Example Program 10: MM_S10_Viz_Subtask

Program Introduction

Description |

This example program consists of two programs: a main program and a sub program. The sub program (background program) triggers the Mech-Viz project to run to obtain the planned path. The main program (the foreground program) moves the robot based on the planned path. Then, the main program triggers the sub program to run when the robot leaves the picking area to obtain the next planned path, shortening the cycle time.

|

||

File path |

Sub program: You can navigate to the installation directory of Mech-Vision and Mech-Viz and find the file by using the Main program: You can navigate to the installation directory of Mech-Vision and Mech-Viz and find the file by using the

|

||

Project |

Mech-Vision and Mech-Viz projects |

||

Prerequisites |

|

|

Program Description

The following part describes the sub program.

| Similar to the MM_S2_Viz_Basic example program, the sub program triggers the Mech-Viz project to run and obtains the planned path code. As such, the features of the sub program that are similar to those of MM_S2_Viz_Basic are not described in this part. For more information about these features, see Example Program 2: MM_S2_Viz_Basic. |

MODULE MM_S10_Sub

!----------------------------------------------------------

! FUNCTION: run Mech-Viz project and get planned path

! in subtask(run together with MM_S10_Viz_Subtask)

! Mech-Mind, 2023-12-25

!----------------------------------------------------------

!define variables

PERS num pose_num_b:=5;

PERS num vis_pose_num_b:=3;

PERS num toolid_b{5}:=[0,0,0,0,0];

PERS num label_b{5}:=[0,0,0,0,0];

PERS num status_b:=2100;

PERS bool flag_vis_b:=FALSE;

CONST jointtarget snap_jps_b:=[[0,0,0,0,90,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]];

PERS jointtarget jps_b{5}:=

[

[[0,0,0,0,90,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]],

[[0,0,0,0,90,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]],

[[0,0,0,0,90,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]],

[[11.1329,49.0771,-36.9666,0.5343,79.2476,-169.477],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]],

[[0,0,0,0,90,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]]

];

PROC main()

flag_vis_b:=FALSE;

!initialize communication parameters (initialization is required only once)

MM_Init_Socket "127.0.0.1",50000,300;

WHILE TRUE DO

IF flag_vis_b=TRUE THEN

MM_Open_Socket;

!trigger Mech-Viz project

MM_Start_Viz 2,snap_jps_b;

!get planned path, 1st argument (1) means getting pose in JPs

MM_Get_VizData 1, pose_num_b, vis_pose_num_b, status_b;

!check whether planned path has been got from Mech-Viz successfully

IF status_b=2100 THEN

!save waypoints of the planned path to local variables one by one

MM_Get_Jps 1,jps_b{1},label_b{1},toolid_b{1};

MM_Get_JPS 2,jps_b{2},label_b{2},toolid_b{2};

MM_Get_JPS 3,jps_b{3},label_b{3},toolid_b{3};

ENDIF

MM_Close_Socket;

flag_vis_b:=FALSE;

ENDIF

ENDWHILE

ENDPROC

ENDMODULEThe above code shows that the sub program sets flag_vis_b to FALSE, initializes the communication parameters, and then continuously listens to the value of flag_vis_b through the WHITE loop.

-

When flag_vis_b is set to TRUE, the sub program triggers the Mech-Viz project to run, obtains the planned path, and then sets flag_vis_b to FALSE.

-

When flag_vis_b is set to FALSE, the sub program continuously listens to the value of flag_vis_b.

The following part describes the main program.

| Similar to the MM_S2_Viz_Basic example program, the main program performs picking and placing based on the planned path code. As such, the features of the main program that are similar to those of MM_S2_Viz_Basic are not described in this part. For more information about these features, see Example Program 2: MM_S2_Viz_Basic. |

MODULE MM_S10_Viz_Subtask

!----------------------------------------------------------

! FUNCTION: run Mech-Viz project and get planned path

! in subtask (run together with MM_S10_Sub)

! Mech-Mind, 2023-12-25

!----------------------------------------------------------

!define local num variables

PERS bool flag_vis_b:=FALSE;

PERS num status_b:=2100;

PERS num pose_num_b:=5;

PERS num toolid_b{5}:=[0,0,0,0,0];

PERS num label_b{5}:=[0,0,0,0,0];

PERS num vis_pose_num_b:=3;

