Set DO

| From version 1.8.0, the “Set DO List” Step is merged with the “Set DO” Step to form the new “Set DO” Step. |

Function

In robotics industry, DO usually stands for digital output. DOs are a type of electrical signal used to control devices or components in an automation system. These digital output signals are represented by the higher or the lower voltage level and are used to enable or disable connected devices or actuators. These devices include suction cups, motors, solenoid valves, relays, indicator lights, and other types of electrical components.

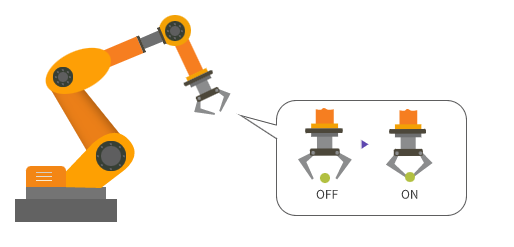

This Step enables external devices to perform specific actions by sending signals, such as opening and closing gripper fingers, turning suction cups on or off, and can also be used to control conveyor belts or trigger alarms, etc.

Parameter Description

General Parameters of Non-Move Steps

Skip Execution

| None |

Default setting. Do not skip the current Step. |

| Simulation only |

Skip the current Step during simulation. The exit port is specified by Out Port When Skip. |

| Always |

Skip the current Step when the project is simulating or running. The exit port is specified by Out Port When Skip. |

| Instruction |

When Simulation only or Always is selected, the current Step will be skipped and the subsequent Step will be executed when running the project. If this parameter is set to None in “Check DI” Step in the project, and there is no external input signal during simulation, the project will be stopped when executing to this Step. In this case, setting the parameter to Simulation only or Always enables the simulation to continue. |

Out Port When Skip

This parameter will take effect when Skip Execution is set to Simulation only or Always. It specifies the exit port when skipping a Step.

Wait Move Precisely

Checked by default. This Step can only start executing when the robot reaches the specific waypoint corresponding to the move-type Step before the “Set DO” Step.

Receiver

Please select the object that actually receives the DO, either the robot, Standard Interface or Adapter. If Adapter is selected, please enter the “Adapter Name.” In addition, there can be multiple receivers.

| If this parameter is not configured, the software cannot send the DO to the receiver. |

Source

The source of the DI can be set to either “Vision Move” or “Custom”.

Vision Move

This option applies to box depalletizing and multi-end tool application scenarios only. According to the depalletizing vacuum gripper or multi-end tool configuration together with the corresponding picking method, the software will automatically compute the DO port numbers of the tool ends that should be activated.

Custom

Specify the DO ports to be set manually.

-

Please follow these steps to configure.

-

Click + to add ports based on the number of ports to be set.

-

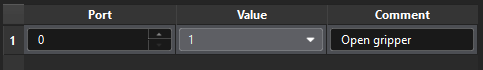

Set the port numbers and values for controlling the external devices, and you can comment on the function of the current port.

-

The port numbers cannot be duplicated. The configuration cannot be completed with duplicated port numbers.

-

To clarify the function of each port, it is recommended to add a comment for each port.

-

Select the line of a specific port and click - to delete the port configuration.

-

-

-

Example

For example, if Port 0 is used to control the gripper, and the gripper opens its fingers when the signal value is 1, the settings is shown below.