Set up Standard Interface Communication with YASKAWA

This section introduces the process of setting up the Standard Interface communication with a YASKAWA robot.

Check Controller and Software Compatibility

-

Ensure that a 6-axis YASKAWA robot is used.

-

Ensure that the robot controller and the controller system software version comply with the following requirements.

Controller Controller system software version DX200

DN3.16.00A-00

YRC1000

YAS2.94.00-00

YRC1000micro

YBS2.31.00-00

The following instructions are based on YRC1000 (YAS2.94.00-00) controller. Details may differ for other teach pendants of the YASKAWA robot. -

Option function requirements: The MotoPlus and Ethernet functions must be enabled.

| If the preceding requirements cannot be met, the standard interface communication cannot be established between the robot and the vision system. Please contact the robot manufacturer to resolve the issue. |

Set up the Network Connection

Connect the Hardware

For YRC1000 controllers, plug the Ethernet cable into the LAN2 (CN106) port. For DX200 controllers, plug the Ethernet cable into the CN104 port.

|

For YRC1000 controller:

|

Set the IP Address

-

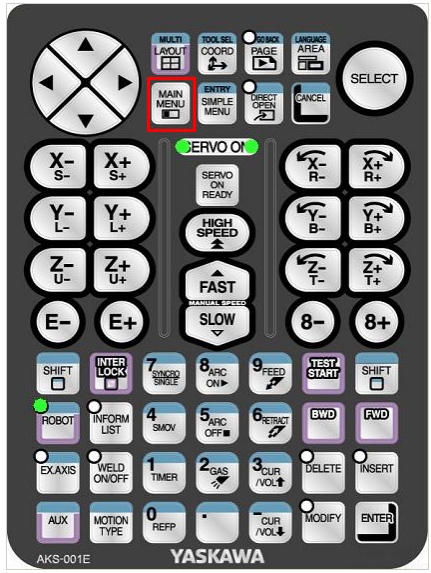

Press and hold the

MAIN MENUkey and power the robot to enter the maintenance mode.

-

The system will enter the normal startup mode if you do not press the

MAIN MENUkey. -

If the robot is already started, please restart the robot while pressing the

MAIN MENUkey.

