Master-Control Communication Setup

This guide shows you how to set up Master-Control communication with a KUKA robot.

Preparation

Check Controller and Software Compatibility

-

Controller model: KUKA KR C4, C5

-

Controller system software version: KSS 8.2, 8.3, 8.5 or 8.6

-

Add-on software package: Ethernet KRL (V 2.2.8, 3.0.3 or 3.1.2.29)

The correspondence between KSS and Ethernet KRL versions is as follows:

| KSS version | Ethernet KRL version |

|---|---|

8.2 or 8.3 |

2.2.8 |

8.5 |

3.0.3 |

8.6 |

3.1.2.29 |

All teach pendant actions in this chapter are performed on KSS 8.6.

Set up the Network Connection

Set the IP Address

-

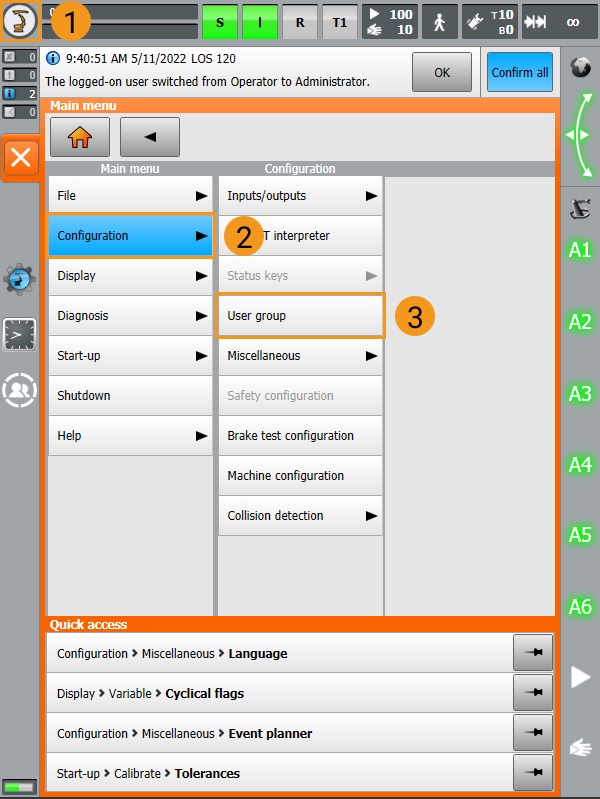

Switch to the Expert mode:

-

Click

, and then select to enter the log-on interface.

, and then select to enter the log-on interface.

-

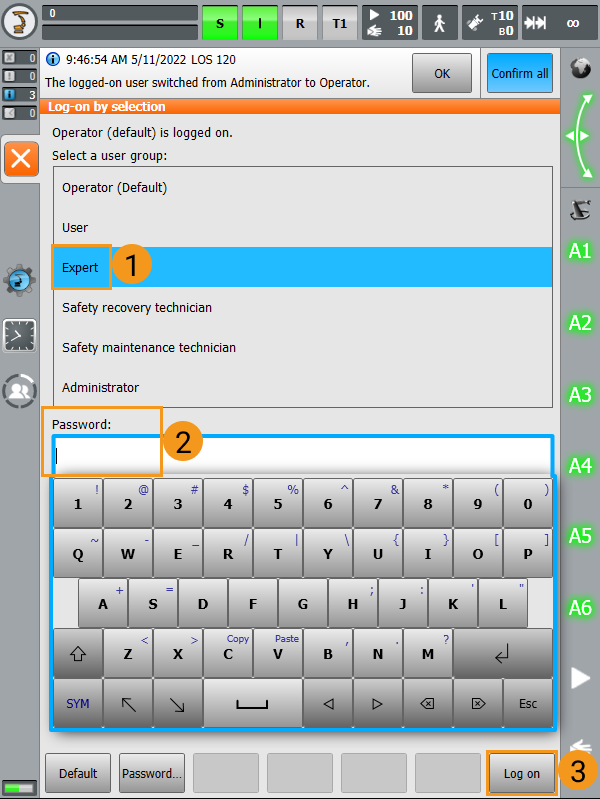

Select Expert, enter the password (the default password is kuka), and click Log on.

-

-

Set the IP address:

-

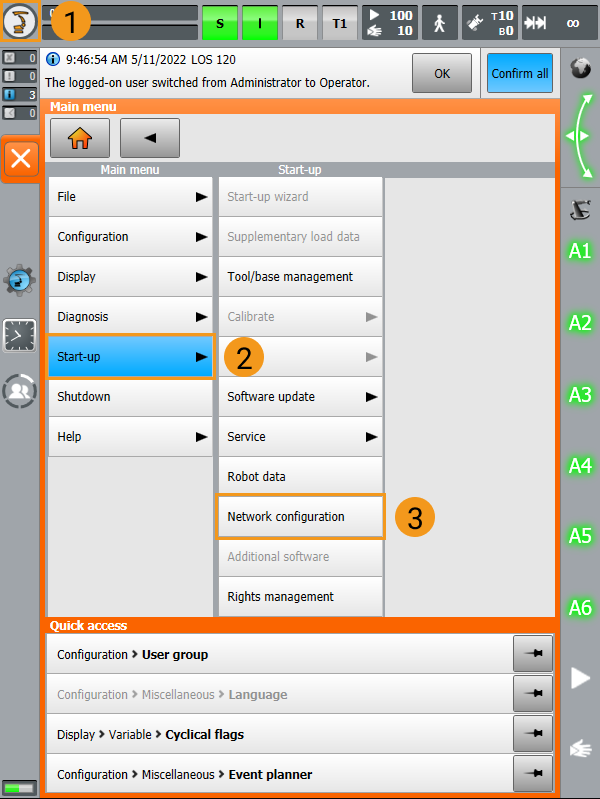

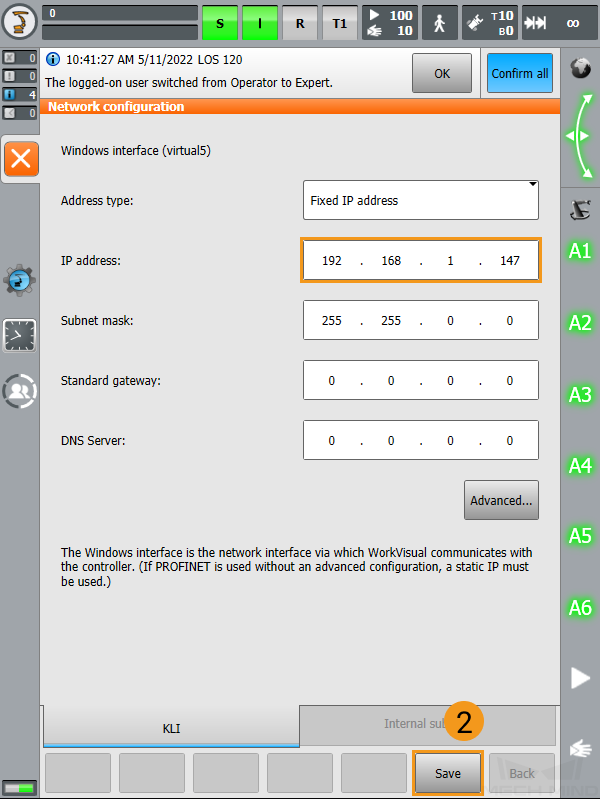

Click

, and then select to enter the network configuration interface.

