Depalletizing Vacuum Gripper Configuration

This section introduces how to configure depalletizing vacuum grippers.

The vacuum gripper configuration is based on the selected tool type. Please refer to Configure End Tool to complete the tool configuration first. In the Tool Configuration window, set the Tool type to Depalletizing vacuum gripper, and click the Configure depalletizing vacuum gripper button at the bottom to open the vacuum gripper configurator.

Introduction

You can configure both single-block vacuum grippers and multi-block vacuum grippers. However, for multi-block vacuum grippers, the rectangular blocks should be of the same size and arranged in a single row.

Configuration Process

-

Configure the vacuum grippers structure.

-

Set the Number of Blocks according to the number of blocks of the actual vacuum gripper. If multiple blocks share the same DO signal, the blocks can be viewed as a whole, and you can set the number of blocks to 1.

-

Set the Spacing according to the actual interval between the blocks.

-

Set the Block length and Block width according to the actual vacuum gripper size.

-

Set Buffer thickness, which will be added to the plane where the TCP is located for collision detection.

-

-

Set the Angle parameter according to the TCP settings in the tool configuration window.

-

Set the DO/DI active value parameter according to the actual situation.

-

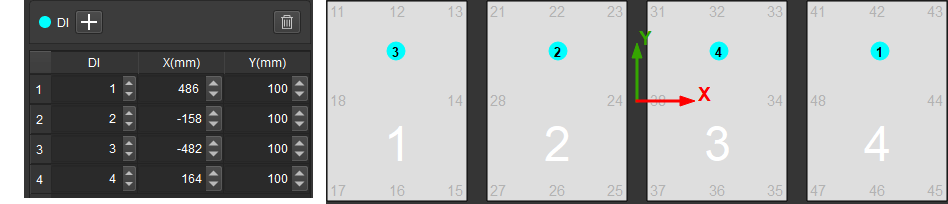

Configure DI Check Point

-

Click + to add a new DI check point. By default, the DI is 0, and the check point is at the center of the vacuum gripper.

-

Modify the value of X and Y or drag the check point to adjust the position of the pick point.

-

Modify the DI parameter to change the ID of the check point.

-

If you want to delete a check point, select it and click ![]() .

.

-

Configure the corresponding DO Value according to the control port number of each vacuum gripper block.

-

Select to save the vacuum gripper configuration to the corresponding tool.

Export the Vacuum Gripper Configuration File

Select to store the configuration file to a specified path.

Import the Vacuum Gripper Configuration File

Select to import the vacuum gripper configuration file.