Collision Detection Parameter Configuration

To prevent the robot from colliding with other objects during picking, Mech-Viz is equipped with the collision detection feature, enabling a flexible detection of collisions between different types of objects.

After adding collision models of scene objects, tools, and target objects as required, you can enable collision detection in the Collisions panel.

This section introduces the configuration of collision detection parameters in common scenarios.

Palletizing and Depalletizing

Recommended Configuration

-

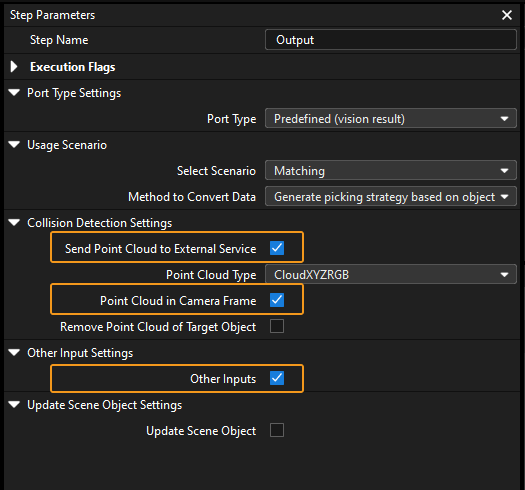

In the Step parameter panel of the Output Step in Mech-Vision, select Depalletizing as the scenario and enable Send Point Cloud to External Service, Point Cloud in Camera Frame, and Other Inputs.

-

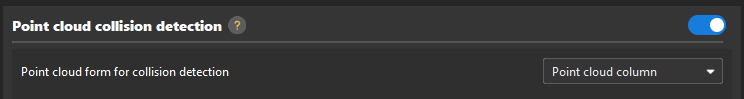

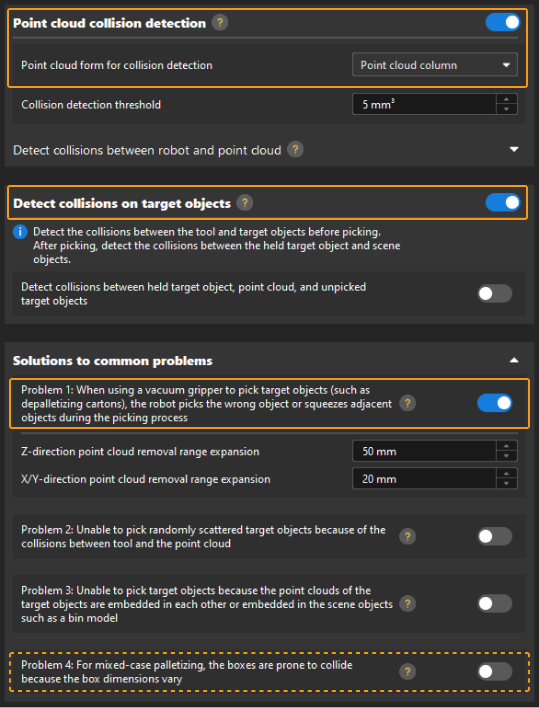

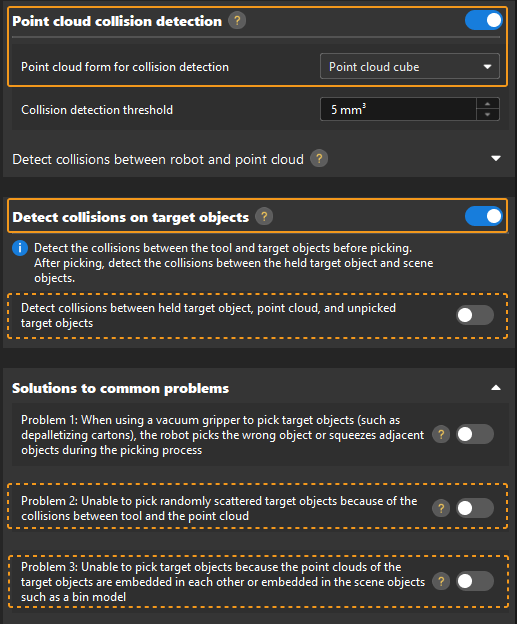

In the Collisions functional panel of Mech-Viz, enable Point cloud collision detection and set Point cloud form for collision detection to Point cloud column.