, and then select to enter the network configuration interface.

-

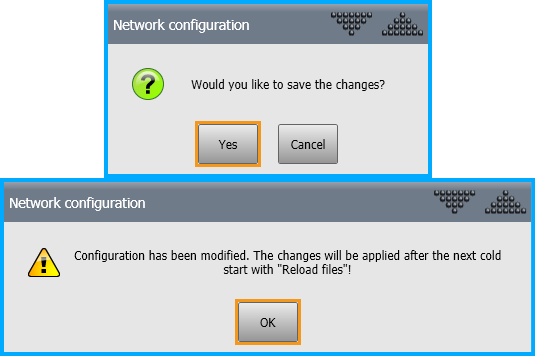

Input an IP address in the same subnet as that of the IPC, and then click Save. Click Yes and OK, respectively, in the next two pop-up windows.

-

-

Restart the robot controller to finish setting the IP address:

-

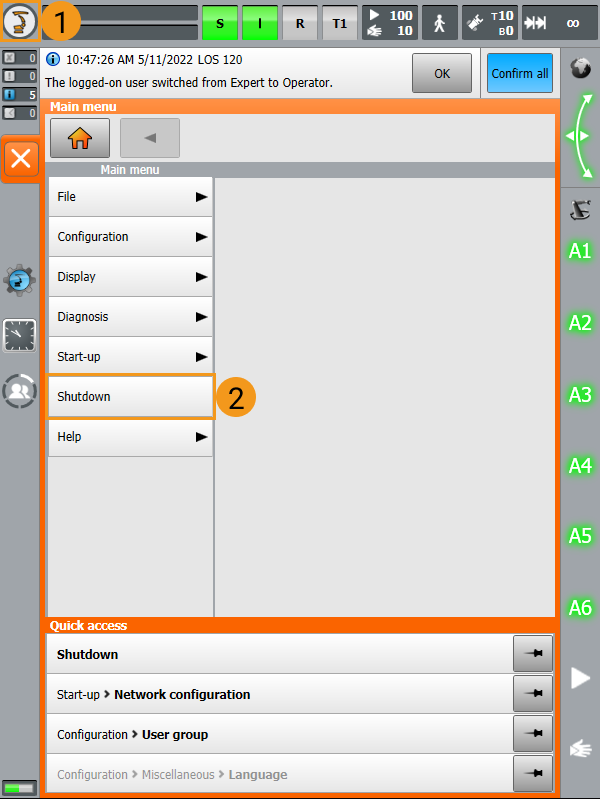

Click

, and select Shutdown to enter the shutdown interface.

, and select Shutdown to enter the shutdown interface.

-

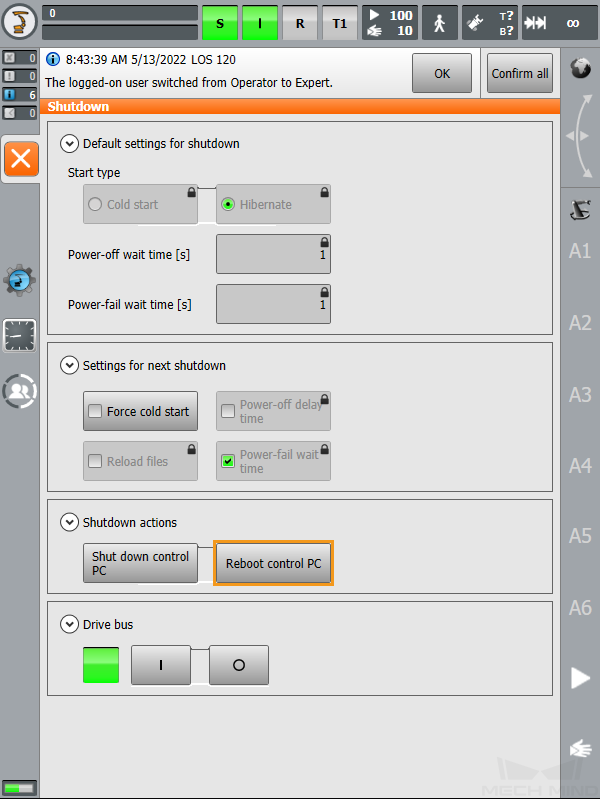

Click Reboot control PC in the shutdown interface.

-

Load the Program Files to the Robot

Back up the Robot Program

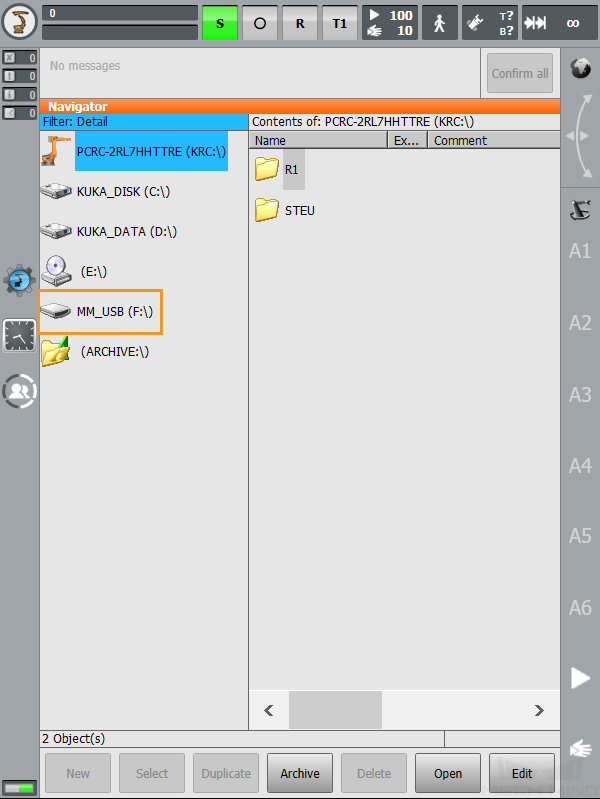

| Make sure you have switched to the expert mode. Otherwise, the flash drive will not show up on the teach pendant. |

-

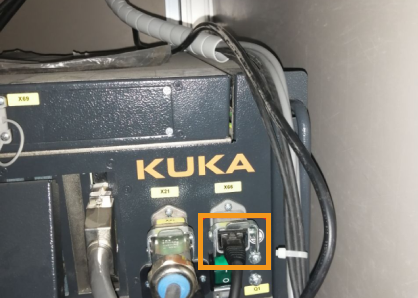

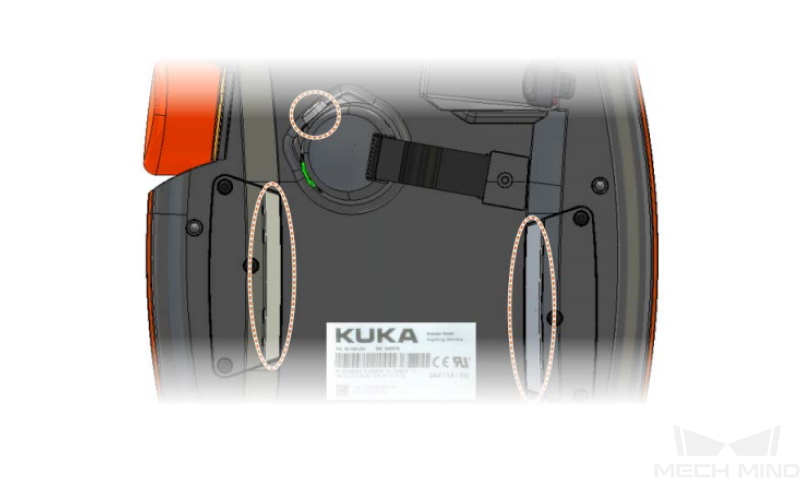

Plug the flash drive storing the backup file into the controller, and make sure that the flash drive shows up on the teach pendant.

