样例程序16:MM_S16_Viz_GetDirection

程序解读

以下为MM_S16_Viz_GetDirection样例程序的代码及相关解释说明。

| 与MM_S15_Viz_GetDoList样例相比,本样例仅修改了如下加粗部分的代码。因此,下文不再重复解释与MM_S15_Viz_GetDoList样例相同部分的代码(详情请参考MM_S15_Viz_GetDoList样例说明)。 |

NOP

'--------------------------------

'FUNCTION: trigger Mech-Viz

'project, then get planned path

'and get box direction using

'command 210

'Mech-Mind, 2023-12-25

'--------------------------------

'clear I50 to I69

CLEAR I050 20

'initialize p variables

SUB P071 P071

SUB P072 P072

SUB P073 P073

'move to robot home position

MOVJ C00000 VJ=50.00

'initialize communication

'parameters (initialization is

'required only once)

CALL JOB:MM_INIT_SOCKET ARGF"192.168.170.22;50000;1"

'move to image-capturing position

MOVJ C00001 VJ=50.00 PL=0

'open socket connection

CALL JOB:MM_OPEN_SOCKET

'trigger Mech-Viz project

CALL JOB:MM_START_VIZ ARGF"2;30"

'get planned path

CALL JOB:MM_GET_PLANDATA ARGF"0;3;51;52;53"

'check whether planned path has

'been got from Mech-Viz

'successfully

IFTHENEXP I053<>2100

'add error handling logic here

'according to different error

'codes

'e.g.: I053=2038 means no

'point cloud in ROI

PAUSE

ENDIF

'get gripper control signal list

CALL JOB:MM_GET_DOLIST ARGF"0;0"

'close socket connection

CALL JOB:MM_CLOSE_SOCKET

'save waypoints of the planned

'path to local variables one

'by one

CALL JOB:MM_GET_PLANPOSE ARGF"1;71;61;31"

CALL JOB:MM_GET_PLANPOSE ARGF"2;72;71;31"

CALL JOB:MM_GET_PLANPOSE ARGF"3;73;81;31"

'get box direction status from

'planned results

SET I005 R047

'follow the planned path to pick

'move to approach waypoint of

'picking

MOVJ P071 VJ=50.00 PL=0

'move to picking waypoint

MOVJ P072 VJ=10.00 PL=0

'set gripper control signal when

'current waypoint is picking

'waypoint

CALL JOB:MM_SET_DOLIST ARGF"0"

