ROKAE Calibration Program

This topic introduces the process of automatic hand-eye calibration when a ROKAE robot communicates with Mech-Mind Vision System through Standard Interface.

| Before proceeding, please make sure that you have finished the sections in Set up Standard Interface Communication with ROKAE previous to Test Standard Interface Communication. |

Teach the Calibration Start Point

-

Move the robot to the start point for calibration.

-

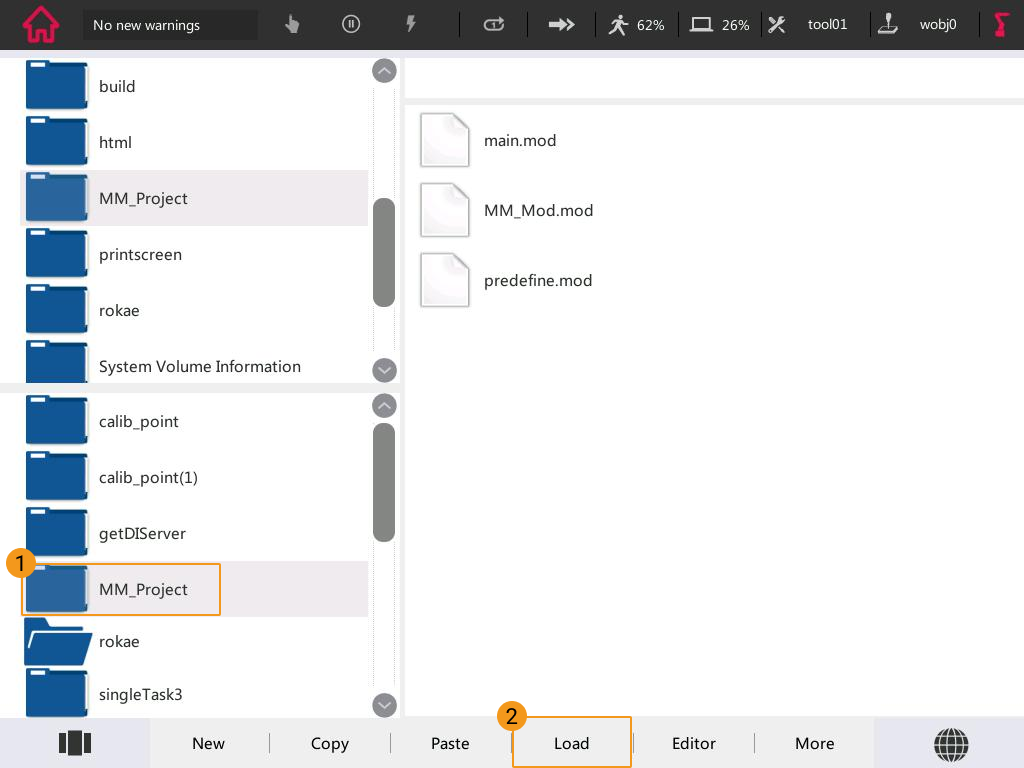

In the Project Manager window on the teach pendant, select the MM_Project folder and press Load.

