Set up Standard Interface Communication with ROKAE

This topic introduces the process of setting up the Standard Interface communication with a ROKAE robot.

Check Hardware and Software Versions

-

The robot in use is a ROKAE industrial robot.

-

The series of the controller is XBC3, and the version is 3.6.

-

The Mech-Mind Software Suite version is 1.7.2 or above.

Start the Robot and Teach Pendant

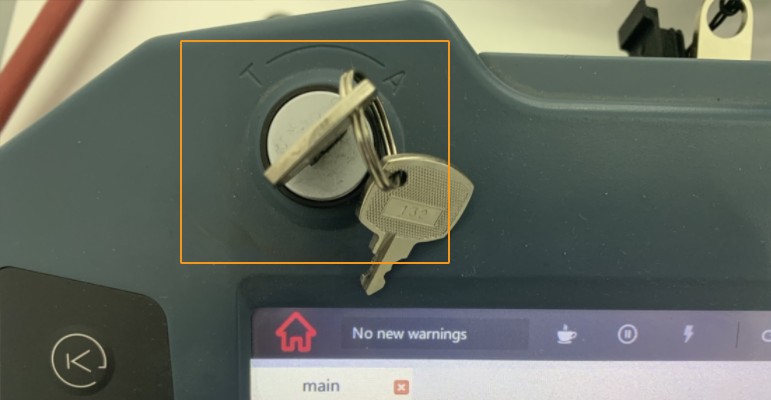

Turn the controller’s power switch on, as shown below. If the controller is started successfully, a welcome interface will appear on the teach pendant.

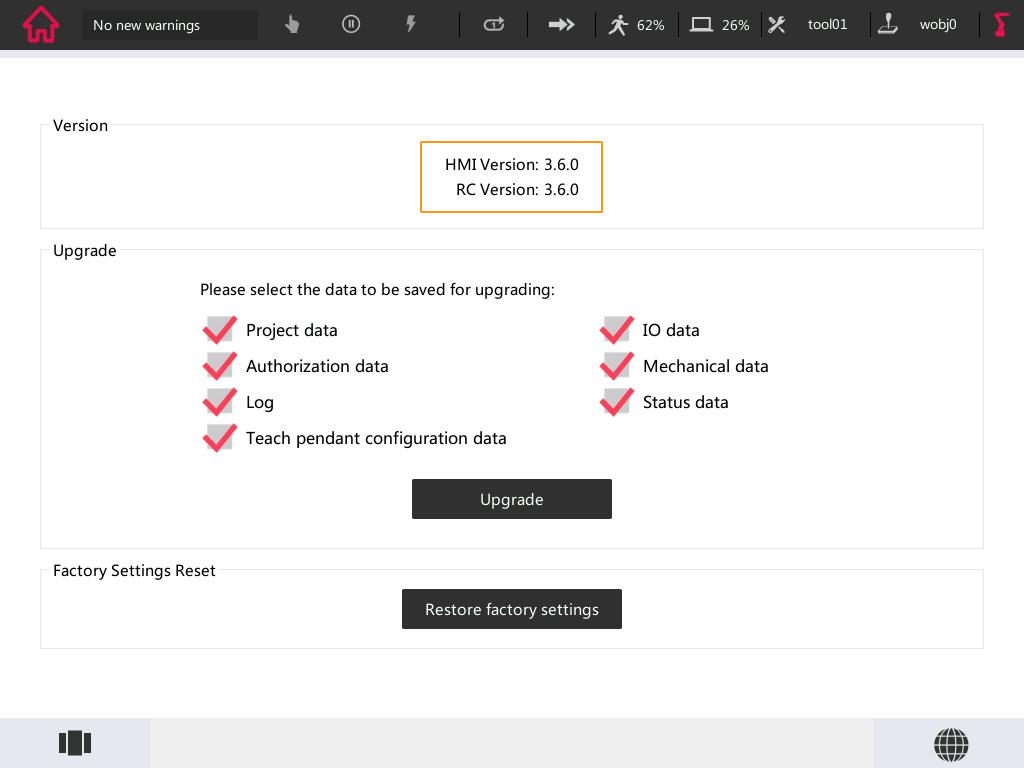

Check the Controller Version

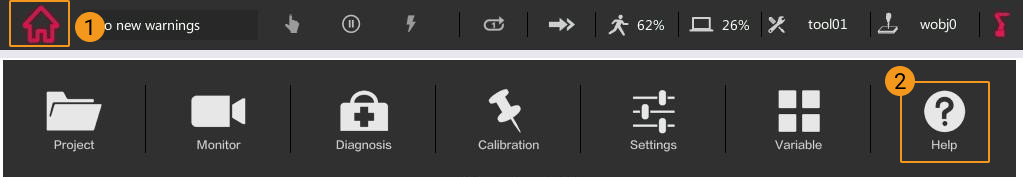

On the teach pendant, press the icon in the upper left corner, and then press Help to check the version.

