样例程序7:MM_S7_Viz_SwitchTCP

程序解读

以下为MM_S7_Viz_SwitchTCP样例程序的代码及相关解释说明。

| 与MM_S2_Viz_Basic样例相比,本样例主要新增了根据末端工具编号切换工具的功能(加粗部分的代码)。因此,下文不再重复解释与MM_S2_Viz_Basic样例相同部分的代码(详情请参考MM_S2_Viz_Basic样例说明)。 |

DEF MM_S7_Viz_SwitchTCP ( )

;---------------------------------------------------

; FUNCTION: trigger Mech-Viz project and get

; planned path, switch TCP according to the label

; Mech-Mind, 2023-12-25

;---------------------------------------------------

;set current tool no. to 1

BAS(#TOOL,1)

;set current base no. to 0

BAS(#BASE,0)

;move to robot home position

PTP HOME Vel=100 % DEFAULT

;initialize communication parameters (initialization is required only once)

MM_Init_Socket("XML_Kuka_MMIND",873,871,60)

;move to image-capturing position

LIN camera_capture Vel=1 m/s CPDAT1 Tool[1] Base[0]

;trigger Mech-Viz project

MM_Start_Viz(2,init_jps)

;get planned path, 1st argument (1) means getting pose in JPs

MM_Get_VizData(2,pos_num,vis_pos_num,status)

;check whether planned path has been got from Mech-Viz successfully

IF status<> 2100 THEN

;add error handling logic here according to different error codes

;e.g.: status=2038 means no point cloud in ROI

halt

ENDIF

;save waypoints of the planned path to local variables one by one

MM_Get_Pose(1,Xpick_point1,label[1],toolid[1])

MM_Get_Pose(2,Xpick_point2,label[2],toolid[2])

MM_Get_Pose(3,Xpick_point3,label[3],toolid[3])

;switch TCP according to the received toolid

;reset tool signals according to received toolid

switch toolid[vis_pos_num]

CASE 1

TOOL_DATA[1]=tool_1

;reset tool signal

CASE 2

TOOL_DATA[1]=tool_2

;reset tool signal

DEFAULT

;add handling logic here if the toolid is invalid

;reset tool signal

halt

endswitch

;follow the planned path to pick

;move to approach waypoint of picking

LIN pick_point1 Vel=1 m/s CPDAT7 Tool[1] Base[0]

;move to picking waypoint

LIN pick_point2 Vel=0.3 m/s CPDAT8 Tool[1] Base[0]

;add object grasping logic here, such as "$OUT[1]=TRUE"

switch toolid[vis_pos_num]

CASE 1

halt

;open tool signal

CASE 2

halt

;open tool signal

DEFAULT

halt

endswitch

;move to departure waypoint of picking

LIN pick_point3 Vel=1 m/s CPDAT9 Tool[1] Base[0]

;move to intermediate waypoint of placing

PTP drop_waypoint CONT Vel=100 % PDAT2 Tool[0] Base[0]

;move to approach waypoint of placing

LIN drop_app Vel=1 m/s CPDAT3 Tool[0] Base[0]

;move to placing waypoint

LIN drop Vel=0.3 m/s CPDAT4 Tool[0] Base[0]

;add object releasing logic here, such as "$OUT[1]=FALSE"

switch toolid[vis_pos_num]

CASE 1

halt

;reset tool signal

CASE 2

halt

;reset tool signal

DEFAULT

halt

endswitch

;move to departure waypoint of placing

LIN drop_app Vel=1 m/s CPDAT3 Tool[0] Base[0]