-

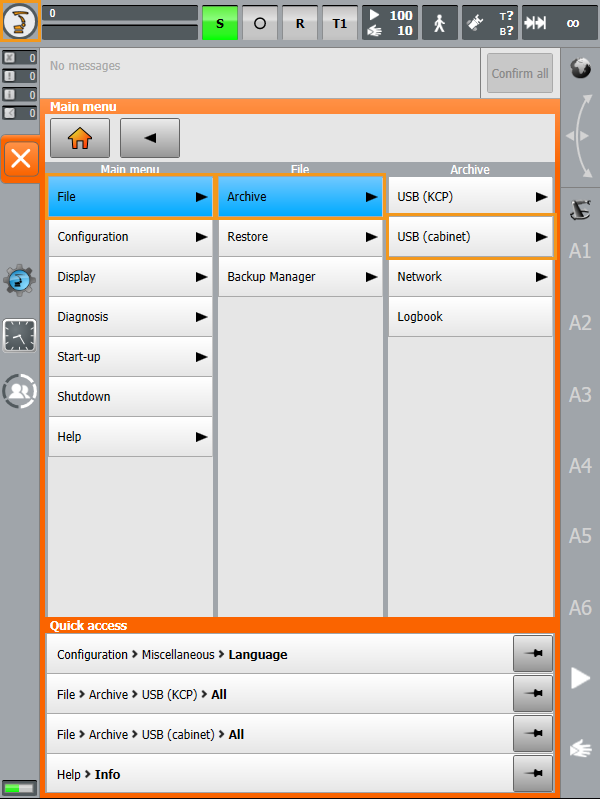

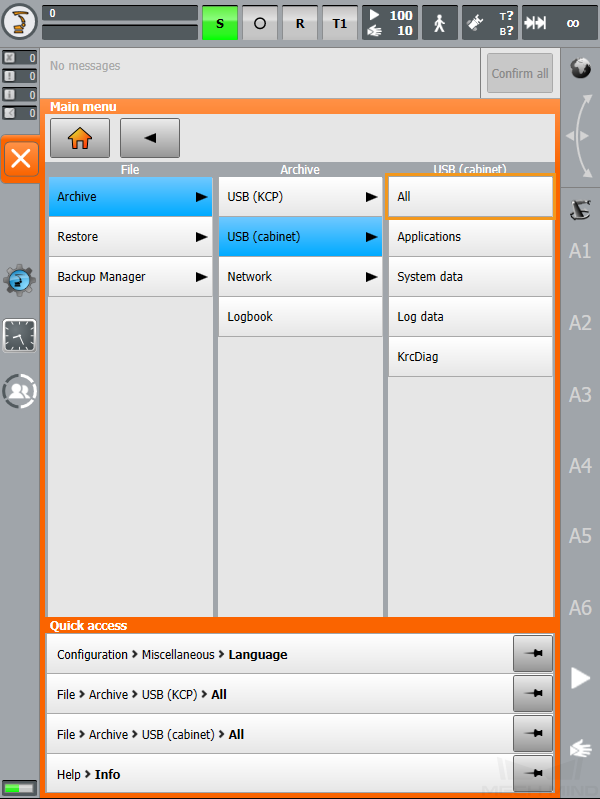

Click

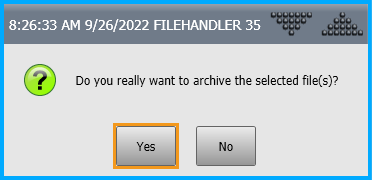

, select , and click Yes in the pop-up window to start the backup process.

, select , and click Yes in the pop-up window to start the backup process.

-

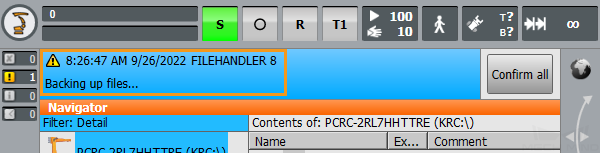

The following message is displayed when backup is in process. Once the backup is completed, this message disappears, and a ZIP file is created in the flash drive. Lastly, remove the flash drive.

Prepare the Files

-

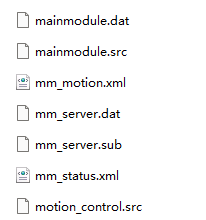

Navigate to

Mech-Center/Robot_Server/Robot_FullControl/kuka/kuka_newfrom the installation directory where Mech-Vision and Mech-Viz are installed. Copy all program files and paste them to your flash drive.

