Step Parameters

Global Configuration

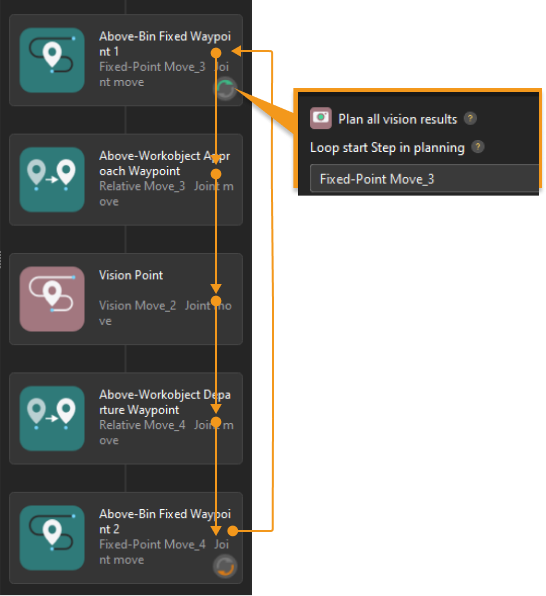

Plan all vision results

Once this option is enabled, the current workflow will be looped until all received vision results are used for the path planning, and then all paths for picking can be output after the planning is completed. You should set a Loop start Step in planning if this option is enabled.

| The “planning” refers to the process when the software attempts to find a collision-free path that the robot can follow to reach the target position. |

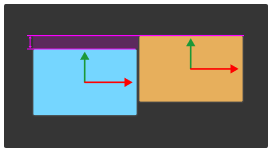

The Loop start Step in planning is the Step where the loop starts in the planning. For example, “Fixed-Point Move_3” is set as the Loop start Step in planning in the figure below, and the software will loop the current workflow until all received vision results are used for the path planning.

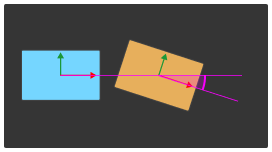

Update bin pose with vision

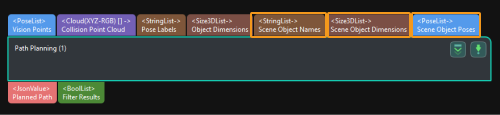

While the camera captures the image for workpiece recognition, the bin will be recognized and located simultaneously. Therefore, the bin pose in the 3D simulation area can be updated dynamically, which facilitates the collision detection algorithm to effectively prevent the robot from colliding with the bin. This feature will provide three fields, “scene_object_names,” “scene_object_sizes,” and “scene_object_poses,” in the vision result to define the name, dimensions, and pose of the scene object to be updated.

To utilize this feature, you should switch on the Enable parameter under Update Scene Object Settings in the Step Parameters panel of the Path Planning Step, and connect the Scene Object Names, Scene Object Dimensions, and Scene Object Poses input ports with corresponding output ports.

Box depalletizing

Once this feature is enabled, the software will enter the depalletizing mode in which the end tool should be set to the depalletizing vacuum gripper. Please select the depalletizing method according to the requirement of the actual scenario.

| Once the box depalletizing feature is enabled, the point cloud of the target workobject will be removed by default, with an “XY-Plane Point Cloud Removal Range Expansion” of 10 mm and “Z-Direction Point Cloud Removal Range Expansion” of 30 mm. For detailed introduction of this feature, please refer to Remove Point Cloud of Target Workobject. |

Single-pick depalletizing

“Single-pick depalletizing” indicates that only one box will be picked at a time during depalletizing.

Please follow these steps to configure:

-

Go to and click + on the right to open the Tool Configuration window.

In this window:

-

Select Depalletizing vacuum gripper as the Tool type.

-

Click the Configure depalletizing vacuum gripper button at the bottom to open the vacuum gripper configurator. You can refer to Depalletizing Vacuum Gripper Configuration to complete the configurations.

-

-

Enable Box depalletizing in the Global configuration.

-

Select Single-pick depalletizing.

-

Set the Min box surface coverage parameter according to the actual situation.

This parameter specifies the minimum proportion of a box’s upper surface covered by the vacuum gripper when the vacuum gripper attempts to pick a box. If the coverage is larger than the value, it is considered that the vacuum gripper is able to pick the box.