PAUSE

'move to departure waypoint of

'picking

MOVJ P073 VJ=50.00 PL=0

'place the box according to its

'direction

IFTHENEXP I005=0

'move to intermediate waypoint of

'placing

MOVJ C00002 VJ=50.00

'move to approach waypoint of

'placing

MOVL C00003 V=166.6 PL=0

'move to placing waypoint

MOVL C00004 V=50.0 PL=0

'add object releasing logic here,

'such as DOUT OT#(1) OFF

PAUSE

'move to departure waypoint of

'placing

MOVL C00005 V=166.6 PL=0

ELSE

'move to intermediate waypoint of

'placing

MOVJ C00006 VJ=50.00

'move to approach waypoint of

'placing

MOVL C00007 V=166.6 PL=0

'move to placing waypoint

MOVL C00008 V=50.0 PL=0

'add object releasing logic here,

'such as DOUT OT#(1) OFF

PAUSE

'move to departure waypoint of

'placing

MOVL C00009 V=166.6 PL=0

ENDIF

'move back to robot home position

MOVJ C00010 VJ=50.00

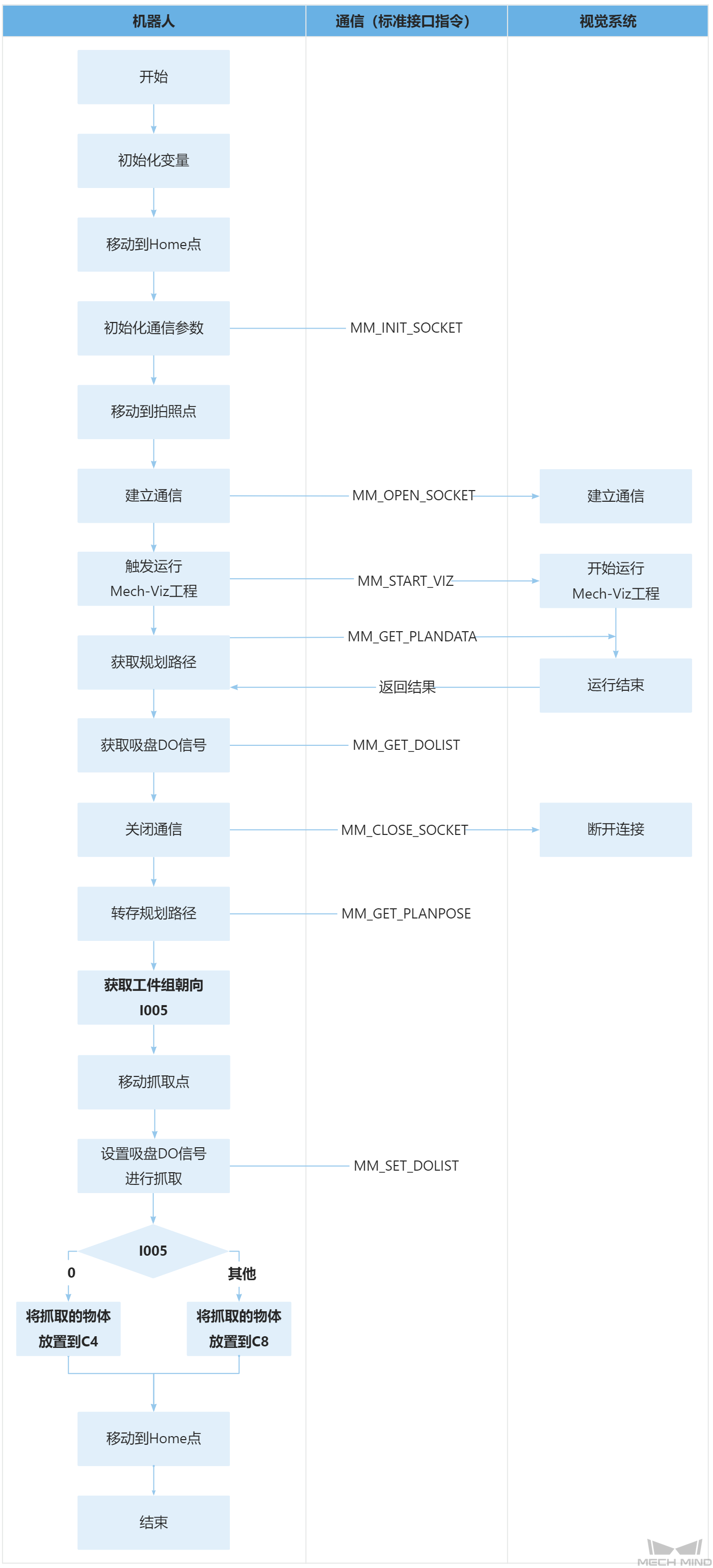

END上述样例程序代码对应的流程如下图所示。

下表是对加粗代码的逻辑解读。用户单击指令名称的超链接便可查看该指令的详细说明。

| 流程 | 代码及说明 | ||

|---|---|---|---|

获取工件组朝向 |

机器人通过MM_GET_PLANDATA指令获取路径点的视觉移动规划数据,然后再通过MM_GET_PLANPOSE指令将路径点的视觉移动规划数据从机器人内存中转存至从R031开始的变量中。R047变量值表示工件组与吸盘长边的朝向关系,0表示平行,1表示垂直。 上述代码表示,将R047变量赋值给I005变量,则I005变量将表示工件组朝向。 |

||

根据工件组朝向采取不同的放置策略 |

上述代码表示,如果工件组与吸盘长边平行(即I005为0),则将该工件组放置在示教的C00004处;否则,将该工件组放置在示教的C00008处。 |