Picking and Placing

In this tutorial, you will first learn about the picking and placing process in this example, and then learn how to configure it.

Picking and Placing Process

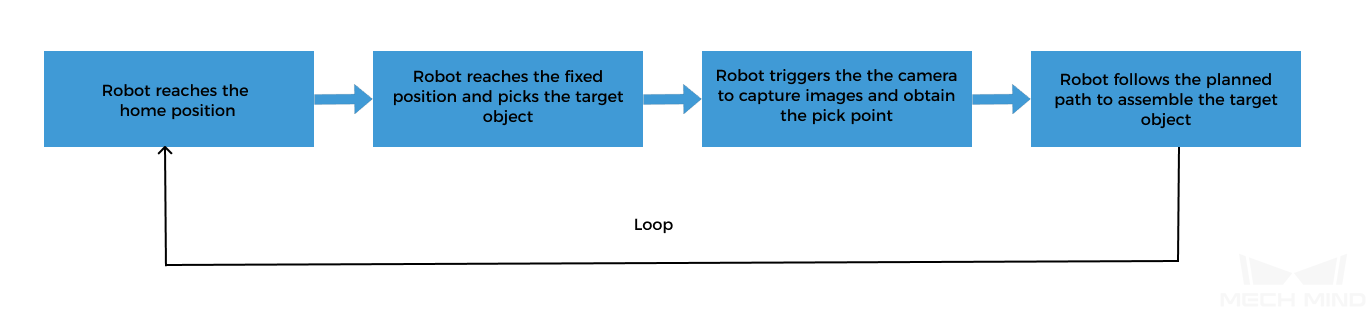

The picking and placing logic in this example is shown in the figure below.

| In this example, the robot picks the bolts from a fixed position, such as a positioning platform, and then uses the pick points output by Mech-Vision as targets for assembly. |

Communication Solution Description

In the above process, the step “robot triggers the camera to capture images and obtain the pick point” requires the robot to use the Standard Interface to communicate with the vision system, and the Standard Interface “uses Mech-Vision to obtain the vision result” from the vision system.

When using this method, you need to write the robot program. Please refer to Configuring the Picking and Placing Process to write the robot program.

Configure the Picking and Placing Process

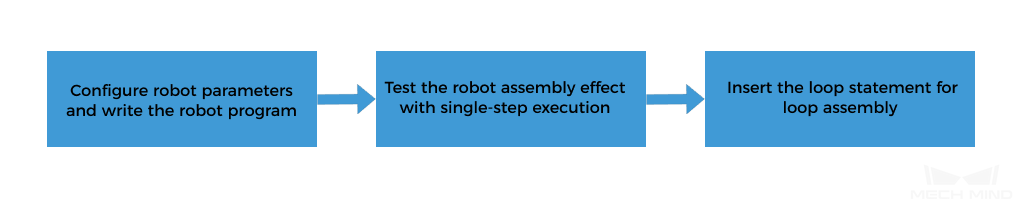

To realize the logical flow of picking and placing, you need to complete the following configurations:

Configure Robot Parameters and Write the Robot Program

YASKAWA’s Standard Interface example program MM_S1_Vis_Basic can basically satisfy the requirements of this example. You can modify the example program. For a detailed explanation of the MM_S1_Vis_Basic program, please refer to the Example Program Explanation.

Based on the example program, please complete the following steps on the robot side:

-

Teach the home position (initial position).

Move the robot to the initial position in the TEACH mode. The initial position should be away from the objects to be picked and surrounding devices, and should not block the camera’s field of view. Record the current robot pose to variable C00000.

-

Specify the IP address of the IPC. Update the IP address and port of the MM_Init_Socket command to those of the IPC.

Before modification After modification (example) 'initialize communication 'parameters (initialization is 'required only once) CALL JOB:MM_INIT_SOCKET ARGF"192.168.170.22;50000;1"

'initialize communication 'parameters (initialization is 'required only once) CALL JOB:MM_INIT_SOCKET ARGF"192.168.10.40;50000;1"

-

Set the DO port signal to expand the gripper. Note that the DO command should be set according to the actual DO port number in use on site.