-

-

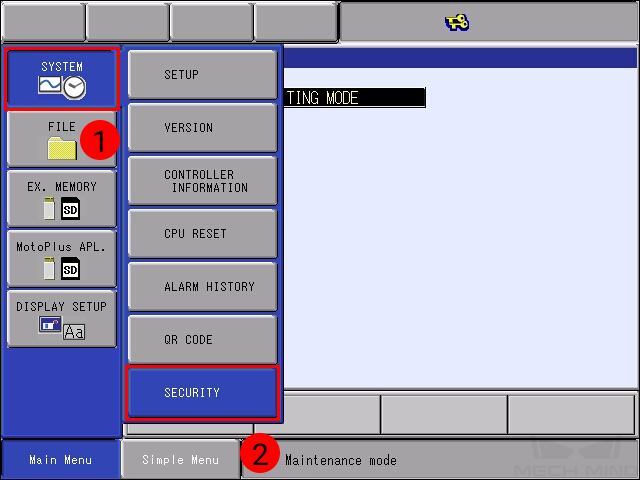

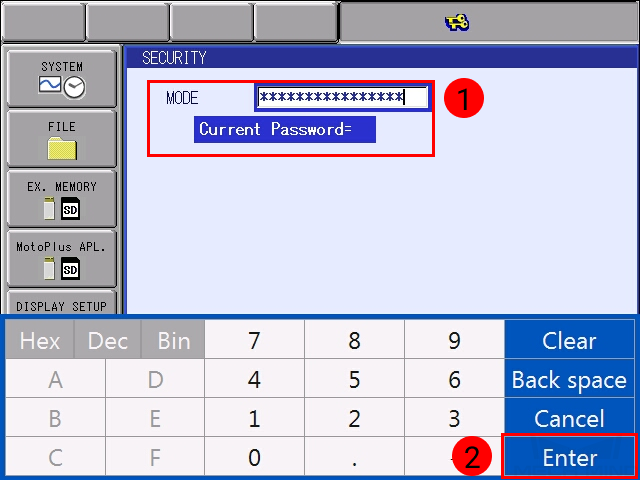

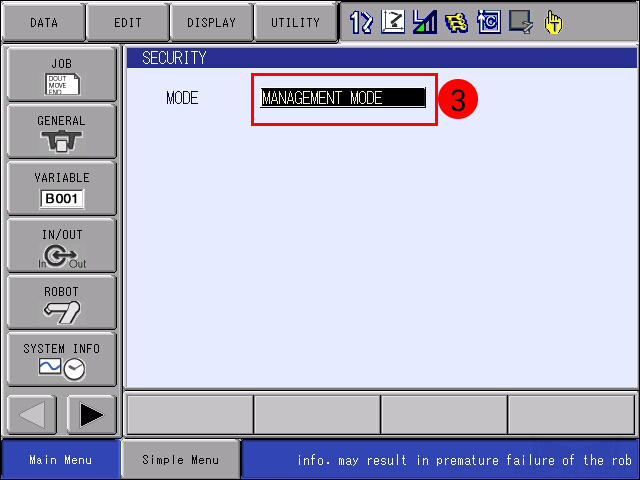

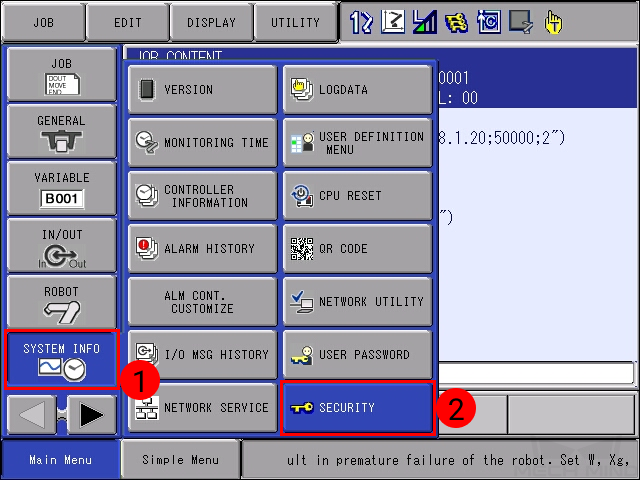

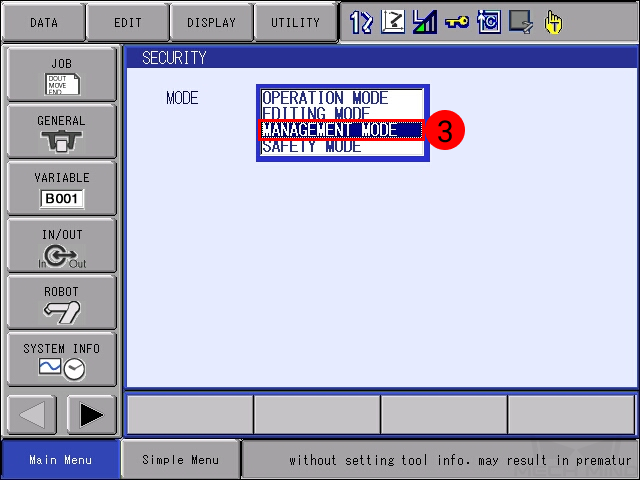

Select . Then select MANAGEMENT MODE.

-

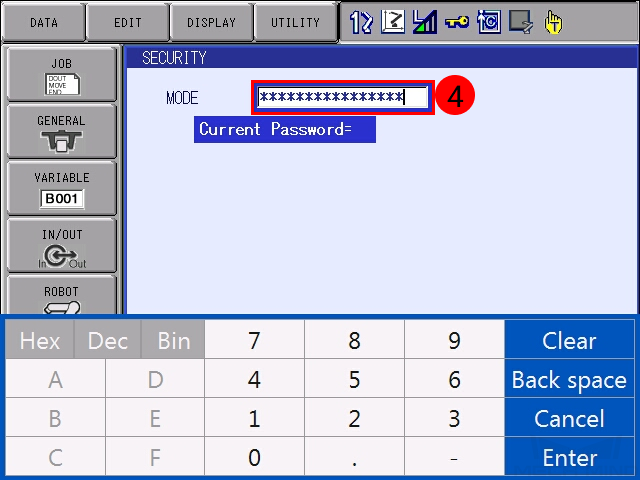

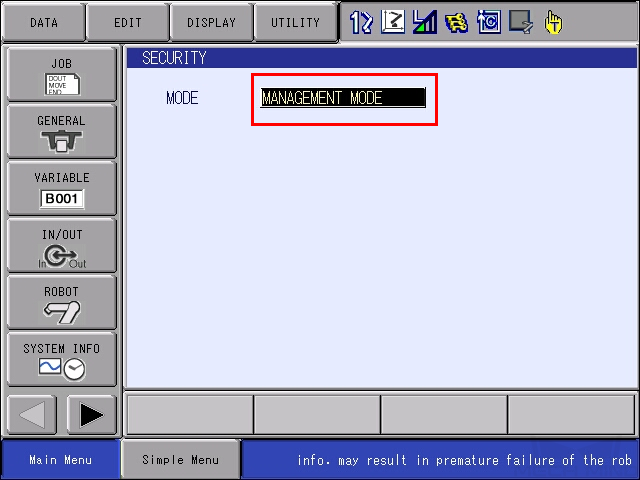

Enter the password (the default password is sixteen 9s), and then click Enter to enter MANAGEMENT MODE.