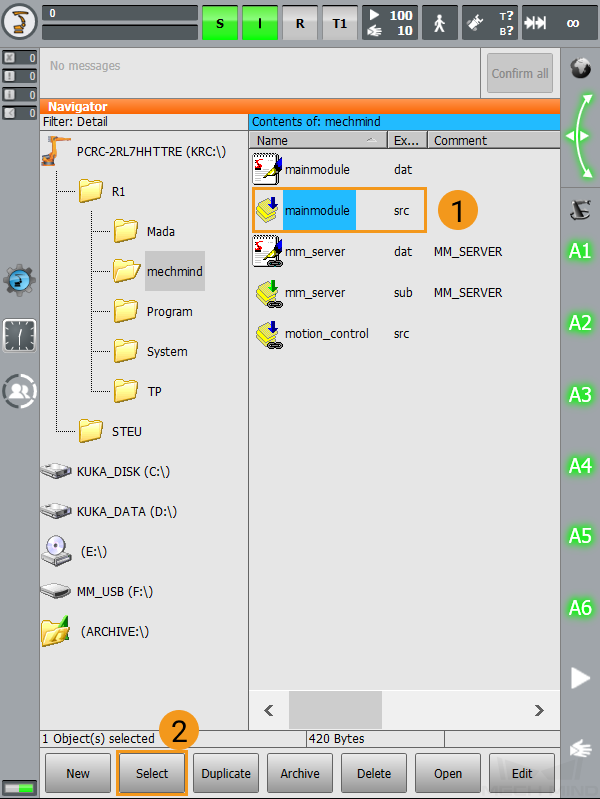

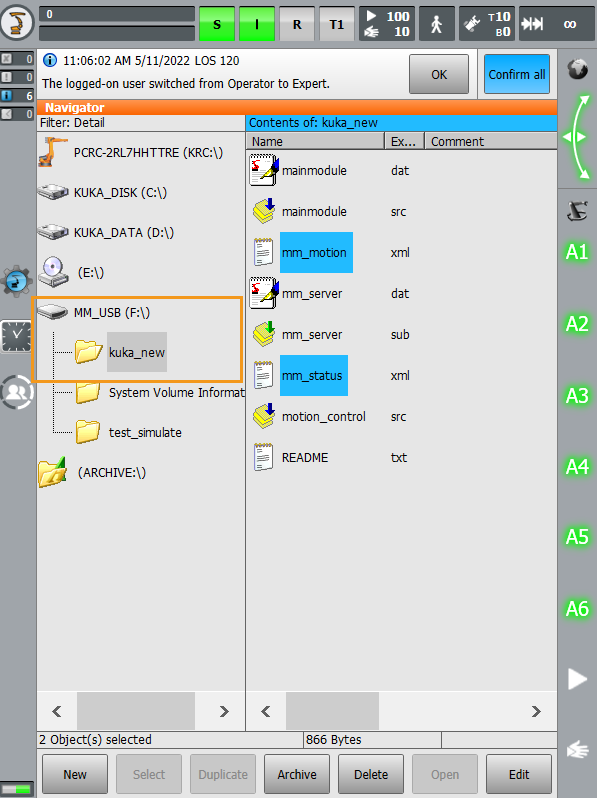

Make sure you have switched to the expert mode. Otherwise, the flash drive will not show up on the teach pendant. -

Plug the flash drive into the controller. Click the flash drive on the left side, and locate the folder which contains the program files.

-

Select the mm_motion file, click Edit, and then click Copy in the pop-up menu bar.

-

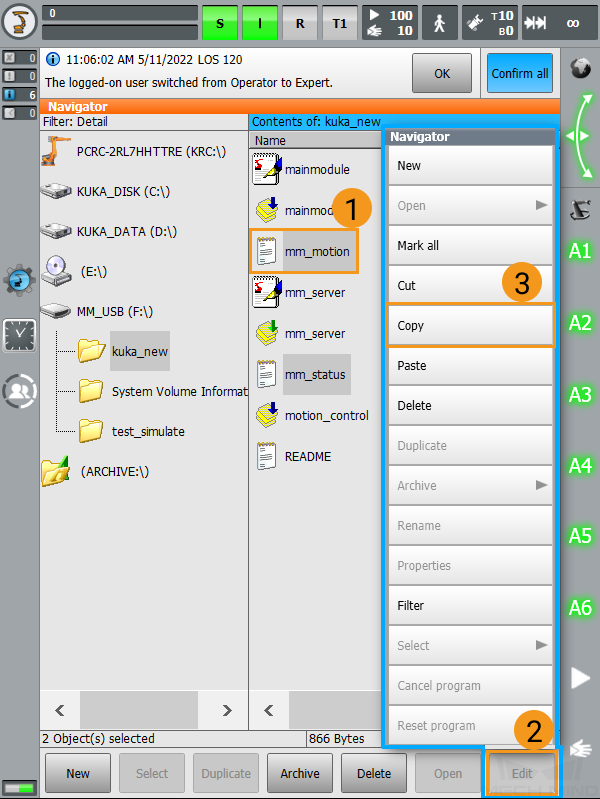

Navigate to

C:\\KRC\\ROBOTER\\Config\\User\\Common\\EthernetKRL, click Edit, and then select Paste in the pop-up menu bar. Repeat the above operation to copy the mm_status file to the target folder.

-

Refer to the above procedures to copy and paste the other five files to the mechmind folder in the R1 folder (Create one if there is no mechmind folder).

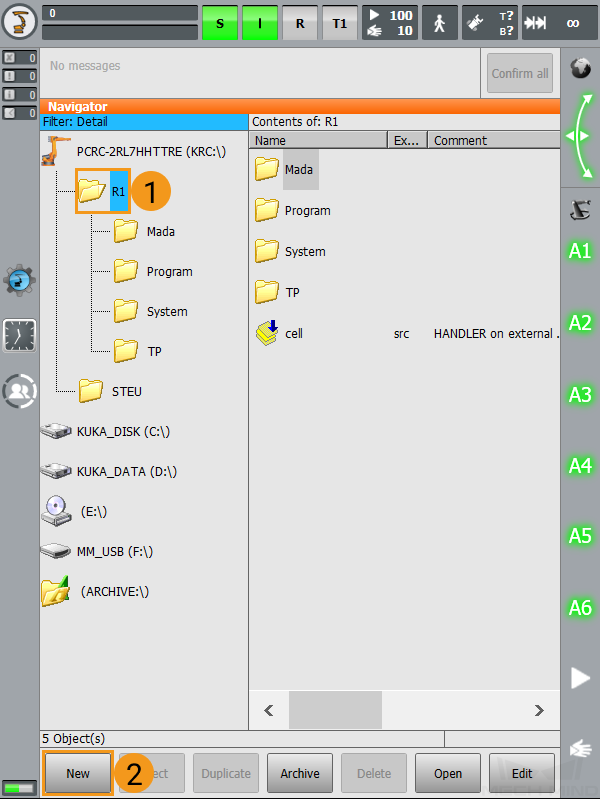

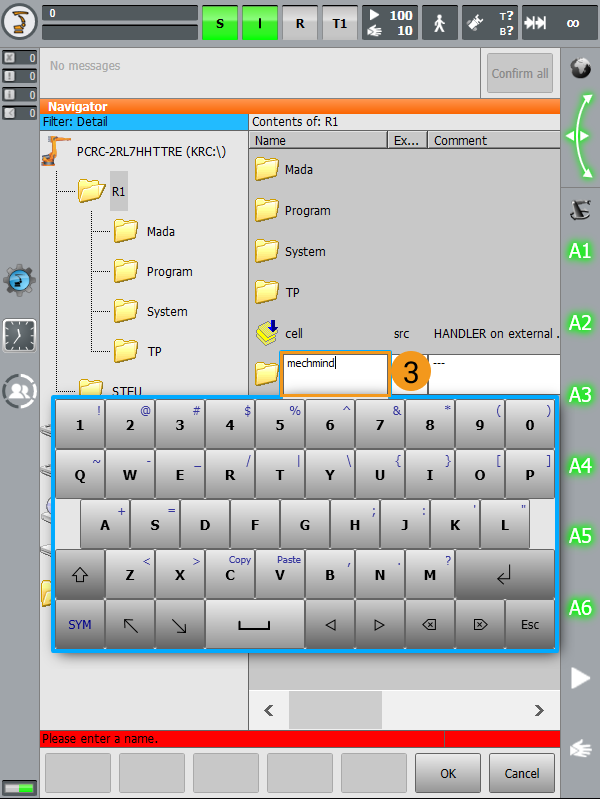

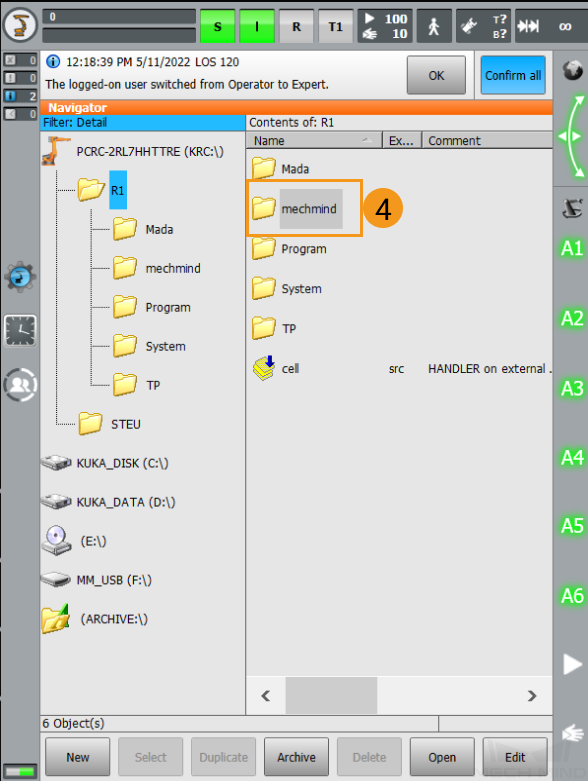

Long-press and drag to select multiple adjacent files. Create the mechmind folder:

Click the R1 folder, and then click New.

