Hardware User Manual

Safety Instructions

|

|

Operating Environment

|

|

Mounting the Product

|

|

Using the Product

|

|

|

Air Supply

|

Usage of Adapter / DIN Rail Power Supply

|

|

|

Laser Safety

|

Certifications

The product is compliant with the following standards and assessment requirements. Please note that the certification statuses may be updated. For more information, please contact the local sales agents.

Compliant with the following requirements and standards:

-

European Electromagnetic Compatibility Standards

-

U.S. ANSI C63.4, 47 CFR PART 15B, and UL 61010-1

-

Canada ICES-003

-

Japan VCCI-CISPR 32:2016

-

South Korea KS C 9832 and KS C 9835

Safety of Laser Products

The laser classification is implemented based on IEC 60825-1:2014 in accordance with the requirements of Laser Notice No. 56 of the FDA (CDRH).

CE

The full text of the EU Declaration of Conformity is available at https://downloads.mech-mind.com/?tab=tab-eu-dec

European Electromagnetic Compatibility Standards:

-

EN 55032:2015+A11:2020+A1:2020

-

EN IEC 61000-3-2:2019+A1:2021

-

EN 61000-3-3:2013+A1:2019+A2:2021

-

EN 55035:2017+A11:2020

All products bearing this symbol are waste electrical and electronic equipment (WEEE as in directive 2012/19/EU) which should not be mixed with unsorted household waste. Instead, you should protect human health and the environment by handing over your waste equipment to a designated collection point for the recycling of waste electrical and electronic equipment, appointed by the government or local authorities. Correct disposal and recycling will help prevent potential negative consequences to the environment and human health. Please contact the local authorities for more information about the location as well as terms and conditions of such collection points.

FCC

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense.

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation of the device.

“Le présent appareil est conforme aux CNR d’Industrie Canada applicables aux appareils radio exempts de licence. L’exploitation est autorisée aux deux conditions suivantes : (1) l’appareil ne doit pas produire de brouillage, et (2) l’utilisateur de l’appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est susceptible d’en compromettre le fonctionnement.”

Package Contents

|

|

|

|

|

|

|

|

|

|

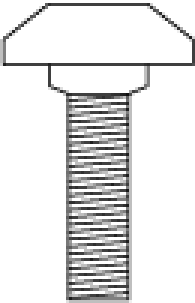

M4 × 8 socket head cap screws (Qty: 8) |

M5 × 8 socket head cap screws (Qty: 8) |

M8 × 20 socket head cap screws (Qty: 2) |

M8 × 20 T-bolts (Qty: 2) |

|

|

M8 nuts (Qty: 2) |

M8 flange nuts (Qty: 2) |

|

|

M8 washers (Qty: 2) |

Ø6 × 10 dowel pins (Qty: 4) |

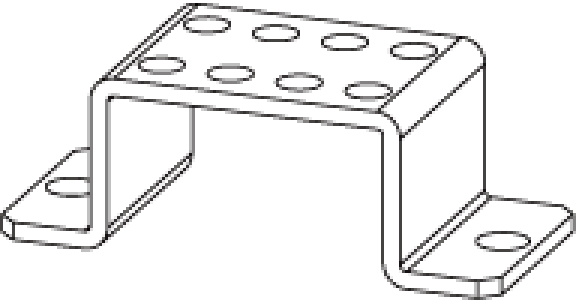

Cable tie mount (Qty: 1) |

Zip ties (Qty: 50) |

|

|

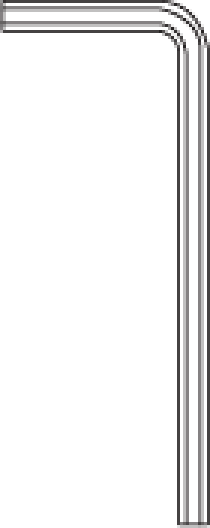

Hex keys (Qty: 3) |

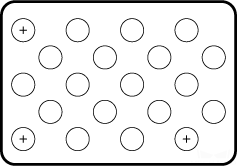

Calibration board (UHP-140-GL only) |

|

|

|

Optional Accessories

DIN rail power supply |

Calibration board (except for UHP-140-GL) |

|

|

|

For the technical specifications of the DIN rail power supply or calibration board, see DIN Rail Power Supply and Calibration Board. |