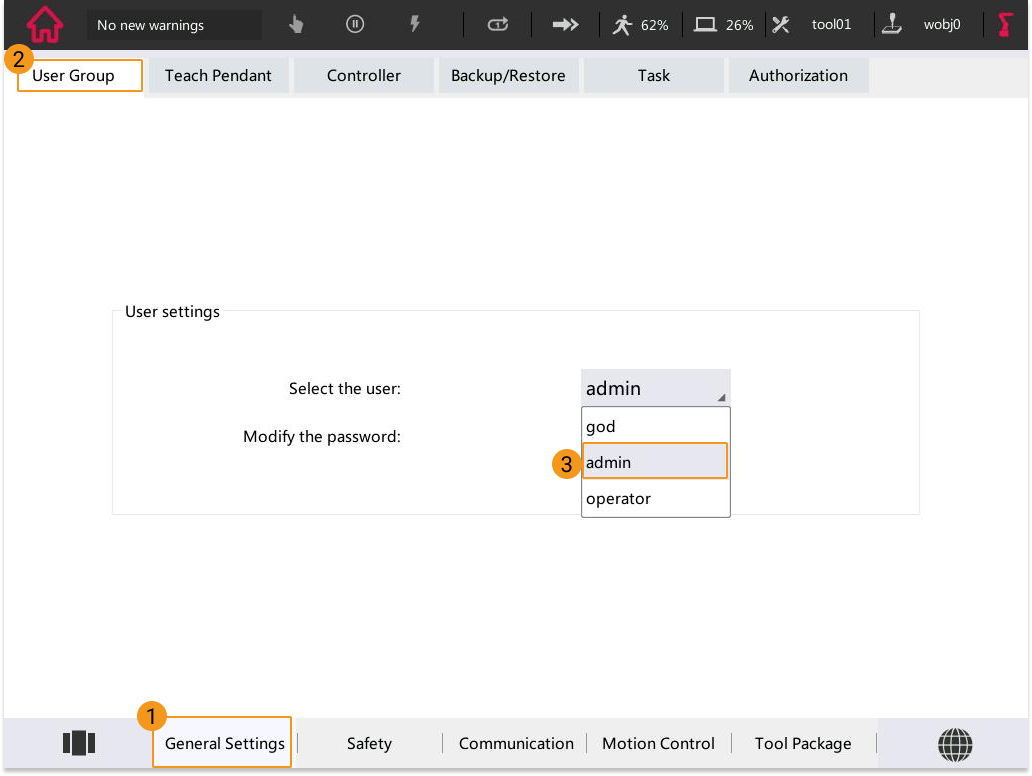

Switch the User Type to Admin

An operator user does not have the right to manage files or operate. Therefore, please switch to the admin user.

-

On the teach pendant, press the icon in the upper left corner, and then press Settings.

-

Press , and select admin.

-

Enter the password 123456 in the pop-up window.

Set up the Network Connection

Connect the Hardware

Use the Ethernet cable to connect the network ports of the IPC and the robot controller.

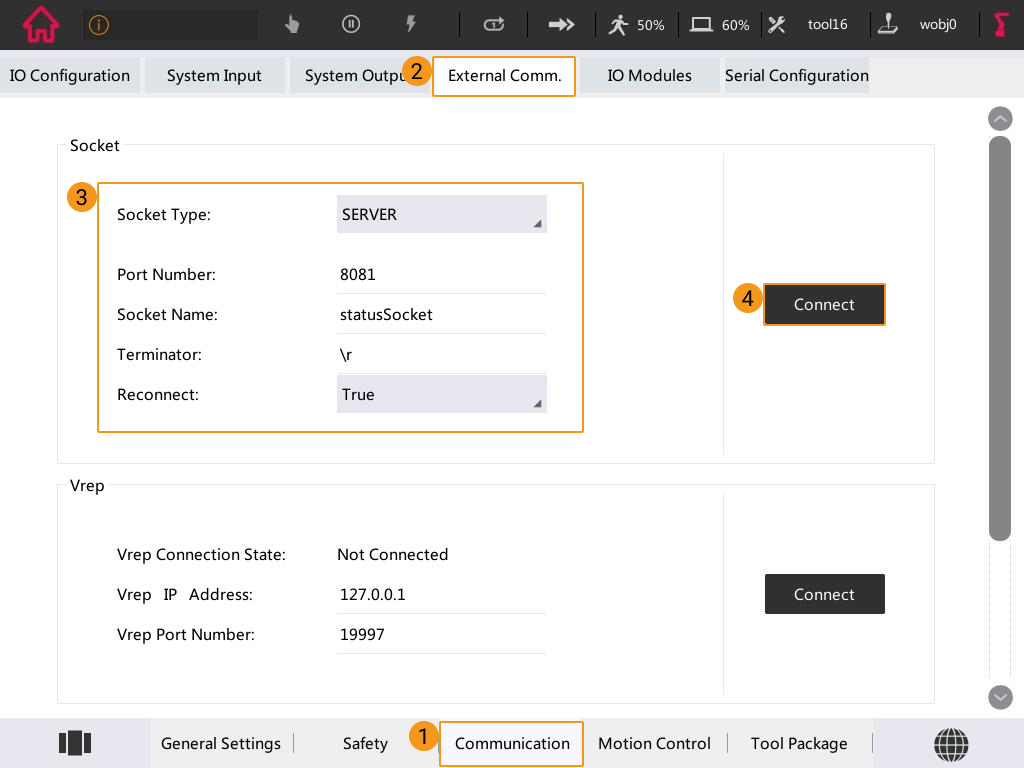

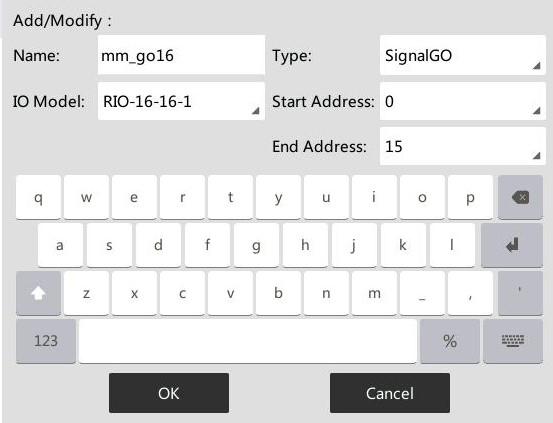

Configure External Communication

-

On the teach pendant, press the icon in the upper left corner, and then press Settings.

-

Press , configure Socket communication as shown in the figure below, and then click Connect.

-

Restart the controller.