-

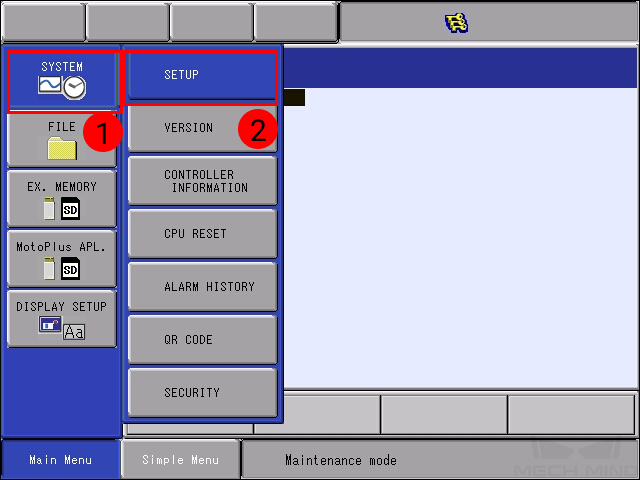

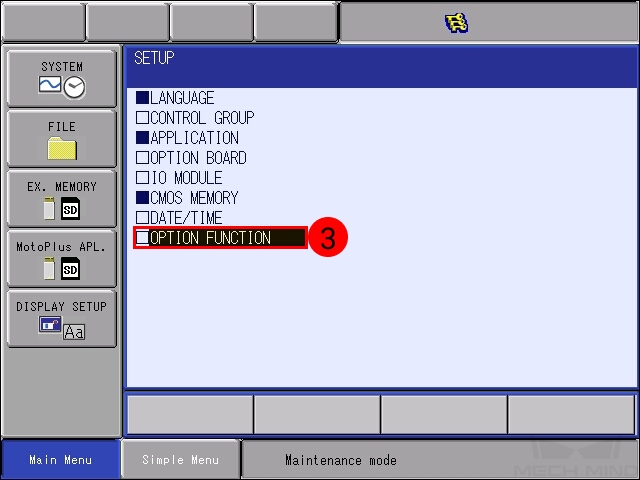

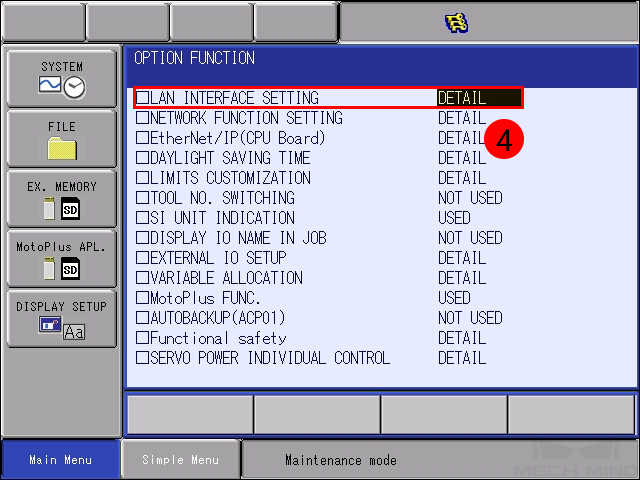

Select . At the OPTION FUNCTION interface, click LAN INTERFACE SETTING.

-

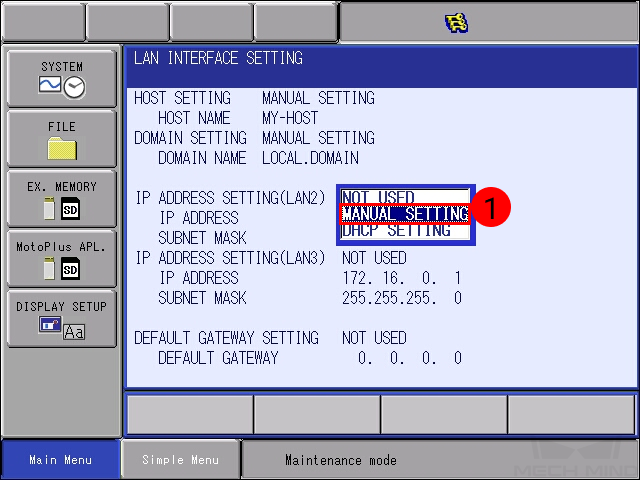

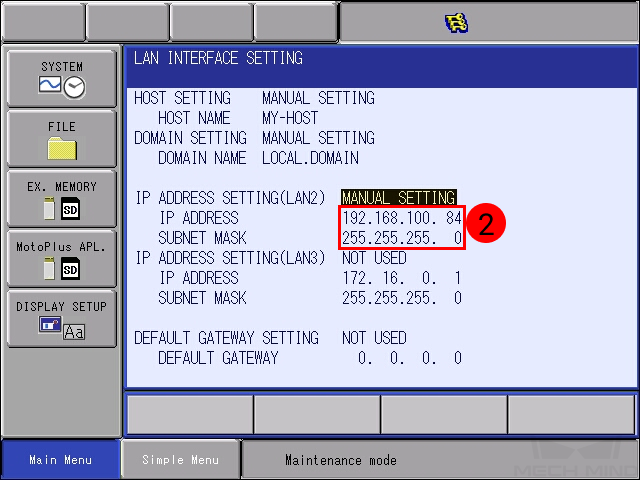

In the drop-down menu of IP ADDRESS SETTING(LAN2), select MANUAL SETTING, and set a proper IP ADDRESS and SUBNET MASK.