Functional Diagrams

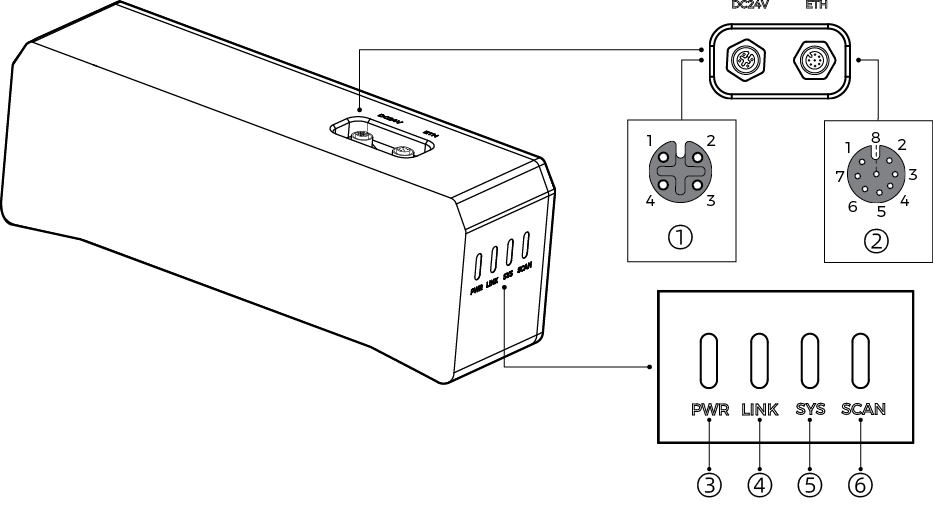

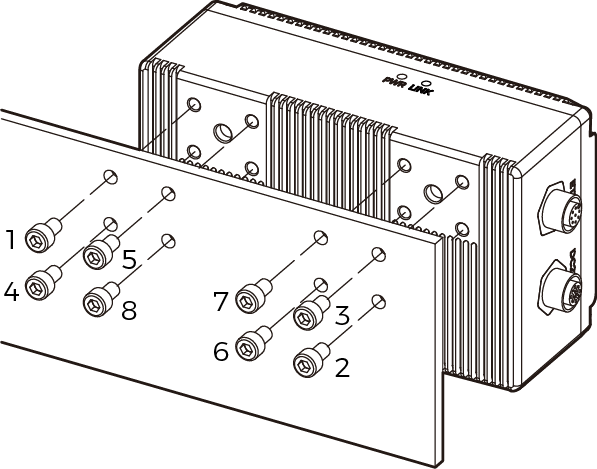

DEEP-GL, LSR S-GL, LSR L-GL, LSR XL-GL, PRO S-GL, PRO M-GL, and UHP-140-GL

No. |

Name |

Function |

|

|---|---|---|---|

① |

DC 24V port |

1: GND |

3: 24 VDC |

2: GND |

4: 24 VDC |

||

② |

ETH port |

1: MD3_P |

5: MD1_P |

2: MD2_N |

6: MD0_N |

||

3: MD2_P |

7: MD3_N |

||

4: MD0_P |

8: MD1_N |

||

③ |

PWR indicator light |

Off: not connected to power |

|

Green: normal voltage |

|||

Solid yellow: voltage lower than 16 V or higher than 28 V |

|||

Solid red: voltage lower than 12 V |

|||

④ |

LINK indicator light |

Off: not connected to network |

|

Solid or blinking green: connected to network |

|||

⑤ |

SYS indicator light |

Off: camera not started |

|

Solid green: camera starting up |

|||

Blinking green: camera operating properly |

|||

Blinking yellow: unstable voltage or abnormal temperature |

|||

Blinking red: malfunctioning |

|||

⑥ |

SCAN indicator light |

Solid green: acquiring and processing data |

|

Not acquiring or processing data |

|||

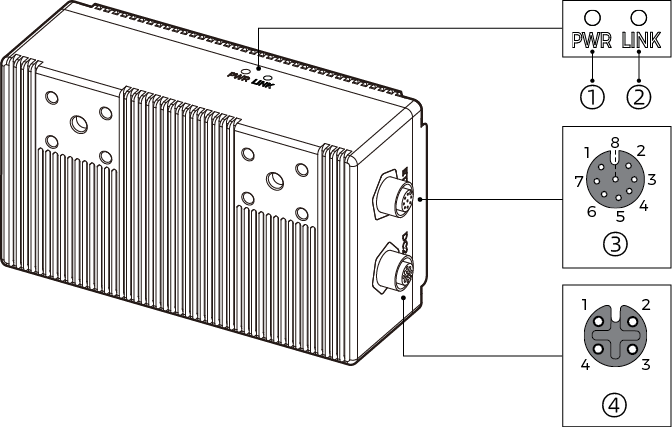