Input mechmind for the folder name, and click OK.

Test Master-Control Communication

Select Program

Set Autostart for Background Program

Switch to the expert mode referring to the above subject.

-

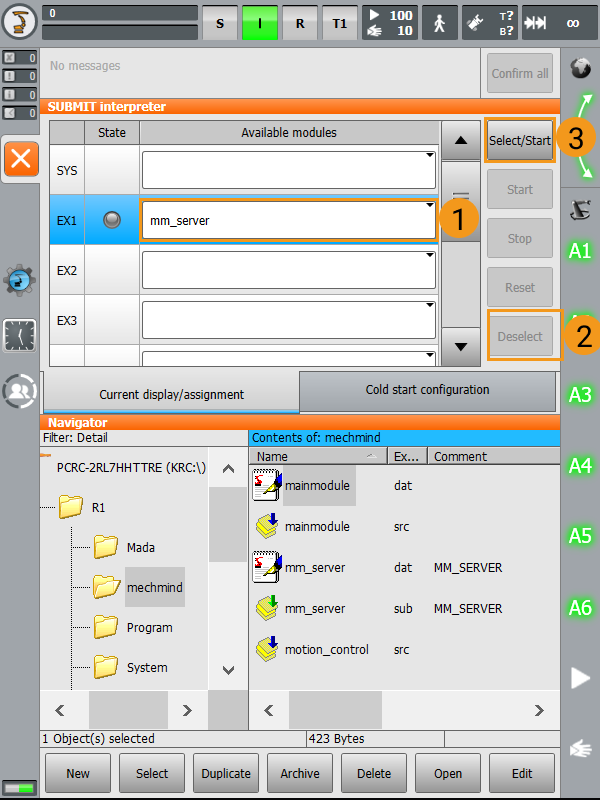

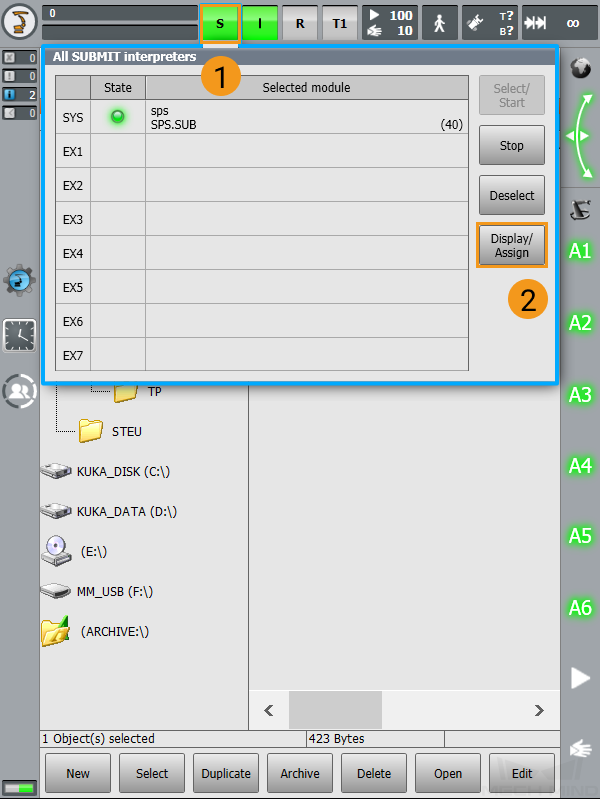

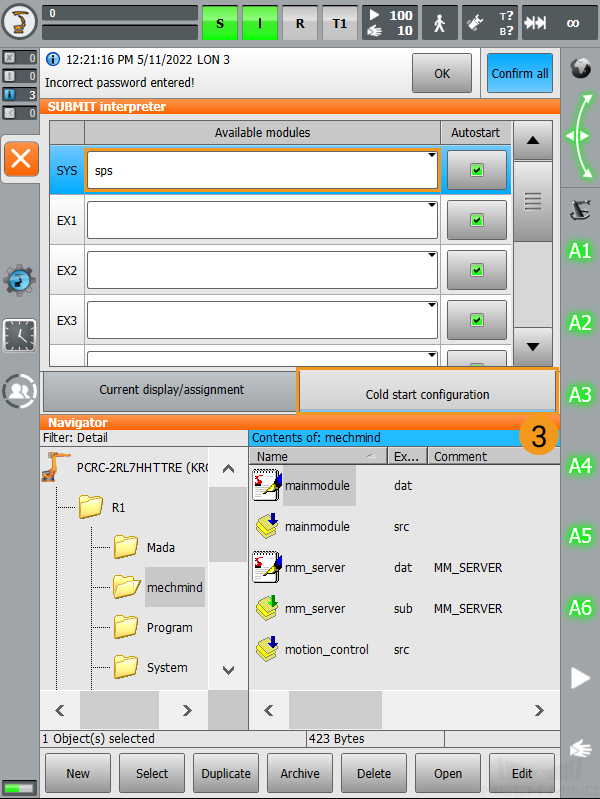

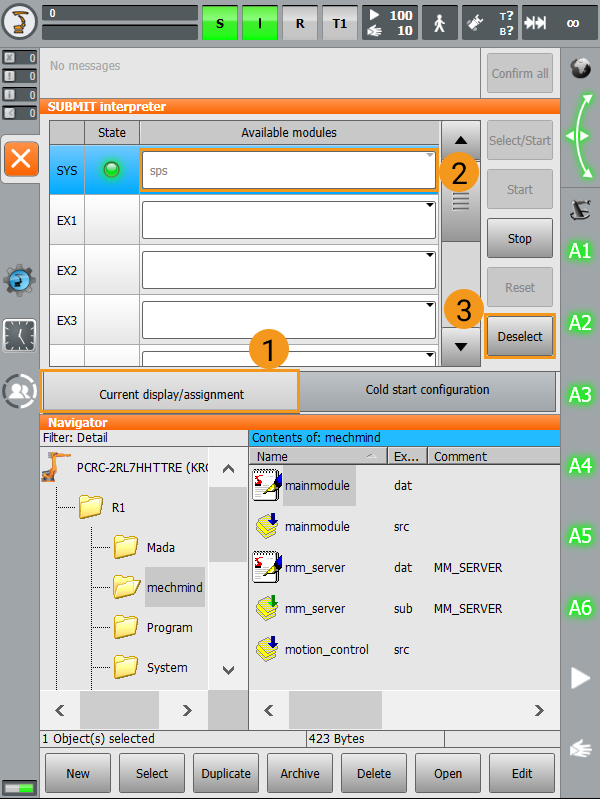

Click S on the teach pendant and then click Display/Assign.