-

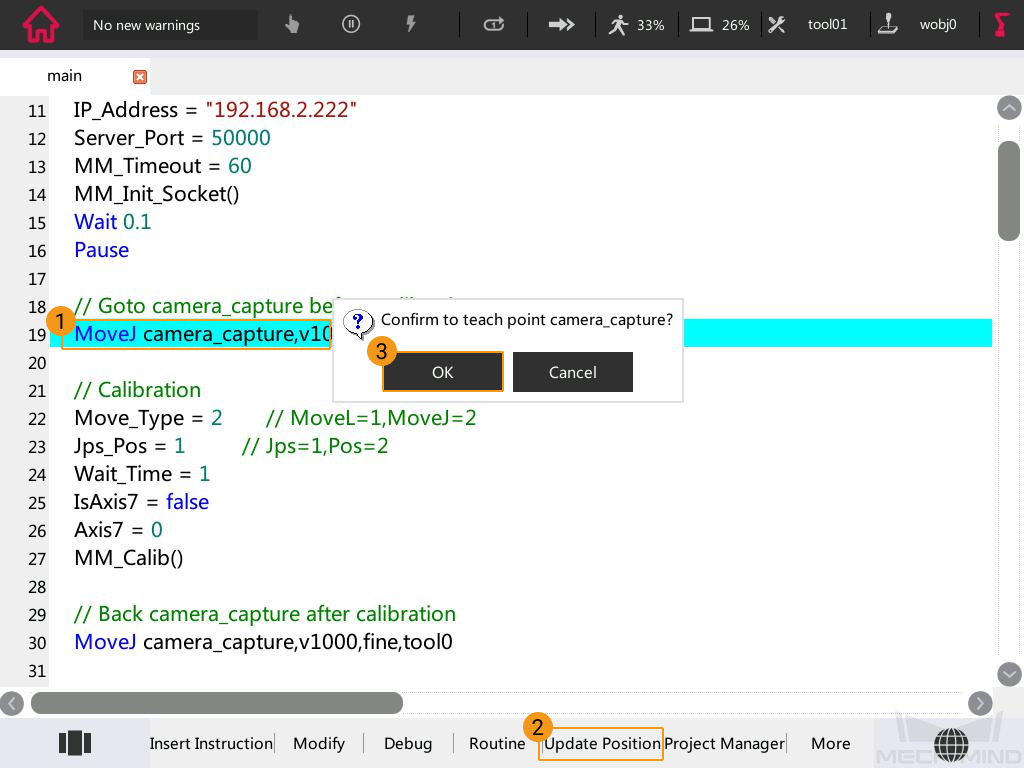

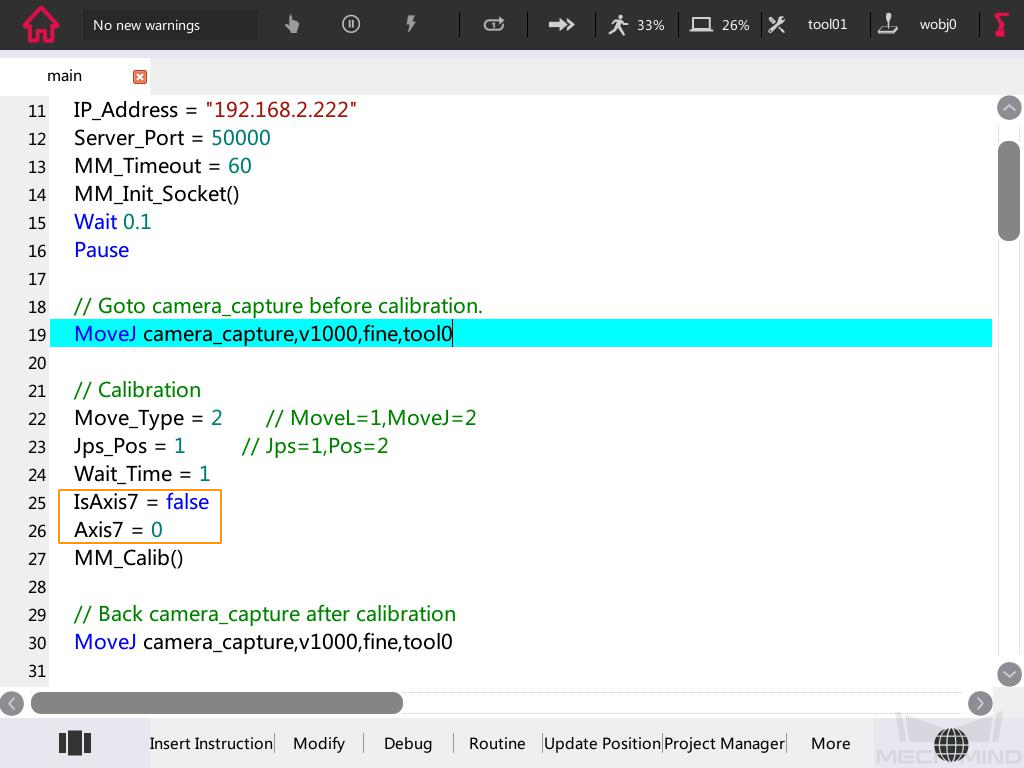

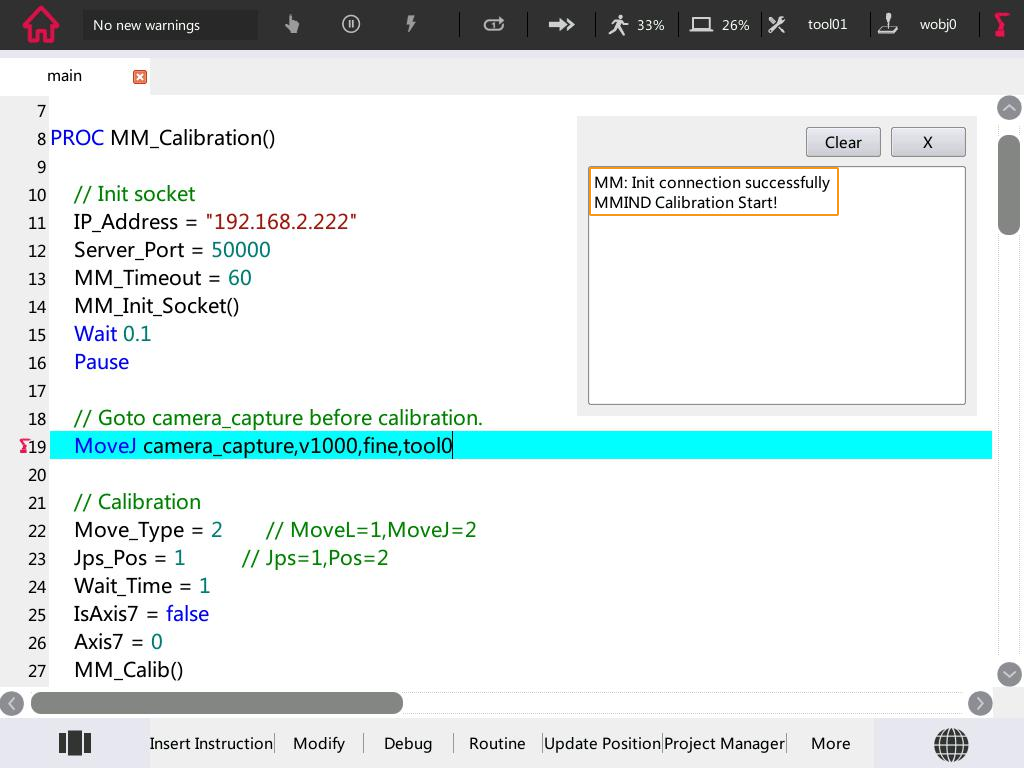

Select the “MoveJ camera_capture,v1000,fine,tool0” line, press Update Position, and then select OK in the pop-up window.

If there is a 7th axis which is controlled by the robot on site, modify “IsAxis7 = false” to “IsAxis7 = true” and modify the value of Axis7 accordingly (Axis7 = XX, XX refers to the current value of the 7th axis). If there is not a 7th axis, or the 7th axis is controlled by a PLC, you can skip this step.

Run the Calibration Program

Please refer to Test Standard Interface Communication to run the calibration program.