-

The IP address of LAN2 should belong to the same subnet as the IPC.

-

The subnet mask should be 255.255.255.0.

-

-

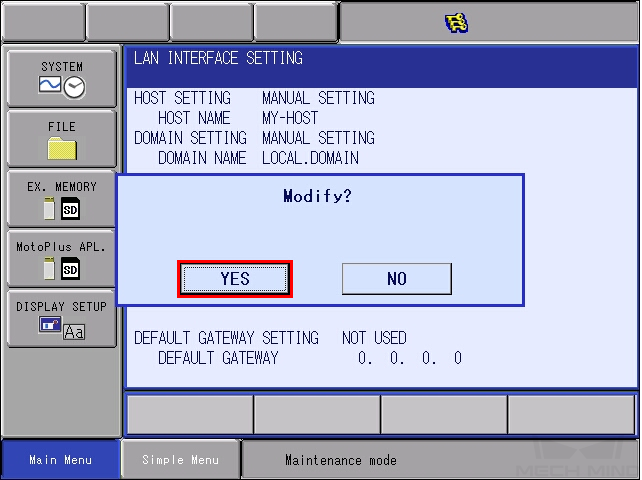

Press the

ENTERkey on the teach pendant, and a message saying *Modify? * will pop up. Click YES.

Set up “Robot and Interface Configuration” in Mech-Vision

-

Click Robot and Interface Configuration in the toolbar of Mech-Vision.

-

Select Listed robot from the Select robot drop-down menu, and then click Select robot model. Select the robot model that you use. Then click Next.

-

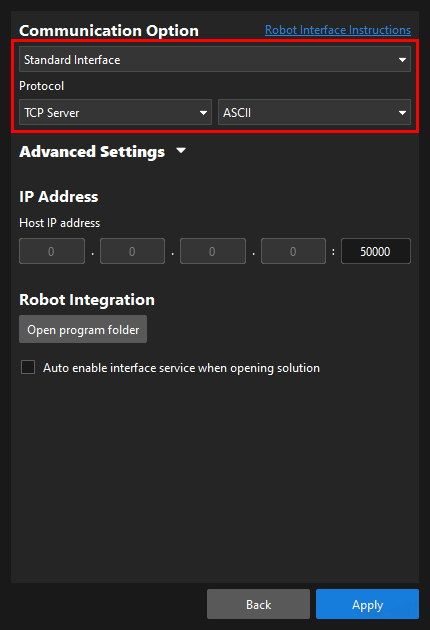

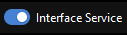

Select Standard Interface for Interface Type, and TCP Server and ASCII for Protocol. Then click Apply.

-

At the main interface of Mech-Vision, make sure the Interface Service in the toolbar is started.

Load the Program Files

| Before you start loading the program file to the robot, please perform file backup as needed. For detailed instructions, please refer to the operator’s manual of the YASKAWA controller. |

Prepare the Files

This section takes the YRC1000 robot as an example. Navigate to Mech-Center\Robot_Interface\YASKAWA from the installation directory of Mech-Mind Software Suite, and copy and paste the JBI folder and the mm_module_yrc1000.out file to the root directory of an empty formatted flash drive. The JBI folder is the foreground program, and the mm_module_yrc1000.out file is the background program.

