样例程序12:MM_S12_Viz_ForLoop

程序解读

以下为MM_S12_Viz_ForLoop样例程序的代码及相关解释说明。

| MM_S2_Viz_Basic是逐个转存规划的路径点,本样例是通过循环转存规划的路径点(加粗部分的代码)。因此,下文不再重复解释与MM_S2_Viz_Basic样例相同部分的代码(详情请参考MM_S2_Viz_Basic样例说明)。 |

1: !-------------------------------- ;

2: !FUNCTION: trigger Mech-Viz ;

3: !project and get planned path, ;

4: !get poses using for-loop ;

5: !structure ;

6: !Mech-Mind, 2023-12-25 ;

7: !-------------------------------- ;

8: ;

9: !set current uframe NO. to 0 ;

10: UFRAME_NUM=0 ;

11: !set current tool NO. to 1 ;

12: UTOOL_NUM=1 ;

13: !move to robot home position ;

14:J P[1] 100% FINE ;

15: !initialize communication ;

16: !parameters(initialization is ;

17: !required only once) ;

18: CALL MM_INIT_SKT('8','127.0.0.1',50000,5) ;

19: !move to image-capturing position ;

20:L P[2] 1000mm/sec FINE ;

21: !trigger Mech-Viz project ;

22: CALL MM_START_VIZ(2,10) ;

23: !get planned path, 1st argument ;

24: !(1) means getting pose in JPs ;

25: CALL MM_GET_VIZ(1,51,52,53) ;

26: !check whether planned path has ;

27: !been got from Mech-Viz ;

28: !successfully ;

29: IF R[53]<>2100,JMP LBL[99] ;

30: !save waypoints of the planned ;

31: !path to local variables using ;

32: !for-loop structure ;

33: FOR R[100]=1 TO R[51] ;

34: R[101]=59+R[100] ;

35: R[102]=69+R[100] ;

36: R[103]=79+R[100] ;

37: CALL MM_GET_JPS(R[100],R[101],R[102],R[103]) ;

38: ENDFOR ;

39: !follow the planned path to pick, ;

40: !in this example waypoint 2 ;

41: !(PR[61]) is picking waypoint ;

42: !move to approach waypoint ;

43: !of picking ;

44:J PR[60] 50% FINE ;

45: !move to picking waypoint ;

46:J PR[61] 10% FINE ;

47: !add object grasping logic here, ;

48: !such as "DO[1]=ON" ;

49: PAUSE ;

50: !move to departure waypoint ;

51: !of picking ;

52:J PR[62] 50% FINE ;

53: !move to intermediate waypoint ;

54: !of placing ;

55:J P[3] 50% CNT100 ;

56: !move to approach waypoint ;

57: !of placing ;

58:L P[4] 1000mm/sec FINE Tool_Offset,PR[2] ;

59: !move to placing waypoint ;

60:L P[4] 300mm/sec FINE ;

61: !add object releasing logic here, ;

62: !such as "DO[1]=OFF" ;

63: PAUSE ;

64: !move to departure waypoint ;

65: !of placing ;

66:L P[4] 1000mm/sec FINE Tool_Offset,PR[2] ;

67: !move back to robot home position ;

68:J P[1] 100% FINE ;

69: END ;

70: ;

71: LBL[99:vision error] ;

72: !add error handling logic here ;

73: !according to different ;

74: !error codes ;

75: !e.g.: status=2038 means no ;

76: !point cloud in ROI ;