'open gripper DOUT OT#(14) ON DOUT OT#(15) OFF

-

Teach the fixed pick point.

Move the robot to the pick point in the TEACH mode. This position is also where the camera captures images. At this position, the robot arm should not block the camera’s FOV. Record the current robot pose to variable C00001.

Before modification After modification (example) 'move to image-capturing position MOVJ C00001 VJ=50.00 PL=0

'move to fixed position of picking MOVJ C00001 VJ=20.00 PL=0

-

Set the signal for the DO port to close the gripper to pick the bolt on the fixed position. Note that the DO command should be set according to the actual DO port number in use on site.

'close gripper DOUT OT#(14) OFF DOUT OT#(15) ON

-

Teach the intermediate point in the assembly process.

Before modification After modification (example) 'move to intermediate waypoint of 'picking MOVJ C00002 VJ=50.00

'move to intermediate waypoint of 'assembly MOVJ C00002 VJ=50.00

-

Modify the comments of assembly-related commands.

Before modification After modification (example) 'move to approach waypoint of 'picking SFTON P070 MOVL P071 V=166.6 PL=0 SFTOF 'move to picking waypoint MOVL P071 V=50.0 PL=0 ... 'move to departure waypoint of 'picking SFTON P070 MOVL P071 V=166.6 PL=0 SFTOF

'move to approach waypoint of 'assembly SFTON P070 MOVL P071 V=166.6 PL=0 SFTOF 'move to assembly waypoint MOVL P071 V=50.0 PL=0 ... 'move to departure waypoint of 'assembly SFTON P070 MOVL P071 V=166.6 PL=0 SFTOF

-

Set the DO port signal to expand the gripper to place the bolt into the pin hole. Note that the DO command should be set according to the actual DO port number in use on site.

Before modification After modification (example) 'add object grasping logic here, 'such as DOUT OT#(1) ON PAUSE

'add object releasing logic here, 'such as DOUT OT#(1) ON DOUT OT#(15) OFF DOUT OT#(14) ON PAUSE

-

Remove the placing-related code in the example program.

'move to intermediate waypoint of 'placing MOVJ C00003 VJ=50.00 'move to approach waypoint of 'placing MOVL C00004 V=166.6 PL=0 'move to placing waypoint MOVL C00005 V=50.0 PL=0 'add object releasing logic here, 'such as DOUT OT#(1) OFF PAUSE 'move to departure waypoint of 'placing MOVL C00006 V=166.6 PL=0

-

Teach the home position.

Move the robot to the home position in the TEACH mode and record the robot pose to variable C00003.

Test the Robot Assembly Effect with Single-Step Execution

Follow these steps to test the robot assembly effect:

-

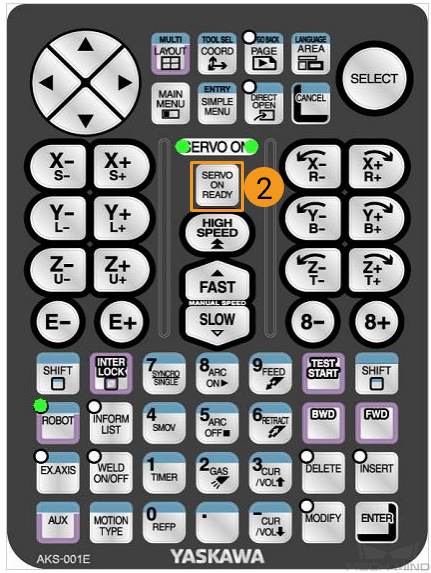

Twist the mode key on the teach pendant to PLAY to enter the REPEAT mode.

-

Press the SERVO ON READY key on the teach pendant, and then press the blue Run button.

-

The robot will automatically run the program to pick and place a target object.

Please pay close attention to the robot’s motion trajectory. In an emergency, press the emergency stop key.

If the robot can successfully pick and place target objects, the robot program meets the requirements.

Insert the Loop Statement for the Assembly Cycle

After testing that the robot can successfully assemble once, you can insert a loop statement in the program to loop the robot assembly.