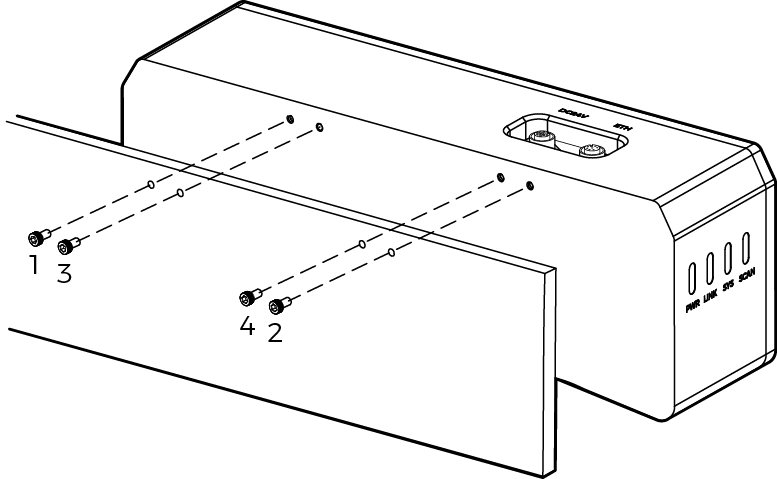

NANO-GL and NANO ULTRA-GL

|

The above figure uses NANO-GL as an example. |

No. |

Name |

Function |

|

|---|---|---|---|

① |

PWR indicator light |

Off: not connected to power |

|

Green: normal voltage |

|||

② |

LINK indicator light |

Off: not connected to network |

|

Solid or blinking green: connected to network |

|||

③ |

ETH port |

1: MD3_P |

5: MD1_P |

2: MD2_N |

6: MD0_N |

||

3: MD2_P |

7: MD3_N |

||

4: MD0_P |

8: MD1_N |

||

④ |

DC 24V port |

1: GND |

3: 24 VDC |

2: GND |

4: 24 VDC |

||

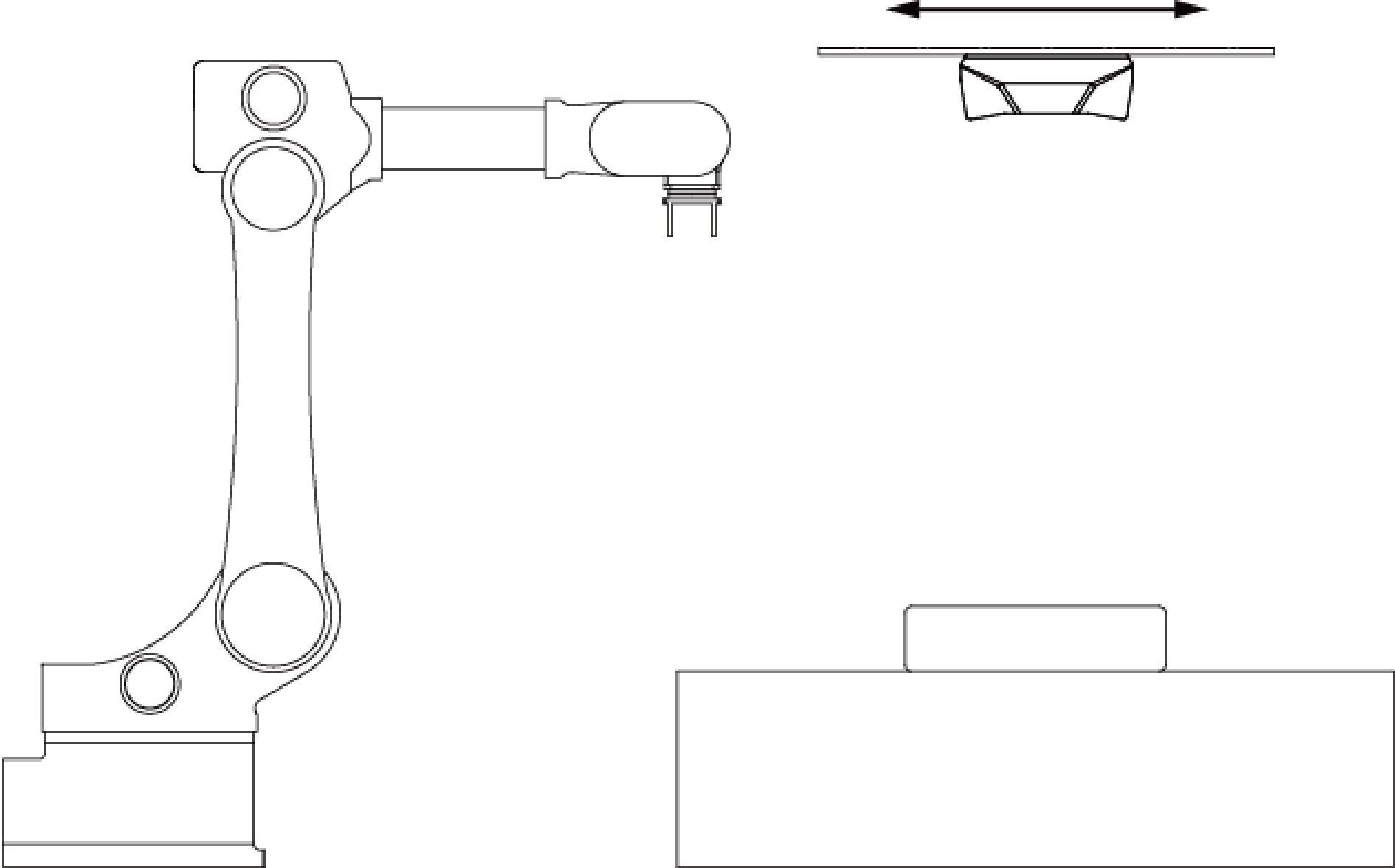

Mount the Camera

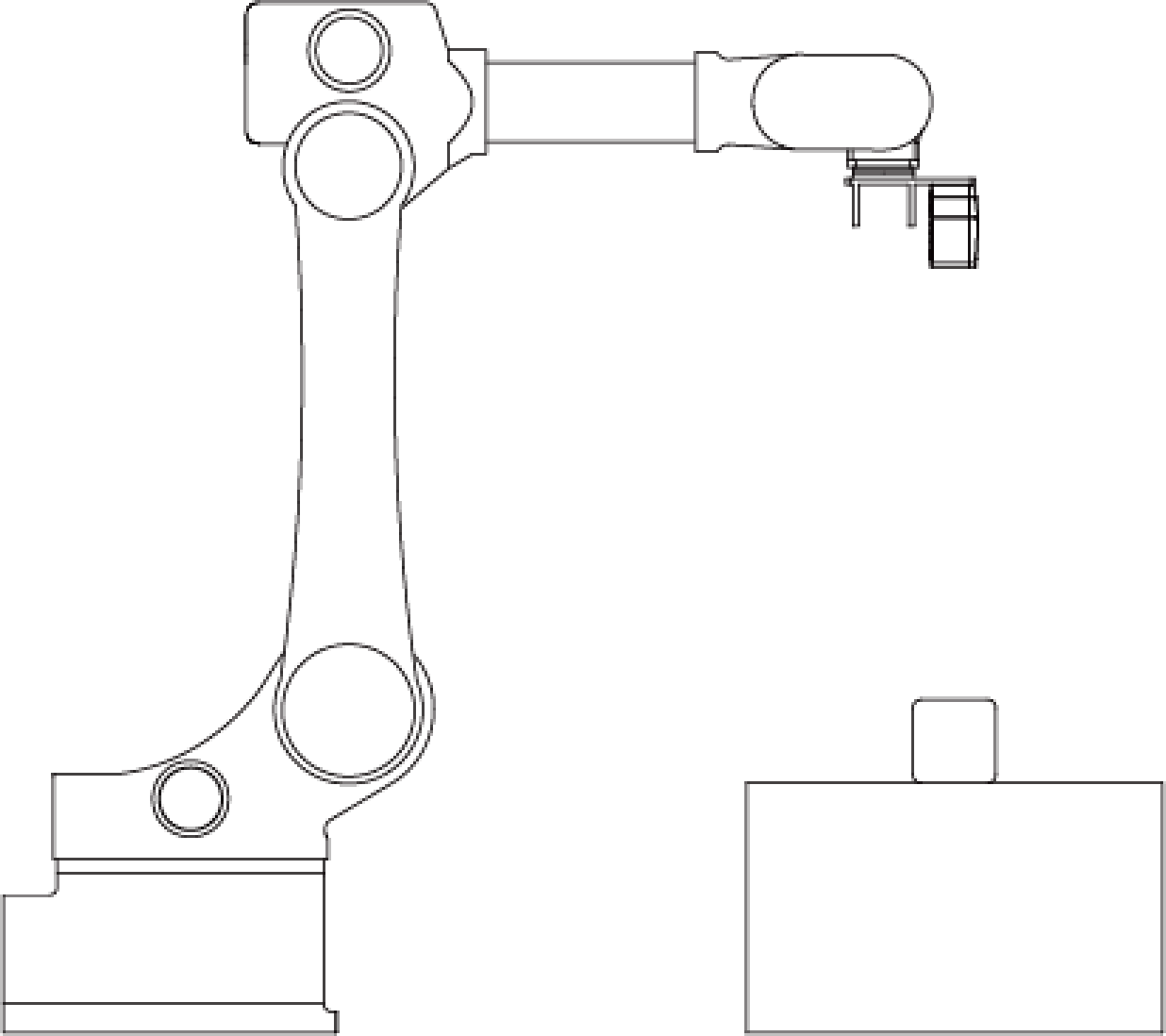

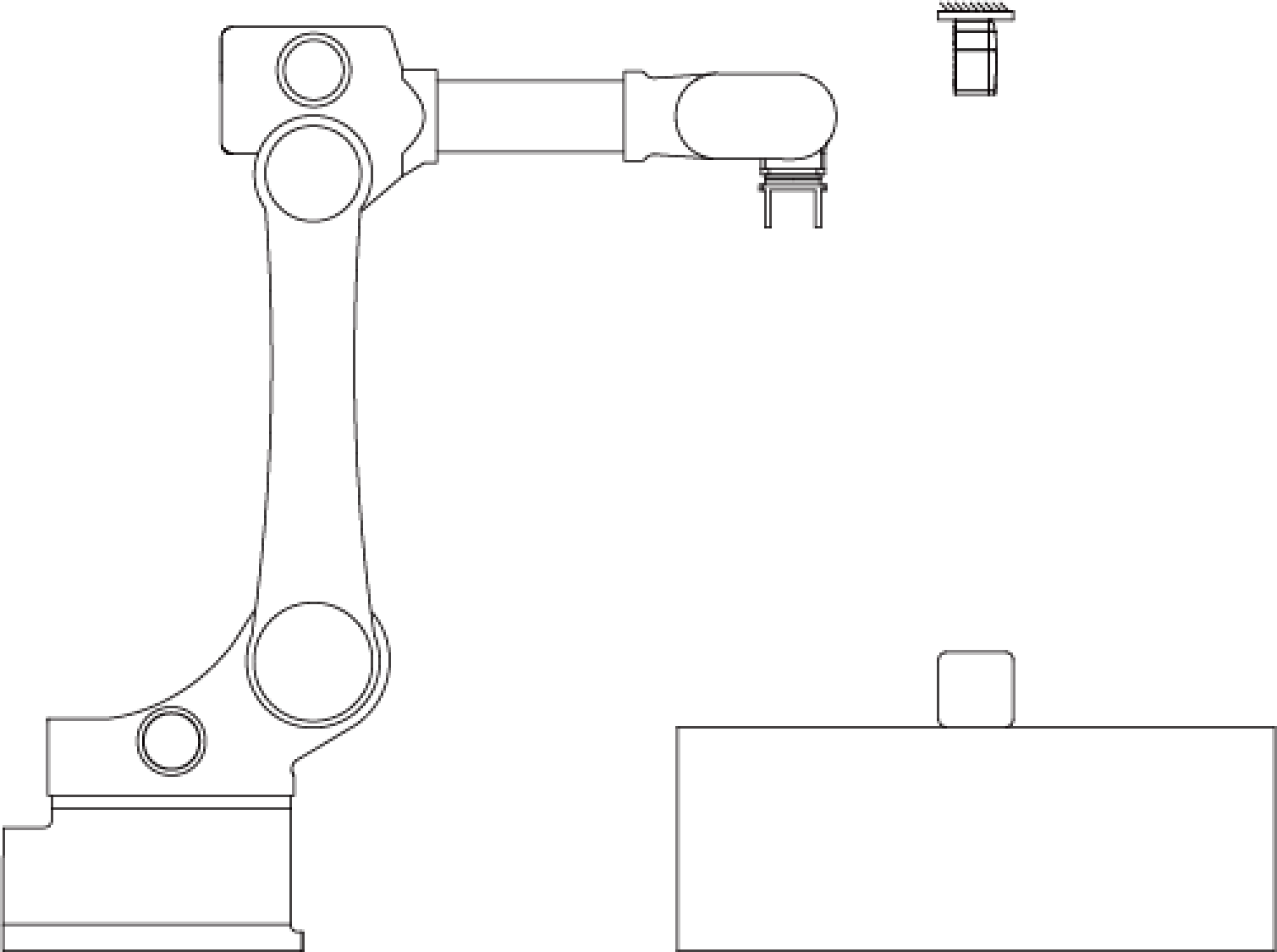

The camera can be mounted in the following setups:

| Setup | Requirements |

|---|---|

Mounted to the robot flange and moves with the robot.

|

|

Mounted to a stationary frame and does not move with the robot.

|

|

Mounted to a linear rail and moves with the linear rail.

|

|

|

After determining the setup, refer to the following sections and secure the camera to the mounting surface through the camera bracket or threaded holes.