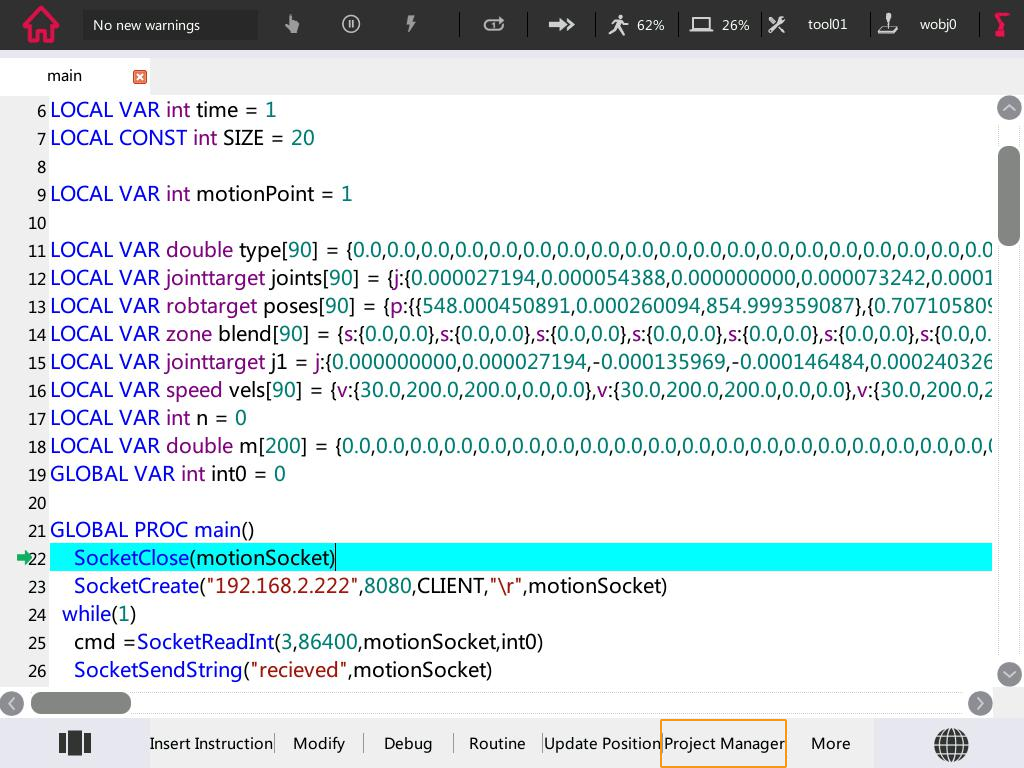

Set the IP Address of the IPC

The default IP address of the ROKAE robot to communicate with the vision system is 192.168.2.160, which cannot be modified currently. However, you can modify the IP address of the IPC (192.168.2.222 is used in this example) to ensure that their IP addresses are in the same subnet. Please refer to Set IP Address of the IPC for detailed instructions.

After modifying the IP address on the IPC, open the Command Prompt window of the IPC, enter “ping 192.168.2.160”, and test whether the connection between the IPC and the robot is successful.

