Index

Starting Index

| Description |

The index of the box to be placed. |

| Value |

Integers, and the default value is 0. |

| Usage |

When there is not any box on the pallet, the value is 0. If the palletizing process pauses and then continues, and N boxes have been palletized, the value should be set to N. Then the software will start with the N+1 box for palletizing. |

Motion Control

Auto Middle Point Force MoveJ

Selected by default, i.e., the robot moves in joint motion type before palletizing.

Entry Force MoveJ/Adjust Force MoveJ/Place Force MoveJ

Unselected by default, i.e., the robot does not need to move in joint motion type when it approaches the pallet, adjusts the pose, and places the box.

When the workspace on site is limited and the palletizing should be performed in linear motion, select the parameter. A limited workspace may lead to singularities. In this case, you can set the robot motion in any process (Entry, Adjust, Place) to joint motion.

Acc&Vel Scale Ratio

| Value |

0–100%, the default value is 100%. |

| Usage Scenario |

This parameter can be configured when the robot’s speed differs between approaching the stack and actually placing the boxes. |

| Description |

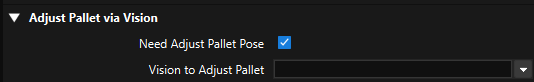

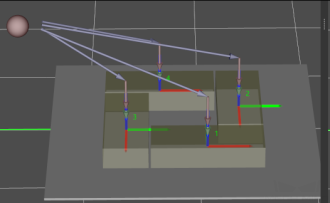

The acceleration and speed when the robot places the boxes, which is calculated by Acceleration & Velocity × Acceleration & Velocity Scale Ratio. The process of the robot entering the stack area can be divided into 3 segments: Segment 1: indicated by purple arrows—approaching the stack The acceleration and velocity when the robot approaches the stack (indicated by purple arrows) are specified in “Basic move settings”, and the acceleration/velocity for the last two segments are Acceleration & Velocity × Acceleration & Velocity Scale Ratio.