|

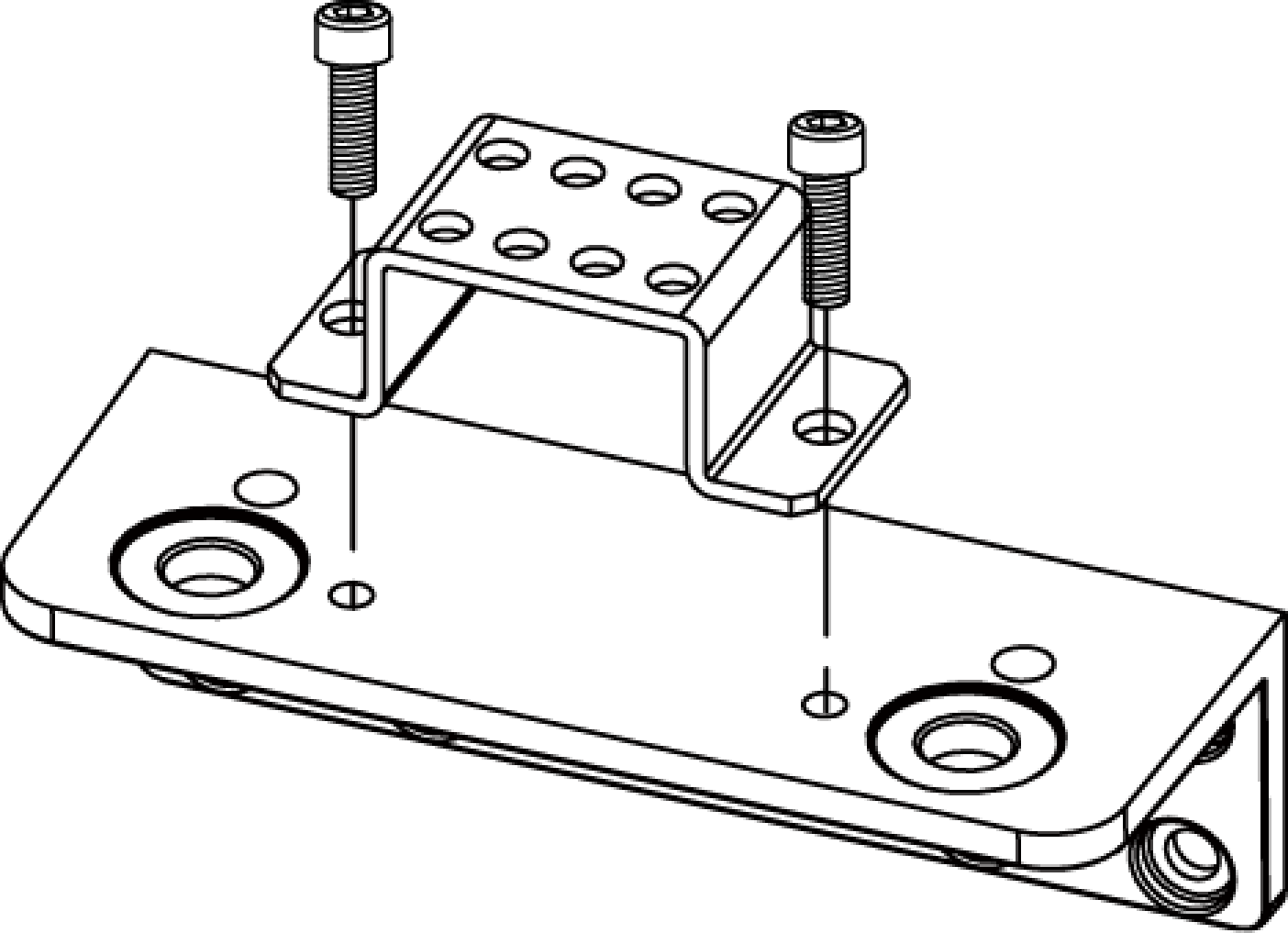

Mount through the Camera Bracket

Using the camera bracket, you can mount the camera to the following types of surfaces:

