,.vispos_num,.ret)Input Parameters

.getpos_type

This parameter specifies the type of waypoint poses to be obtained. can be set to 1 or 2.

-

1: joint positions. After you run this command, run Store Planned Path (joint positions) to access joint position data.

-

2: tool poses. After you run this command, run Store Vision Result or Planned Path (TCP) to access tool pose data.

Output Parameters

.pos_num

This parameter stores the number of waypoints that are returned by the vision system. By default, the vision system sends no more than 20 waypoints at a time. Therefore, the maximum default value of this parameter is 20. To modify the default maximum number of poses to obtain each time as needed, go to Robot and Communication > in the toolbar of Mech-Vision. The upper limit is 30.

.vispos_num

The sequence number of the Vision Move waypoint (i.e., the waypoint corresponding to the Vision Move step in the Mech-Viz project) in the path. If the waypoint does not exist in the path, the petameter value is 0.

If the planned path consists of the following waypoints in sequence: Fixed-Point Move_1, Fixed-Point Move_2, Vision Move, and Fixed-Point Move_3, the sequence number of the Vision Move waypoint is 3.

.ret

This parameter stores the status code of this command. If the command is successfully executed, the status code is 2100. If a command fails to be run, a specific error code is returned. For details, see Status Codes and Troubleshooting.

|

By default, after the robot sends this command, the vision system returns the result in 10 seconds. If the vision system fails to return any result in 10 seconds, a timeout error code is returned. To modify the default timeout period as needed, go to Robot and Communication > in the toolbar of Mech-Vision.

|

Example

CALL mm_get_vizdata(2,posnum,vis_index,statuscode)In the preceding example, the planned path of the Mech-Viz project is obtained, the pose type of the waypoints is TCP, the number of waypoints is stored in posnum, the sequence number of the Vision Move waypoint in the planned path is stored in vis_index, and the status code of the command is stored in statuscode.

Get Vision Move Data or Custom Data

Command

This command obtains Vision Move data from the Mech-Vision project, or the Vision Move data or custom data from the Mech-Viz project. One command call stores all data in robot memory.

|

-

Mech-Vision projects: Vision Move data refers to data output by the Vision Move Step in the path planning tool, which you may enter from the Path Planning Step. Vision Move data includes labels of picked target objects, number of picked target objects, number of target objects to be picked this time, edge or corner ID of vacuum gripper, TCP offset, orientation of target object group, orientation of target object, and dimensions of target object group.

-

Mech-Viz projects:

-

Vision Move data refers to data output by the Vision Move Step in Mech-Viz, including the labels of picked target objects, number of picked target objects, number of target objects to be picked this time, edge or corner ID of vacuum gripper, TCP offset, orientation of target object group, orientation of target object, and dimensions of target object group.

-

Custom data refers to data output by the custom port(s) of the Output Step in Mech-Vision and then forwarded by Mech-Viz.

Select the Output Step, set Port Type to Custom, and then click Open the editor to go to the custom port configuration window. The Customized Keys section of the window displays custom port names, such as customeData1 and customeData2 as shown in the following figure.

-

Data output from Predefined Keys, such as poses, labels, sizes, offsets, is not custom data.

-

You must set Port Type of the Output Step to Custom and select the poses port in the Predefined Keys section in Mech-Vision.

-

-

Calling Sequence

This command should be called after Run Mech-Vision Project or Run Mech-Viz Project.

Command Format

mm_get_plandata(.resource,.getpos_type,.pos_num,.vispos_index,.ret)Input Parameters

.resource

This parameter specifies the source of Vision Move planned data. Value range: 0 to the largest positive integer.

-

0: Get Vision Move data from Mech-Viz.

-

A positive integer: Get Vision Move data from Mech-Vision. The positive integer is the Mech-Vision project ID.

.getpos_type

This parameter specifies the expected returned data format.

-

If .resource is set to 0, the valid value range of .getpos_type is 1 to 4.

Parameter value of .getpos_type

Description of expected returned data (Each field is explained below. If the Mech-Vision project does not have a custom port, no elements of custom data are returned.)

