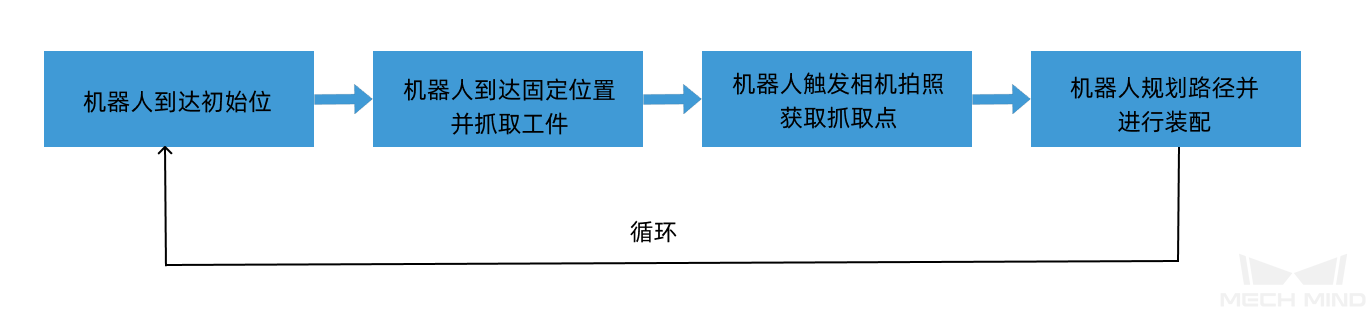

实现抓放

在本教程中,你将先了解本案例实现的抓取和放置流程、然后了解如何完成抓取和放置流程配置。

通信方案说明

在上述流程中,“机器人触发相机拍照并获取抓取点”需要机器人与视觉系统使用标准接口通信方式,并且标准接口与视觉系统的配合方式为“使用Mech-Vision获取视觉结果”。

使用该配合方式时,你需要编写机器人程序。请参考“抓取和放置流程配置”完成机器人程序的编写。

抓取和放置流程配置

要实现抓取和放置逻辑流程,需要依次完成如下配置:

配置机器人参数和编写机器人程序

安川标准接口样例程序MM_S1_Vis_Basic可以基本满足本案例所需要的功能。你可以在样例程序基础上进行修改。关于样例程序MM_S1_Vis_Basic的详细解释,请参考样例程序解读。

基于样例程序,请在机器人端完成如下操作:

-

示教Home点(初始位)。

将机器人移动到示教的初始位。初始位应远离待抓取物体及周边设备,且不遮挡相机视野。完成后,记录此时的机器人位姿到变量C00000。

-

指定工控机IP地址。将MM_Init_Socket指令对应的IP地址和端口更新为工控机IP地址和端口。

修改前 修改后(示例) 'initialize communication 'parameters (initialization is 'required only once) CALL JOB:MM_INIT_SOCKET ARGF"192.168.170.22;50000;1"

'initialize communication 'parameters (initialization is 'required only once) CALL JOB:MM_INIT_SOCKET ARGF"192.168.10.40;50000;1"

-

设置DO端口信号,以张开夹具。注意,DO指令应根据现场实际使用的DO端口号设置。

'open gripper DOUT OT#(14) ON DOUT OT#(15) OFF

-

示教固定的抓取点。

将机器人移动到示教的抓取点。该位置也是相机拍照位。在此位置,机器人手臂应不遮挡相机视野。完成后,记录此时的机器人位姿到变量C00001。

修改前 修改后(示例) 'move to image-capturing position MOVJ C00001 VJ=50.00 PL=0

'move to fixed position of picking MOVJ C00001 VJ=20.00 PL=0

-

设置DO端口信号,以闭合夹具抓取固定位置上的螺栓。注意,DO指令应根据现场实际使用的DO端口号设置。

'close gripper DOUT OT#(14) OFF DOUT OT#(15) ON

-

示教装配过程的过渡点。

修改前 修改后(示例) 'move to intermediate waypoint of 'picking MOVJ C00002 VJ=50.00

'move to intermediate waypoint of 'assembly MOVJ C00002 VJ=50.00

-

修改装配相关指令的注释。

修改前 修改后(示例) 'move to approach waypoint of 'picking SFTON P070 MOVL P071 V=166.6 PL=0 SFTOF 'move to picking waypoint MOVL P071 V=50.0 PL=0 ... 'move to departure waypoint of 'picking SFTON P070 MOVL P071 V=166.6 PL=0 SFTOF

'move to approach waypoint of 'assembly SFTON P070 MOVL P071 V=166.6 PL=0 SFTOF 'move to assembly waypoint MOVL P071 V=50.0 PL=0 ... 'move to departure waypoint of 'assembly SFTON P070 MOVL P071 V=166.6 PL=0 SFTOF

-

设置DO端口信号,以张开夹具放置螺栓到销孔。注意,DO指令应根据现场实际使用的DO端口号设置。

修改前 修改后(示例) 'add object grasping logic here, 'such as DOUT OT#(1) ON PAUSE

'add object releasing logic here, 'such as DOUT OT#(1) ON DOUT OT#(15) OFF DOUT OT#(14) ON PAUSE

-

删除示例程序中与放置相关的代码。

'move to intermediate waypoint of 'placing MOVJ C00003 VJ=50.00 'move to approach waypoint of 'placing MOVL C00004 V=166.6 PL=0 'move to placing waypoint MOVL C00005 V=50.0 PL=0 'add object releasing logic here, 'such as DOUT OT#(1) OFF PAUSE 'move to departure waypoint of 'placing MOVL C00006 V=166.6 PL=0