-

T-slot aluminum extrusion

-

Surface with mounting holes opened

|

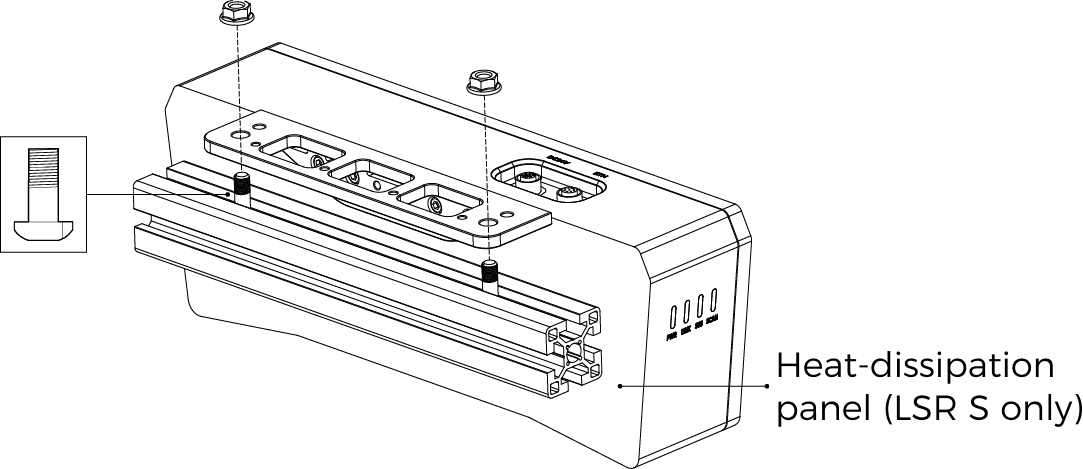

Mount to T-Slot Aluminum Extrusion

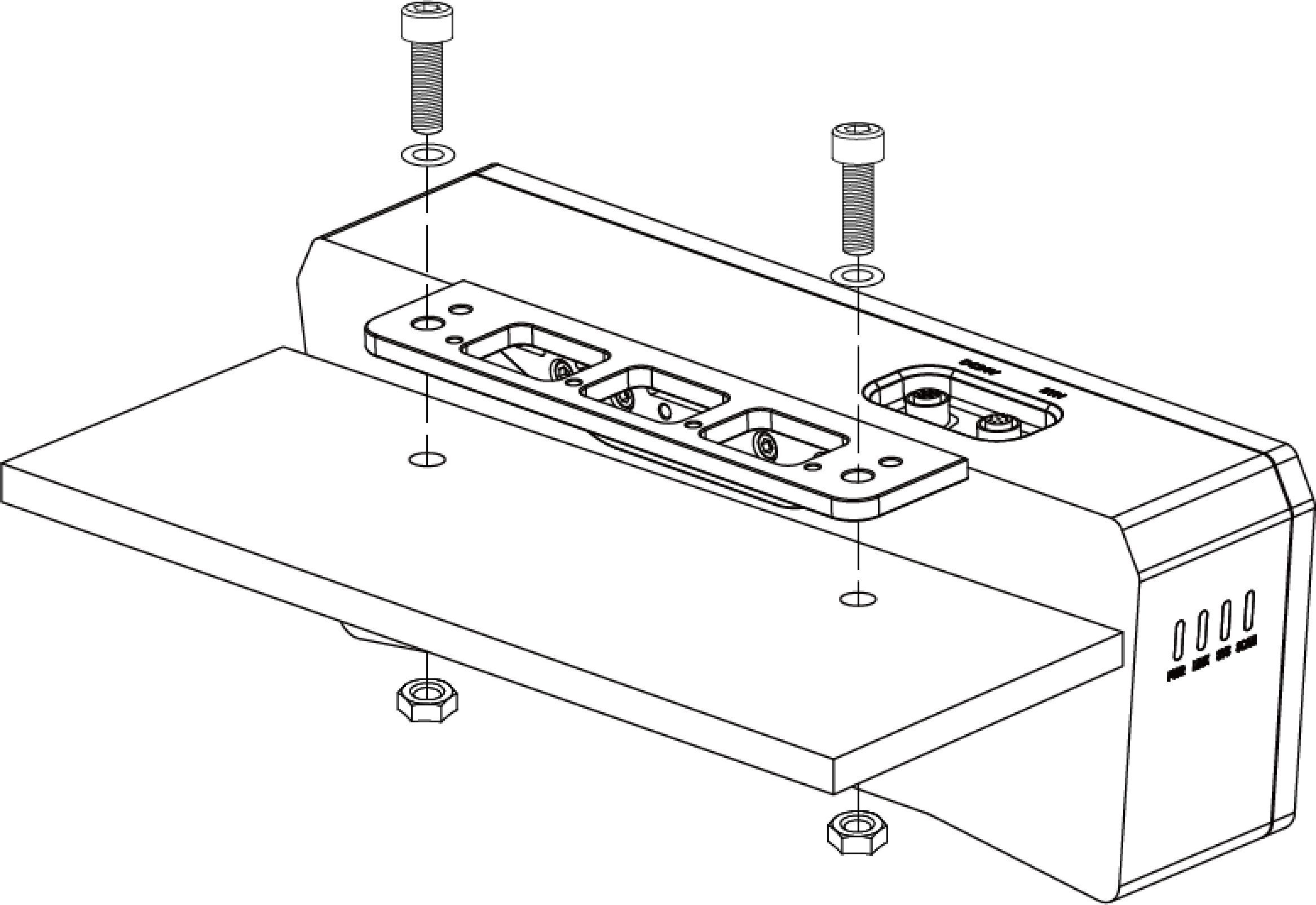

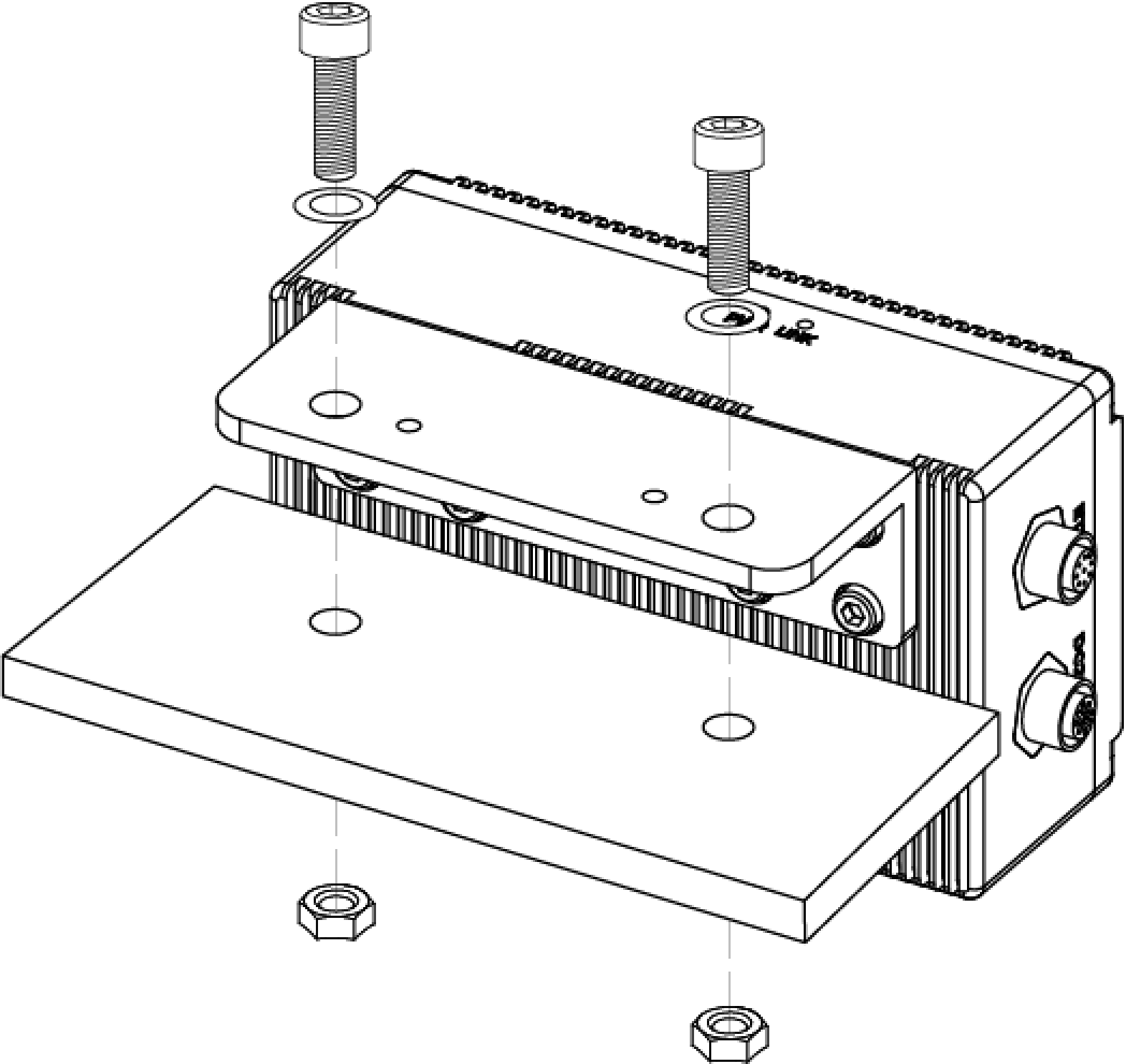

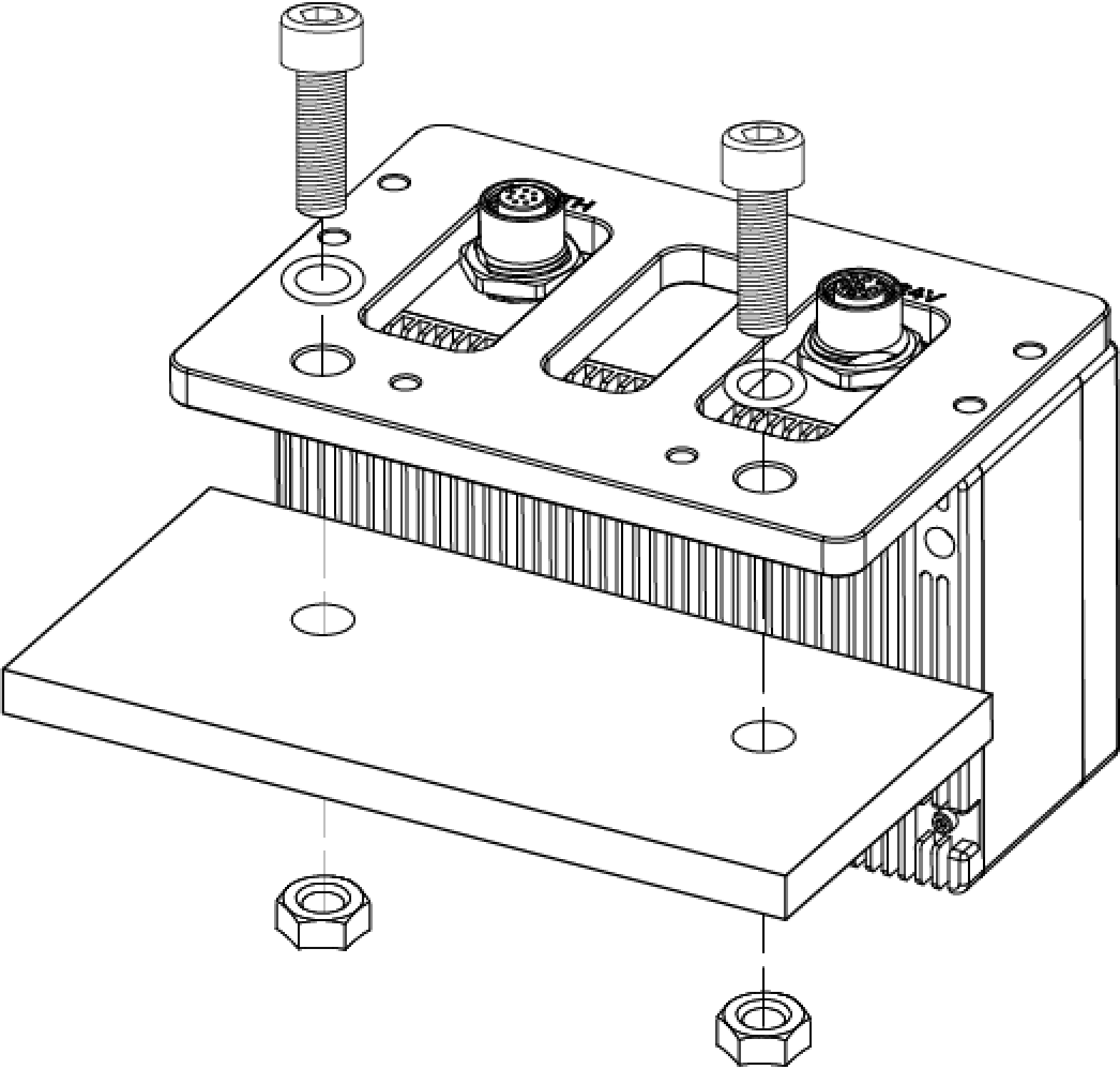

As shown below, place 2 M8 washers and 2 M8 × 20 T-bolts, and then use the open-end wrench to tighten 2 flange nuts. The recommended tightening torque is 12 to 13 N·m.