Waypoint type

Returned data

1

Non-Vision Move waypoint

Pose (JPs), motion type, tool ID, velocity

Vision Move waypoint

Pose (joint positions), motion type, tool ID, velocity, element 1 in custom data, … element N in custom data

2

Non-Vision Move waypoint

Pose (TCP), motion type, tool ID, velocity

Vision Move waypoint

Pose (TCP), motion type, tool ID, velocity, element 1 in custom data, … element N in custom data

3

Non-Vision Move waypoint

Pose (JPs), motion type, tool ID, velocity

Vision Move waypoint

Pose (joint positions), motion type, tool ID, velocity, Mech-Viz Vision Move data, element 1 in custom data, … element N in custom data

4

Non-Vision Move waypoint

Pose (TCP), motion type, tool ID, velocity

Vision Move waypoint

Pose (TCP), motion type, tool ID, velocity, Mech-Viz Vision Move data, element 1 in custom data, … element N in custom data

-

If .resource is set to a positive integer, .getpos_type can be set to 1 to 2.

Parameter value of .getpos_type

Description of expected returned data (Each field is explained below.)

Waypoint type

Returned data

1

Non-Vision Move waypoint

Pose (JPs), motion type, tool ID, velocity

Vision Move waypoint

Pose (joint positions), motion type, tool ID, velocity, Mech-Vision Vision Move data

2

Non-Vision Move waypoint

Pose (TCP), motion type, tool ID, velocity

Vision Move waypoint

Pose (TCP), motion type, tool ID, velocity, Mech-Vision Vision Move data

Pose

The pose of a waypoint can be joint positions (measured in degrees) or TCP (measured in millimeters for three-dimensional coordinates and in degrees for Euler angles) of the robot.

Motion type

The motion type of the robot. Valid values: 1 and 2.

-

1: Joint motion (MOVEJ)

-

2: Linear motion (MOVEL)

Tool ID

The ID of the tool to be used at this waypoint. A value of -1 means that no tool is used at this waypoint.

Velocity

The meaning of velocity varies based on the project type.

-

For Mech-Vision projects, velocity indicates the Simulation Speed value in the path planning tool, in the form of percentage.

-

For Mech-Viz projects, velocity, represented in percentage, indicates the velocity set for a motion-type Step multiplied by the global velocity set in Mech-Viz.

Vision Move data

Data output by the Vision Move Step in Mech-Vision or Mech-Viz, including labels of picked target objects, number of picked target objects, number of target objects to be picked this time, edge or corner ID of vacuum gripper, TCP offset, orientation of target object group, orientation of target object, and dimensions of target object group.

| Name | Description | Number of elements |

|---|---|---|

Labels of picked target objects |

A label consists of 10 integers. The default value is ten 0s. |

10 |

Number of picked target objects |

The total number of picked target objects. |

1 |

Number of target objects to be picked this time |

The number of target objects to be picked this time. |

1 |

Edge or corner ID of vacuum gripper |

The ID of the edge or corner used to pick target objects this time. |

1 |

TCP offset |

The XYZ offset between the center of the target object group and the tool pose center. |

3 |

Orientation of target object group |

The relative position between the target object group and the length of the vacuum gripper. The value is 0 or 1, where 0 stands for parallel and 1 for vertical. |

1 |

Orientation of target object |

The relative position between the length of a target object and that of the vacuum gripper. The value is 0 or 1, where 0 stands for parallel and 1 for vertical. |

1 |

Dimensions of target object group |

The length, width, and height of the target object group to be picked this time. |

3 |

Elements in custom data

The data of all custom ports of a single vision point. For example, data output from ports of the Output Step is presented in the following table. The elements in custom data of the first vision point are [0, 0, 1] and [0, 0]; and the elements in custom data of the second vision point are [1, 0, 0] and [1, 1].

Port name |

poses |

labels |

customData1 |

customData2 |

Output data |

[ [0, 0, 0, 1, 0, 0, 0], [0, 0, 0, 1, 0, 0, 0] ] |

[ "0", "1" ] |

[ [0, 0, 1], [1, 0, 0] ] |

[ [0, 0], [1, 1] ] |

First vision point |

[0, 0, 0, 1, 0, 0, 0] |

0 |

[0, 0, 1] |

[0, 0] |

Second vision point |

[0, 0, 0, 1, 0, 0, 0] |

1 |

[1, 0, 0] |

[1, 1] |

Output Parameters

.pos_num

This parameter stores the number of waypoints that are returned by the vision system.

.vispos_index

This parameter indicates the sequence number of the Vision Move waypoint (i.e., the waypoint corresponding to the “Vision Move” Step) in the planned path. The data type is num. If the path does not contain a “Vision Move” waypoint, the value of this parameter is 0.

For example, if the planned path consists of the following waypoints: "Fixed-Point Move_1", "Fixed-Point Move_2", "Vision Move", "Fixed-Point Move_3", the sequence number of the Vision Move waypoint is 3.

