Example Program 5: MM_S5_Viz_SetBranch

Program Introduction

Description |

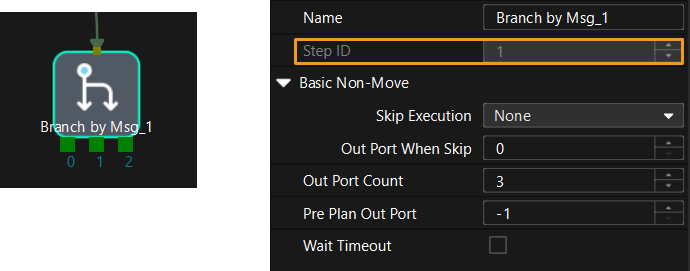

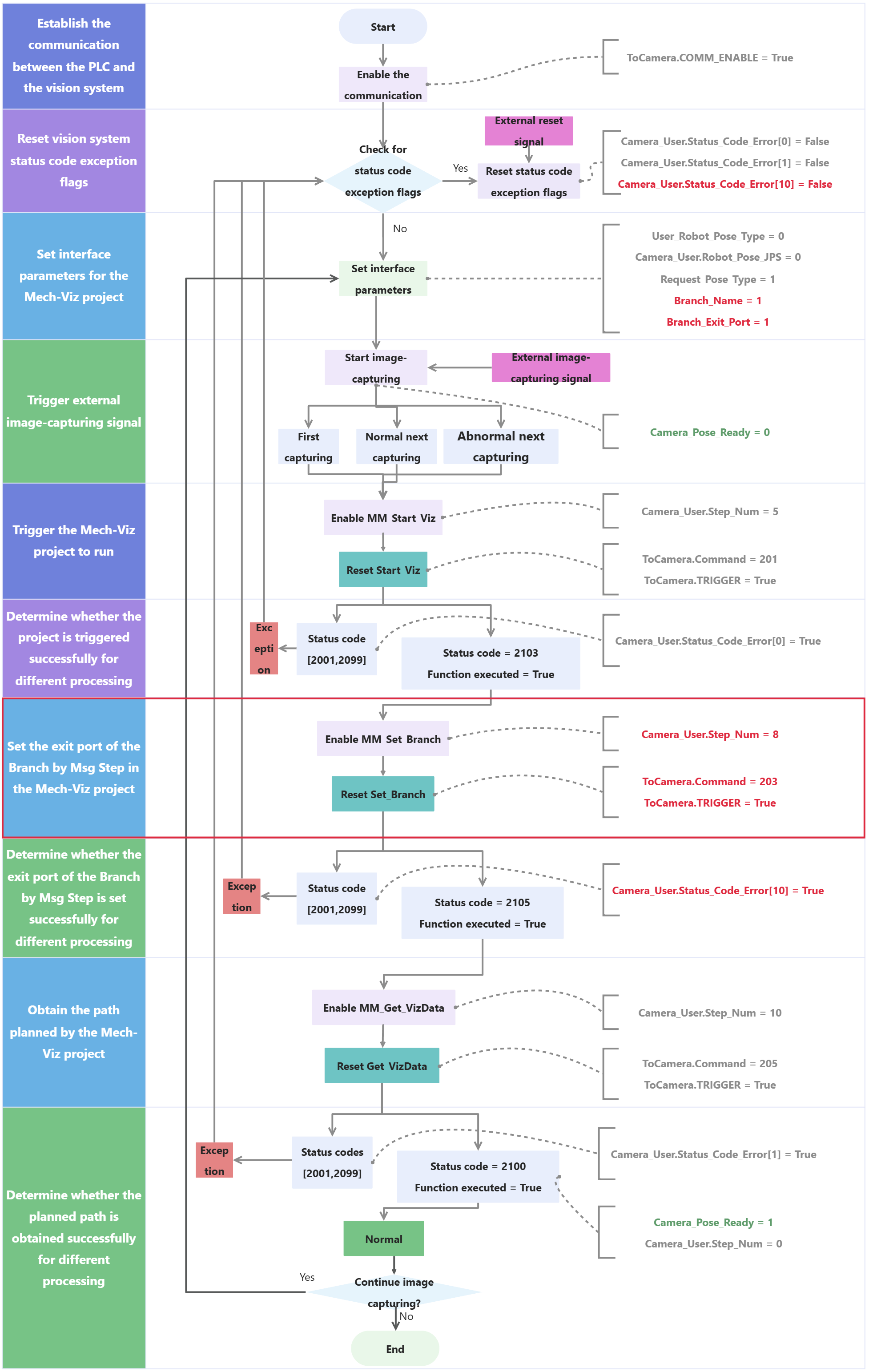

The PLC starts the Mech-Viz project, sets the exit port for the Branch by Msg Step, and then obtains the planned path from the Mech-Viz project. |