|

Load the MotoPlus Application File to the Robot

-

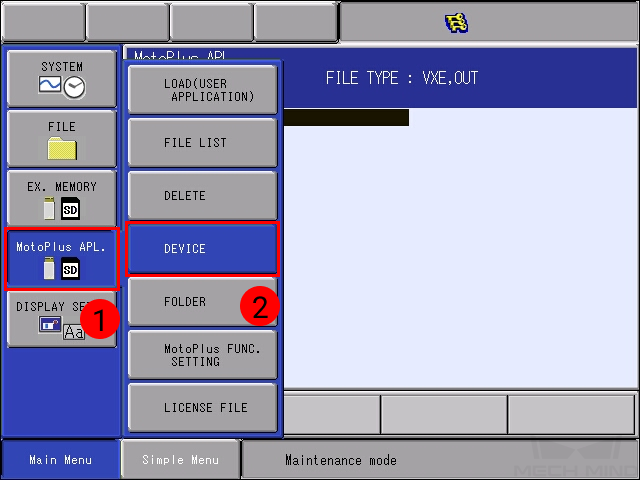

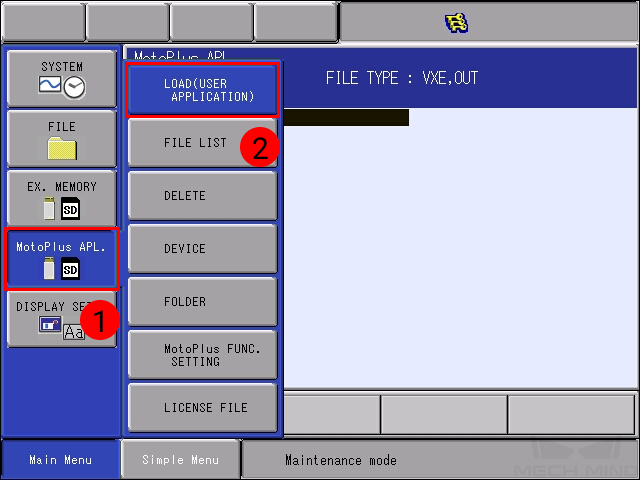

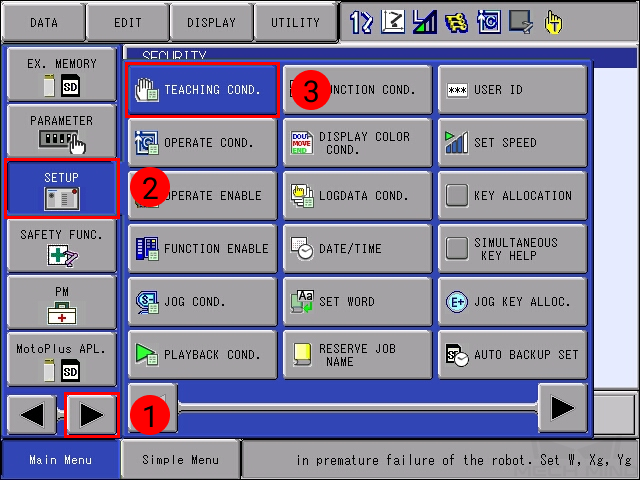

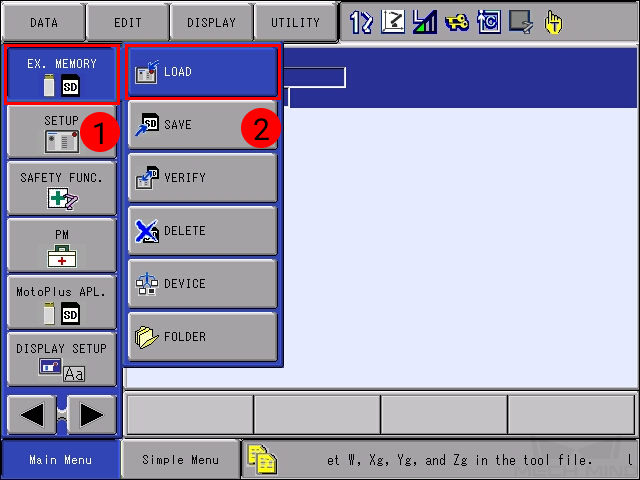

Under the Maintenance mode, select .

-

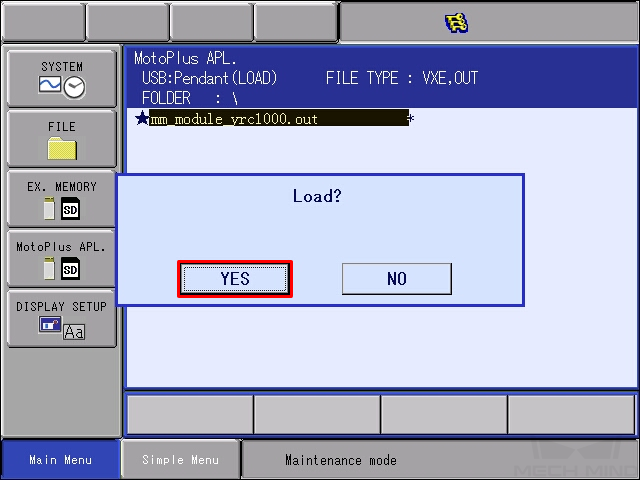

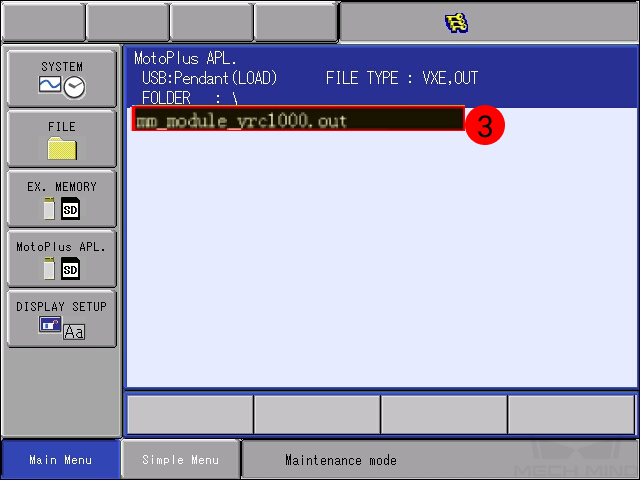

Select . Select mm_module_yrc1000.out, press the

ENTERkey, and select YES in the pop-up window to start loading the program.If the robot controller is DX200, select mm_module_dx200.out.

