Introduction to Gripper Offset

This section introduces the concept of gripper offset, as well as its advantages and disadvantages.

Concept of Offset

Gripper offset refers to a type of gripper structure. The following will introduce two types of gripper offset.

-

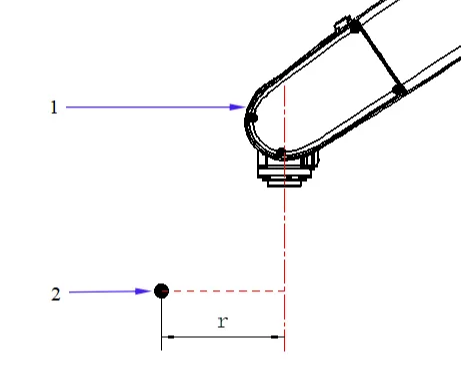

Horizontal offset of gripper

This involves adjusting the gripper’s position when picking the target object so that the gripper has a fixed horizontal distance (i.e. offset radius) from the robot flange pose. The figure below illustrates the offset radius “r” in the horizontal plane between point 1 (robot flange pose) and point 2 (the gripper’s pick point).

-

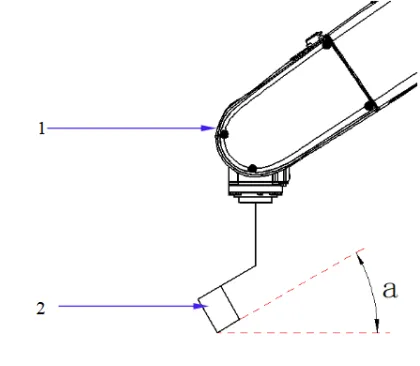

Angle offset of gripper

This involves adjusting the orientation or angle of the TCP when picking the target object. By rotating the TCP at a specific angle, the robot can reach objects that require a non-standard approach angle. The figure below illustrates the angle offset between point 1 (the robot) and point 2 (the gripper).

Advantages of Offset

Gripper offset helps optimize robot picking poses, avoid interferences, and improve flexibility and efficiency in complex situations by predefining position or angle differences in the design.

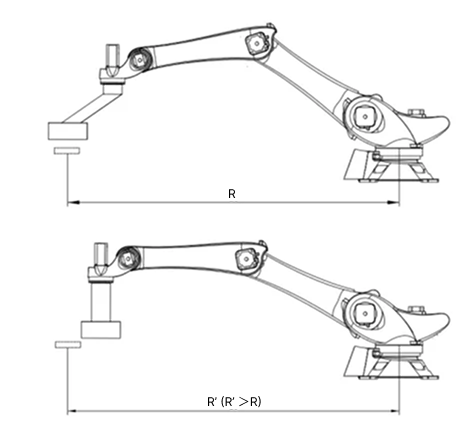

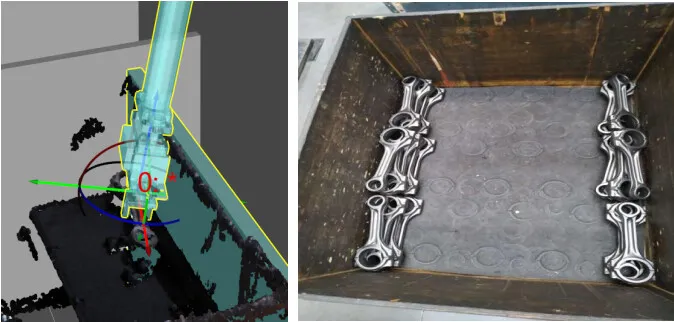

Avoid wrist singularity

In actual projects, target objects often come in various forms and poses. The gripper offset helps avoid singularities in picking.

In the figures above, the pick point has a horizontal distance from the robot flange pose.

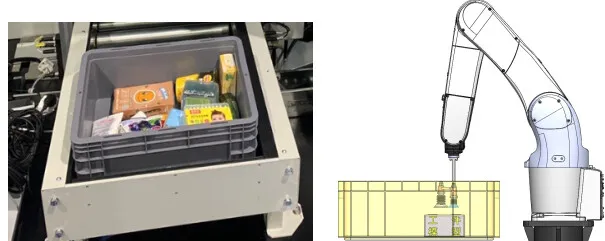

Increase bin clearance rate in limited space

The limited bin space, size or shape of the gripper, and position of the target object can pose challenges to picking, impacting the bin clearance rate. When a gripper without offset is used, it is prone to collide with surrounding scenes. The figures below show such a case.

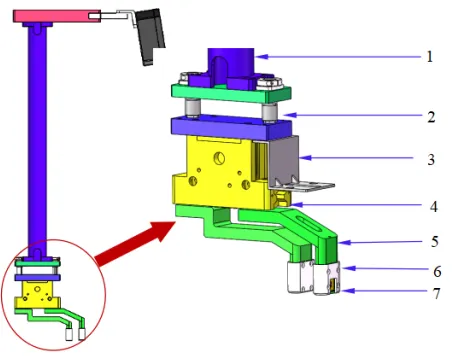

In this case, you should apply an offset to the gripper, corresponding to the green part in the figure below, to pick the objects in the corners. Parts in the figure: 1. Extension arm, 2. Buffering device, 3. Sensor mounting frame, 4. Pneumatic cylinder of gripper, 5. Finger gripper, 6. Gripper finger sleeve, 7. Sensor.

Disadvantages of Offset

When setting gripper offset, the following disadvantages should also be considered, and picking verification should be performed.

Robot available payload reduced

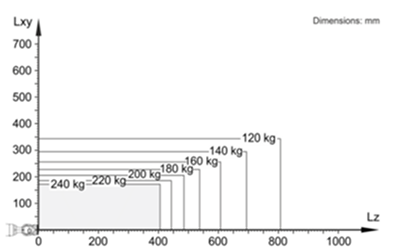

The actual available payload of the robot is subject to the load curve of the robot body and the gripper offset, and must be verified to ensure that the offset payload can meet the project’s picking requirements.

The figure below shows the change of the payload curve at the end of a robot. Lxy represents the offset along the X/Y-axis in the flange reference frame, and Lz represents the offset along the Z-axis in the flange reference frame.

When the offset is greater than 250 mm, the payload of the robot decays severely. However, if the offset is less than 170 mm and increases to 400 mm along the Z-axis, the payload can still be maintained.

Limited picking and placing of target objects with specific poses

In real scenarios, when the target object is not symmetrical 180° along the Z-axis and there is a requirement for the orientation of the target object, if the gripper has an offset, the target object picking and placing will be limited.

For example, in logistics outbound scenarios, cartons are often required to have their barcodes facing outward for manual scanning and picking. If the gripper must align a specific edge with a designated face of the carton, the robot may fail to complete the operation at the limits of its reachable range due to the gripper offset.

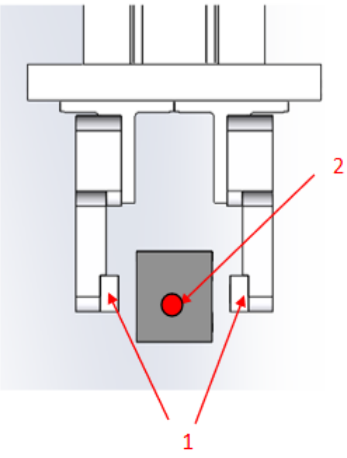

TCP difficult to determine during gripper clamping

The TCP at the gripper clamping point is located at the symmetry center between the two clamping blocks. It is difficult to set the TCP on the robot side after the gripper is offset.

As shown in the figure below, 1 is the gripper block, and 2 is the TCP at the gripper clamping point.