-

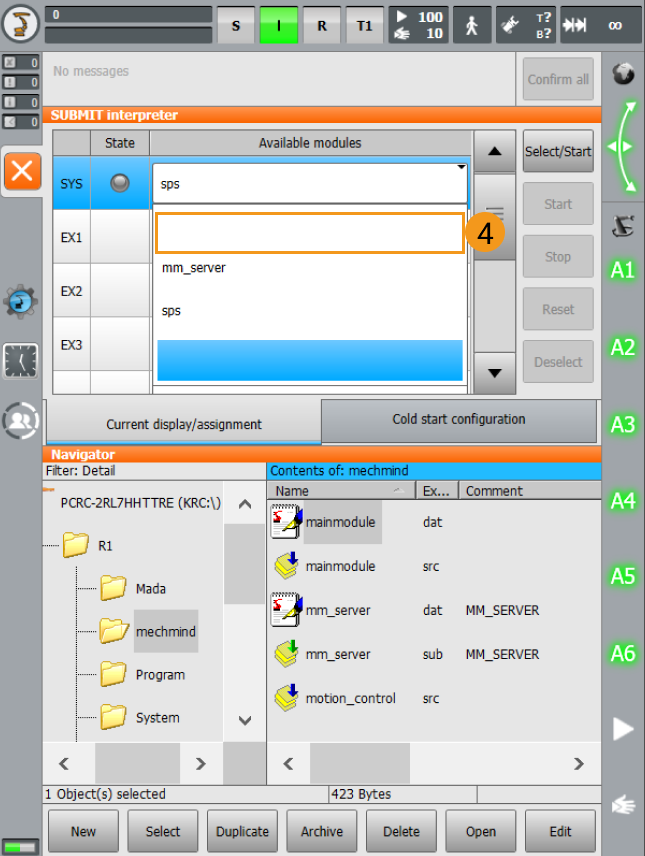

Click Cold start configuration to jump to the Cold start configuration interface.

-

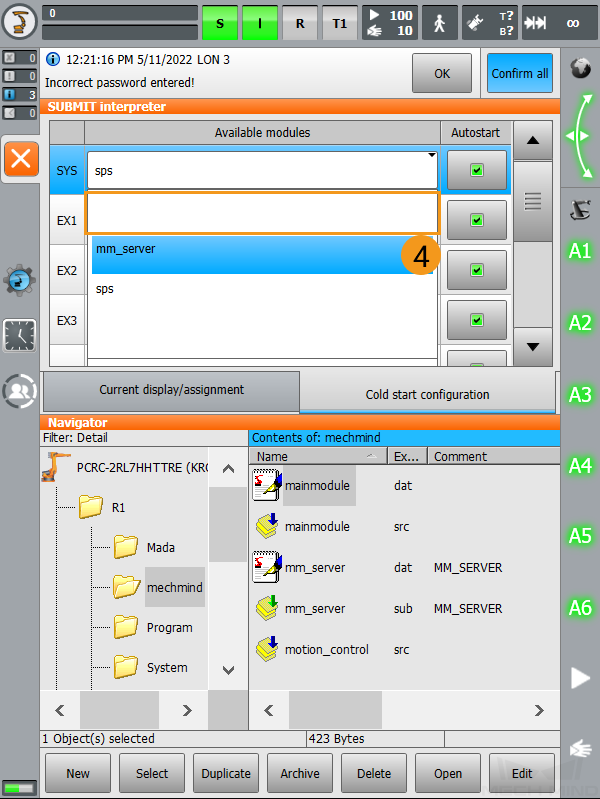

Click the blank in the drop-down menu on the right of SYS.

-

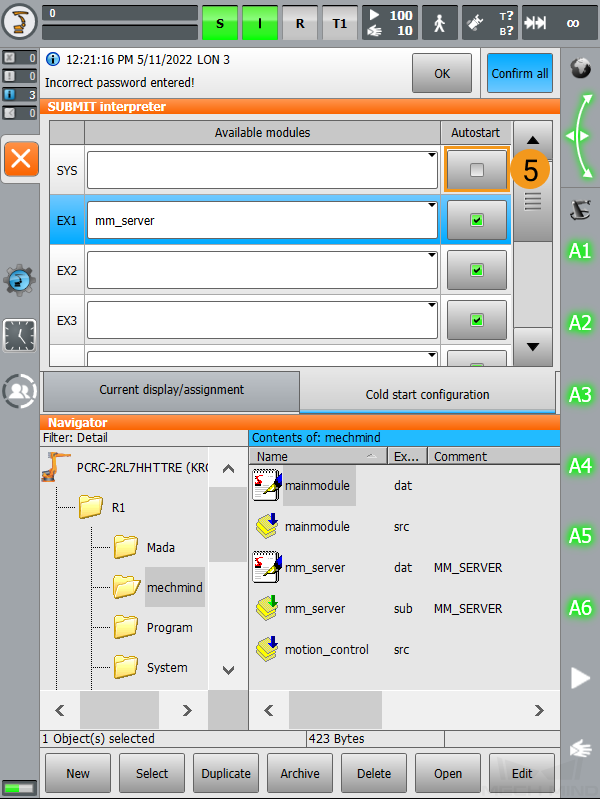

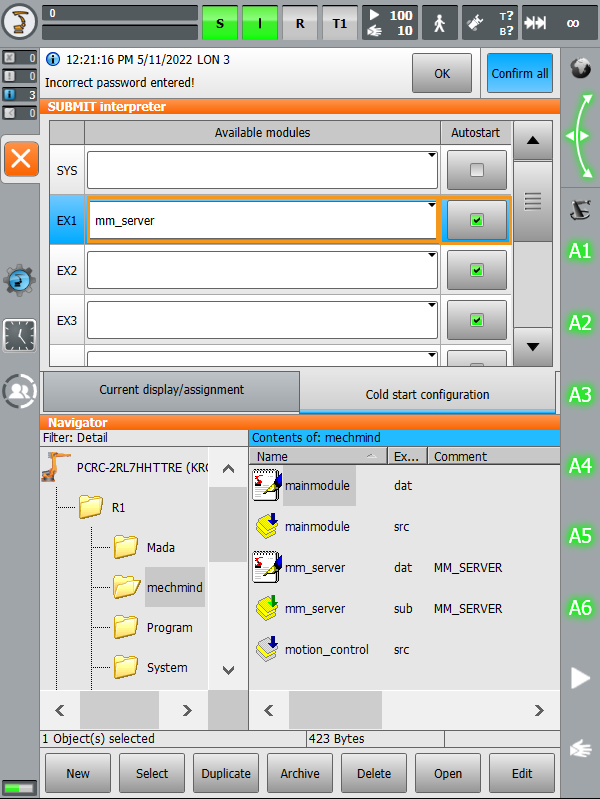

Then, clear the Autostart checkbox on the right of SYS.

-

Similarly, select mm_server in the drop-down menu for EX1, and make sure Autostart is checked.