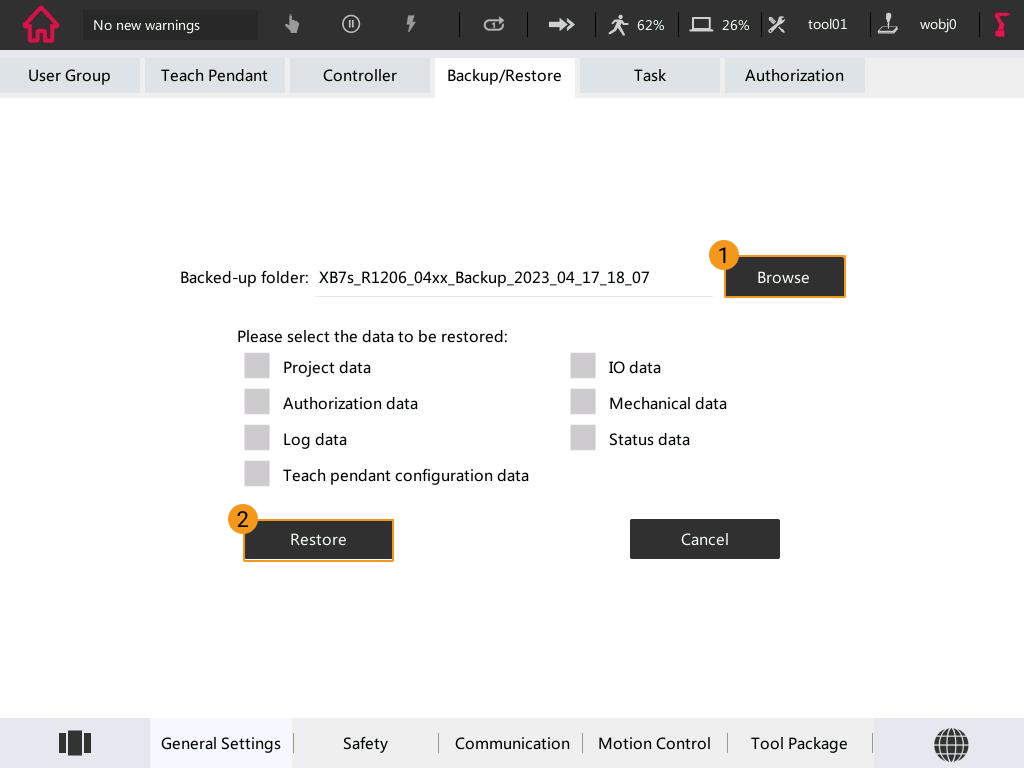

Load the Program Files to the Robot

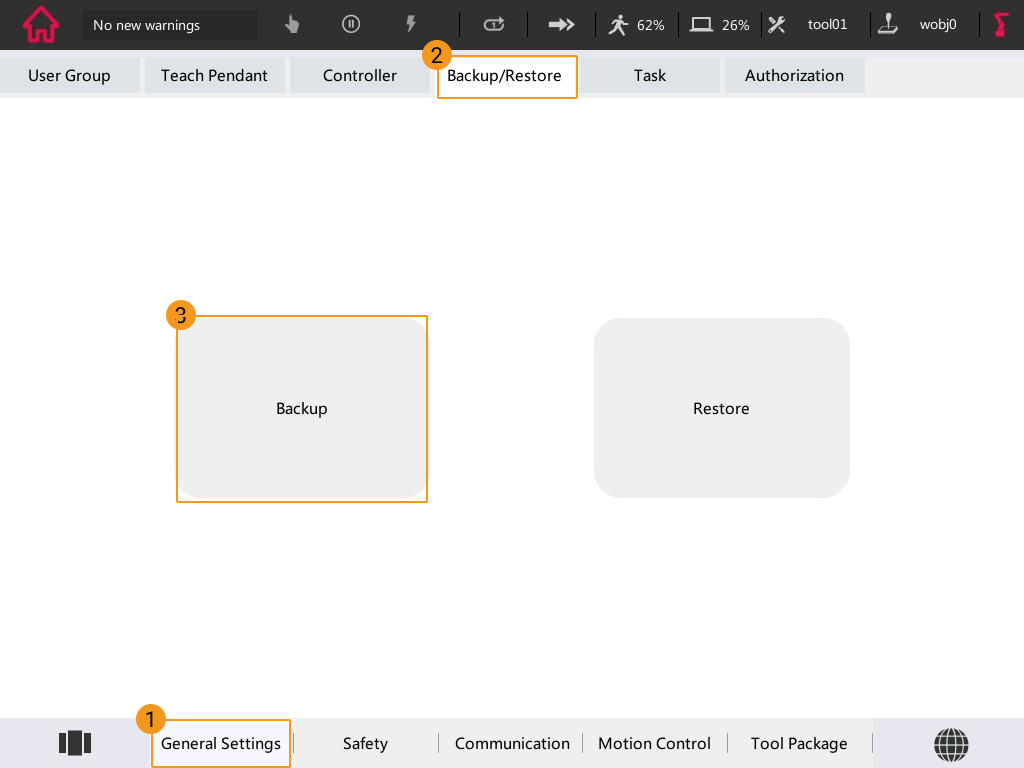

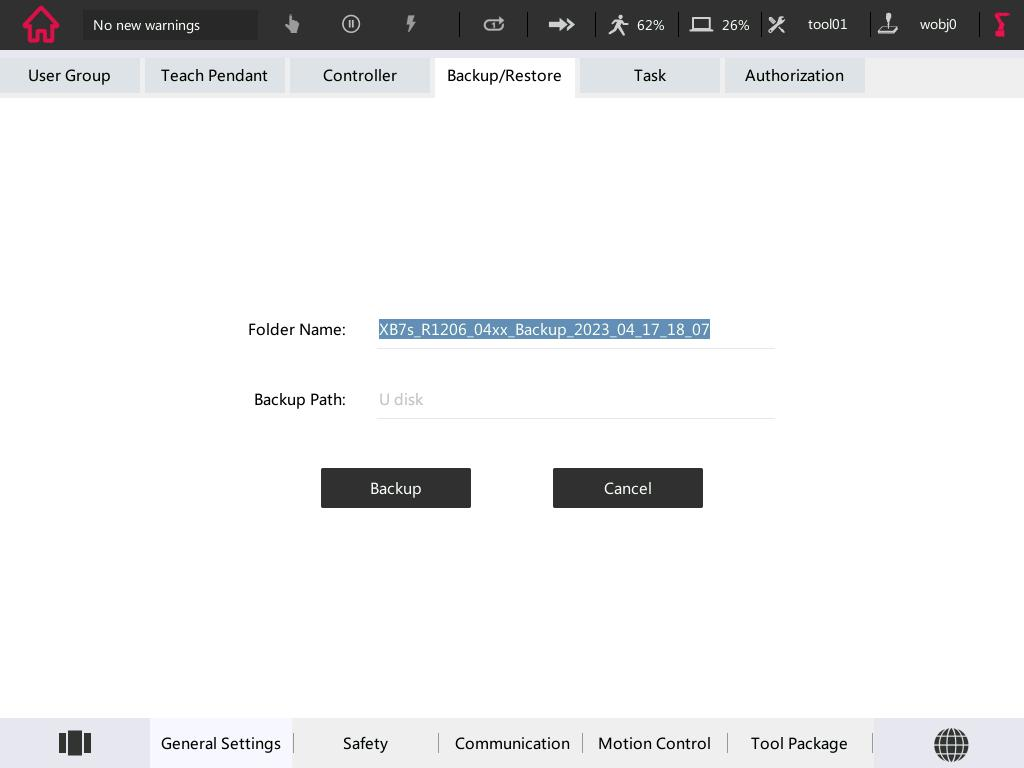

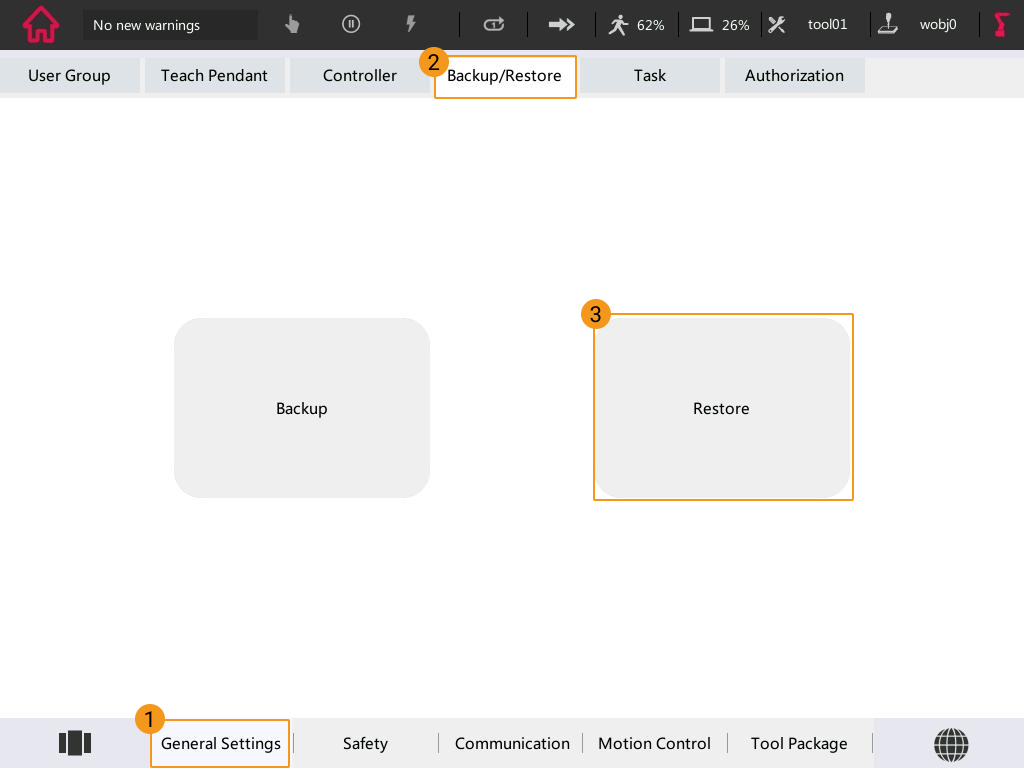

| It is recommended to back up robot system files before loading Master-Control program files to avoid system corruption that may be caused by the loading operation. In case any issue occurs, you can use the backup file to restore the robot system. Please refer to Backup and Restore Robot Files for detailed instructions. |

-

Plug the USB flash drive into the USB port of the IPC. Copy the MM_Project folder, which is stored in

Mech-Center/Robot_Interface/ROKAEin the installation directory of Mech-Mind Software Suite, to the USB flash drive and then remove the USB flash drive safely. -

Plug the USB flash drive with the program files into the USB port on the teach pendant.