.ret

This parameter stores the status code of this command. If the command successfully obtained Vision Move data of the Mech-Vision project, the status code is 1103. If the command successfully obtained the Vision Move data or custom data from the Mech-Viz project, the status code is 2100. If a command fails to be run, a specific error code is returned. For details, see Status Codes and Troubleshooting.

If this command is called successfully, the returned data is stored in variables as shown below.

| Value | Variable (both i and j start from 1) |

|---|---|

Joint positions (J1 - J6) |

vis_pos_j1[i],vis_pos_j2[i],vis_pos_j3[i],vis_pos_j4[i],vis_pos_j5[i],vis_pos_j6[i] |

TCP (XYZOAT) |

vis_pos_x[i],vis_pos_y[i],vis_pos_z[i],vis_pos_o[i],vis_pos_a[i],vis_pos_t[i] |

Velocity |

vis_pos_spd[i] |

Motion type |

vis_pos_type[i] |

Tool ID |

vis_pos_tool[i] |

Vision Move waypoint or not |

If vis_pos_vismove[i] is 1, the waypoint is a Vision Move waypoint. Otherwise, it is a non-Vision Move waypoint. |

Custom data of Mech-Vision |

vis_custom_data[i,j]

|

Vision Move data of Mech-Vision or Mech-Viz |

vis_plan_result[i,j] Only when vis_pos_vismove[i] is 1, vis_plan_result[i,j] has a value. |

The content of the vis_plan_result[i,j] variable is explained in the table below.

| Value | Description | Variable |

|---|---|---|

Labels of picked target objects |

A label consists of 10 integers. The default value is ten 0s. |

vis_plan_result[i,1] ~ vis_plan_result[i.10] |

Number of picked target objects |

The total number of picked target objects. |

vis_plan_result[i,11] |

Number of target objects to be picked this time |

The number of target objects to be picked this time. |

vis_plan_result[i,12] |

Edge or corner ID of vacuum gripper |

The ID of the edge or corner used to pick target objects this time. |

vis_plan_result[i,13] |

TCP offset |

The XYZ offset between the center of the target object group and the tool pose center. |

vis_plan_result[i,14] ~ vis_plan_result[i,16] |

Orientation of target object group |

The relative position between the target object group and the length of the vacuum gripper. The value is 0 or 1, where 0 stands for parallel and 1 for vertical. |

vis_plan_result[i,17] |

Orientation of target object |

The relative position between the length of a target object and that of the vacuum gripper. The value is 0 or 1, where 0 stands for parallel and 1 for vertical. |

vis_plan_result[i,18] |

Dimensions of target object group |

The length, width, and height of the target object group to be picked this time. |

vis_plan_result[i,19] ~ vis_plan_result[i,21] |

Example

CALL mm_get_plandata(0,4,pos_num,vispos_index,statuscode)In the preceding example, the Vision Move data or custom data is obtained from the Mech-Viz project. The number of waypoints is stored in pos_num, the sequence number of the Vision Move waypoint in the path is stored in vispos_index, and the status code of the command is stored in statuscode.

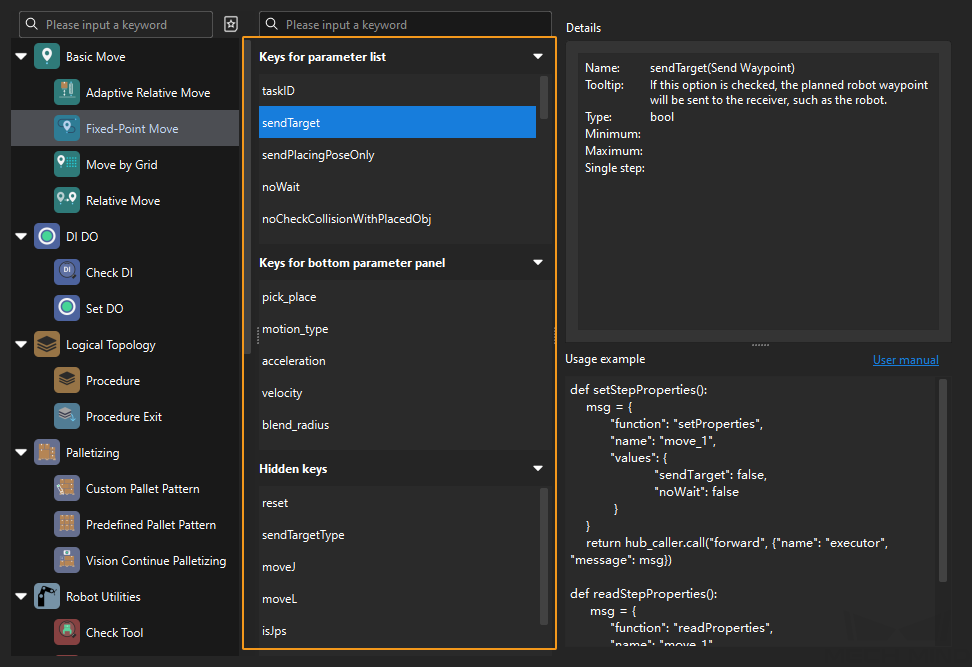

Read Mech-Viz Step Parameter

Calling Sequence

This command should be called before Run Mech-Viz Project.