-

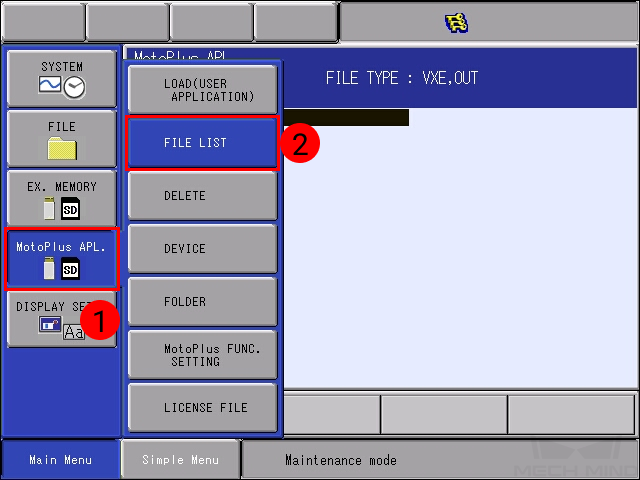

After the installation, select . You can see the installed file here.

Load the Job Files to the Robot

-

Restart the controller without pressing the MAIN MENU key, select , select MANAGEMENT MODE in the drop-down menu, and input the default password (sixteen 9s).

Press

Enterto enter the Maintenance mode.

-

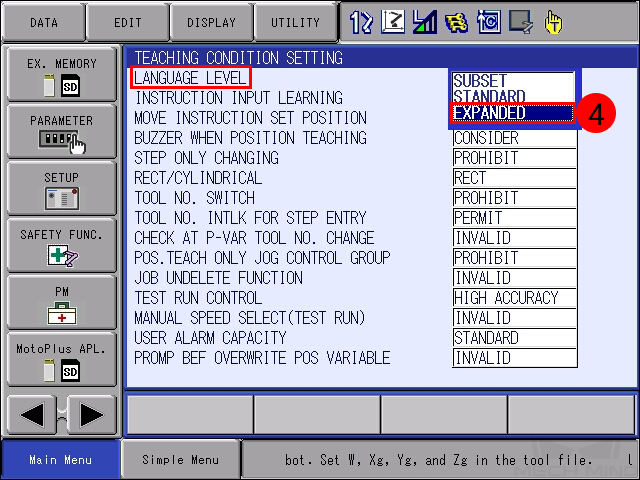

Press the right-arrow button

in the lower-left. Then press , and select EXPANDED in the drop-down menu of LANGUAGE LEVEL.

in the lower-left. Then press , and select EXPANDED in the drop-down menu of LANGUAGE LEVEL.

-

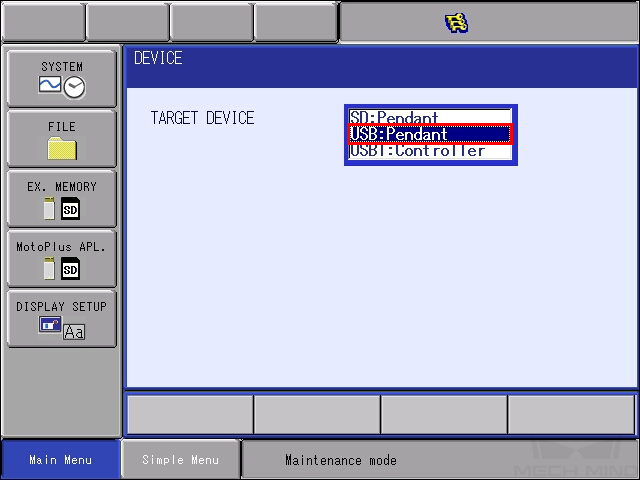

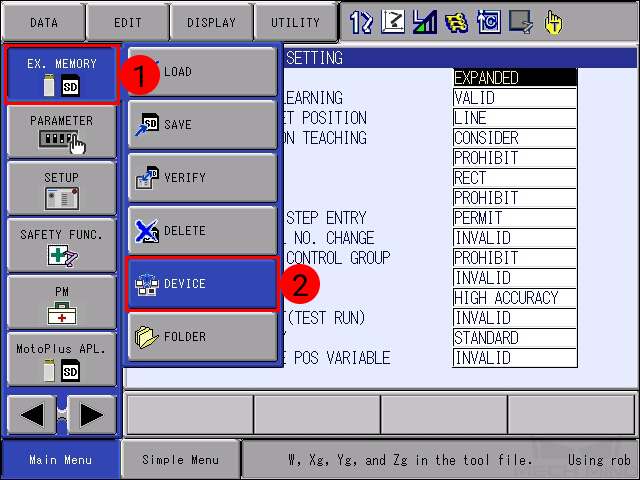

Select , and then select USB:Pendant for DEVICE.