-

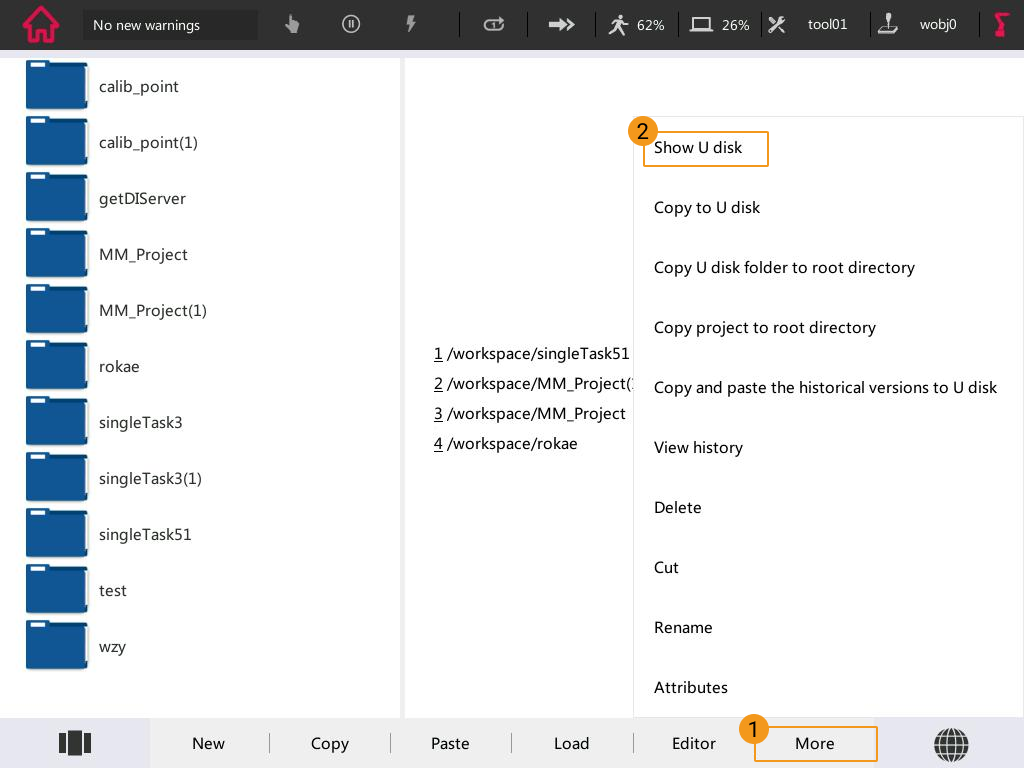

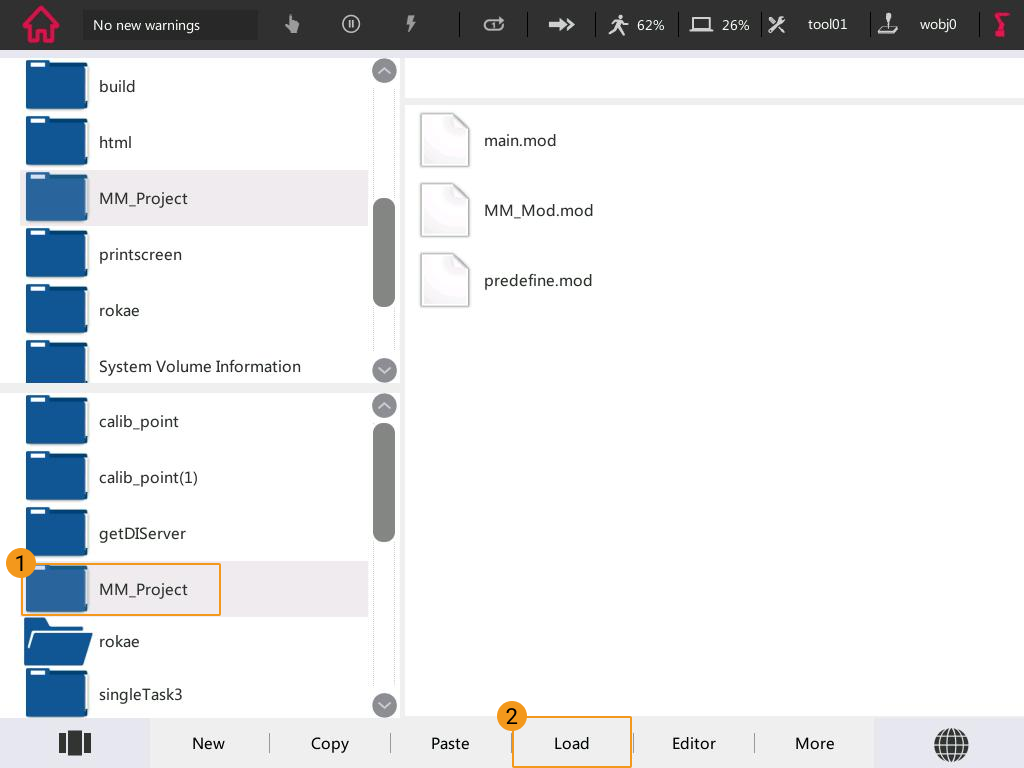

On the teach pendant, press the icon in the upper left corner, and then press Project.

-

Press Project Manager.

