样例程序8:MM_S8_Viz_Subtask

程序简介

功能说明 |

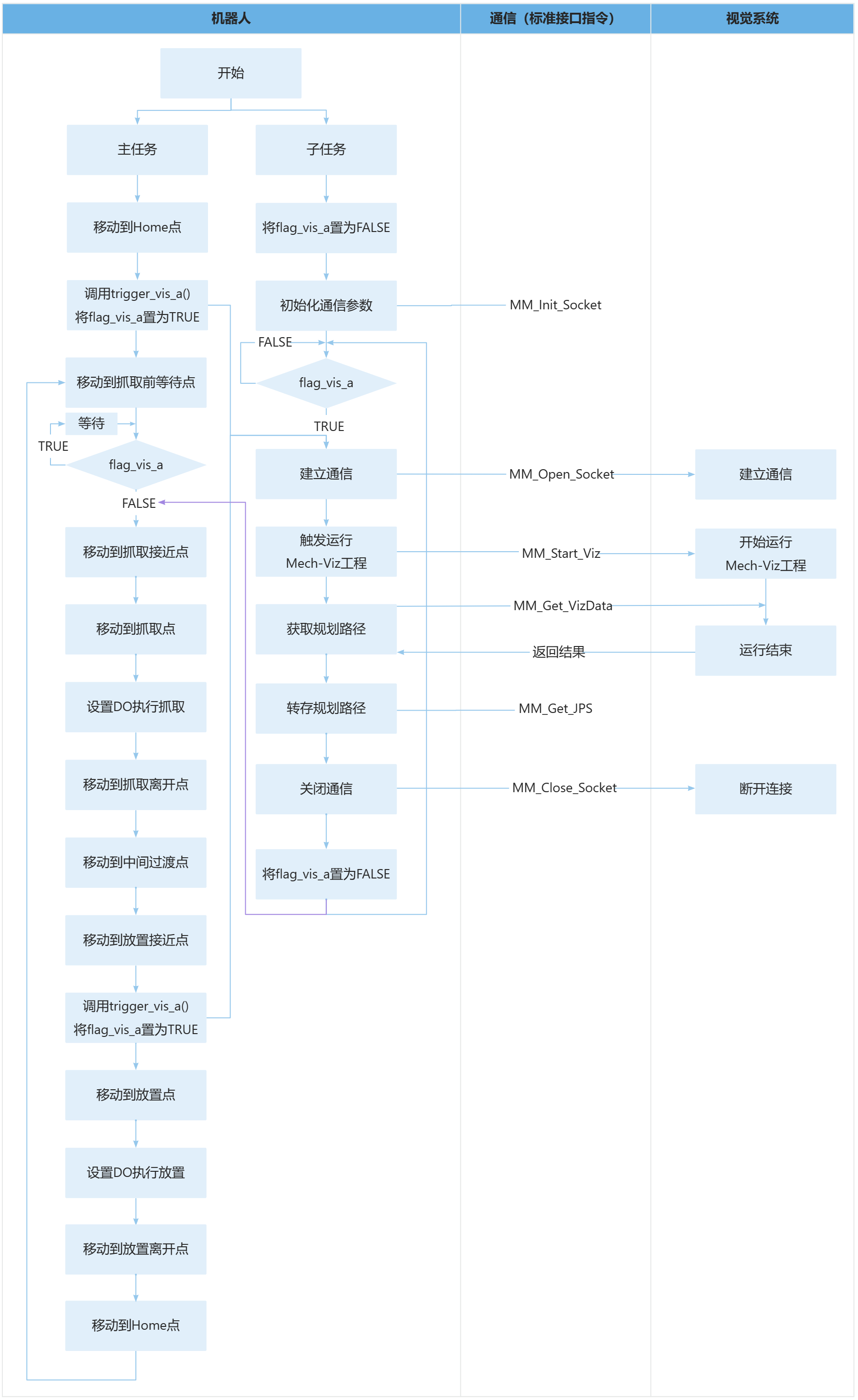

本样例由两个程序组成,其中子程序(后台程序)负责触发Mech-Viz工程运行并获取规划路径;主程序(前台程序)负责根据规划路径移动机器人,且在机器人放置时触发子程序运行,从而提前规划下一轮路径,以缩短节拍。

|

||

文件路径 |

子程序:Mech-Vision和Mech-Viz软件安装目录下 主程序:Mech-Vision和Mech-Viz软件安装目录下

|

||

所需工程 |

Mech-Vision工程和Mech-Viz工程 |

||

使用前提 |

|

|

程序解读

以下为子程序的代码及相关解释说明。

| 在子程序中,触发Mech-Viz工程运行并获取规划路径的代码,与MM_S2_Viz_Basic样例中类似。因此,下文不再重复解释与MM_S2_Viz_Basic样例相同部分的代码(详情请参考MM_S2_Viz_Basic样例说明)。 |

