样例程序7:MM_S7_Viz_SwitchTCP

程序简介

功能说明 |

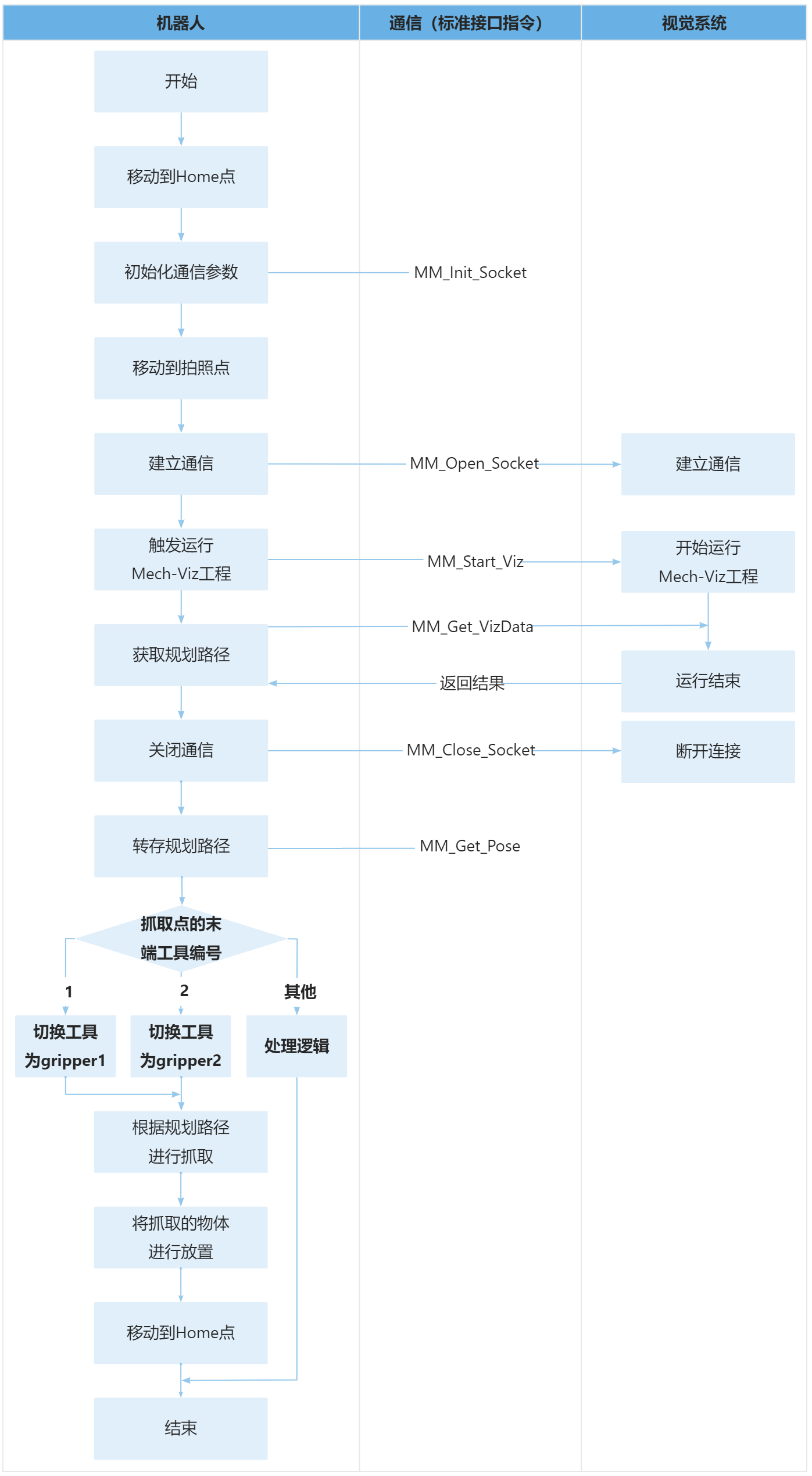

机器人触发Mech-Viz工程运行,并获取路径规划结果,然后根据抓取点的末端工具编号切换相应的末端工具,进而执行抓取和放置操作。 |

||

文件路径 |

Mech-Vision和Mech-Viz软件安装目录下

|

||

所需工程 |

Mech-Vision工程和Mech-Viz工程 |

||

使用前提 |

|

| 此样例程序仅是示例程序。用户需根据实际情况在此基础上进行修改,请勿直接使用该程序。 |

程序解读

以下为MM_S7_Viz_SwitchTCP样例程序的代码及相关解释说明。

| 与MM_S2_Viz_Basic样例相比,本样例主要新增了根据末端工具编号切换工具的功能(加粗部分的代码)。因此,下文不再重复解释与MM_S2_Viz_Basic样例相同部分的代码(详情请参考MM_S2_Viz_Basic样例说明)。 |

MODULE MM_S7_Viz_SwitchTCP

!----------------------------------------------------------

! FUNCTION: trigger Mech-Viz project and get planned path,

! switch TCP according to the label

! Mech-Mind, 2023-12-25

!----------------------------------------------------------

!define local num variables

LOCAL VAR num pose_num:=0;

LOCAL VAR num status:=0;

LOCAL VAR num toolid{5}:=[0,0,0,0,0];

LOCAL VAR num vis_pose_num:=0;

LOCAL VAR num count:=0;

LOCAL VAR num label{5}:=[0,0,0,0,0];

!define local joint&pose variables

LOCAL CONST jointtarget home:=[[0,0,0,0,90,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]];

LOCAL CONST jointtarget snap_jps:=[[0,0,0,0,90,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]];

LOCAL PERS robtarget camera_capture:=[[302.00,0.00,558.00],[0,0,-1,0],[0,0,0,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]];

LOCAL PERS robtarget drop_waypoint:=[[302.00,0.00,558.00],[0,0,-1,0],[0,0,0,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]];