-

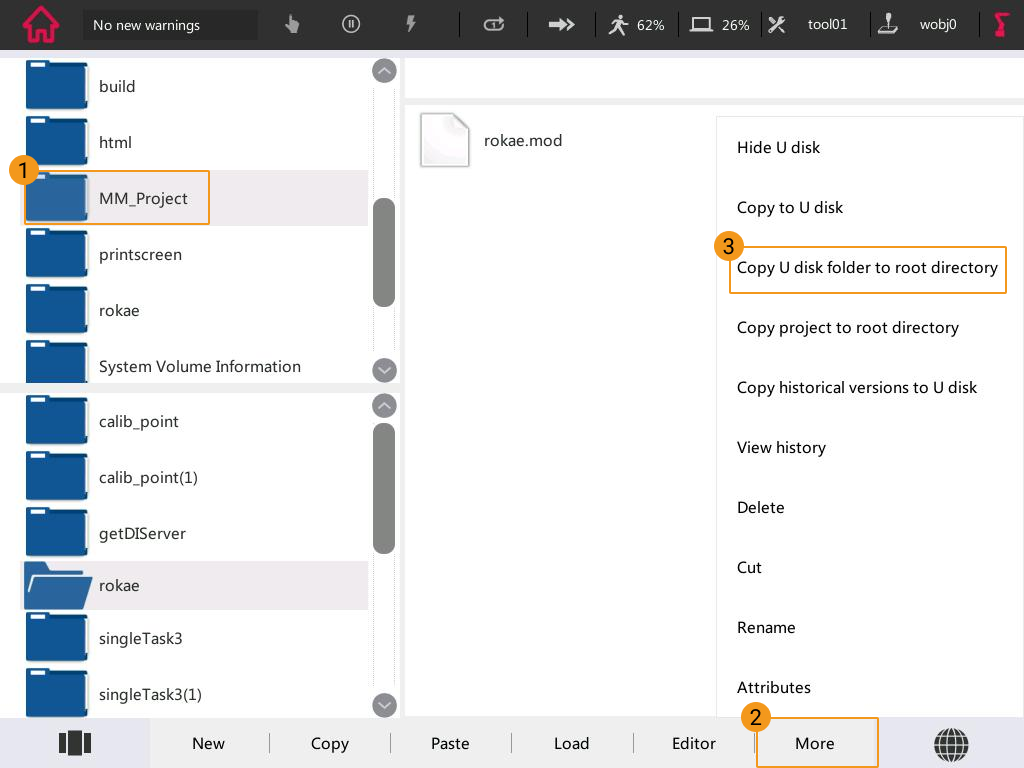

Press More and select Show U disk.

-

Select the MM_Project folder in the flash drive, press More, and select Copy U disk folder to root directory.

Once pasted successfully, the MM_Project folder can be found in the file browser at the bottom left.

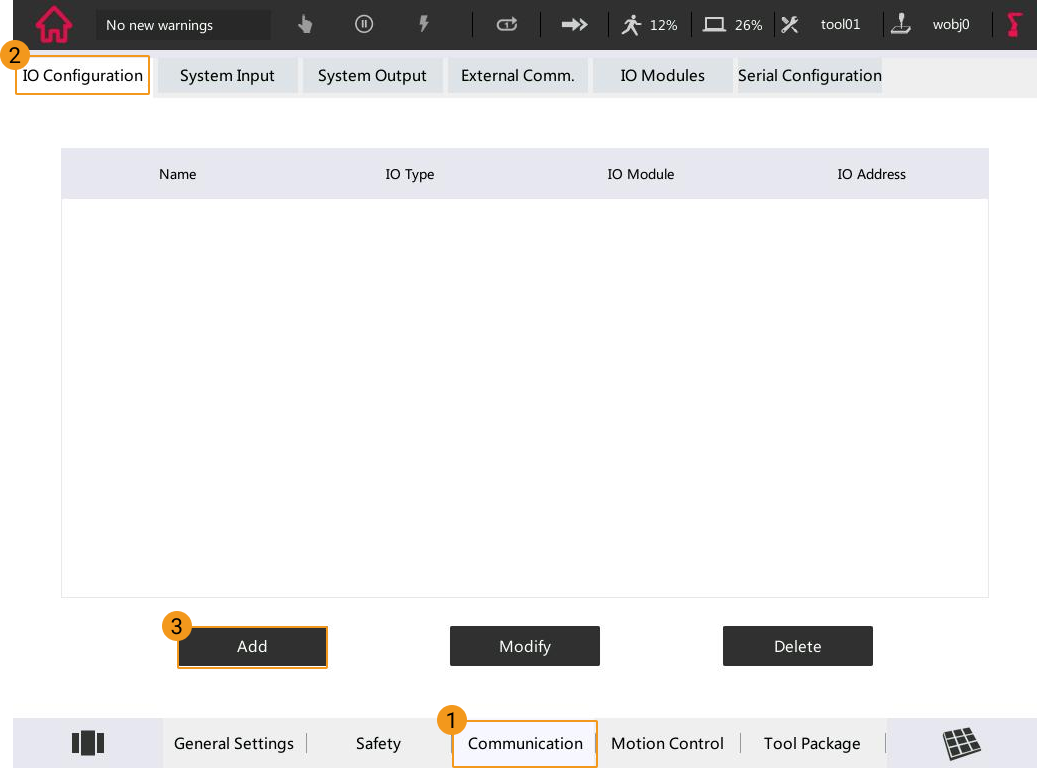

Configure Robot I/O

-

On the teach pendant, press the icon in the upper left corner, and then press Settings.

-

Press in turn.

-

Configure the options as shown in the figure below, and press OK.

Set up “Robot and Interface Configuration” in Mech-Vision

-

Click Robot and Interface Configuration on the toolbar of Mech-Vision.

-

Select Listed robot from the Select robot drop-down menu, and then click Select robot model. Select the robot model that you use, and then click Next.

-

Select Standard Interface for Interface Type, and TCP Server and ASCII for Protocol, and then click Apply.

-

Make sure the Interface Service is started: on the toolbar of Mech-Vision, the Interface Service switch on the far right is flipped and turned to blue.

