Error Analysis Tool

During the actual production process, various issues can arise, such as inaccuracies in camera intrinsic parameters and imprecise picking. These problems often stem from a multitude of factors that can be traced to different stages of production.

This section covers how to use the Error Analysis Tool to troubleshoot the above issues.

Introduction

When an error occurs during recognition and positioning, this tool can be used for troubleshooting. Based on the on-site situation you described, the tool will recommend specific items to check, including camera accuracy, robot absolute accuracy and repeatability, and the result of extrinsic parameters after calibration. This tool cannot be used to check the project logic or analyze the matching accuracy.

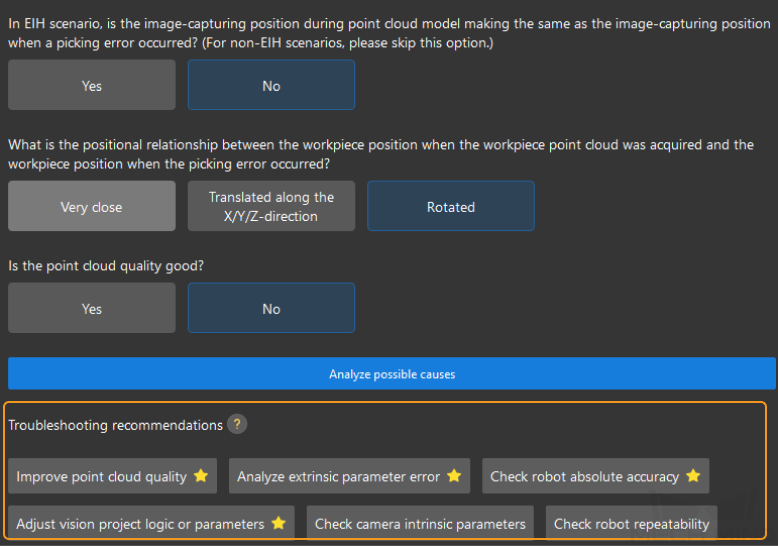

After opening the tool, you will answer the following questions to analyze the possible causes.

-

In EIH scenario, is the image-capturing position during point cloud model making the same as the image-capturing position when a picking error occurred?

-

What is the positional relationship between the workpiece position when the workpiece point cloud was acquired and the workpiece position when the picking error occurred?

-

Is the point cloud quality good?

After completing the questions, click the Analyze possible causes button, and the tool will provide some troubleshooting recommendations for reference.

|

The item with a star icon is most likely to cause the error, so please check it carefully. |

Main Functions

This tool can be used to analyze the causes of the errors related to cameras, robots, and extrinsic parameters.

For camera error analysis, please read the section below.

For robot error analysis, please read the section below.

For extrinsic parameter error analysis, please read the section below.

For system drift auto-correction in EIH setup, please read the section below.