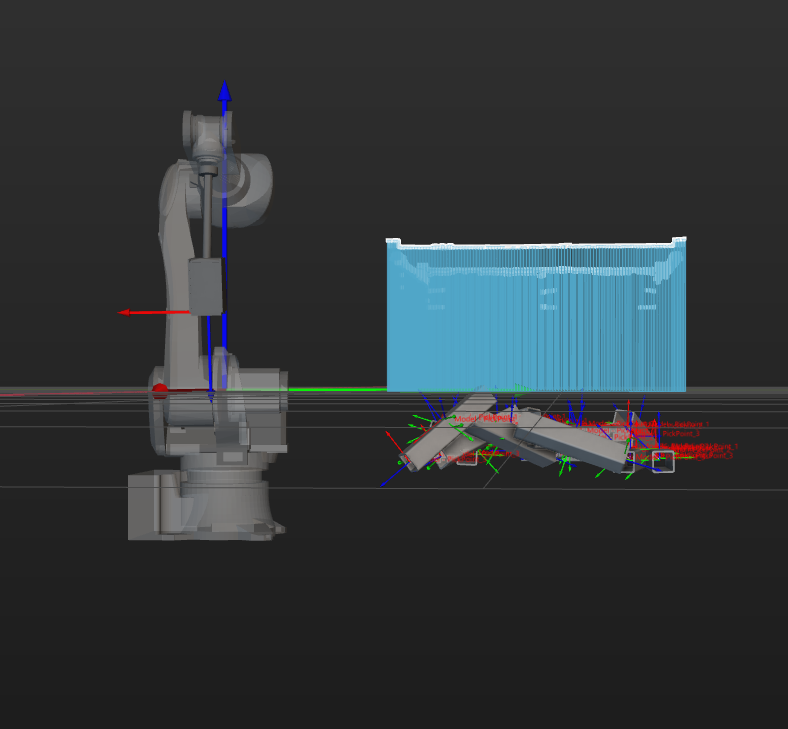

When the Point cloud form for collision detection is Point cloud column, Mech-Viz will generate a collision model by extending the point cloud of the carton’s upper surface (as the starting point) downward along the negative Z-axis of the world reference frame to the floor (as the endpoint) in the 3D simulation area. Using a point cloud column can avoid collisions with other cartons when using vacuum grippers to pick cartons, especially when the vacuum gripper suctions the carton from the side surface.

For a detailed description of Point cloud form for collision detection, please refer to Point Cloud Form for Collision Detection.

By default, the origin of the world reference frame of the 3D simulation interface coincides with that of the robot reference frame. If the origin of the robot reference frame is not beneath the base but instead on the plane (which coincides with the floor) where robot axis 1 is located, the collision model formed by the point cloud columns will not be high enough. In this case, right-click Floor in the project resource tree, adjust the Floor Height to align the floor with the plane of the actual floor.

-

In the Collisions panel of Mech-Viz, enable Detect collisions on target objects, and keep Detect collisions between held target object, point cloud, and unpicked target objects disabled.

Detect collisions between the held carton and other scene objects in subsequent movements.

-

Turn on the switch on the right of Problem 1. For specific parameter configuration instructions, please refer to Solutions to Common Problems.

-

In mixed-case palletizing scenarios, you can turn on the switch on the right of Problem 4 to add a certain thickness to the bottom of the collision model of the box, and use the thickened collision model for collision detection.

Picking Randomly Stacked Objects

Recommended Configuration

-

In the Collisions functional panel of Mech-Viz, enable Point cloud collision detection and set Point cloud form for collision detection to Point cloud cube.

Avoid collisions between the tool and actual target objects through point cloud collision detection.

-

In the Collisions functional panel of Mech-Viz, enable Detect collisions on target objects. If no collision is allowed between the held target object and the unpicked target objects, enable Detect collisions between held target object, point cloud, and unpicked target objects.

Detect collisions between the held target object and other scene objects in subsequent movements.

-

Turn on the switch next to Problems 2 and Problems 3 under Solutions to common problems according to the actual requirements.

-

Problem 2: If the tool can tolerate minor collisions when picking the target object, you can use this solution to increase the picking success rate. The Non-detection range should not be too large to prevent severe collisions.

-

Problem 3: When the point clouds of the target objects are embedded in each other or embedded in the scene objects such as a bin model, collisions will be detected and the path planning will fail. In this case, you can use this solution to increase the bin clearance rate. The Non-detection range should not be too large to prevent severe collisions.

-

Picking Neatly Arranged Objects

Recommended Configuration

-

In the Collisions functional panel of Mech-Viz, enable Point cloud collision detection and set Point cloud form for collision detection to Point cloud column.

When the target objects are neatly arranged, point cloud columns are more suitable for point cloud collision detection.