|

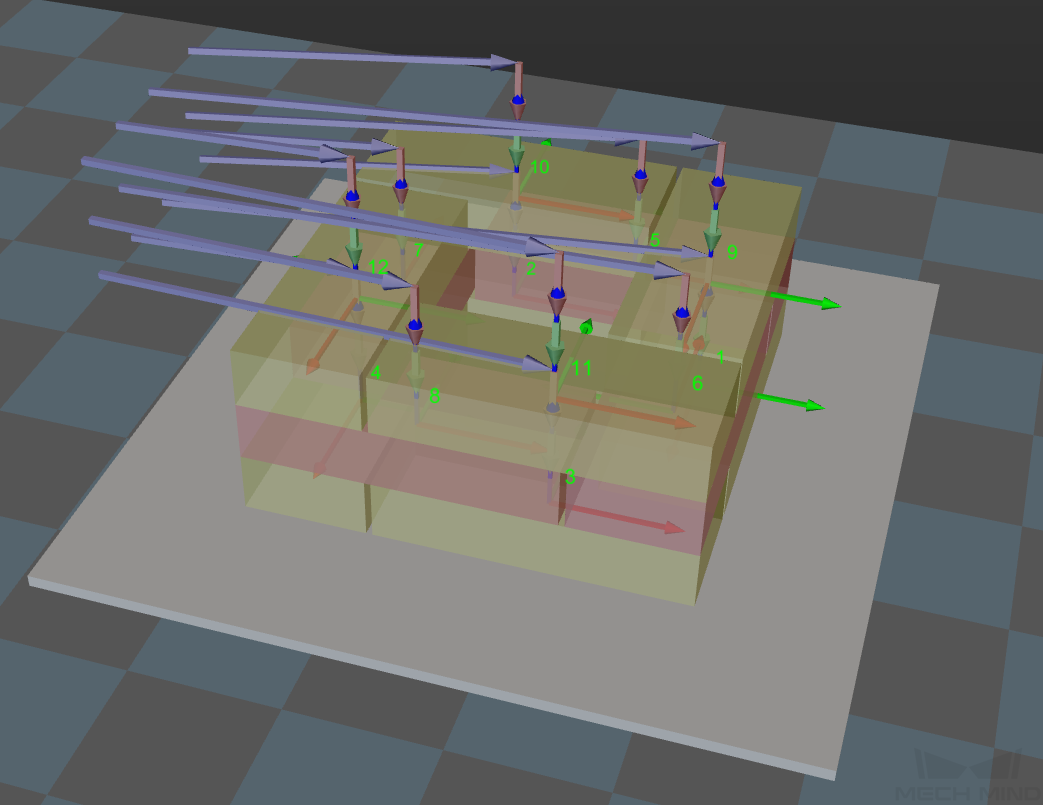

Entry Adjust

The three parameters together determines the path along which the robot enters the stack area. Adjust the entry path to make the held box approaches the palletized boxes at a specified angle, and then the held box will be placed vertically. If the box is directly placed on the stack in a vertical path, collisions may occur between the robot, held box, and the palletized boxes due to accuracy and other factors.

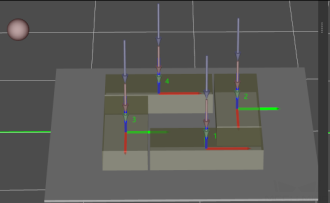

This parameter group determines three positions, as indicated by the red points in the figure, where the box will be moved to when it is placed on the stack. The figure below demonstrates the positions where the box will be moved (in the front view).

Vertical Adjust Length Ratio

| Description |

This parameter affects the “Adjust” position in the figure above. Vertical Adjust Length Ratio = Vertical Adjust Length / Height of the Box |

| Value range |

0–1 |

| Recommended value |

0.5 |

Vertical Margin

| Description |

This parameter affects the “Entry” position in the figure above. The vertical margin is marked in the figure above. |

| Value range |

0–∞; unit: mm. This parameter is used to control the distance above the boxes when the robot approaches the stack. The value should be adjusted according to the on-site situation. |

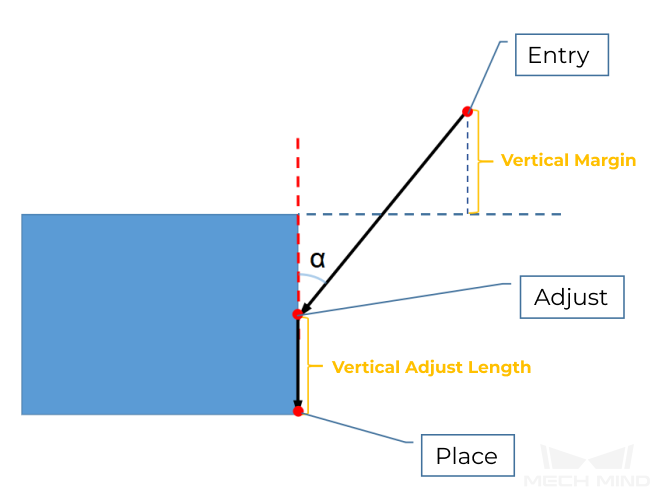

Auto Middle Point

X/Y

Set the position of the auto middle point (indicated by the pink sphere) in the robot reference frame. Based on this point, center coordinates of stacks with different heights will be calculated.

Min Z

When the robot enters the stack area (the path is indicated by the purple arrows), the minimum absolute distance in the Z-direction, i.e., the difference between the Z-direction height and the height of the current layer, as shown in the figure below.

Is Middle Point Traj Vertical

Unselected by default, i.e., the robot will approach the stack from the auto middle point.

Once this option is selected, the robot will approach the stack from directly above each placing position.

Extended Distance For Entry

For some circumstances, the vacuum gripper is too large, and it may collide with the palletized boxes when approaching the stack. The Extended Distance For Entry can be set to avoid collisions in the approaching process and ensure safety.

| Auto Middle Point is introduced as a direction reference when the robot approaches the stack, and the point is not an actual waypoint where the robot will move. The auto middle point should be as far away from the pallet as possible. If the auto middle point is too close to the pallet, collisions may occur when palletizing. |