LOCAL VAR num count:=0;

!define local joint&pose variables

LOCAL CONST jointtarget home:=[[0,0,0,0,90,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]];

LOCAL PERS robtarget pick_wait_point:=[[302.00,0.00,558.00],[0,0,-1,0],[0,0,0,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]];

LOCAL PERS robtarget drop_waypoint:=[[302.00,0.00,558.00],[0,0,-1,0],[0,0,0,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]];

LOCAL PERS robtarget drop:=[[302.00,0.00,558.00],[0,0,-1,0],[0,0,0,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]];

PERS jointtarget jps_b{5}:=

[

[[0,0,0,0,0,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]],

[[0,0,0,0,0,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]],

[[0,0,0,0,0,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]],

[[0,0,0,0,0,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]],

[[0,0,0,0,0,0],[9E+9,9E+9,9E+9,9E+9,9E+9,9E+9]]

];

!define local tooldata variables

LOCAL PERS tooldata gripper1:=[TRUE,[[0,0,0],[1,0,0,0]],[0.001,[0,0,0.001],[1,0,0,0],0,0,0]];

PROC Sample_10()

!set the acceleration parameters

AccSet 50, 50;

!set the velocity parameters

VelSet 50, 1000;

!move to robot home position

MoveAbsJ home\NoEOffs,v3000,fine,gripper1;

!trigger Mech-Viz project and get planned path

trigger_vis_b;

LOOP:

!move to wait position for picking

MoveL pick_wait_point,v1000,fine,gripper1;

!wait until subtask program finished

WaitUntil(flag_vis_b=FALSE);

!check whether planned path has been got from Mech-Viz successfully

IF status_b <> 2100 THEN

!add error handling logic here according to different error codes

!e.g.: status=2038 means no point cloud in ROI

Stop;

ENDIF

!follow the planned path to pick

!move to approach waypoint of picking

MoveAbsJ jps_b{1},v1000,fine,gripper1;

!move to picking waypoint

MoveAbsJ jps_b{2},v300,fine,gripper1;

!add object grasping logic here, such as "setdo DO_1, 1;"

Stop;

!move to departure waypoint of picking

MoveAbsJ jps_b{3},v1000,fine,gripper1;

!move to intermediate waypoint of placing, and trigger Mech-Viz project and get planned path in advance

MoveJSync drop_waypoint,v1000,z50,gripper1,"trigger_vis_b";

!move to approach waypoint of placing

MoveL RelTool(drop,0,0,-100),v1000,fine,gripper1;

!move to placing waypoint

MoveL drop,v300,fine,gripper1;

!add object releasing logic here, such as "setdo DO_1, 0;"

Stop;

!move to departure waypoint of placing

MoveL RelTool(drop,0,0,-100),v1000,fine,gripper1;

!move back to robot home position

MoveAbsJ home\NoEOffs,v3000,fine,gripper1;

GOTO LOOP;

ENDPROC

PROC trigger_vis_b()

flag_vis_b:=TRUE;