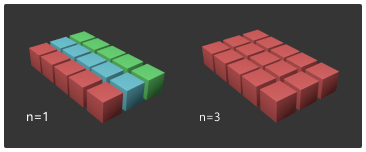

Multi-pick depalletizing

“Multi-pick depalletizing” indicates that boxes will be automatically grouped for depalletizing, and a box group containing multiple boxes will be picked altogether at a time.

Please follow these steps to configure:

-

Click the plus sign next to “Tools” in the resource tree to open the Tool Configuration window.

-

Select Depalletizing vacuum gripper as the Tool type.

-

Click the Configure depalletizing vacuum gripper button at the bottom to open the vacuum gripper configurator. You can refer to Depalletizing Vacuum Gripper Configuration to complete the configurations.

-

-

Enable Box depalletizing in the Global configuration.

-

Select Multi-pick depalletizing.

-

You can set the following parameters according to the actual requirements.

-

Min box surface coverage

This parameter specifies the minimum proportion of a box’s upper surface covered by the vacuum gripper when the vacuum gripper attempts to pick a box. If the coverage is larger than the value, it is considered that the vacuum gripper is able to pick the box.

-

Max rows per group

The allowable maximum number of rows in one box group for multi-pick depalletizing.

-

Spacing upper limit

This parameter limits the maximum distance between two adjacent boxes in the grouping direction. When the distance is smaller than this value, the boxes can be considered to be in a group.

Please note that the value of this parameter cannot be greater than the box width in the vision result. If the set value is greater than the box width, the value will be automatically modified to the box width in the actual execution. -

Deviation upper limit

This parameter limits the maximum deviation distance of a box in the direction perpendicular to the grouping direction. When the deviation distance is smaller than this value, the box can be considered to be in the group.

Please note that the value of this parameter cannot be greater than the box width in the vision result. If the set value is greater than the box width, the value will be automatically modified to the box width in the actual execution. -

Angle deviation upper limit

This parameter limits the angle of rotational deviation of a box relative to the grouping direction. When the rotation angle is smaller than this value, the box can be considered to be in the group.

-

Fixed-Point Move

This Step specifies a fixed pose as the waypoint.

You can adjust the robot pose in one of the three ways below.

-

Adjust the JPs of the robot.

-

Drag the pose manipulator in the 3D simulation area.

-

Enter the pose of the real robot.

-

Move the robot with the teach pendant and record the TCP or joint positions.

-

Click Edit pose (if the robot pose is in the form of TCP) or Edit JPs (if the robot pose is in the form of joint positions) in the Step Parameters.

-

Enter the recorded TCP or JPs and click OK. Then the simulated robot will move to the corresponding pose.

-

Parameter Description

-

Whether to send to robot

Description: Determine whether to send the pose of this Step to the robot.

Example: If Plan and not send is selected, the Path Planning Step will not output the pose of this Step.

-

Motion type

Description: The motion type in which the robot moves to the corresponding pose in this Step. The linear move is typically used in gluing scenarios.

Example: If joint move is selected, the robot will move to the corresponding pose in this Step with the joint movement.

-

Robot pose type

Description: Select the method to adjust the pose.

Relative Move

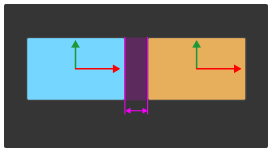

This Step specifies the distance the robot moves along the Z-axis relative to the previous or next waypoint.

Parameter Description

-

Whether to send to robot

Description: Determine whether to send the pose of this Step to the robot.

Example: If Plan and not send is selected, the Path Planning Step will not output the pose of this Step.

-

Motion type

Description: The motion type in which the robot moves to the corresponding pose in this Step. The linear move is typically used in gluing scenarios.

Example: If joint move is selected, the robot will move to the corresponding pose in this Step with the joint movement.

-

Move relative to

Description: The reference pose when the robot moves.

Example: If Pre is selected, the robot will move based on the previous waypoint.

-

Direction

Description: The direction along which the robot moves.

Example: If Along workobject frame Z axis is selected, the robot will move along the Z-axis of the workobject reference frame.

-

Distance

Description: The distance that the robot moves along the direction of movement.

Vision Point

The vision points are targets for picking. The vision poses input to the Path Planning Step will be passed on to this Step.

-

Whether to send to robot

Description: Determine whether to send the pose of this Step to the robot.

Example: If Plan and not send is selected, the Path Planning Step will not output the pose of this Step.

-

Motion type

Description: The motion type in which the robot moves to the corresponding pose in this Step.

Example: If joint move is selected, the robot will move to the corresponding pose in this Step with the joint movement.