LOCAL PERS robtarget drop:=[[302.00,0.00,558.00],[0,0,-1,0],[0,0,0,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]];

LOCAL PERS robtarget pos{5}:=

[

[[502.502,99.5586,399.968],[0.00226227,-0.99991,-0.00439596,0.0124994],[0,0,0,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]],

[[500,100,300],[0.00226227,-0.99991,-0.00439596,0.0124994],[0,0,0,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]],

[[500,100,300],[0.00226227,-0.99991,-0.00439596,0.0124994],[0,0,0,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]],

[[500,100,300],[0.00226227,-0.99991,-0.00439596,0.0124994],[0,0,0,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]],

[[502.502,99.5586,399.968],[0.00226227,-0.99991,-0.00439596,0.0124994],[0,0,0,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]]

];

!define LOCAL tooldata variables

LOCAL PERS tooldata cur_gripper:=[TRUE,[[0,0,0],[1,0,0,0]],[0.001,[0,0,0.001],[1,0,0,0],0,0,0]];

LOCAL PERS tooldata gripper{5}:=,[0.001,[0,0,0.001],[1,0,0,0],0,0,0]],

[TRUE,[[0,0,0],[1,0,0,0]],[0.001,[0,0,0.001],[1,0,0,0],0,0,0]],

[TRUE,[[0,0,0],[1,0,0,0]],[0.001,[0,0,0.001],[1,0,0,0],0,0,0]],

[TRUE,[[0,0,0],[1,0,0,0]],[0.001,[0,0,0.001],[1,0,0,0],0,0,0]],

[TRUE,[[0,0,0],[1,0,0,0]],[0.001,[0,0,0.001],[1,0,0,0],0,0,0]]];

PROC Sample_7()

!set the acceleration parameters

AccSet 50, 50;

!set the velocity parameters

VelSet 50, 1000;