Command Format

mm_get_property(.group_num,.return_value)Input Parameters

.group_num

This parameter corresponds to the Config ID field defined in the property_config file.

|

From the toolbar of Mech-Vision, go to . Click Property Configuration to open the property_config file.

|

Before calling this function, you should define a Config ID and its corresponding Step ID and parameter key name in the following format in the property_config file.

read, Config ID, Step ID, parameter key name

read |

Indicates that this line is used to read the parameter value of a Step. |

Config ID |

Specifies a unique ID, which is a positive integer. One Config ID corresponds to only one parameter value of a Step. To read multiple parameter values, you should set different Config IDs. |

Step ID |

The Step ID of the Step whose parameter is to be read. |

parameter key name |

Specifies the key name of the parameter whose value the robot requires to read. |

|

|

The property_config file can have multiple read commands. The Config ID in these commands must be different. |

Example

In the line below, 5 is the Config ID; 3 is the Step ID; and xCount is the parameter key name. Add this line to the property_config file.

read,5,3,xCountWhen the robot sends the command below, the robot receives the value of the parameter whose key name is xCount.

CALL mm_get_property(5,param_value)In the preceding example, the value of the xCount parameter of the Step with an ID of 3 of the Mech-Viz project is stored in param_value.

Set Mech-Viz Step Parameter

Calling Sequence

This command should be called before Run Mech-Viz Project.

Command Format

mm_set_property(.group_num)Input Parameters

.group_num

This parameter corresponds to the Config ID field defined in the property_config file.

|

From the toolbar of Mech-Vision, go to . Click Property Configuration to open the property_config file.

|

Before sending this command, you should define a Config ID and its corresponding Step ID, parameter key name and parameter value in the following format in the property_config file.

write, Config ID, Step ID, parameter key name, parameter value

write |

Indicates that this line is used to set the parameter value of a Step. |

Config ID |

Specifies an ID, which is a positive integer and can be used repeatedly. |

Step ID |

Specifies the Step whose parameter value the robot requires to read. |

parameter key name |

Specifies the key name of the parameter whose value the robot requires to set. |

parameter value |

Specifies the value that the robot sets for the parameter. |

|

Example

In the line below, 1 is the Config ID and 3 is the Step ID. xOffset, yOffset and zOffset are parameter key names; and 10, 20 and 30 are their respective values. Add this line to the property_config file.

write,1,3,xOffset,10

write,1,3,yOffset,20

write,1,3,zOffset,30When the robot sends the command below, Mech-Viz sets the values of the parameters whose key names are xOffset, yOffset and zOffset respectively to 10, 20 and 30.

CALL mm_set_property(1)In the preceding example, the values of the parameters whose key names are xOffset, yOffset and zOffset are respectively set to 10, 20, and 30.

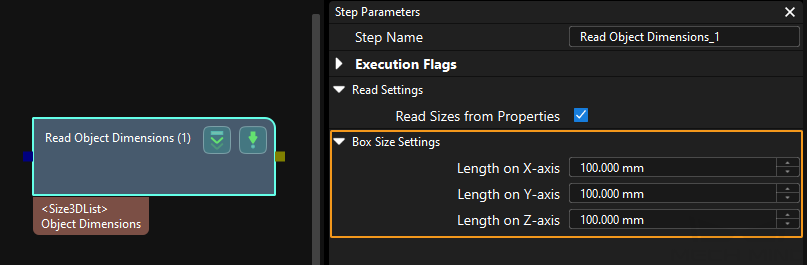

Input Object Dimensions to Mech-Vision Project

Command

This command dynamically inputs object dimensions into the Mech-Vision project. The object dimensions are the values of the Box Size Settings parameters in the Read Object Dimensions Step.

| When you use this command, only one Read Object Dimensions Step is allowed in the Mech-Vision project. Otherwise, the vision system will return an error. |

Calling Sequence

This command should be called before Run Mech-Vision Project.