Add the following loop statement:

LOOP 'move to fixed position of picking MOVJ C00001 VJ=20.00 PL=0 ... MOVJ C00003 VJ=50.00 END LOOP

Reference: Modified Example Program

The final example program is as follows:

NOP

'--------------------------------

'FUNCTION: trigger Mech-Vision

'project and get vision result

'Mech-Mind, 2023-12-25

'--------------------------------

'clear I50 to I69

CLEAR I050 20

'initialize p variables

SUB P070 P070

SUB P071 P071

'set 100mm to z of P070

SETE P070 (3) 100000

'move to robot home position

MOVJ C00000 VJ=50.00

'initialize communication

'parameters (initialization is

'required only once)

CALL JOB:MM_INIT_SOCKET ARGF"192.168.10.40;50000;1"

'open gripper

DOUT OT#(14) ON

DOUT OT#(15) OFF

LOOP

'move to fixed position of picking

MOVJ C00001 VJ=20.00 PL=0

'close gripper

DOUT OT#(14) OFF

DOUT OT#(15) ON

'open socket connection

CALL JOB:MM_OPEN_SOCKET

MOVL P110 V=25.0

'trigger NO.1 Mech-Vision project

CALL JOB:MM_START_VIS ARGF"1;0;2;30"

'get vision result from NO.1

'Mech-Vision project

CALL JOB:MM_GET_VISDATA ARGF"1;51;52"

'check whether vision result has

'been got from Mech-Vision

'successfully

IFTHENEXP I052<>1100

'add error handling logic here

'according to different error

'codes

'e.g.: I052=1003 means no point

'cloud in ROI

'e.g.: I052=1002 means no

'vision result

PAUSE

ENDIF

'close socket connection

CALL JOB:MM_CLOSE_SOCKET

'save first vision point data to

'local variables

CALL JOB:MM_GET_POSE ARGF"1;71;61;62"

'move to intermediate waypoint of

'assembly

MOVJ C00002 VJ=50.00

'move to approach waypoint of

'assembly

SFTON P070

MOVL P071 V=166.6 PL=0

SFTOF

'move to assembly waypoint

MOVL P071 V=50.0 PL=0

'add object releasing logic here,

'such as DOUT OT#(1) ON

DOUT OT#(15) OFF

DOUT OT#(14) ON

PAUSE

'move to departure waypoint of

'assembly

SFTON P070

MOVL P071 V=166.6 PL=0

SFTOF

'move back to robot home position

MOVJ C00003 VJ=50.00’move to fixed position of picking

MOVJ C00001 VJ=20.00 PL=0

'close gripper

DOUT OT#(14) OFF

DOUT OT#(15) ON

'open socket connection

CALL JOB:MM_OPEN_SOCKET

MOVL P110 V=25.0

'trigger NO.1 Mech-Vision project

CALL JOB:MM_START_VIS ARGF"1;0;2;30"

'get vision result from NO.1

'Mech-Vision project

CALL JOB:MM_GET_VISDATA ARGF"1;51;52"

'check whether vision result has

'been got from Mech-Vision

'successfully

IFTHENEXP I052<>1100

'add error handling logic here

'according to different error

'codes

'e.g.: I052=1003 means no point

'cloud in ROI

'e.g.: I052=1002 means no

'vision result

PAUSE

ENDIF

'close socket connection

CALL JOB:MM_CLOSE_SOCKET

'save first vision point data to

'local variables

CALL JOB:MM_GET_POSE ARGF"1;71;61;62"

'move to intermediate waypoint of

'assembly

MOVJ C00002 VJ=50.00

'move to approach waypoint of

'assembly

SFTON P070

MOVL P071 V=166.6 PL=0

SFTOF

'move to assembly waypoint

MOVL P071 V=50.0 PL=0

'add object releasing logic here,

'such as DOUT OT#(1) ON

DOUT OT#(15) OFF

DOUT OT#(14) ON

PAUSE

'move to departure waypoint of

'assembly

SFTON P070

MOVL P071 V=166.6 PL=0

SFTOF

'move back to robot home position

MOVJ C00003 VJ=50.00

END LOOP

ENDNow you have deployed a 3D vision–guided positioning and assembly application.