!move to robot home position

MoveAbsJ home\NoEOffs,v3000,fine,cur_gripper;

!initialize communication parameters (initialization is required only once)

MM_Init_Socket "127.0.0.1",50000,300;

!move to image-capturing position

MoveL camera_capture,v1000,fine,cur_gripper;

!open socket connection

MM_Open_Socket;

!trigger Mech-Viz project

MM_Start_Viz 2,snap_jps;

!get planned path, 1st argument (2) means getting pose in TCP

MM_Get_VizData 2, pose_num, vis_pose_num, status;

!check whether planned path has been got from Mech-Viz successfully

IF status <> 2100 THEN

!add error handling logic here according to different error codes

!e.g.: status=2038 means no point cloud in ROI

Stop;

ENDIF

!close socket connection

MM_Close_Socket;

!save waypoints of the planned path to local variables one by one

MM_Get_Pose 1,pos{1},label{1},toolid{1};

MM_Get_Pose 2,pos{2},label{2},toolid{2};

MM_Get_Pose 3,pos{3},label{3},toolid{3};

!reset tool signals according to received toolId

IF toolid{vis_pose_num}=1 Then

cur_gripper:=gripper{toolid{vis_pose_num}};

!reset tool signal;

ELSEIF toolid{vis_pose_num}=2 Then

cur_gripper:=gripper{toolid{vis_pose_num}};

!reset tool signal;

ELSE

Stop;

!reset tool signal;

ENDIF

!follow the planned path to pick

!move to approach waypoint of picking

MoveL pos{1},v1000,fine,cur_gripper;

!move to picking waypoint

MoveL pos{2},v300,fine,cur_gripper;

!add object grasping logic here

IF toolid{vis_pose_num}=1 Then

Stop;

!open tool signal;

ELSEIF toolid{vis_pose_num}=2 Then

Stop;

!open tool signal;

ELSE

Stop;

!open tool signal;

ENDIF

!move to departure waypoint of picking

MoveL pos{3},v1000,fine,cur_gripper;

!move to intermediate waypoint of placing

MoveJ drop_waypoint,v1000,z50,cur_gripper;

!move to approach waypoint of placing

MoveL RelTool(drop,0,0,-100),v1000,fine,cur_gripper;

!move to placing waypoint

MoveL drop,v300,fine,cur_gripper;

!add object releasing logic here

IF toolid{vis_pose_num}=1 Then

Stop;

!reset tool signal;

ELSEIF toolid{vis_pose_num}=2 Then

Stop;

!reset tool signal;

ELSE

Stop;

!reset tool signal;

ENDIF

!move to departure waypoint of placing

MoveL RelTool(drop,0,0,-100),v1000,fine,cur_gripper;

!move back to robot home position

MoveAbsJ home\NoEOffs,v3000,fine,cur_gripper;

ENDPROC

ENDMODULE上述样例程序代码对应的流程如下图所示。

下表为新增代码的逻辑解读。

| 流程 | 代码及说明 | ||

|---|---|---|---|

获取规划路径 |

因此,整条指令表示机器人获取Mech-Viz工程返回的规划路径。

|

||

转存规划路径 |

因此,“MM_Get_Pose 1,pos{1},label{1},toolid{1}”整条指令表示将第一个路径点的工具位姿、标签和末端工具编号分别转存至指定变量。

|

||

根据末端工具编号切换末端工具 |

toolid{vis_pose_num}表示抓取点的末端工具编号值。用户可根据toolid{vis_pose_num}变量值,决定机器人移动到对应位姿(抓取点)时所使用的末端工具,即根据末端工具编号切换末端工具。上述代码的逻辑说明如下所示。

当机器人移动至抓取点时,用户可根据末端工具编号打开相应工具对应的DO信号,例如样例中如下代码。 当机器人移动至放置点时,用户可根据末端工具编号关闭并重置相应工具对应的DO信号,例如样例中如下代码。 |