样例程序21:MM_S21_1Robot_3IPC_Sequentially

程序解读

以下为MM_S21_1Robot_3IPC_Sequentially样例程序的代码及相关解释说明。

| 本样例侧重讲解一台机器人如何连接多台工控机的使用方法。每台工控机上视觉系统运行的逻辑流程,可参考MM_S5_Viz_SetBranch样例的解释说明(详情请参考MM_S5_Viz_SetBranch样例说明)。 |

1: !-------------------------------- ;

2: !FUNCTION: set up communication ;

3: !between 1Robot and 3IPC ;

4: !Sequentially ;

5: !Mech-Mind, 2024-4-25 ;

6: !-------------------------------- ;

7: ;

8: !set current uframe NO. to 0 ;

9: UFRAME_NUM=0 ;

10: !set current tool NO. to 1 ;

11: UTOOL_NUM=1 ;

12: LBL[10] ;

13: ;

14: !initialize communication ;

15: !parameters(initialization is ;

16: !required once change IPC tcp ;

17: !service ;

18: CALL MM_INIT_SKT('6','192.168.1.20',50000,5) ;

19: !trigger Mech-Viz project ;

20: CALL MM_START_VIZ(0,60) ;

21: WAIT .20(sec) ;

22: !set branch, "MM_SET_BCH ;

23: CALL MM_SET_BCH(1,1) ;

24: ;

25: !initialize communication ;

26: !parameters(initialization is ;

27: !required once change IPC tcp ;

28: !service ;

29: CALL MM_INIT_SKT('7','192.168.1.200',50000,5) ;

30: !trigger Mech-Viz project ;

31: CALL MM_START_VIZ(0,61) ;

32: WAIT .20(sec) ;

33: !set branch, "MM_SET_BCH ;

34: CALL MM_SET_BCH(1,2) ;

35: ;

36: !initialize communication ;

37: !parameters(initialization is ;

38: !required once change IPC tcp ;

39: !service ;

40: CALL MM_INIT_SKT('8','192.168.1.50',50000,5) ;

41: !trigger Mech-Viz project ;

42: CALL MM_START_VIZ(0,62) ;

43: WAIT .20(sec) ;

44: !set branch, "MM_SET_BCH ;

45: CALL MM_SET_BCH(1,2) ;

46: ;

47: !initialize communication ;

48: !parameters(initialization is ;

49: !required once change IPC tcp ;

50: !service ;

51: CALL MM_INIT_SKT('6','192.168.1.20',50000,5) ;

52: !get planned path, 1st argument ;

53: !(1) means getting pose in JPs ;

54: CALL MM_GET_VIZ(1,51,52,53) ;

55: !save the first waypoint of the ;

56: !planned path to local variables ;

57: !one by one ;

58: CALL MM_GET_JPS(1,70,71,72) ;

59: ;

60: !initialize communication ;

61: !parameters(initialization is ;

62: !required once change IPC tcp ;

63: !service ;

64: CALL MM_INIT_SKT('7','192.168.1.200',50000,5) ;

65: !get planned path, 1st argument ;

66: !(2) means getting pose in TCP ;

67: CALL MM_GET_VIZ(2,54,55,56) ;

68: !save the first waypoint of the ;

69: !planned path to local variables ;

70: !one by one ;

71: CALL MM_GET_POS(1,71,73,74) ;

72: ;

73: !initialize communication ;

74: !parameters(initialization is ;

75: !required once change IPC tcp ;

76: !service ;

77: CALL MM_INIT_SKT('8','192.168.1.50',50000,5) ;

78: !get planned path, 1st argument ;

79: !(1) means getting pose in JPs ;

80: CALL MM_GET_VIZ(1,57,58,59) ;

81: !save the first waypoint of the ;

82: !planned path to local variables ;

83: !one by one ;

84: CALL MM_GET_JPS(1,72,75,76) ;

85: ;

86: WAIT 5.00(sec) ;

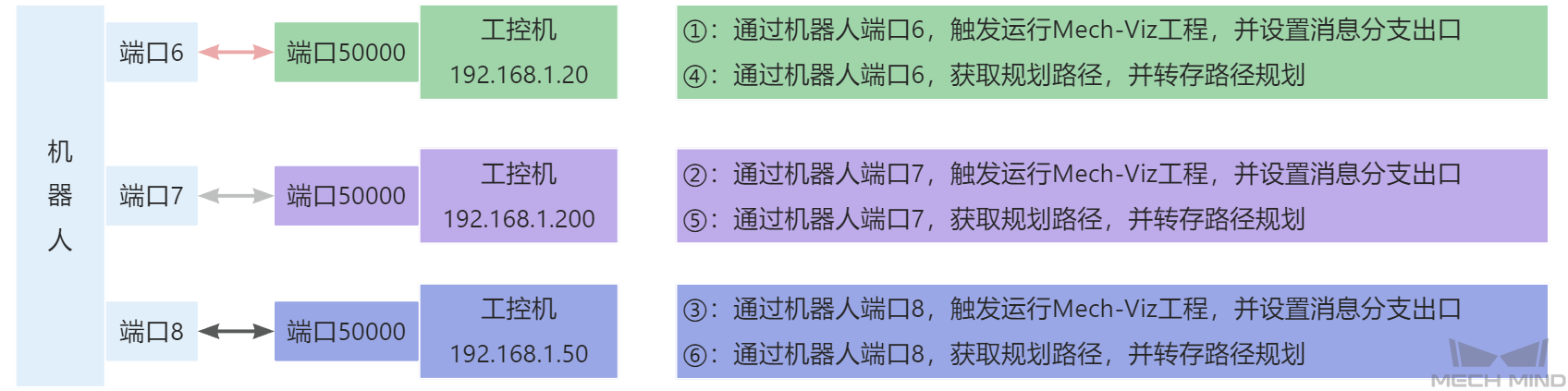

87: JMP LBL[10] ;上述样例程序代码对应的示意图如下所示。图中的①~⑥表示程序执行顺序。

下表为上述代码的逻辑解读。用户单击指令名称的超链接便可查看该指令的详细说明。

| 工控机IP地址及端口号 | 代码及说明 | ||

|---|---|---|---|

192.168.1.20:50000 |

机器人端口6与工控机(192.168.1.20)端口50000的通信流程如下。

|

|

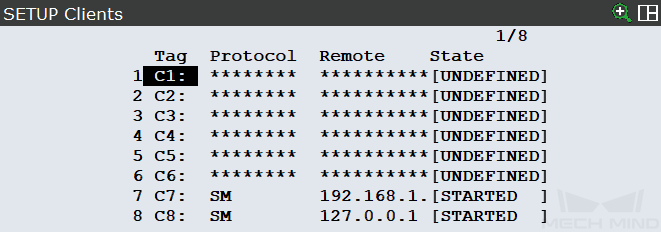

FANUC机器人系统设置中共有8个端口,如下图。用户在MM_INIT_SKT指令中使用未定义端口时,需要重启控制器才可生效,否则机器人无法与视觉系统通信,并报错。

|