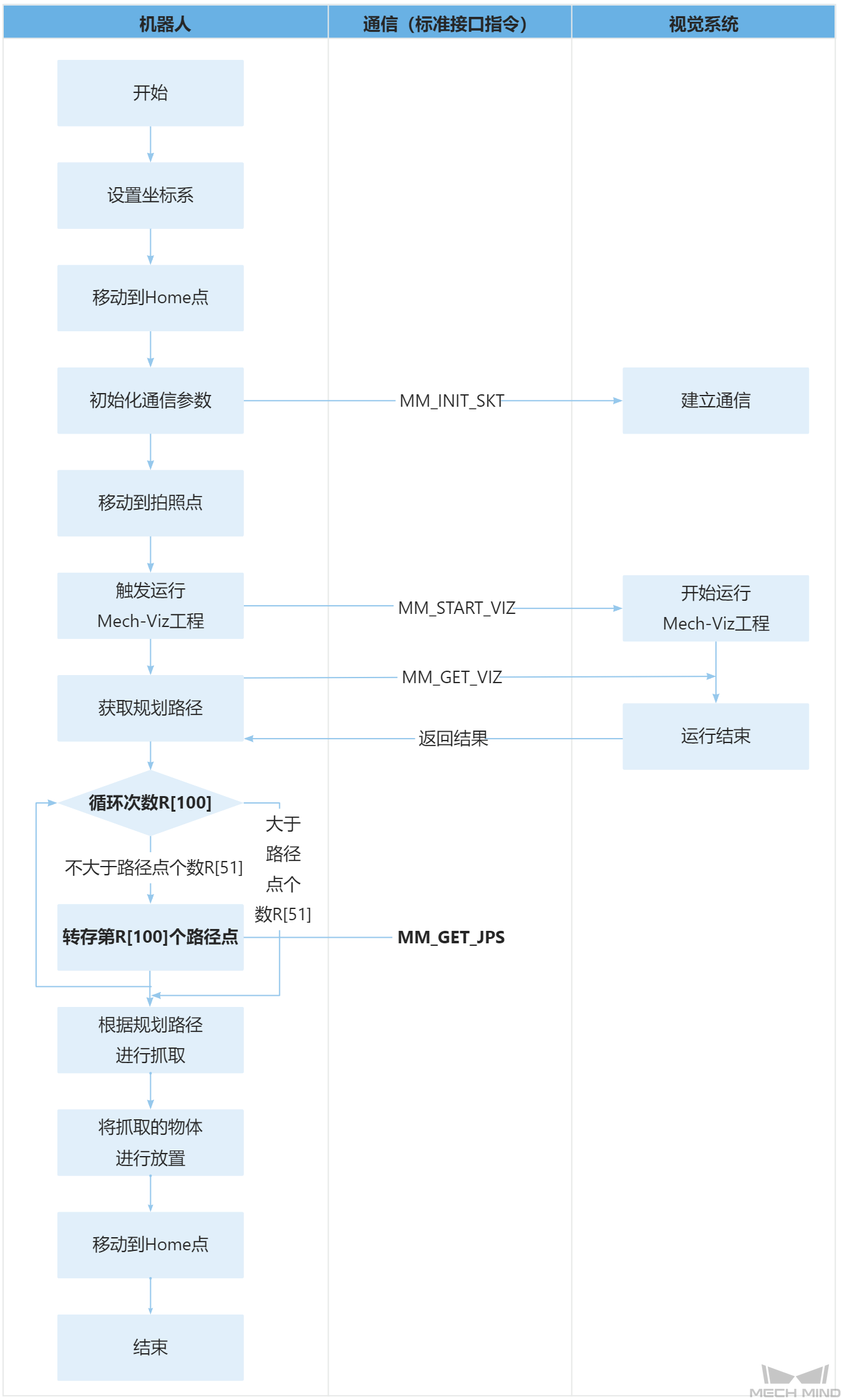

77: PAUSE ;上述样例程序代码对应的流程如下图所示。

下表为通过循环转存规划路径的逻辑解读。用户单击指令名称的超链接便可查看该指令的详细说明。

| 流程 | 代码及说明 |

|---|---|

通过循环转存规划路径 |

假设本样例规划的路径有3个路径点,则上述循环等同于MM_S2_Viz_Basic样例中如下三条指令。 |