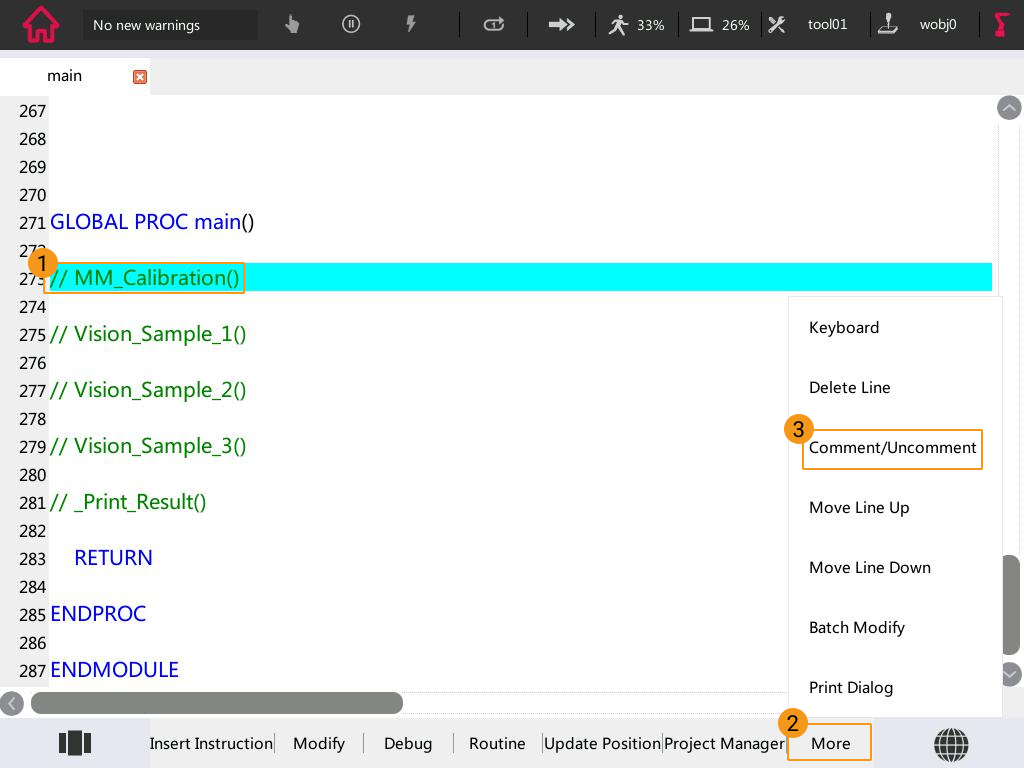

Test Standard Interface Communication

-

In the Project Manager window on the teach pendant, select the MM_Project folder and press Load.

-

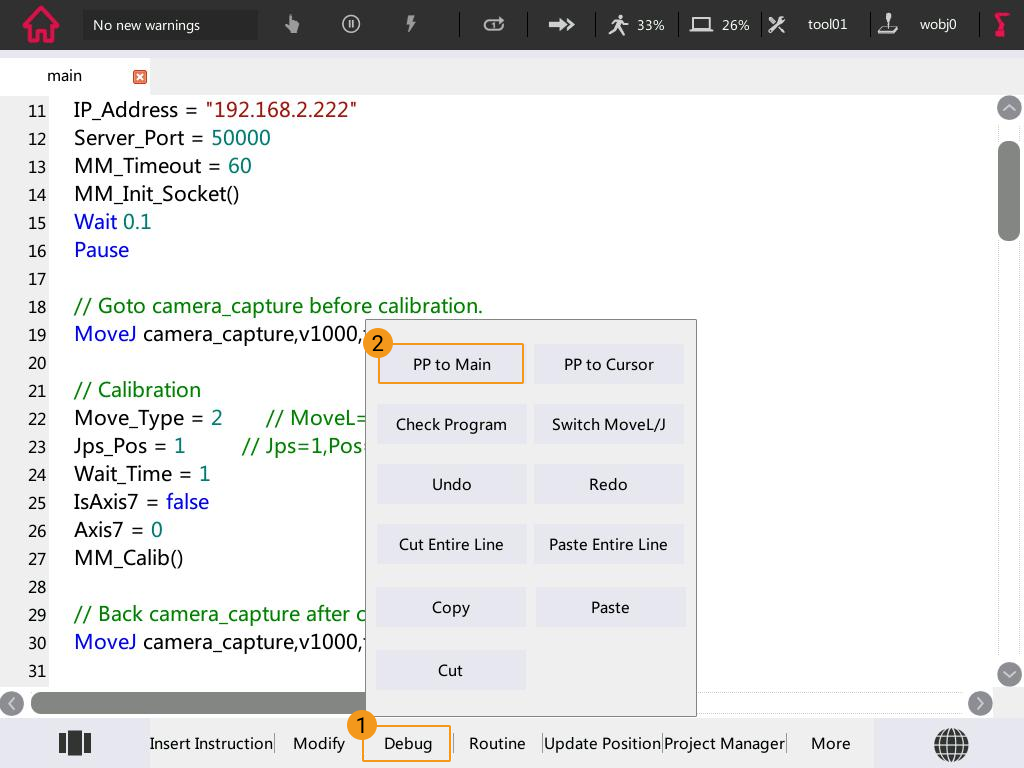

Select the “// MM_Calibration()” line, and press .

-

Then press .

-

Switch the manual mode to automatic mode. The figure below shows the teach pendant in the automatic mode.

Select Ok in the pop-up window as shown below.

-

Press the button on the controller as shown in the figure below. If the once-flashing indicator light turns to be always on, the servo is successfully turned on in the automatic mode.

-

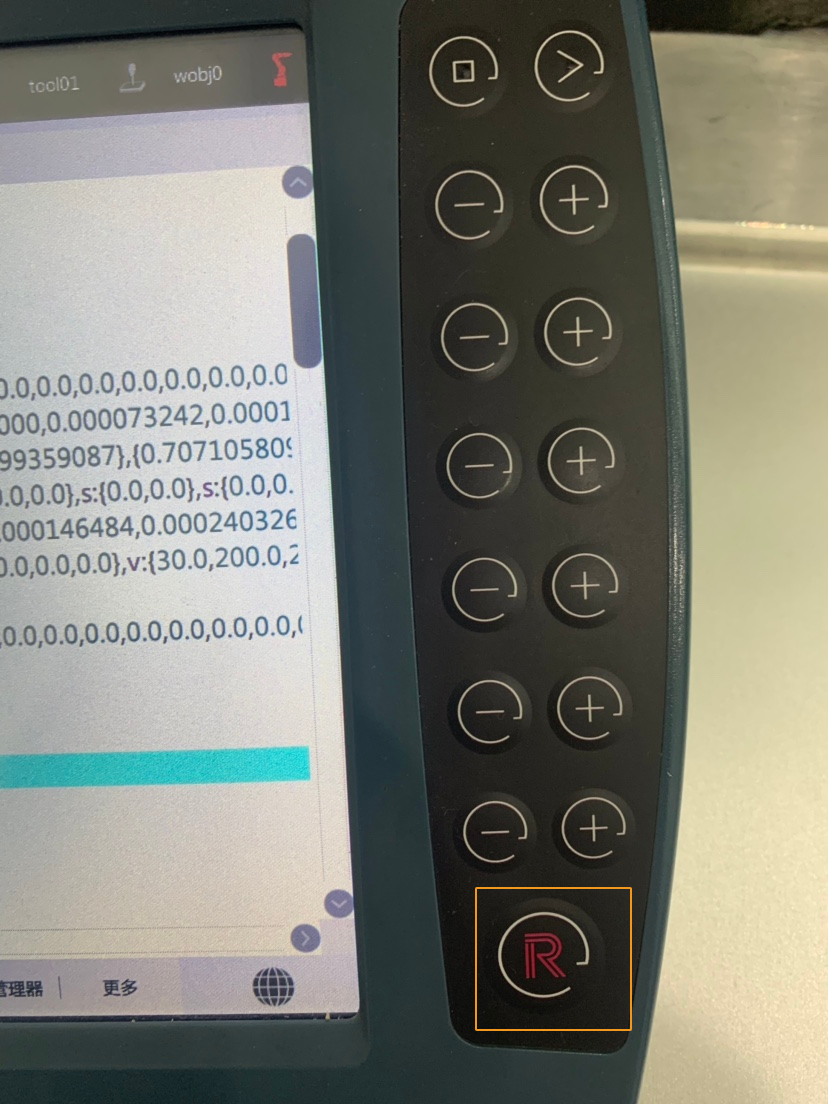

Press the R button in the lower right corner to power on the robot.

