Rotational Relaxation

This section introduces the rotational relaxation of the workobject.

Introduction

When the robot picks certain workobjects, the picking pose of the robot is allowed to be rotated flexibly within a specific angle range, which is the rotational relaxation. By setting the rotational relaxation, the robot can utilize such tolerance flexibly to avoid problems such as collisions and singularities.

If the placing pose is set to the “workobject pose” and the robot picks the workobject with rotational relaxation. The software will automatically record the angle deviation between the actual picking pose and the workobject pose. When the robot places the workobject, the software will adjust the tool pose according to the angle deviation and ensure that the workobject can be placed in a correct position.

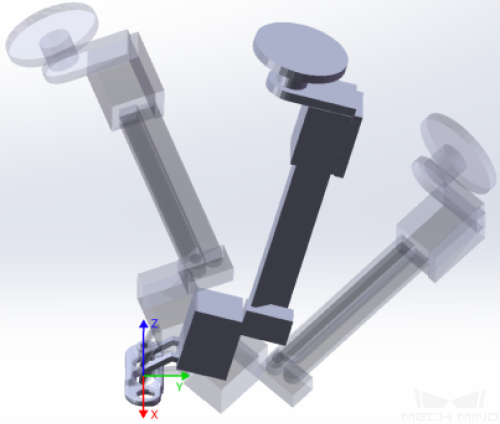

Determine the Reference Axis

As shown in the figure below, the tool can pick the workobject flexibly within certain degrees around the X-axis of the workobject pose, and therefore the X-axis is the reference axis.

Attempt Range and Step

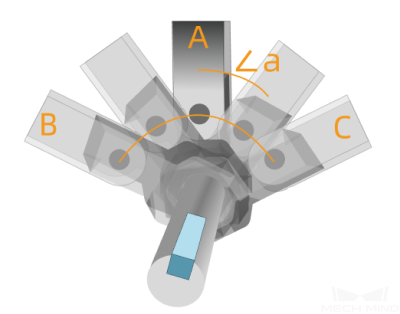

The attempt range is the maximum allowable angle deviation between the picking pose and the vision pose. The angle between B and C represents the attempt range.

The Step specifies the degree interval between two picking attempts. The angle ∠a in the figure below represents the step.

“A” represents the picking pose when the tool is at the pick point, while “B” and “C” represent the pose when the tool picks at the margin of the relaxation range.

Number of Attempts

The number of attempts is calculated automatically from the attempt range and step.

Assuming that the step is 5° and the attempt range is ±10°, then the number of attempts in one direction can be calculated by 10/5 = 2, which is 2 attempts by the degree of 5° and 10°. The total number of attempts = 1 + 2 * 2 = 5, which are by the degrees -10°, -5°, 0°, 5°, and 10°.