-

DEEP-GL, LSR S-GL, LSR L-GL, LSR XL-GL, PRO S-GL, PRO M-GL, and UHP-140-GL:

-

NANO-GL:

-

NANO ULTRA-GL:

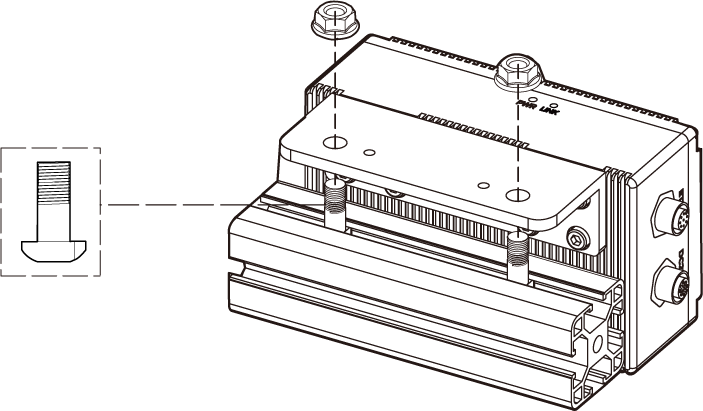

Mount to Surface with Mounting Holes Opened

As shown below, place 2 M8 washers and 2 M8 × 20 socket head cap screws, and then use the open-end wrench to tighten 2 nuts. The recommended tightening torque is 12 to 13 N·m.

-

DEEP-GL, LSR S-GL, LSR L-GL, LSR XL-GL, PRO S-GL, PRO M-GL, and UHP-140-GL:

-

NANO-GL:

-

NANO ULTRA-GL:

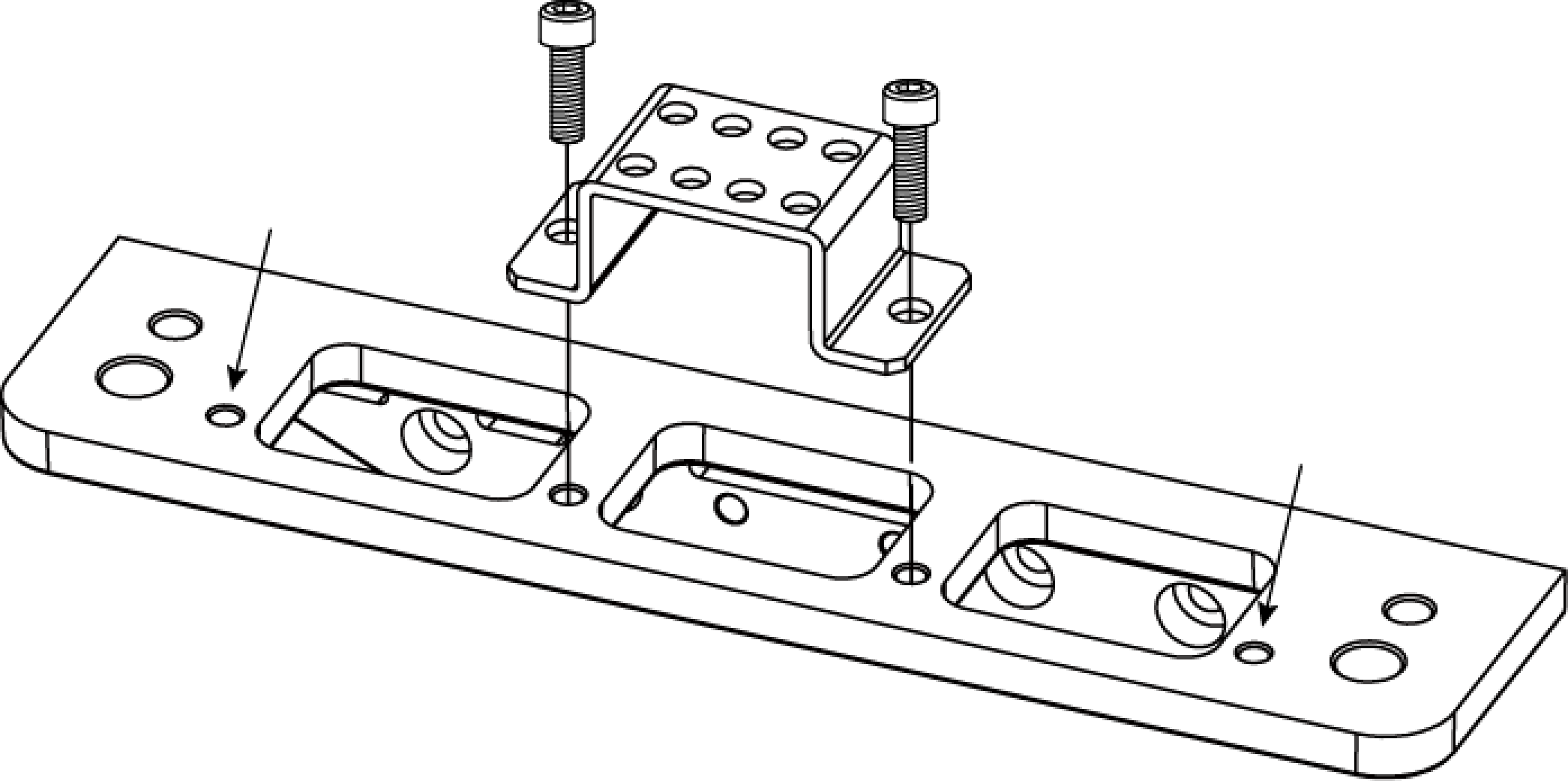

Mount the Cable Tie Mount

After mounting the cable tie mount, you can secure the cables with zip ties to avoid damaging the cables by strain.

As shown below, use the hex key to tighten 2 M5 × 8 socket head cap screws. The recommended tightening torque is 2.2 to 2.5 N·m.

-

DEEP-GL, LSR S-GL, LSR L-GL, LSR XL-GL, PRO S-GL, PRO M-GL, and UHP-140-GL: You can use the threaded holes at different positions (indicated by arrows) to mount the cable tie mount.

-

NANO-GL:

-

NANO ULTRA-GL:

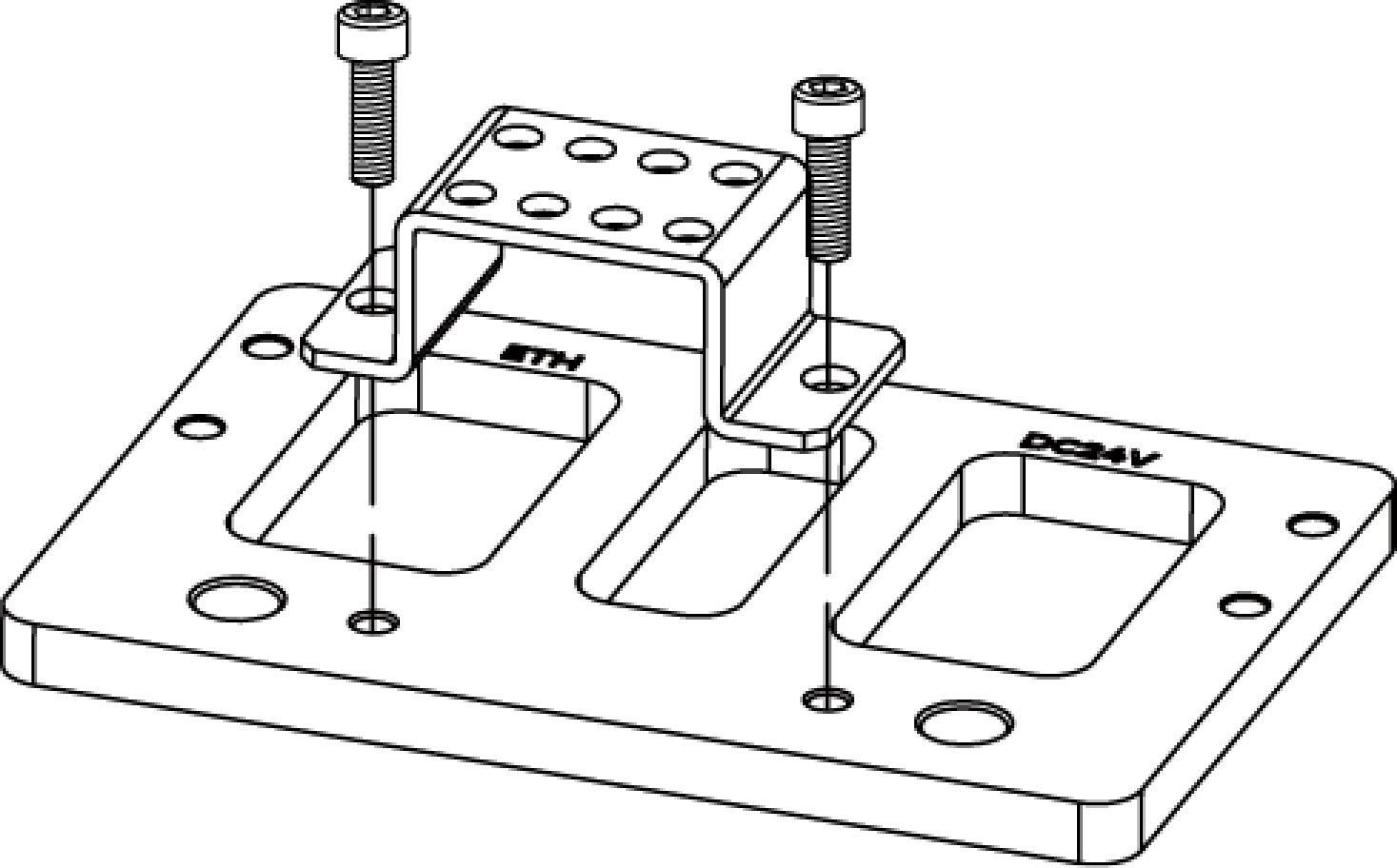

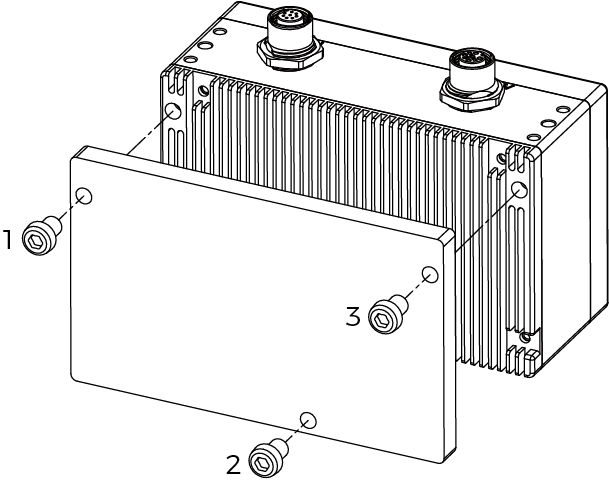

Mount through Threaded Holes on the Back

|

When mounting LSR S-GL and NANO ULTRA-GL using this method, ensure that the back of the camera is in close contact with a metal surface for heat dissipation, so that the camera does not overheat and malfunction. |

-

Use the hex key to remove the camera bracket. For LSR S-GL and NANO ULTRA-GL, also remove the heat-dissipation panel.

-

As shown below, place the socket head cap screws of the corresponding specification into the mounting holes. Then, use the hex key to loosely screw on the screws in the specified order, and then fully tighten all the bolts in the specified order.

-

NANO ULTRA-GL: M4 × 8 socket head cap screws (recommended tightening torque: 1.4 to 1.6 N·m)

-

Other models: M5 × 8 socket head cap screws (Recommended tightening torque: 2.2 to 2.5 N·m)

The number of screws required differs by model.

-

-

DEEP-GL, LSR S-GL, LSR L-GL, LSR XL-GL, PRO S-GL, PRO M-GL, and UHP-140-GL:

-

NANO-GL:

-

NANO ULTRA-GL:

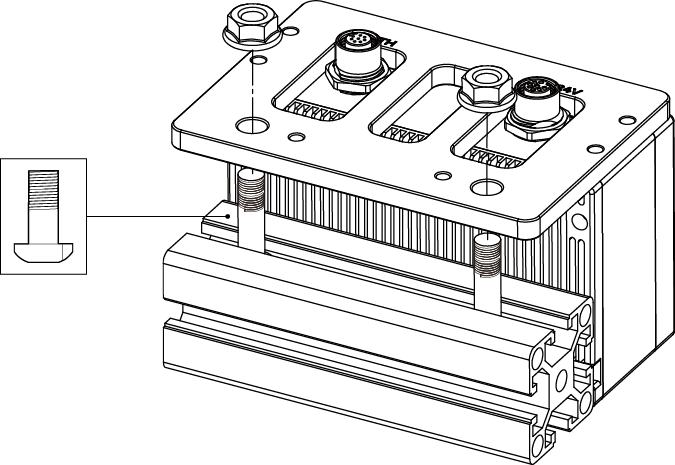

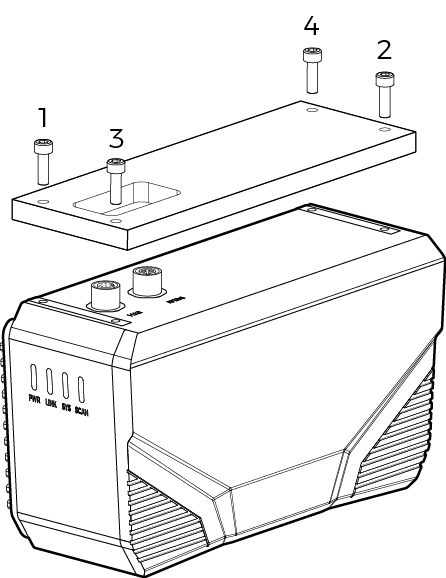

Mount through Threaded Holes at the Top

The following models provide threaded holes for mounting at the top: LSR S-GL, LSR XL-GL, NANO ULTRA-GL, and UHP-140-GL.

-

Use the hex key to remove the camera bracket.

-

As shown below, place the socket head cap screws of the corresponding specification into the mounting holes. Then, use the hex key to loosely screw on the screws in the specified order, and then fully tighten all the bolts in the specified order.

-

NANO ULTRA-GL: M4 × 8 socket head cap screws (recommended tightening torque: 1.4 to 1.6 N·m)

-

Other models: M5 × 8 socket head cap screws (Recommended tightening torque: 2.2 to 2.5 N·m)

-

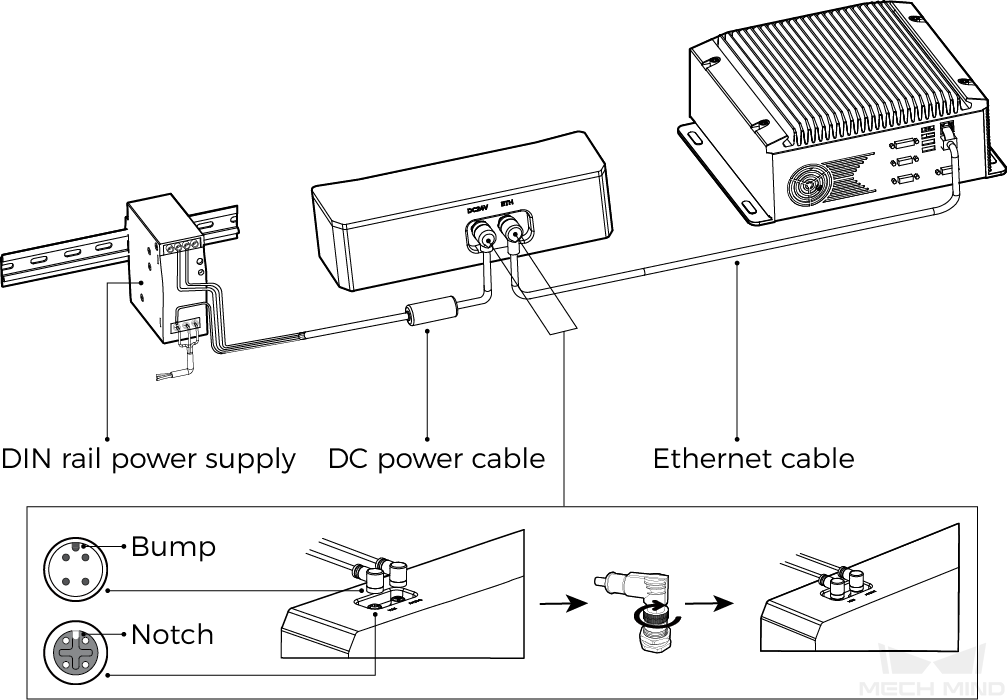

Connect the Camera

Ethernet Cable and DC Power Cable

-

Ethernet cable: Insert the M12-A connector of the Ethernet cable into the ETH port on the camera, and insert the RJ45 connector into the Ethernet port on the IPC.