MODULE MM_S8_Sub

!----------------------------------------------------------

! FUNCTION: run Mech-Viz project and get planned path

! in subtask (run together with MM_S8_Viz_Subtask)

! Mech-Mind, 2023-12-25

!----------------------------------------------------------

!define variables

PERS num pose_num_a:=5;

PERS num vis_pose_num_a:=3;

PERS num toolid_a{5}:=[0,0,0,0,0];

PERS num label_a{5}:=[0,0,0,0,0];

PERS num status_a:=2100;

PERS bool flag_vis_a:=FALSE;

CONST jointtarget snap_jps_a:=[[0,0,0,0,90,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]];

PERS jointtarget jps_a{5}:=

[

[[0,0,0,0,90,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]],

[[0,0,0,0,90,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]],

[[0,0,0,0,90,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]],

[[11.1329,49.0771,-36.9666,0.5343,79.2476,-169.477],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]],

[[0,0,0,0,90,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]]

];

PROC main()

flag_vis_a:=FALSE;

!initialize communication parameters (initialization is required only once)

MM_Init_Socket "127.0.0.1",50000,300;

WHILE TRUE DO

IF flag_vis_a=TRUE THEN

MM_Open_Socket;

!trigger Mech-Viz project

MM_Start_Viz 2,snap_jps_a;

!get planned path, 1st argument (1) means getting pose in JPs

MM_Get_VizData 1, pose_num_a, vis_pose_num_a, status_a;

!check whether planned path has been got from Mech-Viz successfully

IF status_a=2100 THEN

!save waypoints of the planned path to local variables one by one

MM_Get_Jps 1,jps_a{1},label_a{1},toolid_a{1};

MM_Get_JPS 2,jps_a{2},label_a{2},toolid_a{2};

MM_Get_JPS 3,jps_a{3},label_a{3},toolid_a{3};

ENDIF

MM_Close_Socket;

flag_vis_a:=FALSE;

ENDIF

ENDWHILE

ENDPROC

ENDMODULE上述代码表示,子程序在运行时,首先将flag_vis_a设置为FALSE,并初始化通信参数,然后通过WHILE循环持续监听flag_vis_a值。

-

当flag_vis_a为TRUE时,子程序发触发Mech-Viz工程运行并获取规划路径,然后将flag_vis_a设置为FALSE。

-

当flag_vis_a为FALSE时,子程序持续判断flag_vis_a的值。

以下为主程序的代码及相关解释说明。

| 在主程序中,根据规划路径进行抓取与放置的代码,与MM_S2_Viz_Basic样例中类似。因此,下文不再重复解释与MM_S2_Viz_Basic样例相同部分的代码(详情请参考MM_S2_Viz_Basic样例说明)。 |

MODULE MM_S8_Viz_Subtask

!----------------------------------------------------------

! FUNCTION: run Mech-Viz project and get planned path

! in subtask (run together with MM_S8_Sub)

! Mech-Mind, 2023-12-25

!----------------------------------------------------------

!define local num variables

PERS bool flag_vis_a:=FALSE;

PERS num status_a:=2100;

PERS num pose_num_a:=5;

PERS num toolid_a{5}:=[0,0,0,0,0];

PERS num label_a{5}:=[0,0,0,0,0];

PERS num vis_pose_num_a:=3;

LOCAL VAR num count:=0;

!define local joint&pose variables

LOCAL CONST jointtarget home:=[[0,0,0,0,90,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]];

LOCAL PERS robtarget pick_wait_point:=[[302.00,0.00,558.00],[0,0,-1,0],[0,0,0,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]];

LOCAL PERS robtarget drop_waypoint:=[[302.00,0.00,558.00],[0,0,-1,0],[0,0,0,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]];