File path |

You can navigate to the installation directory of Mech-Vision and Mech-Viz and find the file by using the |

Project |

Mech-Vision project and Mech-Viz project (The Branch by Msg Step needs to be configured beforehand.) |

Prerequisites |

|

| This example program is provided for reference only. Before using the program, please modify the program according to the actual scenario. |

Program Description

This part describes the MM_S5_Viz_SetBranch example program.

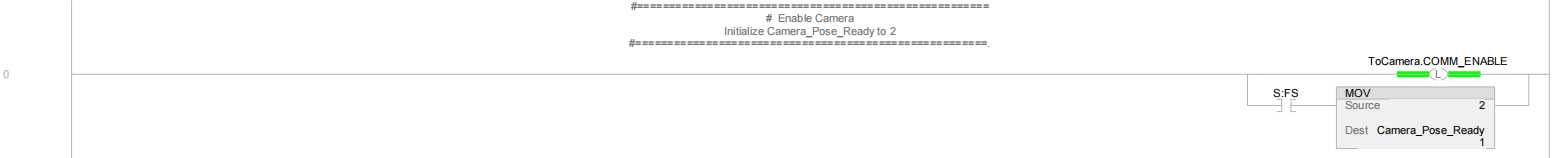

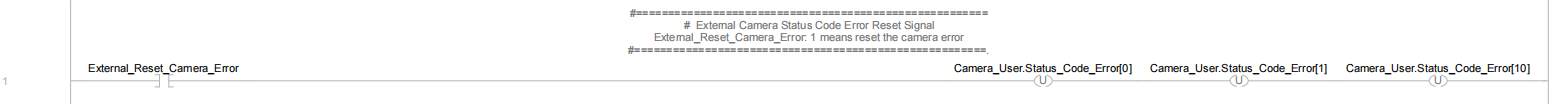

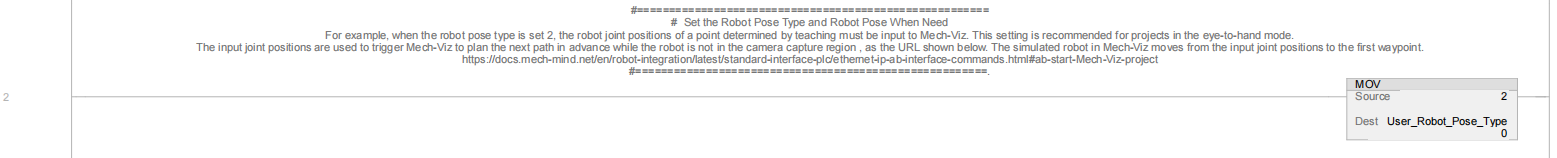

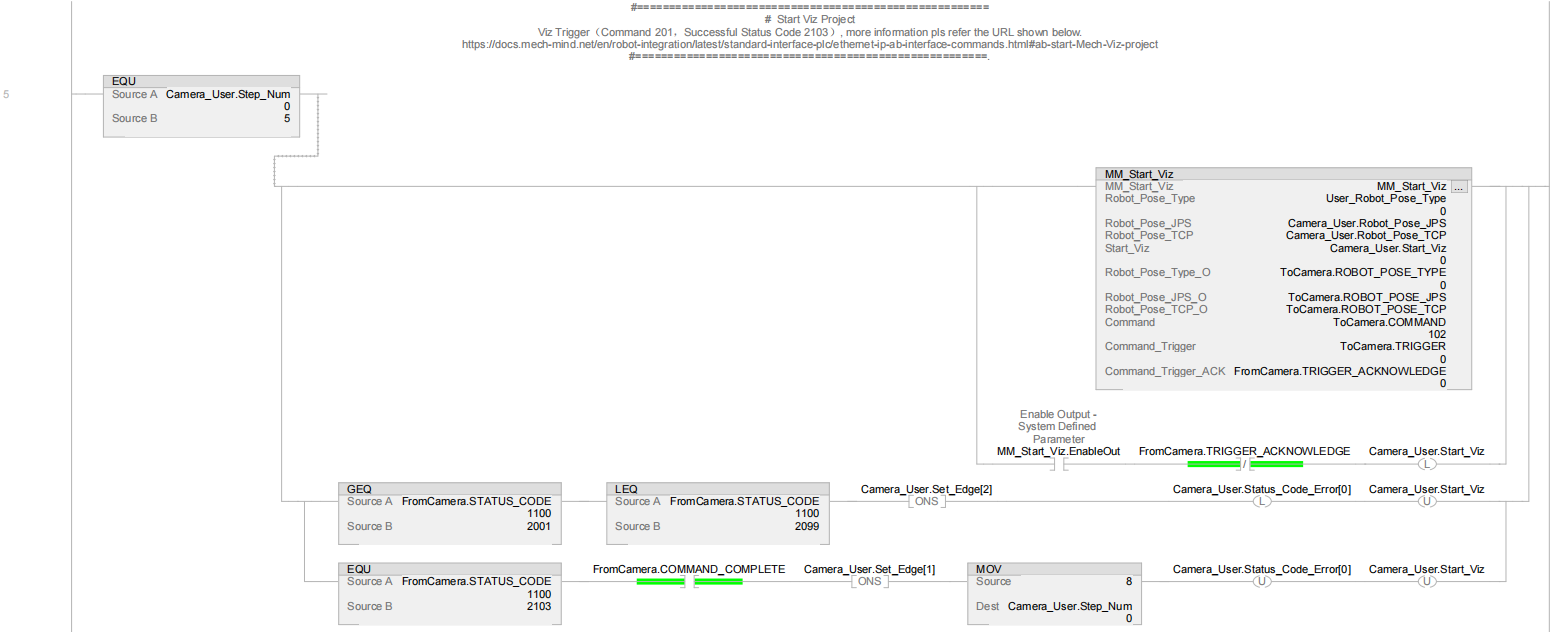

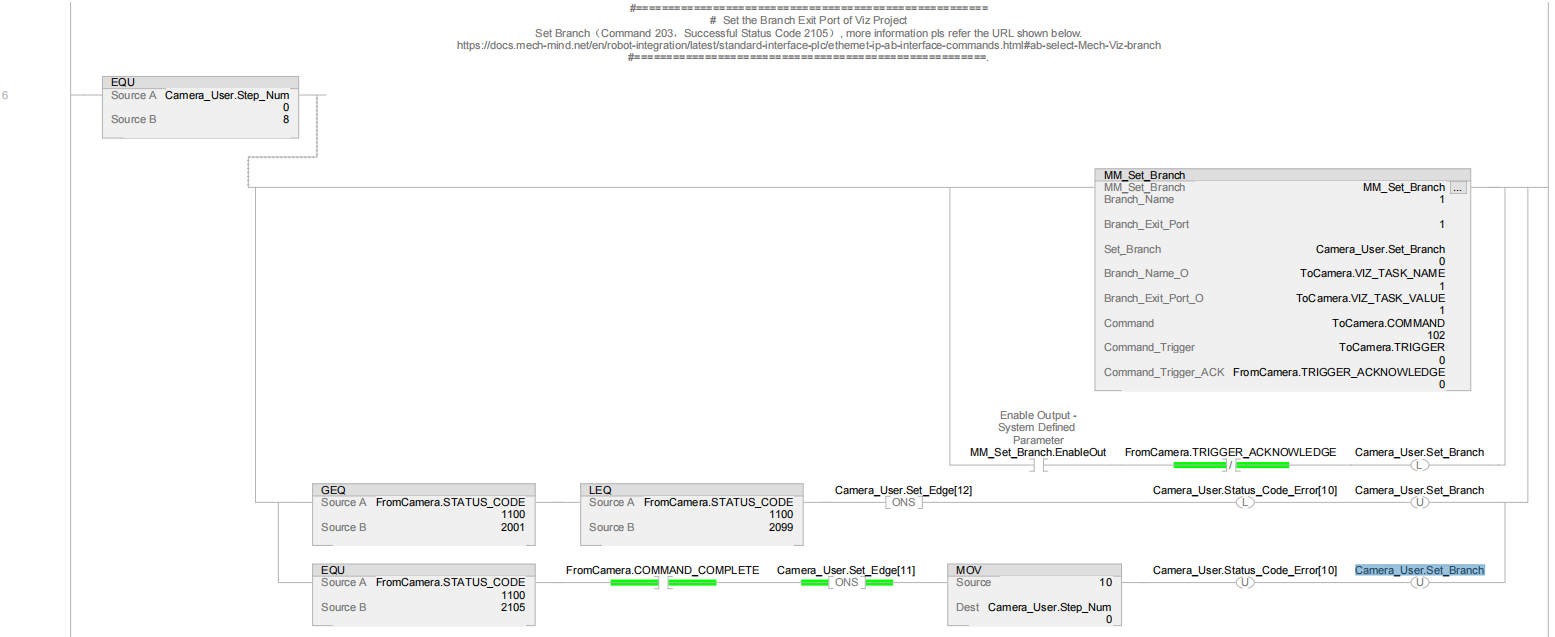

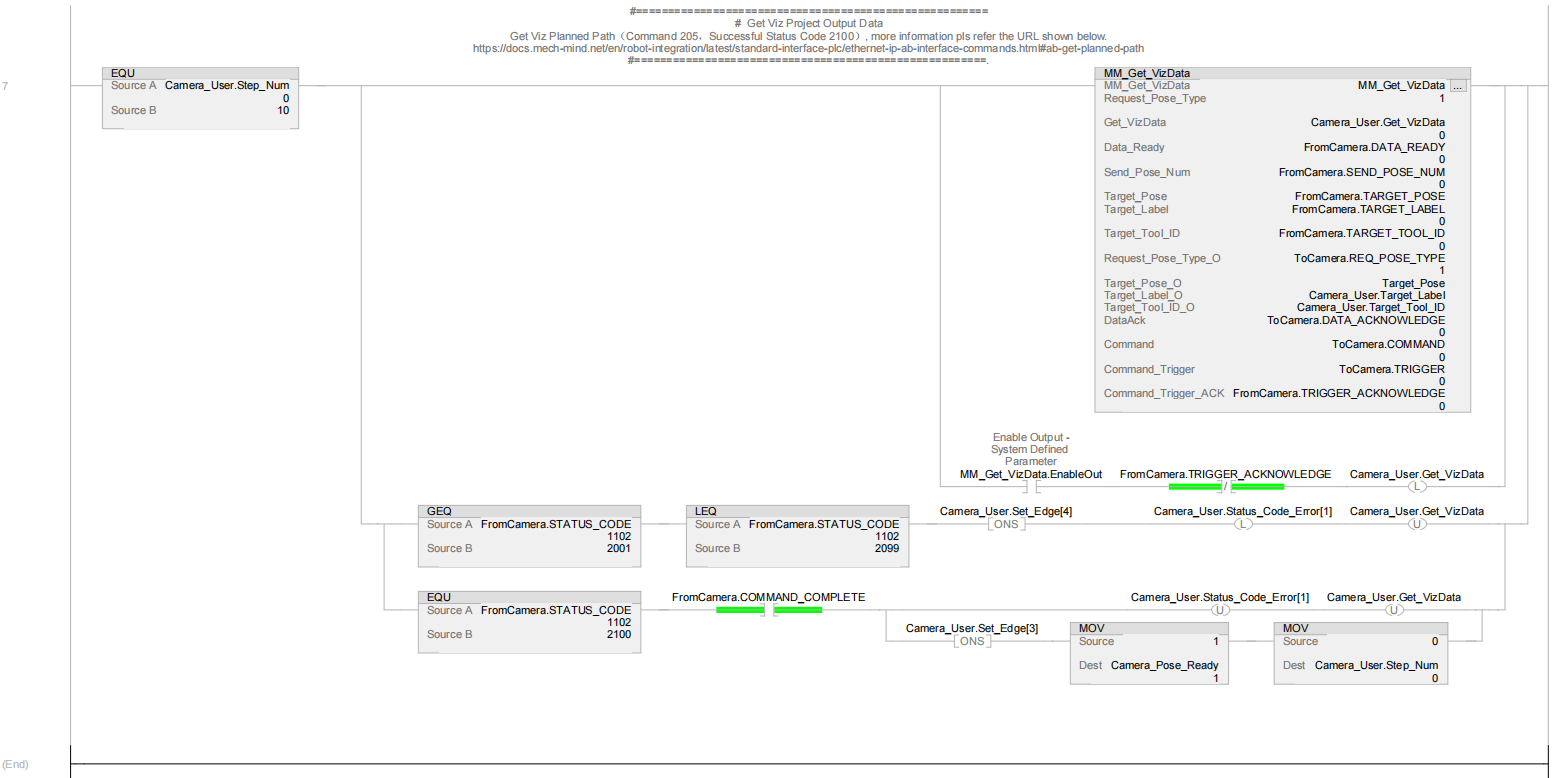

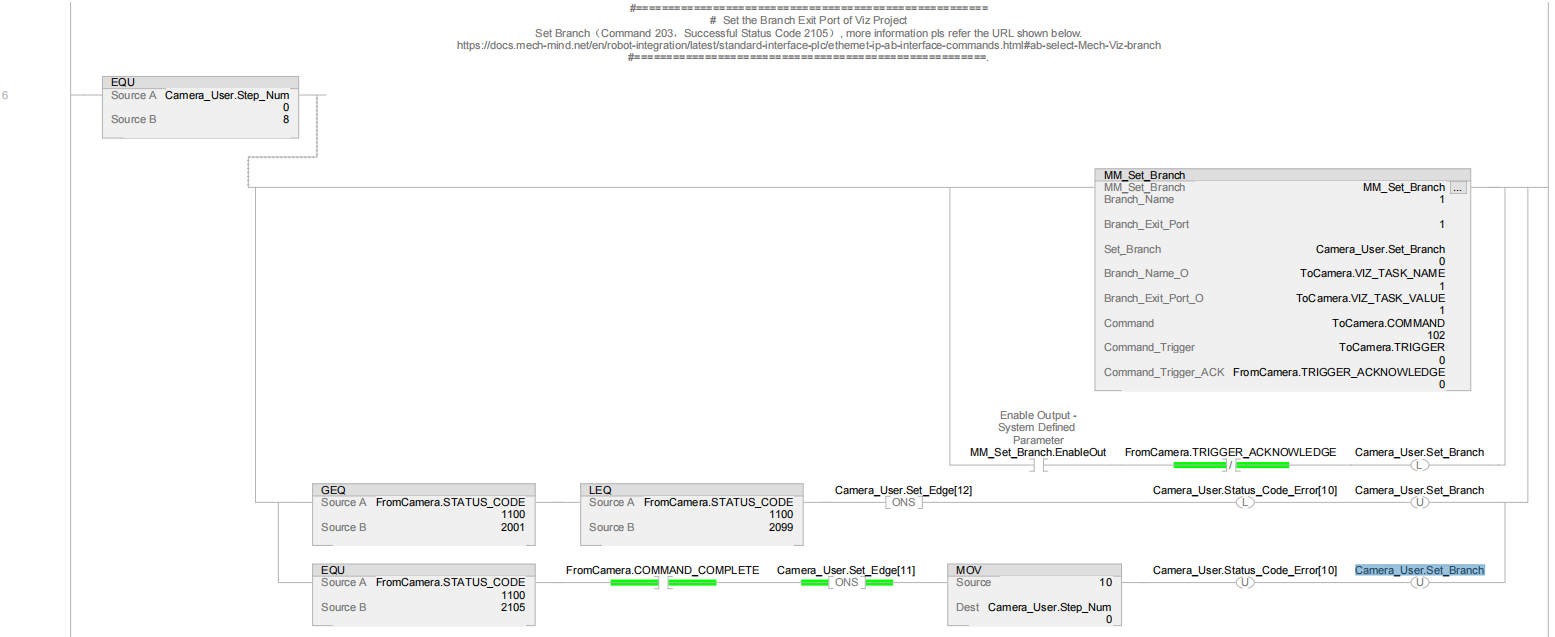

| The only difference between the MM_S5_Viz_SetBranch example program and the MM_S2_Viz_Basic example program is that MM_S5_Viz_SetBranch can set the exit port of the Branch by Msg Step in the Mech-Viz project (Rung 6). As such, only the feature of setting the exit port of the Branch by Msg Step is described in the following section. For information about the parts of MM_S5_Viz_SetBranch that are consistent with those of MM_S2_Viz_Basic, see Example Program: MM_S2_Viz_Basic. |

The figure below describes the process of the above example program. The feature of setting the exit port of the Branch by Msg Step in the Mech-Viz project in the above program is shown in the section indicated by the red line in the figure below.

The table below describes the process of setting the exit port of the Branch by Msg Step in the Mech-Viz project.

|

| Feature | Description | ||

|---|---|---|---|

Set the exit port for the Branch by Msg Step in the Mech-Viz project and determine the subsequent operations based on whether the exit port is set successfully |

Rung 6 indicates that if Camera_User.Step_Num is equal to 8, the following operations are performed.

|