Check Intrinsic Parameters

This section describes how to check camera intrinsic parameters and quickly correct the intrinsic parameters.

Intrinsic Parameter Check Method

| Before checking the intrinsic parameters, refer to Calibration Board Selection and select the proper calibration board according to the camera model and the actual working distance. |

To use Intrinsic Parameter Tool to check intrinsic parameters of the camera, follow these steps.

-

In 1. Place calibration board and check image quality, check whether the 2D image and depth map satisfy the image requirements.

-

Place the calibration board within the camera’s FOV and ensure that it is within the recommended working distance of the camera and perpendicular to the camera’s central axis:

-

Click the Acquire images button to acquire the 2D image and depth map of the calibration board. Please ensure that the obtained 2D images and depth maps meet the following standards:

-

The circles on the calibration board are completely captured.

-

The overall calibration board in the 2D image should have balanced brightness, not too dark, too bright, or uneven. The calibration circles should be clear.

-

The calibration circles in the depth map should be intact.

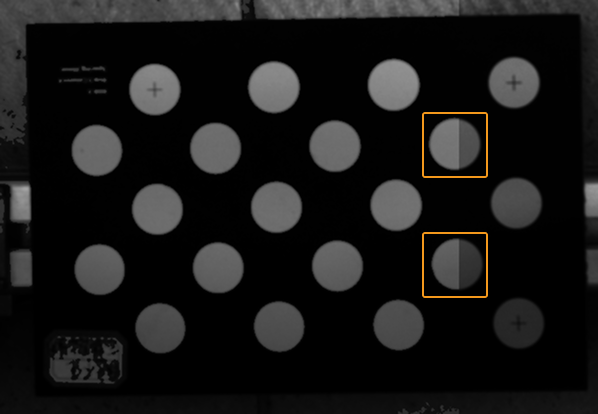

Examples of 2D images of the calibration board:

Image too dark, the circles on the calibration board cannot be easily discerned. Image brightness uneven, the circles on the calibration board cannot be easily discerned. Circles on the calibration board are complete, and circle boundaries are clearly visible. Image too bright, the circles on the calibration board cannot be easily discerned.

If the acquired 2D image does not satisfy the image requirements, refer to Adjust 2D And 3D Exposure Parameters During Calibration to adjust the parameters.

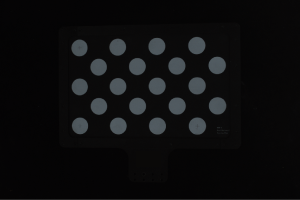

Examples of depth maps of the calibration board:

Exposure time too short, the circles on the calibration board are incomplete. Circles on the calibration board / the entire calibration board are complete. Exposure time too long, some or all the circles on the calibration board are lost.

If the acquired depth map does not satisfy the image requirements, refer to Adjust 2D And 3D Exposure Parameters During Calibration to adjust the 3D parameters.

For more information about parameter adjustment, see Parameter Reference Guide.

-

-

-

In 2. Select model of placed calibration board, set the specifications of the calibration board:

-

For standard calibration board, select Standard for Calibration board category, and choose the calibration board model according to the label on the calibration board.

-

For customized calibration board, select Customized for Calibration board category, choose the appropriate Calibration board type as shown in the illustration, and set the Rows, Columns, and Spacing.

-

-

In 3. Check and process intrinsic parameters, click Check intrinsic parameters to start checking intrinsic parameters of the camera. When the check is completed, a window of the check results will pop up.

Correct Intrinsic Parameters

This function can assist you in resolving the issue of large errors in the intrinsic parameters. It is recommended to use the intrinsic parameter correction feature in the following scenarios:

-

The scalar difference value in the intrinsic parameter check results exceeds the values in the table below.

-

The project has high precision requirements for the camera, and the current camera precision does not meet the actual needs.

| Model | Scalar difference value |

|---|---|

DEEP-GL |

0.6% |

LSR L-GL, LSR S-GL, Laser L Enhanced |

0.5% |

LSR XL-GL |

0.4% |

PRO M-GL, PRO S-GL, PRO XS-GL, NANO-GL, NANO ULTRA-GL |

0.3% |

|

If no abnormalities are found during the intrinsic parameter check, you can click the Start correcting intrinsic parameters button to correct intrinsic parameters on the Correct Intrinsic Parameters page.

Place Calibration Board

When using the Correct Intrinsic Parameters function, place the calibration board according to the following requirements:

-

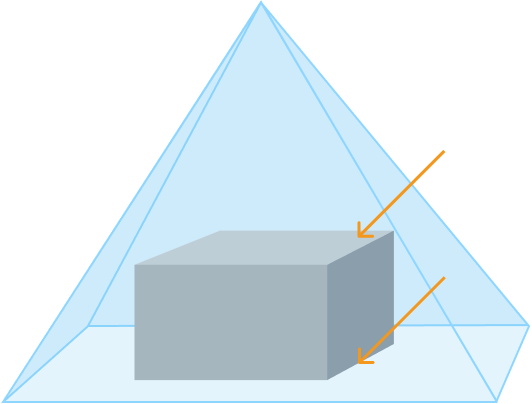

Ensure that the plane of the calibration board is as perpendicular as possible to the camera’s central axis:

-

Place the calibration board on the following two planes: the top surface of the target object (Plane 1) and the bottom surface (Plane 2). Ensure that the distance between the two planes is at least 100 mm.

For example, for bin-picking or (de)palletizing applications, the calibration board should be placed at the top and bottom of the bin or palletized load.

-

Ensure that the calibration board remains within the camera’s field of view.

This tool provides assistance to ensure that the calibration board remains within the camera’s field of view. Follow these steps to use the tool:

-

Click the Start acquisition images button and move the calibration board to different positions on the current plane, and the 2D image and depth map of the calibration board will refresh at a fixed frequency (approximately once every 5 seconds).

-

If both the 2D image and depth map are complete, it indicates that the position is within the camera’s field of view. If either the 2D image or depth map is missing, it indicates that the position may be outside the camera’s field of view.

-

After confirming the camera’s field of view on the current plane, click the Stop acquisition images button. Then, refer to the next section and add the data from the current plane.

-

After adding the data from the current plane, refer to this process and continue adding data from the other plane.

-

The start/stop acquisition images button and other buttons on this page cannot be used at the same time.

-

Acquire and Validate Data

The calibration board must be moved on two planes (Plane 1 and Plane 2) and click the Acquire data button to acquire data of the calibration board in different positions. The data validated is considered valid. The validation standards are as follows:

| Validation item | Validation value |

|---|---|

Minimum area coverage |

25% |

Minimum length coverage |

50% |

Minimum width coverage |

50% |

Minimum data sets |

3 |

When acquiring data on two planes, the following requirements must be met:

-

First acquire the data from Plane 1, and then acquire the data from Plane 2.

-

When there is data from Plane 2, the data from Plane 1 cannot be modified.

-

After the data from both planes has been acquired and validated, click the Correct Intrinsic Parameters button to start the intrinsic parameter correction.

| You can use the Areas covered by acquired data below to assist in adjusting the position of the calibration board, ensuring that the acquired data passes validation. |

After the acquired data from both Plane 1 and Plane 2 pass validation, you can click the Correct Intrinsic Parameters button to start the intrinsic parameter correction. If an error message is displayed during data acquisition and adding, refer to the next section for troubleshooting.

If the intrinsic parameter correction is successful, click the Update intrinsic parameters button in the Correct Intrinsic Parameters Result popup window to apply the corrected intrinsic parameters and improve the camera accuracy.

If the intrinsic parameter correction fails, refer to the instructions in the popup window for troubleshooting.