Command Format

mm_set_boxsize(.job,.length,.width,.height)Input Parameters

.job

Mech-Vision project ID. You can view the project ID of a Mech-Vision project in the Project List section of Mech-Vision. The project ID is the number before the project name.

.length, .width, and .height

The preceding three parameters sequentially input the length, width, and height of the object to the Mech-Vision project. The length, width, and height are measured in millimeters (mm). These values are read by the Read Object Dimensions Step and set for the parameters Length on X-axis, Length on Y-axis and Length on Z-axis.

Get Message from Notify Step

Command

When the Mech-Vision project or Mech-Viz project is executing the Notify Step, the vision system returns the message predefined in the Notify Step.

Before sending this command, complete the following settings for the Notify Step:

-

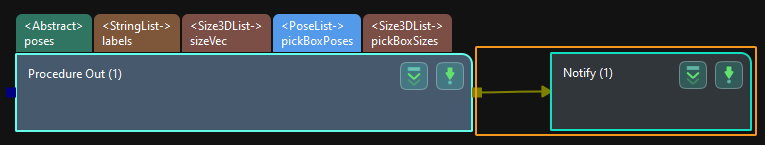

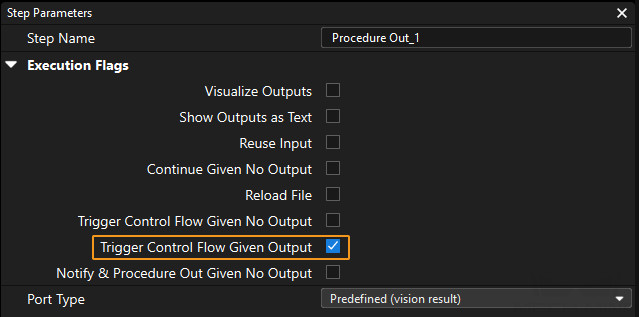

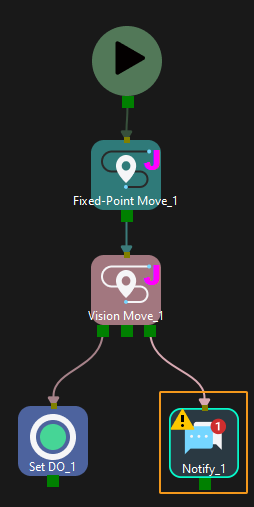

For a Notify Step in the Mech-Vision project:

-

Connect the Notify Step to the right side of another Step. The Output Step is used in the example in the image below.

-

Select Trigger Control Flow Given Output in the parameter panel of the Output Step.

-

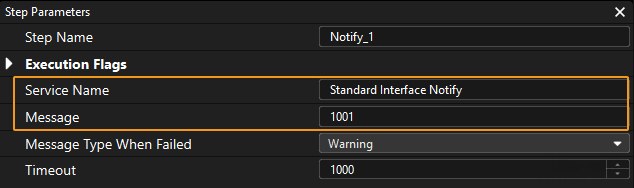

In the parameter panel of the Notify Step, enter Standard Interface Notify (a required value) for Service Name. Enter a positive integer for Message, for example, 1001.

-

-

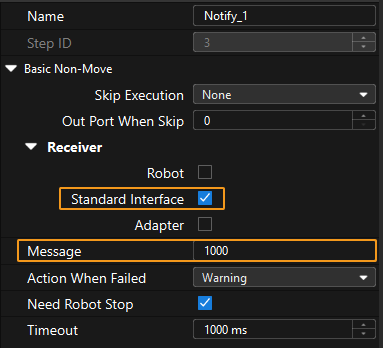

For a Notify Step in the Mech-Viz project:

-

Connect the Notify Step to a proper Step in the workflow.

-

In the parameter panel of the Notify Step, select Standard Interface. Enter a positive integer for Message, for example, 1000.

-

Calling Sequence

This command should be called right after Run Mech-Vision Project or Run Mech-Viz Project.

Command Format

mm_get_notify(.msg)Output Parameters

.msg

This parameter stores the message from the Notify Step. Only positive integer messages are supported at the moment.

| When the Notify Step is executed in the Mech-Vision or Mech-Viz project, the message remains in the buffer of the vision system for only three second. Therefore, you should consider the timing of calling this command to ensure successful message retrieval. |

Calibration

Command

This command is used for robot hand-eye calibration (extrinsic parameter calibration). This command must be used together with the Camera Calibration setting to complete automatic calibration. You can find Camera Calibration in the toolbar of Mech-Vision. For more information, see Kawasaki Automatic Calibration.