;move back to robot home position

PTP HOME Vel=100 % DEFAULT

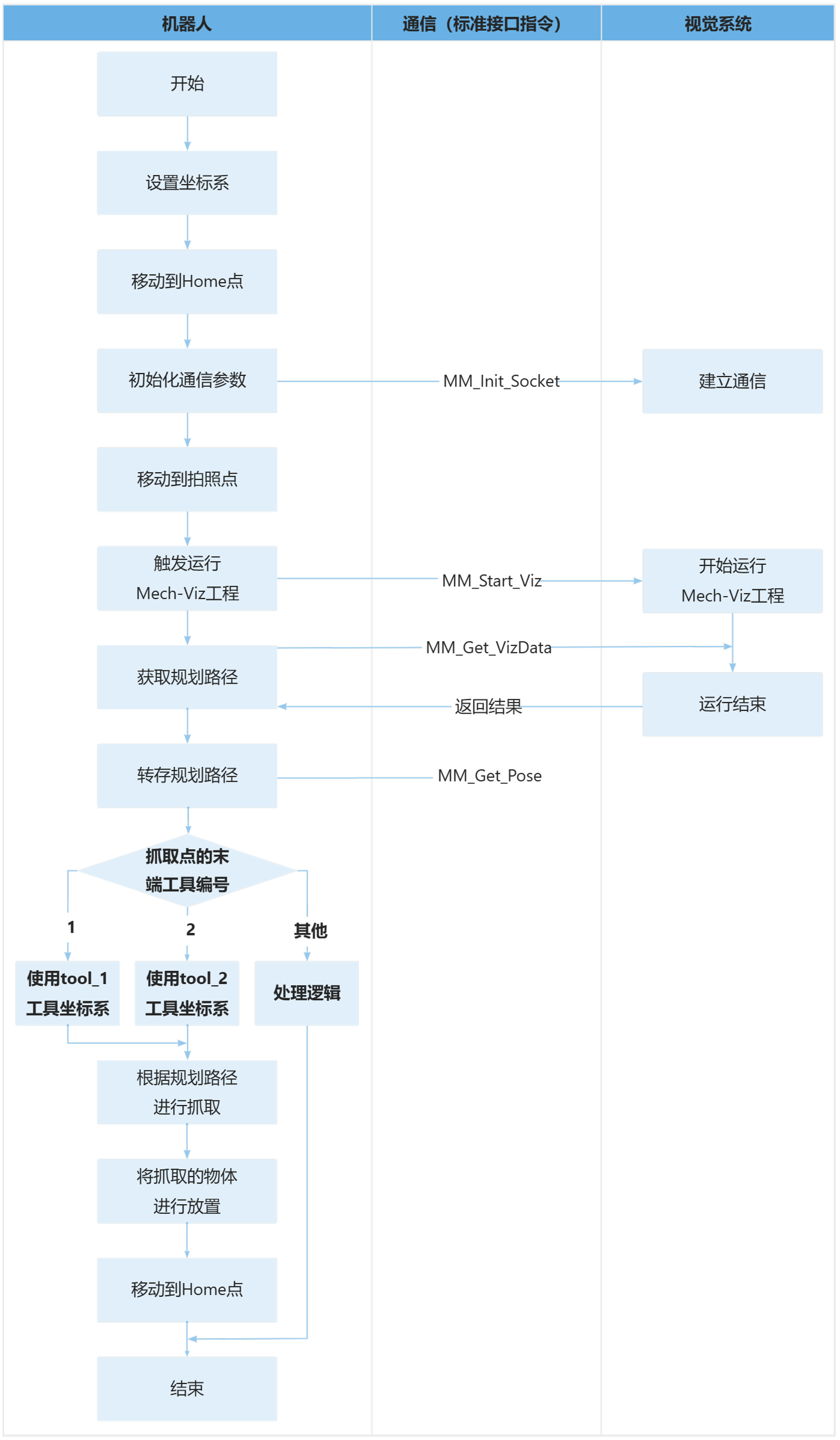

END上述样例程序代码对应的流程如下图所示。

下表为新增代码的逻辑解读。

| 流程 | 代码及说明 | ||

|---|---|---|---|

获取规划路径 |

因此,整条指令表示机器人获取Mech-Viz工程返回的规划路径。

|

||

转存规划路径 |

因此,“MM_Get_Pose(1,Xpick_point1,label[1],toolid[1])”整条指令表示将第一个路径点的工具位姿、标签和末端工具编号分别转存至指定变量。

|

||

根据末端工具编号切换末端工具 |

toolid[vis_pos_num]表示抓取点的末端工具编号值。用户可根据toolid[vis_pos_num]变量值,决定机器人移动到对应位姿(抓取点)时所使用的末端工具,即根据末端工具编号切换末端工具。上述代码的逻辑说明如下所示。

当机器人移动至抓取点时,用户可根据末端工具编号打开相应工具对应的DO信号,例如样例中如下代码。 当机器人移动至放置点时,用户可根据末端工具编号关闭并重置相应工具对应的DO信号,例如样例中如下代码。 |