-

DC power cable: Insert the M12-A connector of the DC power cable into the DC 24V port on the camera.

When inserting the Ethernet cable and DC power cable:

-

Align the bump in the connector with the notch in the port.

-

Tighten the nut. The recommended tightening torque is 0.7 N·m. A gap of about 2 mm remains after the nut is fully tightened.

|

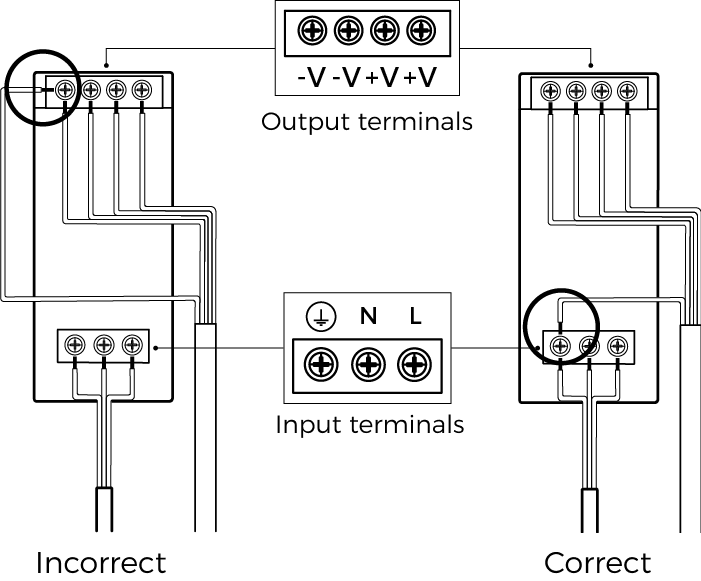

DIN rail power supply

|

-

Use a flat screwdriver to loosen the screws on the terminals of the DIN rail power supply.

-

Connect the DC power cable: Insert the two wires with the +V labels into the two +V output terminals on the DIN rail power supply, the two wires with the -V labels into the two -V output terminals, and the wire with the PE label into the ground terminal (

).

). -

Connect the AC power cable: Insert the live wire into the L input terminal on the DIN rail power supply, the neutral wire into the N input terminal, and the ground wire into the ground terminal (

).

). -

Use the flat screwdriver to tighten the screws on the terminals.

|

| For more information about cable selection, cable voltage adjustment, and precautions for using the DIN rail power supply, see Camera Accessories. |

Use the Camera

Warm Up

To ensure that the accuracy of the data acquired by the product reaches the values listed in the technical specifications, please use the Warm-Up Tool to warm up the product before using it.

-

Recommended warm-up time: 60 minutes for UHP-140-GL and LSR S-GL, and 30 minutes for other models.

-

Recommended data acquisition interval: Warm up the product with the data acquisition interval in actual use. If the data acquisition interval in actual use is not fixed, it is recommended to warm up with the average data acquisition interval. For example, in actual use, data is acquired every 6 to 10 seconds, then during warm-up, data should be acquired every 8 seconds.

Download and Install Mech-Eye SDK

The product is controlled by the accompanying software Mech-Eye SDK. Visit Mech-Mind Download Center to download and install the latest version of Mech-Eye SDK.

Use Mech-Eye SDK

Through Mech-Eye SDK, you can connect to the product and control it to acquire image and point cloud data. It is recommended to check the accuracy of the product by checking the intrinsic parameters through Mech-Eye SDK before you use the product to acquire data for the first time.

|

When you connect to the product in Mech-Eye SDK for the first time, you may need to upgrade the firmware of the product. |

Maintenance

Regular Inspections

The camera is a precision instrument. Please perform the following inspections regularly to make sure that the camera is in optimal working condition.

Check External Conditions

| Inspection | Issue-resolving measure | Recommended frequency |

|---|---|---|

Whether the enclosure is worn, scratched, or deformed. |

|

Once everyday |

Whether the lens glass has any water stains or condensation. |

Contact Technical Support or return the product to Mech-Mind for repair. |

Check Cables

| Inspection | Issue-resolving measure | Recommended frequency |

|---|---|---|

Whether the cables are securely connected to devices. |

Secure the connection. |

Once everyday |

Whether cables are bent or twisted. |

Improve the cable routing to avoid excessive bending or twisting of the cables. The bending radius should not be less than 8 times the outer diameter of the cable (8D). |

|

Whether cables are aged, worn, or torn. |

Contact Mech-Mind to acquire a replacement. |

|

Whether cables emit a burnt smell. |

Contact Mech-Mind to replace the cable and identify the location and cause of the burnt smell to avoid recurrence. |

Check Camera Bracket

| Inspection | Issue-resolving measure | Recommended frequency |

|---|---|---|

Whether the camera bracket wobbles and whether the screws are loose. |

Tighten the screws. |

Once every 2 weeks |

Whether the camera bracket is deformed. |

The camera may have been involved in a collision. Check the intrinsic parameters through Mech-Eye SDK. If the intrinsic parameters have changed, stop using the camera and contact Mech-Mind. |

Check Intrinsic Parameters

| Inspection | Issue-resolving measure | Recommended frequency |

|---|---|---|

Check if the errors in the intrinsic parameters are large through Mech-Eye SDK. |

Correct the intrinsic parameters. If the errors are still large after the correction, please contact Mech-Mind. |

Once every 6 months |

Cleaning

Disconnect the product from power before cleaning. When cleaning the surface of the product, please use a clean soft cloth to gently wipe off the dust and debris. When cleaning the windows, to avoid scratching, you can use a clean, soft lint-free cloth with lens cleaner or glass cleaner to carefully wipe the windows. It is recommended to clean the product once everyday.

|

Storage

-

LSR S-GL: The product is rated as IP67. The enclosure of the product can prevent dust and water from entering and affecting the functions of the product. Please avoid soaking the product in water or placing it outdoors for an extended period of time. When not using, please store the product in an indoor, dry, cool, and well ventilated place. The storage temperature of the product is -20–60°C.

-

Models other than LSR S-GL: The product is rated as IP65. The enclosure of the product can prevent dust from entering and affecting the functions of the product. Please avoid soaking the product in water, installing it in a highly humid environment, or placing it outdoors for an extended period of time. When not using, please store the product in an indoor, dry, cool, and well ventilated place. The storage temperature of the product is -20–60°C.

|

Transportation

When transporting the product, please use the original packaging to ensure enough protection for the product and avoid damages induced by the transportation process.

Troubleshooting

For more information about common issues and troubleshooting guidance, see Troubleshooting.

Disclaimer

It is strongly recommended to use the power supply and cables provided by Mech-Mind to ensure compliance with the safety and EMC standards. Mech-Mind shall not be liable for any issues caused by using the power supply and cables provided by a third party.

Trademark and Legal Statement

Mech-Mind and Mech-Mind series logos including  are registered trademarks of Mech-Mind Robotics Technologies Co., Ltd. and other related entities.

are registered trademarks of Mech-Mind Robotics Technologies Co., Ltd. and other related entities.

© Copyright 2026, Mech-Mind Robotics Technologies Co., Ltd.

Unless authorized in writing in advance by Mech-Mind Robotics Technologies Co., Ltd. (“Mech-Mind”), no part of the trademarks shall be used, reproduced, modified, transmitted, transcribed, or used or sold with other products as a bundle by any entity or individual in any form for any reason.

Any infringement of Mech-Mind’s trademark rights will be punished in accordance with the law.

Mech-Mind reserves all rights regarding this user manual. According to copyright laws, unless authorized by Mech-Mind, this user manual shall not be reproduced, modified, or issued in part or in its entirety by any entity or individual. Users who purchased and use the product may download, print, or copy the user manual for personal use or use inside the belonging organization. Unless authorized by Mech-Mind, the contents of the user manual may not be used for any other purposes.