-

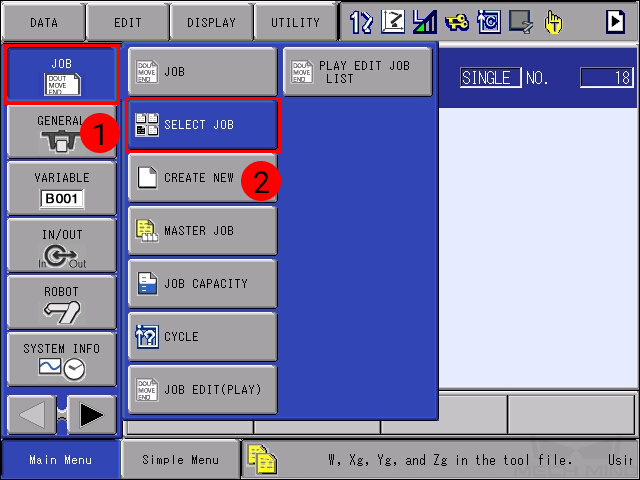

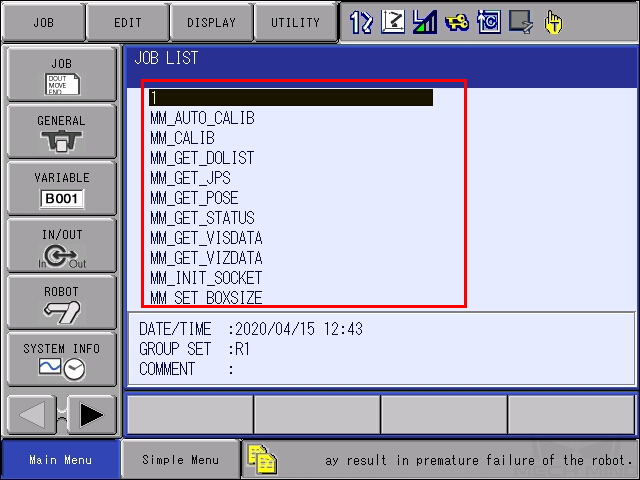

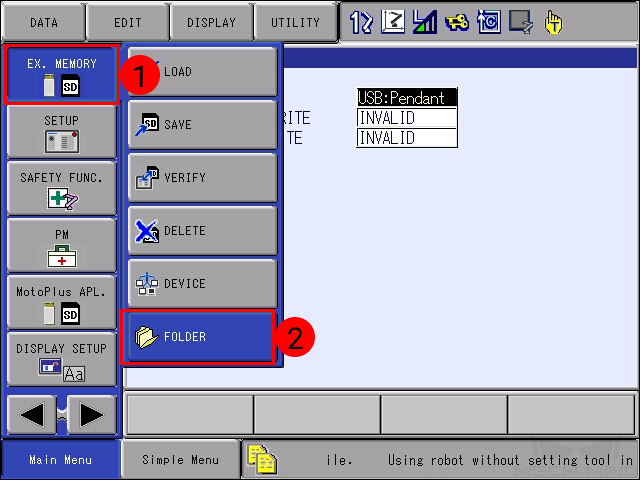

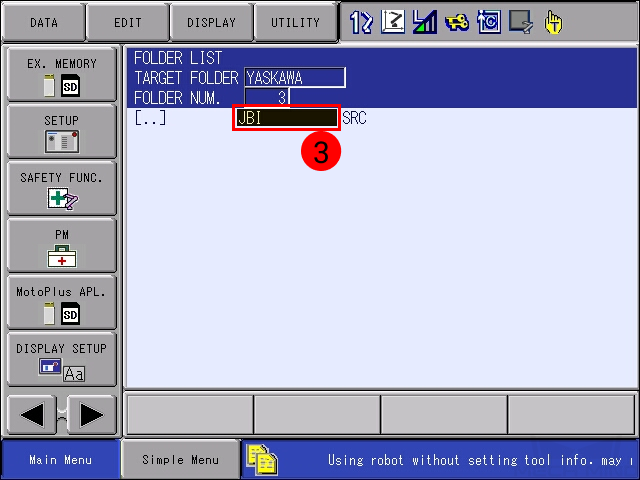

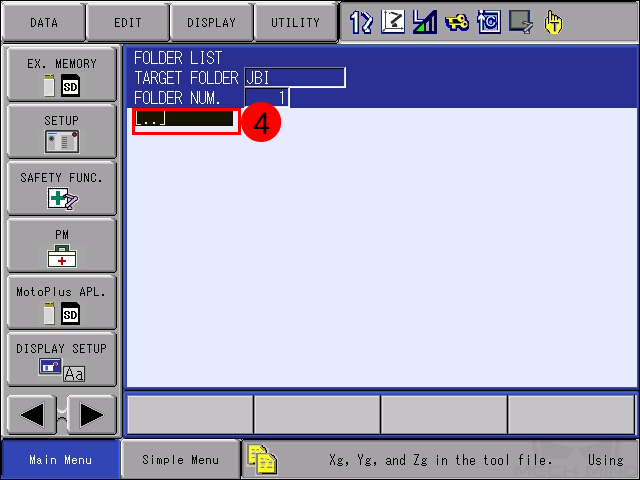

Click . In the FOLDER list, select and enter the JBI folder.