-

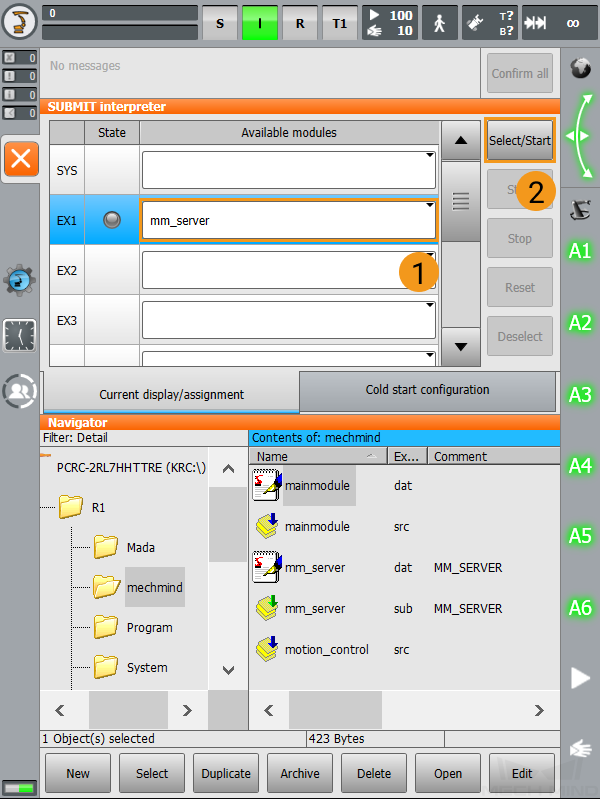

Click Current display/assignment to jump to the current display/assignment interface. Click the text box to the right of SYS, and then click Deselect.

-

Click the text box to the right of SYS again, and select the blank in the drop-down menu.

-

Similarly, select mm_server from the drop-down menu for EX1, and click Select/Start.

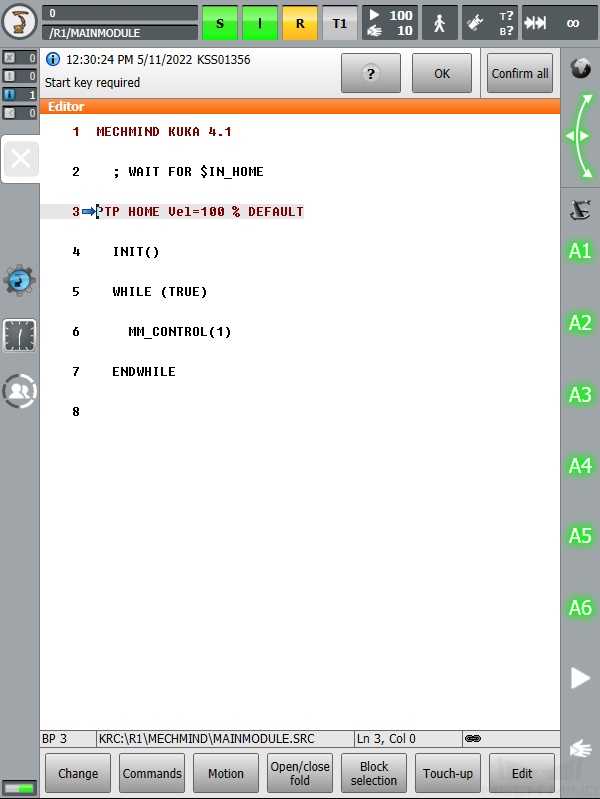

Run Program in the AUT Mode

-

How to switch the mode: Turn the key switch to horizontal, select T1 or AUT in the pop-up dialog box on the screen, and then turn the switch back to vertical.

-

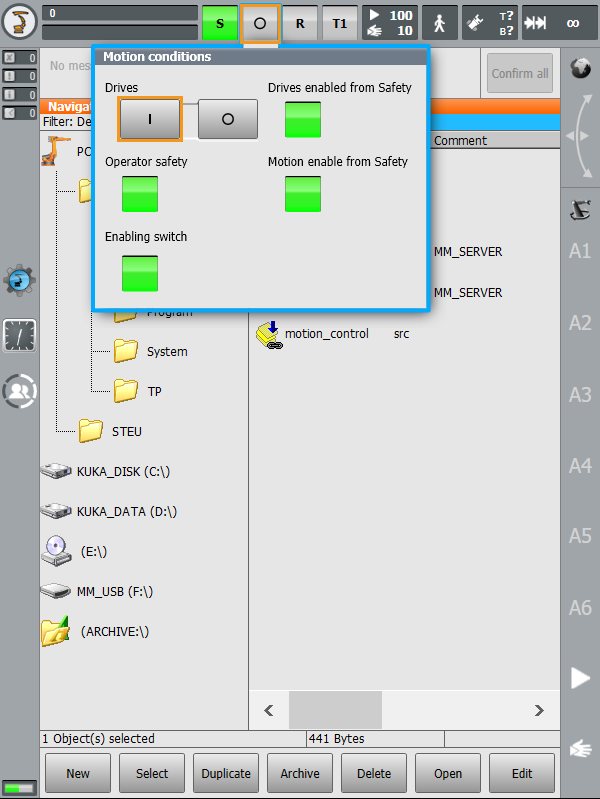

Switch to the T1 mode following the above step. Click O, and click I in the pop-up window to switch the status of Drives. If the status of Drives is I at the start, ignore this step.

-

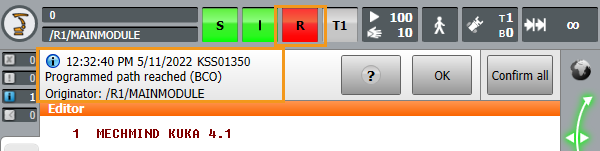

Set an appropriate velocity for the robot before moving it, and observe its motion to avoid accidents. Press the enabling switch (either one of three) on the back of the pendant and the green start button on the front at the same time to move the robot back to the Home position. When the screen displays a message saying Programmed path reached (BCO), release the enabling switch and the green start button.

-

Switch to AUT mode as described in the above step, and press the start button to run the master-control program (the R icon should turn green).