-

Press Debug and select PP to Main.

-

Click the icon as shown below to adjust the program’s running speed.

-

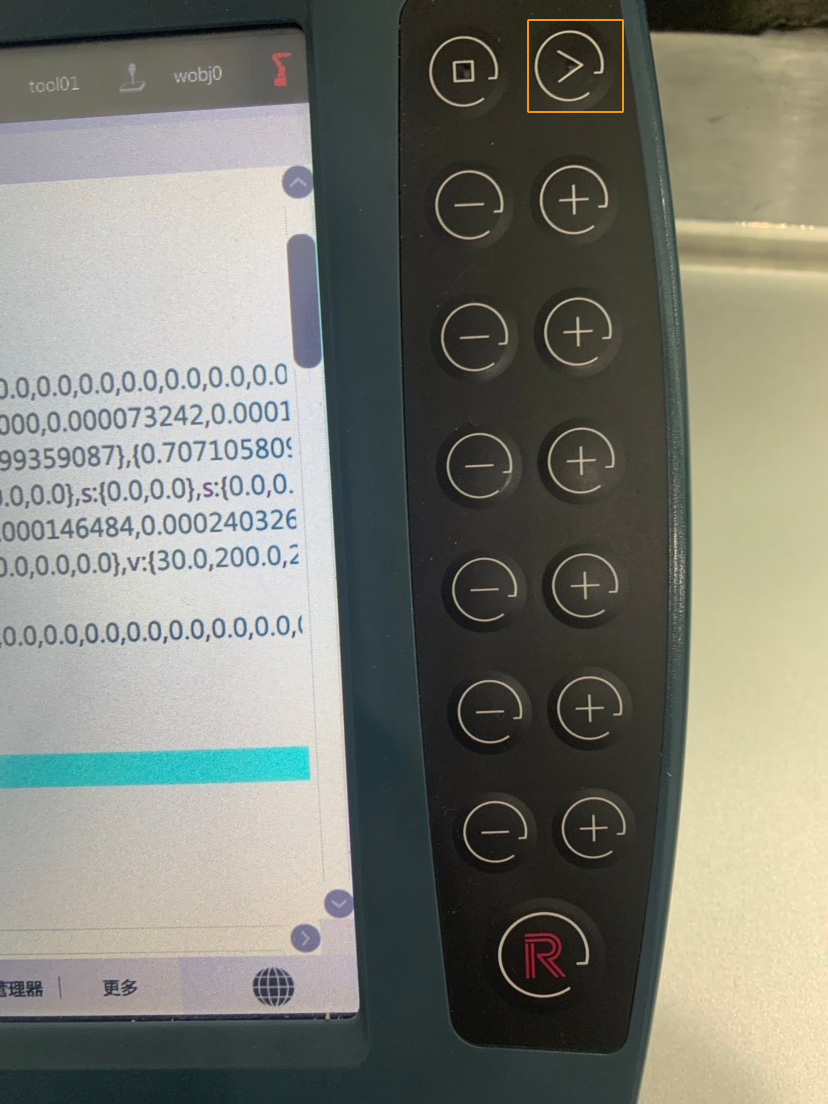

Press the button as shown below to run the program.

-

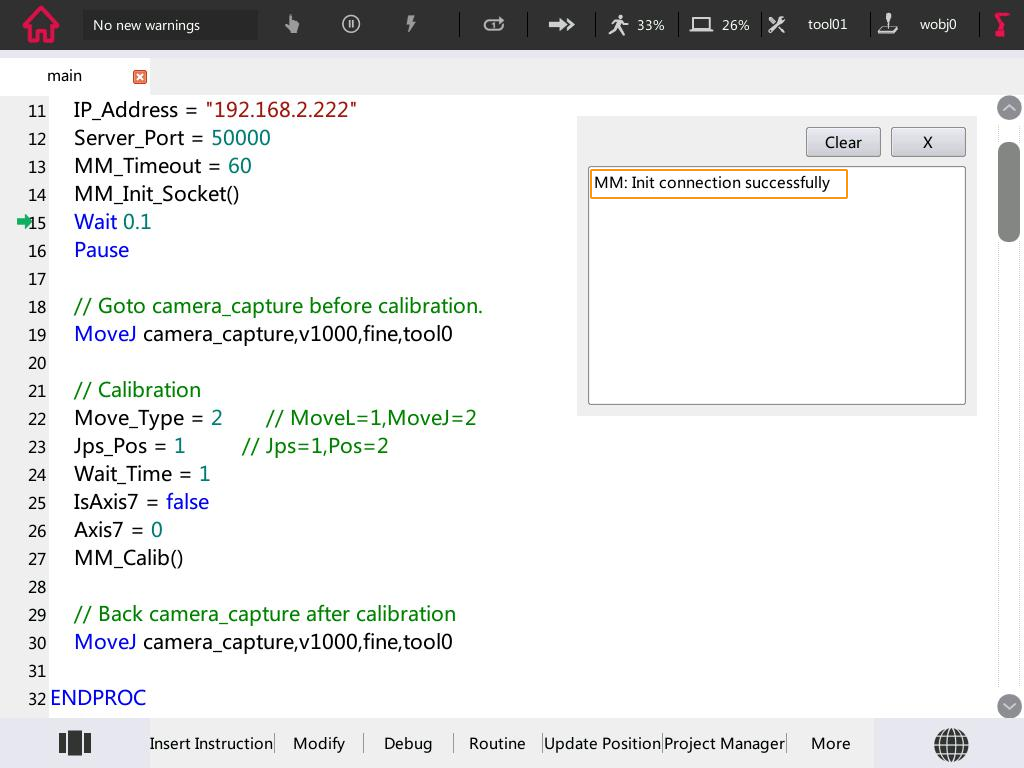

If the robot is connected successfully, a message saying MM:Init connection successfully shows on the teach pendant.