-

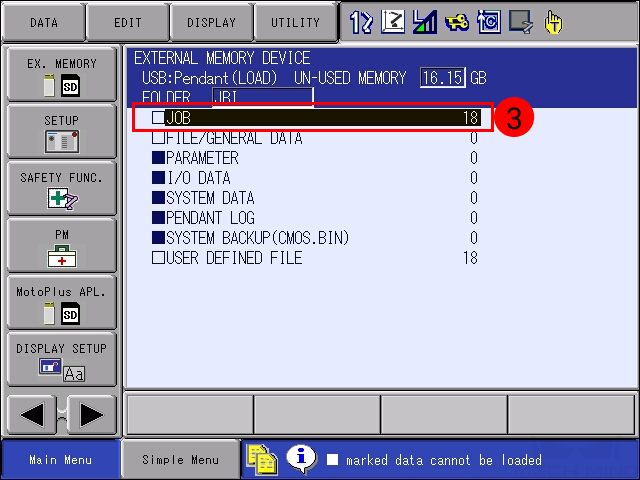

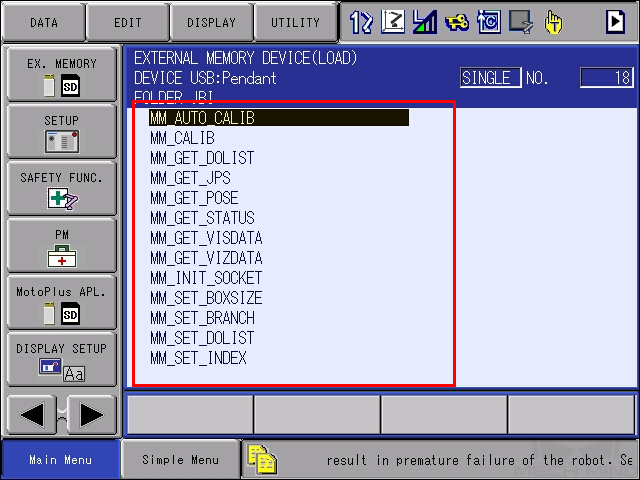

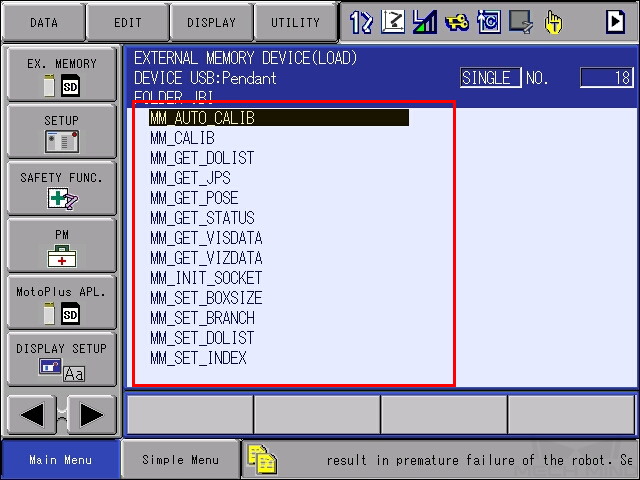

Select . Select JOB, and the programs to be loaded will be displayed.

-

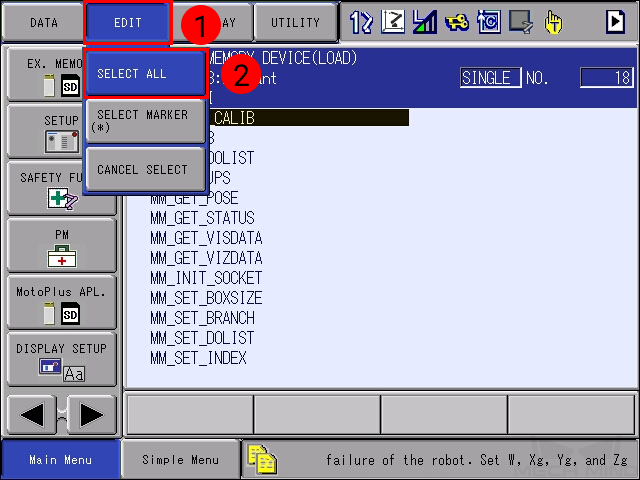

Select .

-

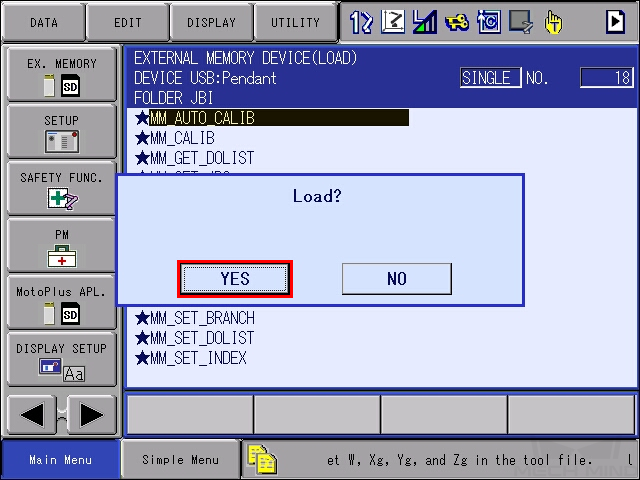

Press the

ENTERkey. Select YES in the pop-up message to start loading the programs.

-

After loading completes, go to . You can see all the job files displayed.