LOCAL PERS robtarget drop:=[[302.00,0.00,558.00],[0,0,-1,0],[0,0,0,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]];

PERS jointtarget jps_a{5}:=

[

[[0,0,0,0,89,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]],

[[0,0,0,0,89,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]],

[[0,0,0,0,89,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]],

[[11.1329,49.0771,-36.9666,0.5343,79.2476,-169.477],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]],

[[0,0,0,0,90,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]]

];

!define local tooldata variables

LOCAL PERS tooldata gripper1:=[TRUE,[[0,0,0],[1,0,0,0]],[0.001,[0,0,0.001],[1,0,0,0],0,0,0]];

PROC Sample_8()

!set the acceleration parameters

AccSet 50, 50;

!set the velocity parameters

VelSet 50, 1000;

!move to robot home position

MoveAbsJ home\NoEOffs,v3000,fine,gripper1;

!trigger Mech-Viz project and get planned path

trigger_vis_a;

LOOP:

!move to wait position for picking

MoveL pick_wait_point,v1000,fine,gripper1;

!wait until subtask program finished

WaitUntil(flag_vis_a=FALSE);

!check whether planned path has been got from Mech-Viz successfully

IF status_a <> 2100 THEN

!add error handling logic here according to different error codes

!e.g.: status=2038 means no point cloud in ROI

Stop;

ENDIF

!follow the planned path to pick

!move to approach waypoint of picking

MoveAbsJ jps_a{1},v1000,fine,gripper1;

!move to picking waypoint

MoveAbsJ jps_a{2},v300,fine,gripper1;

!add object grasping logic here, such as "setdo DO_1, 1;"

Stop;

!move to departure waypoint of picking

MoveAbsJ jps_a{3},v1000,fine,gripper1;

!move to intermediate waypoint of placing

MoveJ drop_waypoint,v1000,z50,gripper1;

!move to approach waypoint of placing

MoveL RelTool(drop,0,0,-100),v1000,fine,gripper1;

!trigger Mech-Viz project and get planned path in advance

trigger_vis_a;

!move to placing waypoint

MoveL drop,v300,fine,gripper1;

!add object releasing logic here, such as "setdo DO_1, 0;"

Stop;

!move to departure waypoint of placing

MoveL RelTool(drop,0,0,-100),v1000,fine,gripper1;

!move back to robot home position

MoveAbsJ home\NoEOffs,v3000,fine,gripper1;

GOTO LOOP;

ENDPROC

PROC trigger_vis_a()

flag_vis_a:=TRUE;

ENDPROC

ENDMODULE上述样例程序代码对应的流程如下图所示。

下表为主程序核心代码的逻辑解读。

| 流程 | 代码及说明 |

|---|---|

触发Mech-Viz工程运行并获取规划路径 |

上述代码表示,主程序调用trigger_vis_a()函数。该函数的代码如下所示。 上述代码表示,在trigger_vis_a()函数中将flag_vis_a设置为TRUE,此时子程序检测到flag_vis_a为TRUE,便触发Mech-Viz工程运行并获取规划路径。 |

通过循环(抓取→触发下一轮规划→放置)提前规划下一轮路径 |

上述代码表示,主程序循环执行LOOP与GOTO LOOP之间的代码。 上述代码表示,机器人移动到抓取前的一个等待点,等待子程序获取并转存规划路径(即flag_vis_a从TRUE变为FALSE)。 上述代码表示,机器人根据规划的路径先移动到抓取接近点(jps_a{1}),然后移动到抓取点(jps_a{2}),进行抓取(例如,setdo DO_1, 1;),再依次移动到抓取离开点(jps_a{3})、放置过渡点(drop_waypoint)、放置接近点(RelTool(drop,0,0,-100))。 上述代码表示,主程序程序再次调用trigger_vis_a()函数,即再次触发Mech-Viz工程运行并获取规划路径。此处机器人已处于放置区域,因此机器人此时可以提前规划下一轮抓取路径,而不必等待放置完成后再规划下一轮抓取路径。 上述代码表示,机器人先移动到放置点(drop),然后进行放置操作(例如,setdo DO_1, 0;),然后依次移动到放置离开点(RelTool(drop,0,0,-100))、Home点。 |