-

示教Home点。

将机器人移动到示教的Home点,并记录机器人位姿到C00003。

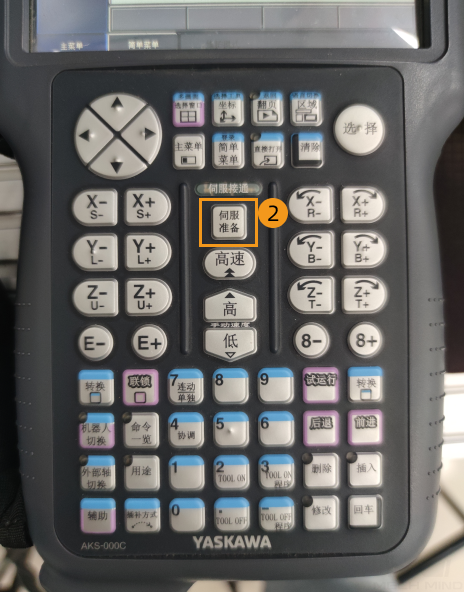

单步运行测试机器人装配效果

执行如下步骤测试机器人装配效果:

-

在示教器上旋转模式钥匙到PLAY进入再现模式。

-

按下示教器伺服准备键后,然后按蓝色运行按钮。

-

机器人将自动执行机器人程序,完成一个工件的抓取和放置。

请密切关注机器人移动轨迹,紧急情况及时按下急停键。

如果机器人可以成功抓取和放置工件,则说明机器人程序符合要求。

插入循环语句实现循环装配

在测试机器人可以成功完成单次装配,可以在程序中插入循环语句,实现机器人循环装配。

加入如下循环语句:

LOOP 'move to fixed position of picking MOVJ C00001 VJ=20.00 PL=0 ... MOVJ C00003 VJ=50.00 END LOOP

参考:修改后的样例程序

最终修改后的样例程序如下:

NOP

'--------------------------------

'FUNCTION: trigger Mech-Vision

'project and get vision result

'Mech-Mind, 2023-12-25

'--------------------------------

'clear I50 to I69

CLEAR I050 20

'initialize p variables

SUB P070 P070

SUB P071 P071

'set 100mm to z of P070

SETE P070 (3) 100000

'move to robot home position

MOVJ C00000 VJ=50.00

'initialize communication

'parameters (initialization is

'required only once)

CALL JOB:MM_INIT_SOCKET ARGF"192.168.10.40;50000;1"

'open gripper

DOUT OT#(14) ON

DOUT OT#(15) OFF

LOOP

'move to fixed position of picking

MOVJ C00001 VJ=20.00 PL=0

'close gripper

DOUT OT#(14) OFF

DOUT OT#(15) ON

'open socket connection

CALL JOB:MM_OPEN_SOCKET

MOVL P110 V=25.0

'trigger NO.1 Mech-Vision project

CALL JOB:MM_START_VIS ARGF"1;0;2;30"

'get vision result from NO.1

'Mech-Vision project

CALL JOB:MM_GET_VISDATA ARGF"1;51;52"

'check whether vision result has

'been got from Mech-Vision

'successfully

IFTHENEXP I052<>1100

'add error handling logic here

'according to different error

'codes

'e.g.: I052=1003 means no point

'cloud in ROI

'e.g.: I052=1002 means no

'vision result

PAUSE

ENDIF

'close socket connection

CALL JOB:MM_CLOSE_SOCKET

'save first vision point data to

'local variables

CALL JOB:MM_GET_POSE ARGF"1;71;61;62"

'move to intermediate waypoint of

'assembly

MOVJ C00002 VJ=50.00

'move to approach waypoint of

'assembly

SFTON P070

MOVL P071 V=166.6 PL=0

SFTOF

'move to assembly waypoint

MOVL P071 V=50.0 PL=0

'add object releasing logic here,

'such as DOUT OT#(1) ON

DOUT OT#(15) OFF

DOUT OT#(14) ON

PAUSE

'move to departure waypoint of

'assembly

SFTON P070

MOVL P071 V=166.6 PL=0

SFTOF

'move back to robot home position

MOVJ C00003 VJ=50.00’move to fixed position of picking

MOVJ C00001 VJ=20.00 PL=0

'close gripper

DOUT OT#(14) OFF

DOUT OT#(15) ON

'open socket connection

CALL JOB:MM_OPEN_SOCKET

MOVL P110 V=25.0

'trigger NO.1 Mech-Vision project

CALL JOB:MM_START_VIS ARGF"1;0;2;30"

'get vision result from NO.1

'Mech-Vision project

CALL JOB:MM_GET_VISDATA ARGF"1;51;52"

'check whether vision result has

'been got from Mech-Vision

'successfully

IFTHENEXP I052<>1100

'add error handling logic here

'according to different error

'codes

'e.g.: I052=1003 means no point

'cloud in ROI

'e.g.: I052=1002 means no

'vision result

PAUSE

ENDIF

'close socket connection

CALL JOB:MM_CLOSE_SOCKET

'save first vision point data to

'local variables

CALL JOB:MM_GET_POSE ARGF"1;71;61;62"

'move to intermediate waypoint of

'assembly

MOVJ C00002 VJ=50.00

'move to approach waypoint of

'assembly

SFTON P070

MOVL P071 V=166.6 PL=0

SFTOF

'move to assembly waypoint

MOVL P071 V=50.0 PL=0

'add object releasing logic here,

'such as DOUT OT#(1) ON

DOUT OT#(15) OFF

DOUT OT#(14) ON

PAUSE

'move to departure waypoint of

'assembly

SFTON P070

MOVL P071 V=166.6 PL=0

SFTOF

'move back to robot home position

MOVJ C00003 VJ=50.00

END LOOP

END至此,你已完成了3D视觉引导机器人定位装配应用的部署。