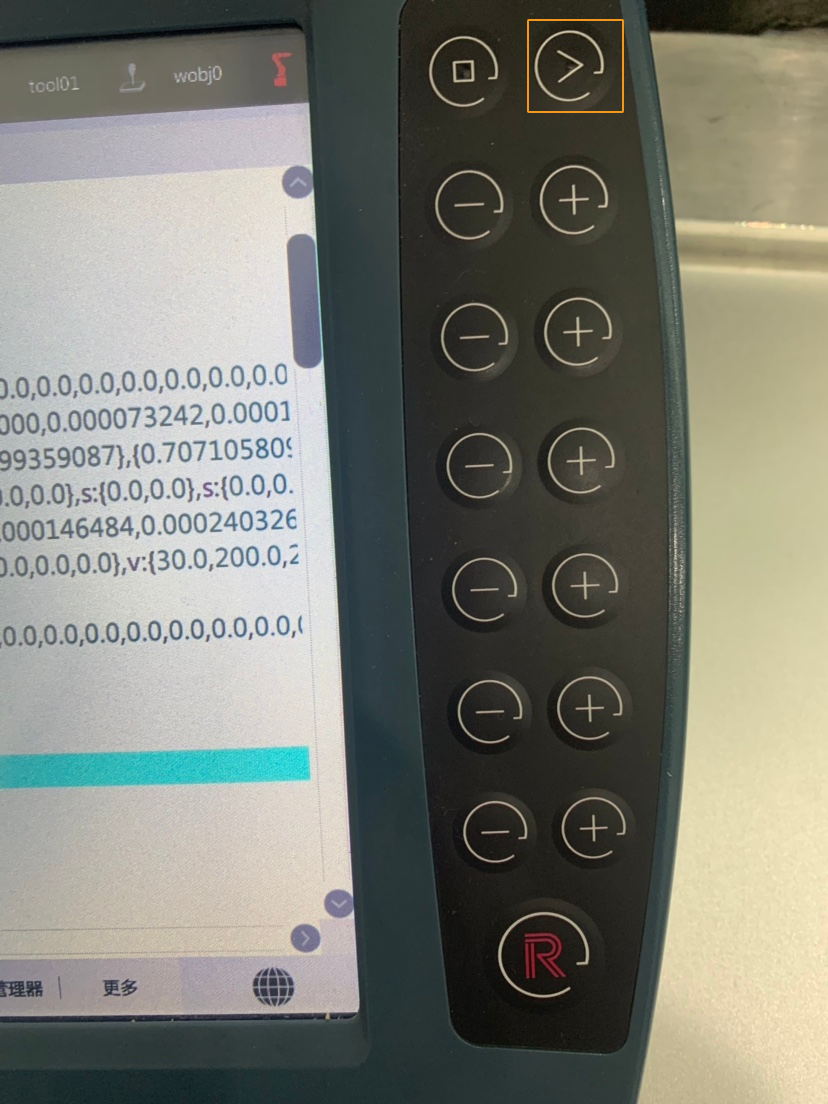

When the message “MM:Init connection successfully” appears in the dialog box on the teach pendant, press the Execute button as shown below again to continue the calibration program.

Proceed to the next section when the following messages are displayed:

-

In the print window of the teach pendant: MMIND Calibration Start!

-

On the Console tab of Mech-Vision Log panel: Entering the calibration process, please start the calibration in Mech-Vision.

Complete Calibration in Mech-Vision

-

In Mech-Vision, click Camera Calibration (Standard) on the toolbar, or select from the menu bar.

-

Follow the instructions based on different camera mounting methods to complete the configuration.

-

If the camera is mounted in the Eye to Hand mode, please refer to Complete Automatic Calibration in the Eye to Hand Scenario.

-

If the camera is mounted in the Eye in Hand mode, please refer to Complete Automatic Calibration in the Eye in Hand Scenario.

-

| If the robot does not reach the next calibration point within 60 seconds, Mech-Vision will report a timeout error and stop the calibration process. In such cases, please select and run the calibration program on the teach pendant again, and restart the calibration process in Mech-Vision. |