ENDPROC

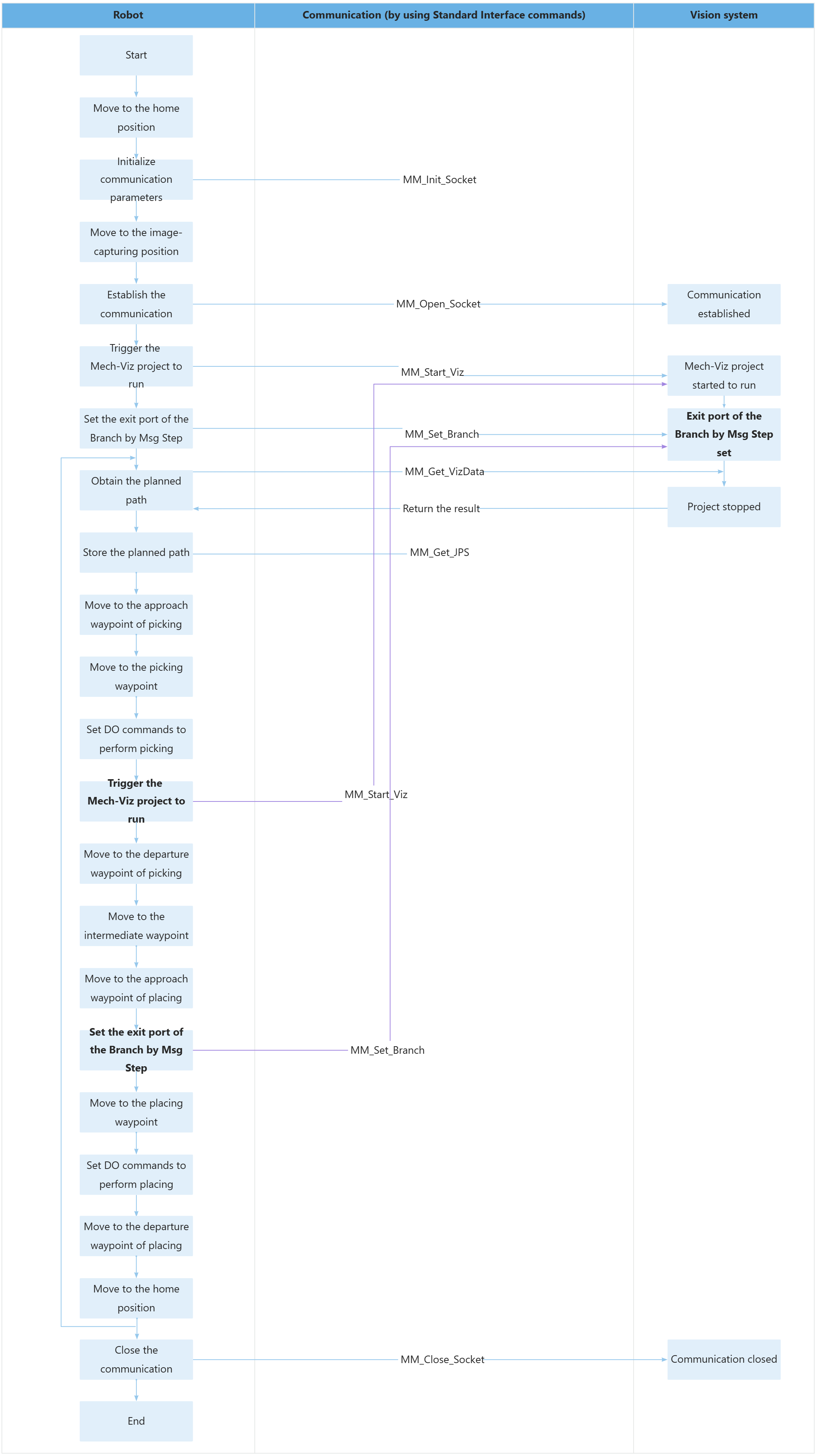

ENDMODULEThe workflow corresponding to the above example program code is shown in the figure below.

The table below illustrates the core code of the main program.

| Feature | Code and description | ||

|---|---|---|---|

Trigger the Mech-Viz project to run and obtain the planned path |

In the above example, the main program calls the trigger_vis_b() function. The code for this function is shown below. In the above example, when flag_vis_b is set to TRUE in the trigger_vis_b() function, the sub program will detect the TRUE value, trigger the Mech-Viz project to run, and then obtain the planned path. |

||

Plan the next path in advance by looping (picking→triggering the next round of path planning→placing) |

The above code indicates that the main program loops through the code between LOOP and GOTO LOOP. In the above example, the robot moves to a waiting waypoint before picking and waits for the sub program to obtain and store the planned path (i.e., flag_vis_b changes from TRUE to FALSE). In the above example, the robot moves along the planned path to the approach waypoint of picking (jps_b{1}) and then to the picking waypoint (jps_b{2}), performs picking (for example, setdo DO_1, 1;), and then moves to the departure waypoint of picking (jps_b{3}). In the above code, the robot moves to the target position (drop_waypoint, i.e., the intermediate waypoint during placing) and calls the trigger_vis_b() function at the target position. The main program calls the trigger_vis_b() function again to trigger the Mech-Viz project to run and obtain the planned path. Now that the robot resides outside the area for placing, the robot can plan the next picking path in advance without waiting for the placing to complete and then planning the next picking path.

The above example indicates that the robot moves to the approach waypoint of placing (RelTool(drop,0,0,-100)) and then to the placing waypoint (drop), performs placing (such as setdo DO_1, 0;), and then moves to the departure waypoint of placing (RelTool(drop,0,0,-100)) and then to the home position. |