Create a Mech-Viz Project

-

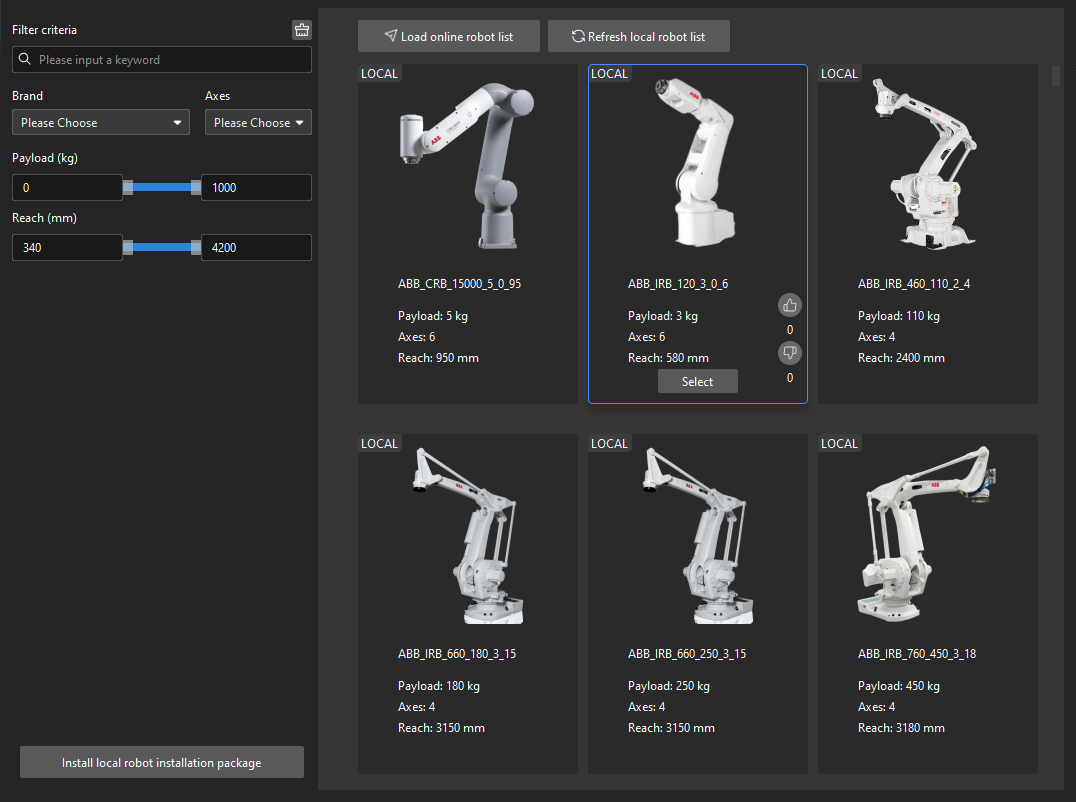

Open Mech-Viz, press Ctrl+N on the keyboard to create a new project. Select the robot model corresponding to your real robot brand and model on the interface as shown below.

-

Press Ctrl+S and create or select a folder to save the project.

-

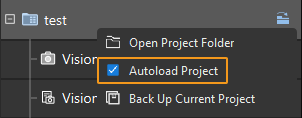

Right-click the project name in the left panel in Mech-Viz and select Autoload Project.

Connect to the Robot

-

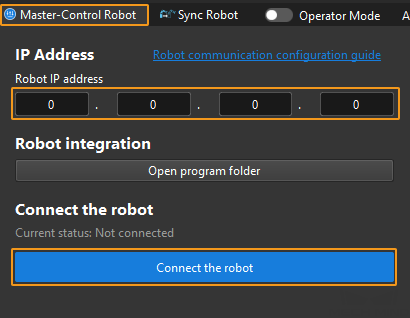

Click Master-Control Robot on the toolbar of Mech-Viz.

-

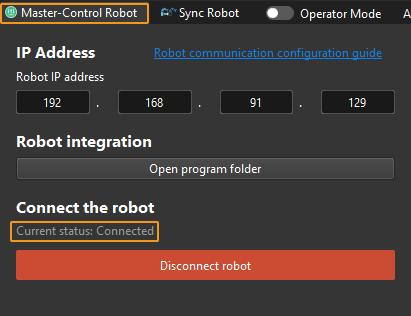

Input the IP address of the real robot in Robot IP address (the IP address in the picture is only an example). Click Connect the robot.

If Mech-Viz successfully connects the real robot, the current status will change to Connected. Meanwhile, the icon in the toolbar will turn from blue to green.

If the connection fails, please double-check the robot IP address.

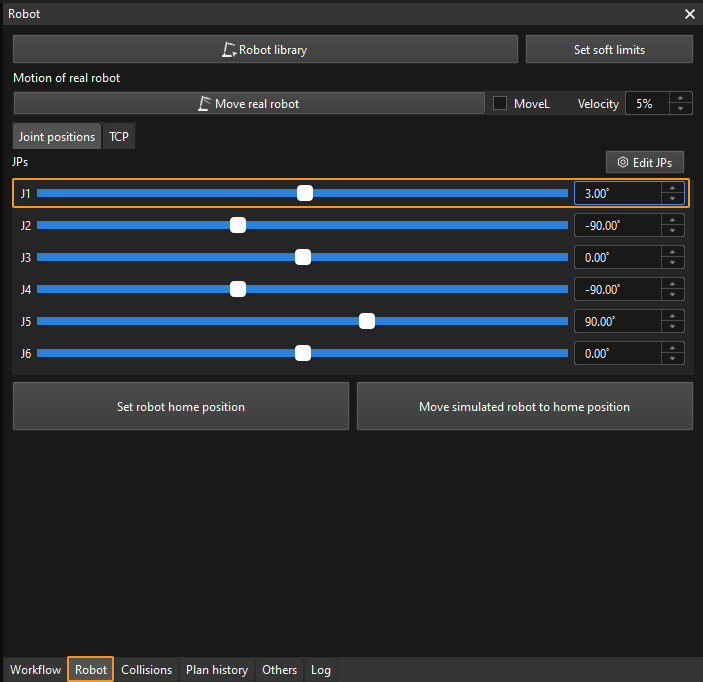

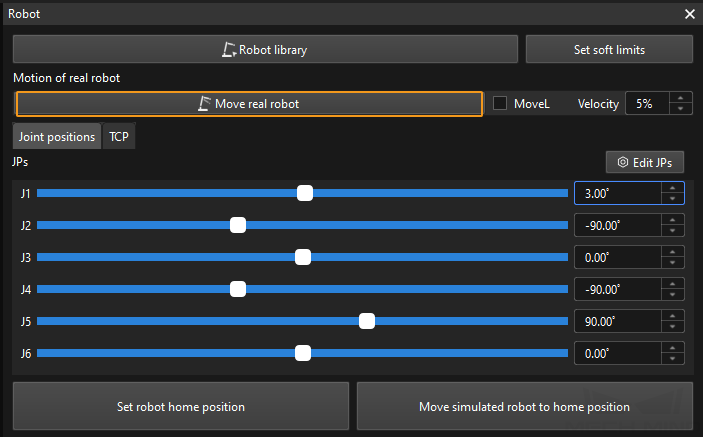

Move the Robot

-

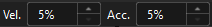

In the toolbar of Mech-Viz, change the “Vel.” (velocity) and “Acc.” (acceleration) parameters to 5%.

-

Click Sync Robot in the toolbar, and you can synchronize the poses of the simulated robot in the 3D simulation space with the poses of the real robot. Then click Sync Robot again to unselect it.

-

In the Robot tab, slightly adjust the value of “J1”, for example, from 0˚ to 3˚. This operation will move the simulated robot.

-

Click Move real robot and check if the real robot has moved. If the real robot has reached the JPs set for the simulated robot, the master-control communication is working.

When moving the robot, please ensure the safety of personnel. In the case of an emergency, press the emergency stop button on the teach pendant!

Notes

-

If you failed to master-control the robot via Mech-Viz but can successfully

ping the robot IPon the IPC, please restart Mech-Viz software. -

If the robot lost communication with Mech-Viz when running, it will automatically try to reconnect. If the robot still cannot connect Mech-Viz, you can try restarting the background program with these steps:

Click S, select mm_server from the drop-down menu, click Deselect, and click Select/Start. If an error message pops up, click Confirm all. After restarting the program, repeat the “Run Program in the AUT Mode” steps.